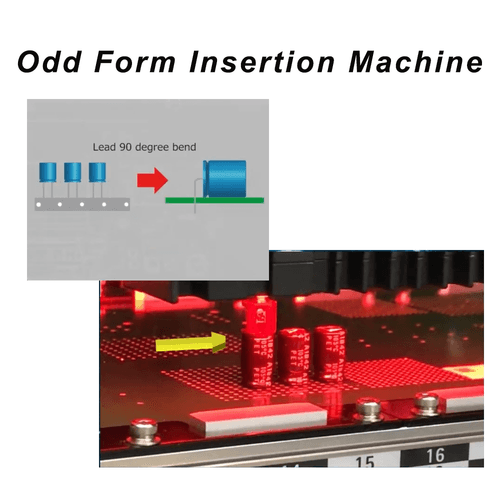

JukI JM-20 For Seamlessly Inserting Axial Components

Showroom Location: Japan

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: Ordinary Product

Warranty of core components: 1 Year

Core Components: Motor, PLC, Pump

Place of Origin: Japan

Warranty: 1 Year

Condition: New

Brand Name: JUKI

Model Number: JM20

Application: DIP PCB Production Line

Usage: PCB Production Line

Specifications

Board size

(JM-100, Standard specification, Single clamping): 50×50 mm~410×360 mm ; (JM-100, Standard specification, Double clamping): 50×50 mm~800×360 mm (JM-100, Clinch specification, Single clamping): 80×100 mm~410×360 mm ; (JM-100, Clinch specification, Double clamping): 80×100 mm~800×360 mm (JM-20, L size PCB): 410×360 mm ; (JM-20, XL size PCB): 410×560 mm (JM-20, L size PCB, Double clamping): 800×360 mm ; (JM-20, XL size PCB, Double clamping): 800×560 mm

PCB weight

(JM-100): Max. 4 kg (JM-20): Max. 5.5 kg

Component height

(JM-100): Max. 30 mm (JM-20): Max. 55 mm

Component size

(JM-100, Laser recognition): 0603~50 mm ; (JM-100, Vision recognition): □3 mm~78×48 mm or 85×25 mm (JM-20, Laser recognition): 0603~50 mm ; (JM-20, Vision recognition): □3 mm~50 mm *7, 1005~24 mm *2

Insertion speed (Insertion components) optimum

(JM-100, Vacuum nozzle): 0.6 sec/part *4, *5 ; (JM-100, Gripper nozzle): 0.8 sec/part *4, *5 (JM-20, Vacuum nozzle): 0.8 sec/part *2 ; (JM-20, Gripper nozzle): 1.3 sec/part *3, *4

Placement accuracy (SMT)

(JM-100, Laser recognition): ±100 μm (3σ) (JM-20, Vision recognition): ±100 μm (3σ)

Power supply

(JM-100): 3-phase AC200~415V (JM-20): 3-phase AC200~415V

Apparent power

(JM-100): 2.3 kVA (JM-20): 2.0 kVA

Circuit breaker

(JM-100): Standard (JM-20): Standard

Operation air pressure

(JM-100): 0.5±0.05 MPa (JM-20): 0.5±0.05 MPa

Air consumption (standard)

(JM-100): 81 L/min (JM-20): 50 L/min

Conveyor height (JM-100): 900±20 mm (JM-20): 900±20 mm

Machine dimensions (W×D×H)

(JM-100): 1,500×1,650×1,450 mm ; (JM-100): 1,500×1,650×1,450 mm (JM-20): 1,500×1,657×1,550 mm ; (JM-20): 1,500×1,657×1,550 mm

Mass (approximately)

(JM-100): 1,300 kg (JM-20): 1,760 kg ; (JM-20): 1,985 kg

Notes:

*1 Using following conditions (Applicable part: Aluminum electrolytic capacitor (φ8mm), Feeder: two MRF-6, Placement conditions: Simultaneous pick, sequential insertions using 2 nozzles)

*2 Using following conditions (Applicable part: Connector (4 pin), Insertion conditions: 2 sequential picks and insertions using 2 nozzles)

*3 Using following conditions (Applicable parts: Aluminum electrolytic capacitor (φ8mm) when the component height is 28mm, board transport, and BOC mark recognition time are not included.)

*4 Board transport and fiducial recognition not included.

Packaging and delivery

Selling Units: Single item

Single package size: 1500X1505X1450 cm

Single gross weight: 1650.000 kg