Introduction

In the ever-evolving landscape of manufacturing, automatic insertion machines have emerged as a cornerstone of efficiency and precision. These machines streamline the assembly process, significantly reducing labor costs and minimizing human error. As industries seek to enhance productivity, the role of auto insertion machines becomes increasingly vital.

Importance of Automatic Insertion Machines

Automatic insertion machines are essential in modern manufacturing environments where speed and accuracy are paramount. By automating the insertion process, these machines not only boost production rates but also ensure that components are placed with impeccable precision. This reliability is particularly crucial in sectors like electronics, where even a minor error can lead to significant failures down the line.

Benefits of Precision in Manufacturing

Precision in manufacturing translates directly into higher quality products and greater customer satisfaction. With fastener insertion machines, manufacturers can achieve consistent results that meet stringent industry standards. The ability to maintain this level of quality while increasing output is what sets companies apart in today’s competitive market.

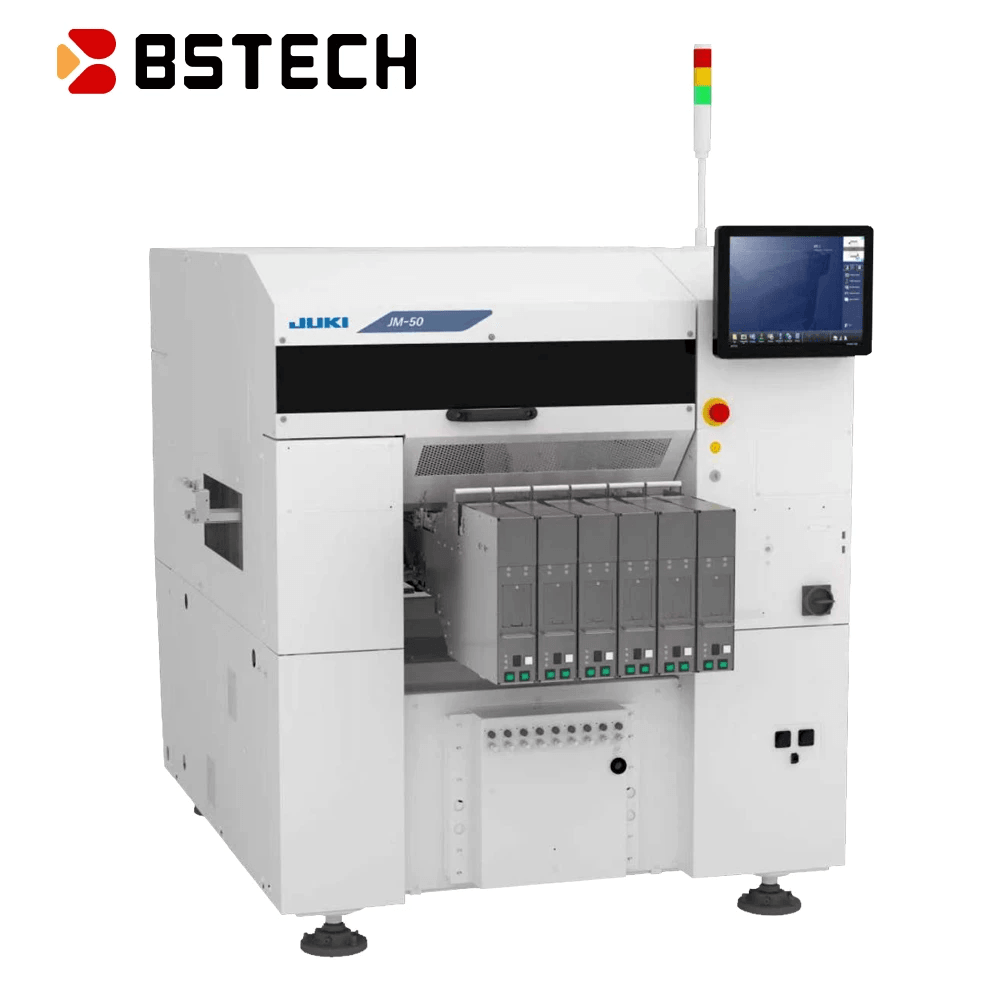

Overview of Bensun Technology

Bensun Technology stands at the forefront of innovation in insertion solutions, offering a comprehensive range of equipment tailored to meet diverse manufacturing needs. Their focus on developing cutting-edge auto insertion machines for PCB assemblies highlights their commitment to enhancing operational efficiency and product quality. With a customer-centric approach, Bensun has established itself as a trusted partner for businesses looking to optimize their assembly processes.

Understanding Insertion Machines

Insertion machines are the unsung heroes of modern manufacturing, streamlining processes that once required extensive manual labor. These machines automate the insertion of components into various substrates, significantly reducing human error and increasing efficiency. With a variety of types available, including the Auto Insertion Machine and Fastener Insertion Machine, manufacturers can choose solutions tailored to their specific needs.

Definition and Types of Insertion Machines

At its core, an insertion machine is designed to place components into designated positions on a circuit board or assembly. There are several types of insertion machines available today, including manual options for smaller operations and automated variants like the Auto Insertion Machine for PCB assemblies. Fastener Insertion Machines specifically focus on affixing fasteners with precision, making them essential in industries where reliability is paramount.

How Auto Insertion Machines Work

Auto insertion machines utilize advanced technology to automate the process of inserting components into assemblies quickly and accurately. They typically employ robotic arms or conveyor systems to pick up parts from feeders and place them precisely where needed. This automation not only speeds up production but also enhances consistency—ensuring that every component is inserted correctly every time.

Applications in Various Industries

Insertion machines find applications across a wide array of industries—from electronics manufacturing to automotive assembly lines. The versatility of the Auto Insertion Machine allows it to adapt to different types of components and materials, making it a favorite among manufacturers looking for efficiency without sacrificing quality. Fastener Insertion Machines are particularly valuable in construction and aerospace sectors where secure fastening is critical for safety and performance.

The Rise of Fastener Insertion Machines

The manufacturing landscape is evolving, and at the forefront of this transformation are fastener insertion machines. These machines have become indispensable in various industries due to their ability to streamline processes and enhance productivity. As companies strive for efficiency, the rise of fastener insertion technology represents a significant leap forward in precision engineering.

Advantages of Using Fastener Insertion Machines

Fastener insertion machines offer a plethora of advantages that make them a game-changer in manufacturing. First and foremost, they significantly reduce labor costs by automating the fastening process, allowing human operators to focus on more complex tasks. Additionally, these machines ensure consistent quality and precision, minimizing errors that can arise from manual insertion methods.

Another key advantage is the speed at which fastener insertion machines operate. With rapid cycle times and the ability to handle multiple fasteners simultaneously, these machines drastically improve throughput in production lines. Furthermore, their adaptability means they can be used across various applications—from automotive assembly to electronics manufacturing—making them an essential tool for modern factories.

Case Studies of Fastener Insertion Efficiency

Real-world applications of fastener insertion machines highlight their efficiency and effectiveness across different sectors. For instance, a leading automotive manufacturer implemented an auto insertion machine for PCB assemblies in their production line and reported a 30% reduction in assembly time while maintaining high-quality standards. This case illustrates how investing in advanced machinery can lead to significant operational improvements.

In another example, an electronics company adopted fastener insertion technology that allowed them to increase their output by 50%. By integrating these auto insertion machines into their workflow, they not only enhanced productivity but also improved product reliability through consistent fastening techniques. Such success stories demonstrate that embracing innovation can yield impressive results.

Key Features of Fastener Insertion Technology

Fastener insertion technology comes equipped with several key features that set it apart from traditional methods. One notable feature is its programmable settings that allow users to customize fastening parameters according to specific project requirements—this level of flexibility ensures compatibility with various types of fasteners and materials used in production processes.

Additionally, modern fastener insertion machines often include advanced sensors and feedback systems that monitor performance in real-time. This capability enables manufacturers to detect issues early on, reducing downtime and enhancing overall efficiency on the production floor. With features like automated feeding systems and user-friendly interfaces, these machines are designed not just for functionality but also for ease-of-use.

The Role of Auto Insertion Machines in PCB Assemblies

In the fast-paced world of electronics, the role of auto insertion machines in PCB assemblies cannot be overstated. These machines are essential for ensuring that components are placed accurately and efficiently on printed circuit boards. With the increasing complexity of modern electronics, an auto insertion machine for PCB assemblies has become a necessity for manufacturers looking to maintain high standards and meet production demands.

Importance of Auto Insertion Machines for PCB Assemblies

Auto insertion machines play a crucial role in the manufacturing of PCBs by automating the component placement process. This automation not only streamlines operations but also significantly reduces human error, leading to higher quality products. As electronic devices continue to shrink in size while increasing in functionality, the demand for precise and reliable insertion machines has skyrocketed.

Moreover, these machines cater to various types of components—whether through-hole or surface mount—making them versatile tools in any assembly line. The importance is further underscored by their ability to handle high volumes without sacrificing accuracy, thus enabling companies to scale their operations effectively. Ultimately, an efficient auto insertion machine can be a game changer in achieving cost-effective production while adhering to stringent quality standards.

How They Enhance Quality and Speed

One of the standout benefits of using an auto insertion machine is its capacity to enhance both quality and speed during PCB assembly processes. By employing advanced technology such as vision systems and precision robotics, these machines ensure that every component is inserted exactly where it needs to be—with minimal deviation from specifications. This level of precision translates into fewer defects and reworks, which can save valuable time and resources.

Speed is another significant advantage; with fastener insertion machines working tirelessly at high speeds, manufacturers can dramatically increase their output rates without compromising on quality. The ability to produce more units within shorter time frames gives companies a competitive edge in today's market where rapid turnaround times are crucial. Therefore, investing in an auto insertion machine not only improves efficiency but also establishes a reputation for reliability among customers.

Innovations in PCB Assembly Processes

The landscape of PCB assembly processes is continually evolving thanks to innovations driven by technology advancements like those found in modern insertion machines. For instance, many auto insertion machines now incorporate AI algorithms that optimize placement strategies based on real-time data analysis—this leads to smarter decision-making during production runs. Such innovations enable manufacturers to anticipate potential issues before they arise, thereby maintaining smooth operations.

Additionally, developments like modular designs allow for easy upgrades and customization according to specific manufacturing needs or changing market demands—making fastener insertion technology more adaptable than ever before. These enhancements not only improve operational efficiency but also foster greater collaboration between design engineers and production teams as they work with increasingly sophisticated machinery tailored specifically for their requirements. As we look ahead, it's clear that innovation will continue shaping how we approach PCB assembly processes.

Bensun Technology: A Leader in Insertion Solutions

In the realm of precision manufacturing, Bensun Technology stands out as a trusted name in insertion solutions. With a comprehensive suite of services and advanced machinery, including auto insertion machines and fastener insertion machines, Bensun is committed to enhancing efficiency across various industries. Their dedication to innovation ensures that they remain at the forefront of technology, particularly with their auto insertion machine for PCB assemblies.

Overview of Bensun’s Services and Offerings

Bensun Technology offers a diverse range of products and services tailored to meet the unique needs of their clients. Their lineup includes state-of-the-art insertion machines designed for both high-volume production and specialized applications. Whether it’s an auto insertion machine or a fastener insertion machine, Bensun provides solutions that enhance productivity while maintaining impeccable quality standards.

The company also specializes in custom solutions, ensuring that each client receives equipment tailored specifically to their operational needs. This adaptability makes Bensun a go-to partner for businesses looking to streamline their manufacturing processes with cutting-edge technology. Furthermore, they provide ongoing support and maintenance services to ensure that all machinery operates at peak performance.

Customer-Centric Approach in Equipment Solutions

At the heart of Bensun Technology's success is its unwavering commitment to customer satisfaction. The team prioritizes understanding client requirements before recommending specific equipment solutions, ensuring that every auto insertion machine or fastener insertion machine meets precise operational demands. This customer-centric approach fosters long-lasting relationships built on trust and reliability.

Bensun invests time in training clients on how to maximize the capabilities of their new equipment, particularly with complex systems like those used in PCB assemblies. By providing thorough onboarding processes and continuous support, they empower customers to achieve optimal results from their investment in technology. This focus on service excellence distinguishes Bensun from competitors who may overlook the importance of post-purchase engagement.

Success Stories and Client Testimonials

Bensun Technology has garnered numerous success stories from satisfied clients who have transformed their operations through innovative insertion solutions. For instance, one electronics manufacturer reported a 30% increase in efficiency after integrating an auto insertion machine for PCB assemblies into their production line—proof that smart investments yield significant returns. Clients frequently highlight how fastener insertion machines have drastically reduced assembly times while improving accuracy.

Testimonials often emphasize not just the quality of the machinery but also the exceptional support received throughout the process—from initial consultation through installation and beyond. Many customers appreciate how Bensun’s team remains accessible for troubleshooting or upgrades as technology evolves within their industries. These stories are testaments not only to product excellence but also to a partnership ethos that defines Bensun's approach.

Future Trends in Insertion Technology

The landscape of insertion technology is rapidly evolving, driven by advancements in automation and innovative engineering solutions. As industries continue to seek ways to enhance productivity and efficiency, the future of insertion machines looks promising. The integration of smart technologies will redefine how we perceive and utilize auto insertion machines across various sectors.

Automation and the Future of Insertion Machines

Automation is set to revolutionize the functionality of insertion machines, making them more efficient than ever before. With the rise of Industry 4.0, auto insertion machines are being designed to work seamlessly with IoT devices, allowing for real-time monitoring and adjustments during production processes. This level of automation not only reduces labor costs but also minimizes human error, leading to higher precision in fastener insertion tasks.

Moreover, as manufacturers increasingly adopt automated solutions, we can expect a shift towards flexible manufacturing systems that can adapt to varying production demands. Fastener insertion machines will likely incorporate advanced algorithms that optimize their performance based on specific requirements or changes in product design. The future is bright for those who embrace these technological advancements in their operations.

Predictions for Insertion Machine Innovations

Looking ahead, several key innovations are anticipated in the realm of auto insertion machines that will further enhance their capabilities. One major trend is the development of machine learning algorithms that enable these devices to learn from previous tasks and improve over time—essentially becoming smarter with each use. This could lead to faster cycle times and improved accuracy for PCB assemblies.

Additionally, we might see an increase in hybrid models that combine traditional fastener insertion methods with cutting-edge robotic technologies. These innovations will not only boost productivity but also allow for greater customization options within manufacturing processes. As companies strive for operational excellence, staying abreast of these trends will be crucial for maintaining a competitive edge.

How Companies Can Stay Ahead with Technology

To stay ahead in this rapidly changing landscape, companies must actively invest in training their workforce on new technologies related to auto insertion machines and fastener insertion techniques. Embracing continuous education ensures that employees are well-equipped to leverage the latest advancements effectively—maximizing productivity while minimizing downtime during transitions between old and new systems.

Furthermore, businesses should foster partnerships with tech innovators like Bensun Technology who specialize in cutting-edge equipment solutions tailored specifically for PCB assemblies and other applications requiring precision fastener placement. By collaborating with industry leaders, companies can gain insights into best practices while accessing state-of-the-art machinery designed for optimal performance.

Lastly, keeping an eye on emerging trends such as sustainable manufacturing practices or eco-friendly materials can position organizations favorably within their markets as they adapt their operations accordingly—ultimately enhancing both reputation and profitability.

Conclusion

In the ever-evolving landscape of manufacturing, precision is no longer optional; it’s essential. Automatic insertion machines have emerged as pivotal tools in this transformation, enabling businesses to enhance efficiency and accuracy like never before. As industries continue to embrace automation, the role of fastener insertion machines will only grow more significant, paving the way for smarter production lines.

Transforming Manufacturing with Precision Insertion

Precision insertion is revolutionizing how products are assembled across various sectors. The introduction of auto insertion machines has streamlined processes, reducing human error and increasing throughput in manufacturing environments. With fastener insertion machines taking center stage, companies can achieve remarkable levels of consistency and quality that were previously unattainable.

Bensun Technology’s Commitment to Quality

At the forefront of this technological wave is Bensun Technology, a company dedicated to delivering top-tier solutions for modern manufacturing challenges. Their auto insertion machine for PCB assemblies exemplifies this commitment by merging cutting-edge technology with user-centric design principles. Through continuous innovation and customer feedback, Bensun ensures that its products not only meet but exceed industry standards.

The Future of Fastener Insertion Solutions

Looking ahead, the future of fastener insertion solutions appears bright and filled with potential advancements. As automation becomes increasingly sophisticated, we can expect even more innovative features in auto insertion machines that will further enhance their capabilities in various applications. Companies that embrace these trends will undoubtedly stay ahead of the curve, ensuring they remain competitive in a rapidly changing marketplace.