Introduction

In today's fast-paced manufacturing landscape, the need for efficient and intelligent storage solutions has never been more critical. Intelligent Storage Systems (ISS) are revolutionizing how businesses manage their resources, especially in the SMT (Surface Mount Technology) industry. By leveraging advanced technologies, these systems enhance smt storage management, ensuring that materials are organized, accessible, and optimized for production efficiency.

Understanding Intelligent Storage Systems

Intelligent Storage Systems encompass a variety of technologies designed to streamline the storage and retrieval of materials in manufacturing environments. These systems utilize automation, data analytics, and real-time monitoring to improve smt storage management processes significantly. By integrating these core components, businesses can transition from traditional storage methods to more efficient solutions that adapt to their specific needs.

Importance of SMT Storage Management

Effective smt storage management is crucial for maintaining productivity and minimizing waste in manufacturing operations. As companies strive for greater efficiency and reduced costs, optimizing storage practices becomes a vital component of their overall strategy. Without proper management of materials and inventory within the SMT framework, companies risk delays in production cycles and increased operational costs.

Key Benefits for the SMT Industry

The implementation of Intelligent Storage Systems offers numerous advantages tailored specifically for the SMT industry. Enhanced organization leads to quicker access to components, reducing downtime during production runs—a key factor in maintaining competitive advantage. Furthermore, improved tracking capabilities enable manufacturers to optimize inventory levels while minimizing excess stock, ultimately driving down costs associated with smt storage management.

What is an Intelligent Storage System

In the realm of SMT storage management, understanding what constitutes an intelligent storage system is crucial. These systems are designed to optimize the way data and materials are stored, retrieved, and managed within a manufacturing environment. By leveraging advanced technologies, they ensure that resources are used efficiently, reducing waste and improving overall productivity.

Definition and Core Components

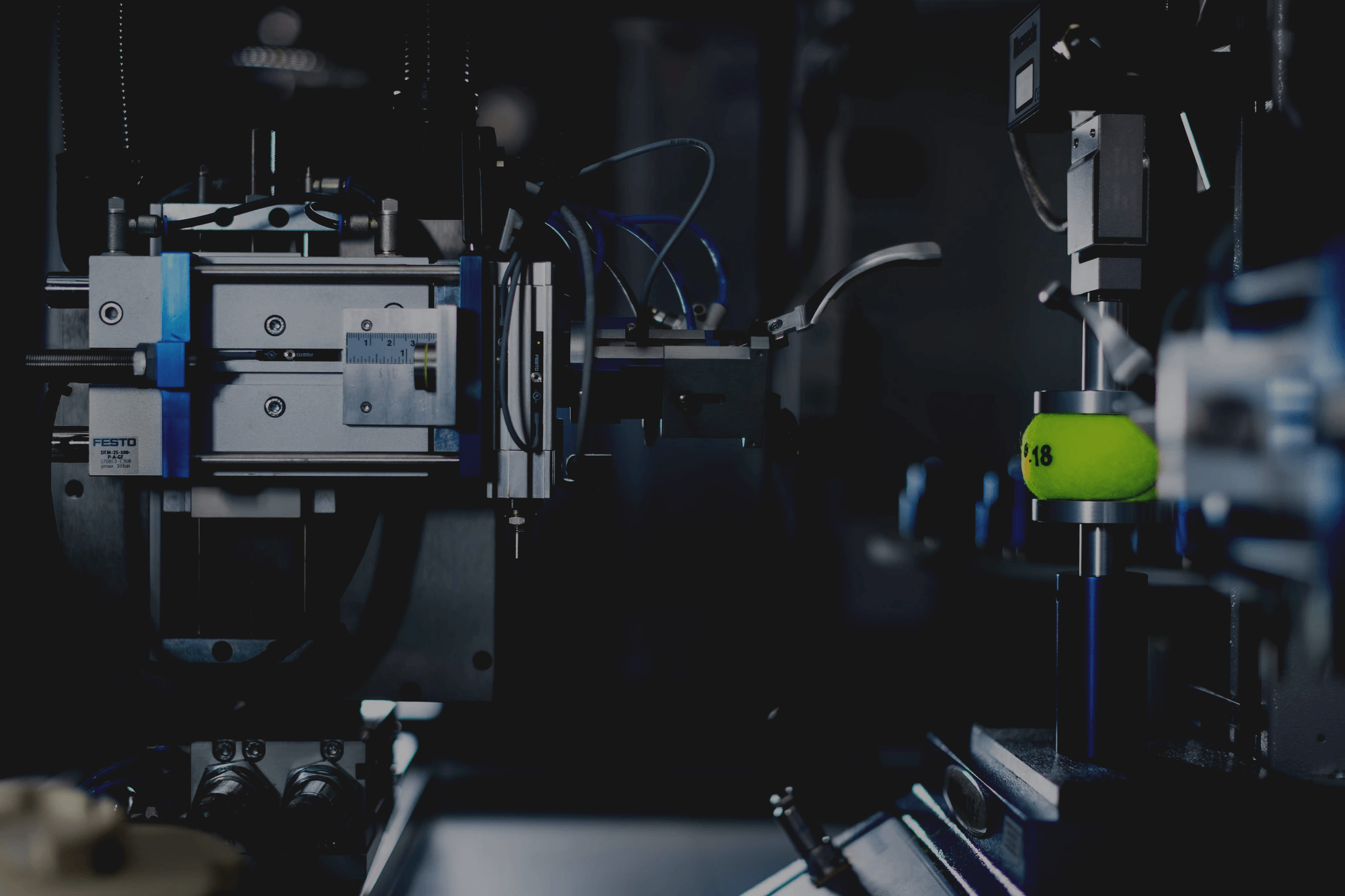

An intelligent storage system can be defined as a sophisticated framework that integrates hardware and software to manage inventory dynamically. The core components typically include automated storage and retrieval systems (AS/RS), inventory management software, sensors for real-time tracking, and data analytics tools. Together, these elements enable seamless communication between various parts of the SMT process, allowing for timely updates on stock levels and resource availability.

Comparison with Traditional Storage Solutions

When comparing intelligent storage systems to traditional solutions in SMT storage management, the differences become glaringly apparent. Traditional systems often rely on manual processes that can lead to inefficiencies such as overstocking or stockouts due to human error. In contrast, intelligent systems utilize automation and real-time data analysis to streamline operations—resulting in higher accuracy rates and reduced operational costs.

Real-World Applications in the SMT Industry

The applications of intelligent storage systems within the SMT industry are both diverse and impactful. For instance, companies can implement automated warehousing solutions that dramatically reduce retrieval times for components needed on production lines. Additionally, predictive analytics can help forecast demand trends based on historical data—allowing businesses to adjust their inventory strategies proactively rather than reactively.

Assessing Your Current Storage Solutions

In the fast-paced world of SMT (Surface Mount Technology), efficient storage management is crucial for maintaining productivity and minimizing costs. To ensure that your organization is operating at peak efficiency, it’s imperative to assess your current storage solutions thoroughly. This section will explore how to identify inefficiencies in SMT storage management, conduct a comprehensive needs analysis, and highlight a case study demonstrating successful improvements.

Identifying Inefficiencies in SMT Storage Management

The first step in assessing your current SMT storage management is pinpointing inefficiencies that may be holding your operations back. Common issues include disorganized inventory, delays in retrieving components, and inadequate tracking systems that lead to overstocking or shortages. By closely examining these areas, you can uncover hidden bottlenecks that hinder productivity and escalate operational costs.

Once you’ve identified these inefficiencies, it becomes easier to prioritize which areas require immediate attention within your SMT storage management strategy. For instance, if the retrieval process takes too long due to poor organization, implementing a more systematic approach could yield significant time savings. Ultimately, recognizing these pain points will set the stage for more effective solutions moving forward.

Conducting a Storage Needs Analysis

Conducting a thorough storage needs analysis is essential for aligning your SMT storage management practices with the demands of your operations. This involves evaluating current inventory levels, understanding usage patterns of components and materials, and forecasting future needs based on production schedules. By gathering this data, you can make informed decisions about what types of intelligent storage systems are most suitable for your business.

Additionally, engaging with team members who handle inventory daily can provide valuable insights into practical challenges they face with existing systems. Their firsthand experience can help shape recommendations for improvements tailored specifically to their workflows within SMT storage management. A well-rounded needs analysis not only highlights gaps but also reveals opportunities for enhancing efficiency through better technology or processes.

Case Study: Improvements by Bensun Technology

Bensun Technology serves as an exemplary case study illustrating the transformative impact of refining SMT storage management practices through intelligent systems. Faced with significant inefficiencies due to outdated manual processes and poor inventory visibility, Bensun undertook a comprehensive assessment of their current solutions. By identifying key bottlenecks and conducting an extensive needs analysis involving all stakeholders, they were able to pinpoint specific areas ripe for improvement.

The implementation of an intelligent storage system led to remarkable results; Bensun reported a 30% reduction in retrieval times and improved accuracy in inventory counts thanks to automated tracking features integrated into their new solution. These enhancements not only streamlined operations but also reduced excess stock levels significantly—freeing up valuable capital previously tied up in unused materials within their SMT storage management framework. The success story of Bensun Technology underscores the importance of continuous assessment and adaptation in achieving operational excellence.

Steps to Implement an Intelligent Storage System

Implementing an intelligent storage system is like embarking on a thrilling adventure—one that requires careful planning, the right tools, and a well-prepared crew. In the realm of SMT storage management, this journey can lead to remarkable improvements in efficiency and productivity. Let’s navigate through the essential steps to ensure your transition is smooth and successful.

Planning and Strategy Development

The first step in implementing an intelligent storage system is crafting a robust plan that aligns with your business objectives. Begin by assessing your current SMT storage management processes and identifying areas ripe for improvement; this will serve as the foundation for your strategy. As you develop your plan, engage stakeholders across departments to gather insights and foster buy-in—after all, collaboration is key when it comes to making significant changes.

Once you have a clear understanding of inefficiencies, set specific goals for what you hope to achieve with your new system. Whether it's reducing retrieval times or improving inventory accuracy in SMT storage management, having measurable targets will help guide your efforts. Finally, outline a timeline that includes milestones for each phase of implementation; this will keep everyone on track and accountable throughout the process.

Selecting the Right Technology and Equipment

With a solid plan in place, it’s time to dive into selecting technology that fits seamlessly into your SMT storage management framework. Start by researching various intelligent storage solutions available on the market—consider factors such as scalability, compatibility with existing systems, and user-friendliness. A thorough evaluation will help you pinpoint options tailored to your specific needs while ensuring they can grow alongside your business.

Don’t forget about equipment! From automated guided vehicles (AGVs) to smart shelving units equipped with sensors, investing in cutting-edge technology can significantly enhance operational efficiency in SMT storage management. Engage with vendors who specialize in these technologies; their expertise can provide valuable insights into which solutions best meet your requirements.

Training Your Team for a Smooth Transition

A new system is only as good as the people operating it; thus, training is paramount during this transition phase of SMT storage management implementation. Develop comprehensive training programs that cover not only how to use the new technology but also its benefits—understanding why these changes matter can motivate employees to embrace them wholeheartedly. Consider using hands-on workshops or simulations so team members can practice their skills in real-time scenarios.

Moreover, ongoing support should be part of your training strategy; designate champions within teams who can assist others as questions arise post-implementation. This peer-to-peer support fosters confidence among staff while reinforcing best practices within SMT storage management operations. Remember: investing time in training now pays off later through increased efficiency and reduced errors down the line.

Integrating Automation into SMT Storage Management

In the fast-paced world of the SMT industry, integrating automation into storage management is no longer just a luxury—it's a necessity. Automated storage solutions streamline processes, reduce human error, and significantly enhance operational efficiency. By embracing these technologies, companies can optimize their SMT storage management, leading to better resource allocation and improved productivity.

Benefits of Automated Storage Solutions

Automated storage solutions bring a plethora of benefits to the table for SMT storage management. First and foremost, they drastically cut down on manual labor, allowing employees to focus on more strategic tasks rather than mundane inventory checks or retrievals. Additionally, these systems provide real-time data access and tracking capabilities that enhance visibility across the supply chain—making it easier to manage stock levels and predict future needs.

Moreover, automated systems contribute to improved space utilization within warehouses or production areas by maximizing vertical storage options that traditional methods often overlook. This efficient use of space not only reduces overhead costs but also allows for quicker retrieval times during operations—a win-win for any SMT company looking to boost its bottom line.

How Automation Enhances Efficiency and Accuracy

When it comes to efficiency in SMT storage management, automation is a game changer. Automated systems minimize human error through precise algorithms and programmed workflows that ensure tasks are completed accurately every time. This level of accuracy is crucial in an industry where precision is paramount; even minor errors can lead to significant setbacks in production timelines.

Furthermore, automation enhances speed by executing repetitive tasks at lightning-fast rates compared to manual efforts. For example, automated guided vehicles (AGVs) can transport materials quickly across large facilities without delays associated with human intervention or decision-making processes. As such, organizations can expect faster turnaround times and increased throughput—all while maintaining high standards of quality control.

Notable Examples of Automation in Action

Several companies have successfully integrated automation into their SMT storage management practices with remarkable outcomes. For instance, Bensun Technology implemented an automated inventory system that reduced retrieval times by 50%, allowing them to meet customer demands more effectively while cutting operational costs dramatically. Another standout example includes a leading electronics manufacturer that adopted robotic arms for component handling; this innovation not only minimized handling errors but also accelerated assembly lines significantly.

These examples illustrate how embracing automation can transform traditional approaches to SMT storage management into streamlined operations that are both efficient and scalable. As businesses continue adapting to evolving market demands, leveraging automated solutions will be essential for staying competitive in this dynamic landscape.

Measuring Success and ROI

In the realm of SMT storage management, measuring success and return on investment (ROI) is crucial for determining the effectiveness of any implemented strategies. Organizations need to assess whether their intelligent storage systems are delivering tangible benefits, such as improved efficiency and reduced costs. By focusing on key performance indicators (KPIs), companies can gain insights that drive continuous improvement in their storage management practices.

Key Performance Indicators for Storage Management

To effectively evaluate SMT storage management, organizations should establish clear KPIs that reflect their specific goals and objectives. Common indicators include inventory turnover rates, order fulfillment accuracy, and space utilization metrics. By regularly monitoring these KPIs, businesses can identify areas for optimization and ensure their intelligent storage systems are functioning at peak performance.

Another vital KPI to consider is the time taken to retrieve items from storage; shorter retrieval times often correlate with enhanced operational efficiency. Additionally, tracking equipment downtime can provide insights into potential bottlenecks in the system. Ultimately, a well-defined set of KPIs enables organizations to make data-driven decisions that enhance their SMT storage management strategies.

Analyzing Cost Savings Over Time

When implementing an intelligent storage system, organizations should carefully analyze cost savings over time to determine ROI accurately. This involves comparing pre-implementation costs with ongoing expenses after the new system has been integrated into operations. Factors such as reduced labor costs due to automation and decreased inventory holding costs significantly contribute to overall savings in SMT storage management.

Moreover, it’s essential to account for indirect cost savings resulting from improved accuracy and efficiency—think fewer errors leading to less waste or rework! Companies should also consider potential revenue increases from enhanced customer satisfaction due to faster order processing times as part of their financial analysis. In summary, a comprehensive approach to analyzing cost savings will provide a clearer picture of how an intelligent storage system impacts the bottom line.

Success Stories from the SMT Industry

The success stories emerging from the SMT industry highlight the transformative effects of adopting intelligent storage systems in enhancing operational efficiency. For instance, a major electronics manufacturer reported a 30% reduction in inventory holding costs after implementing an automated warehousing solution tailored for SMT storage management needs. This shift not only streamlined processes but also freed up valuable floor space for production activities.

Another notable example comes from a leading automotive parts supplier that leveraged real-time data analytics within its smart warehouse environment—resulting in a 25% increase in order fulfillment speed! Such impressive outcomes underscore how effectively integrating technology can revolutionize traditional approaches to SMT storage management while driving significant improvements across various operational metrics.

In conclusion, measuring success through established KPIs and analyzing cost savings over time are paramount for businesses looking to maximize ROI on their intelligent storage systems investments. As demonstrated by inspiring case studies within the industry, embracing innovation can lead not just to better numbers but also create opportunities for growth and increased competitiveness.

Conclusion

In the rapidly evolving landscape of technology, intelligent storage systems stand at the forefront of innovation, especially in SMT storage management. As industries increasingly rely on data-driven decisions, the future promises even more sophisticated solutions that will redefine how we approach storage challenges. By embracing these advancements, businesses can prepare for a seamless transition into a more efficient operational framework.

Future Trends in Intelligent Storage Systems

The future of intelligent storage systems is set to be shaped by advancements in artificial intelligence and machine learning, enabling predictive analytics and automated decision-making processes. These technologies will enhance SMT storage management by allowing companies to anticipate needs and streamline operations proactively. As data volumes continue to grow exponentially, the integration of cloud-based solutions will also become crucial for ensuring scalability and flexibility in managing vast amounts of information.

Enhancing Operational Efficiency in SMT

Enhancing operational efficiency in SMT requires a strategic approach that leverages intelligent storage systems to minimize downtime and maximize productivity. By adopting these advanced solutions, companies can optimize their inventory processes and reduce waste—key factors in achieving lean manufacturing goals. Ultimately, effective SMT storage management not only boosts performance but also contributes to greater competitiveness within the industry.

Final Thoughts on SMT Storage Management

In conclusion, investing in intelligent storage systems represents a pivotal step towards optimizing SMT storage management practices for businesses looking to thrive in today's fast-paced environment. The combination of automation, real-time data analytics, and robust technology ensures that organizations can meet their evolving demands head-on while achieving significant cost savings over time. As we look ahead, embracing these innovations will be essential for any company aiming for long-term success.