Introduction

In the fast-paced world of electronic manufacturing, maintaining optimal temperatures for electronic components is crucial. PCB cooling solutions play a pivotal role in ensuring that these components are not only produced efficiently but also remain reliable throughout their lifecycle. With the increasing complexity of electronics products, understanding the nuances of cooling systems has become essential for electronics manufacturers looking to enhance their production processes.

Importance of PCB Cooling Solutions

The significance of effective PCB cooling solutions cannot be overstated; they are vital in preventing overheating, which can lead to severe damage to sensitive electronic parts. As a distributor of electronic components, recognizing the importance of cooling mechanisms helps ensure that products meet quality standards and perform reliably under various conditions. Furthermore, adequate cooling directly influences defect rates, making it a top priority for electronics manufacturers aiming to produce high-quality electronic products.

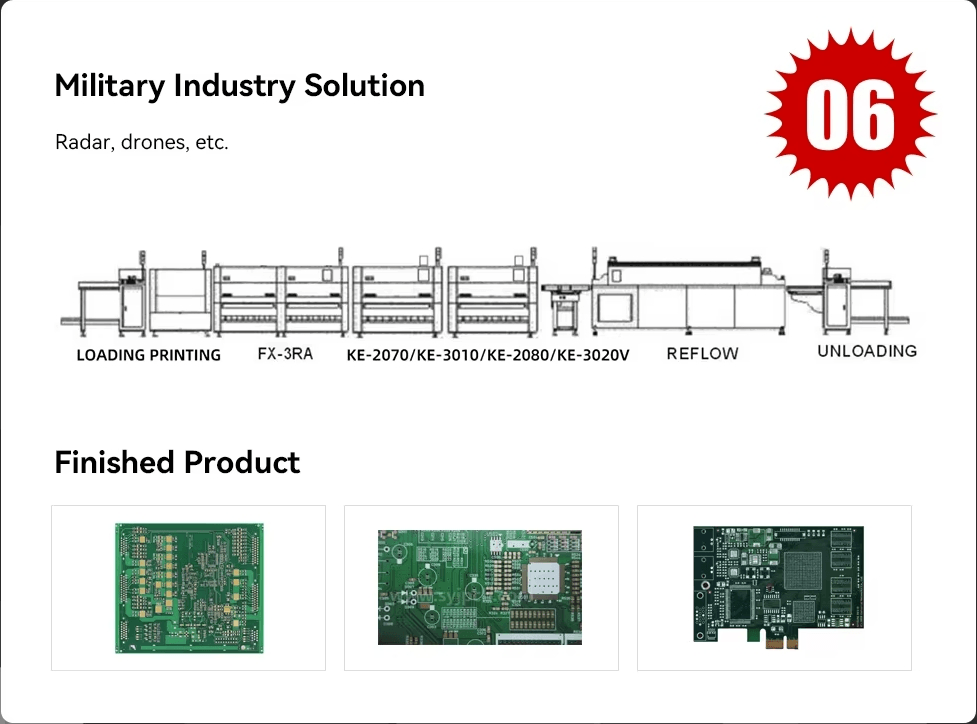

Understanding SMT Processes

Surface Mount Technology (SMT) processes have revolutionized how electronic components are assembled onto PCBs, allowing for greater efficiency and precision. However, these processes generate substantial heat during reflow soldering, necessitating robust cooling solutions to protect the integrity of electronic parts. By grasping the intricacies of SMT workflows, businesses can better appreciate how effective PCB cooling contributes to overall production efficiency and product reliability.

The Role of Bensun Technology

Bensun Technology stands out in the realm of PCB cooling solutions by offering innovative machines designed specifically for SMT lines. As an established player in this industry, Bensun Technology provides advanced systems that cater to the unique needs of electronics manufacturers and distributors alike. By integrating cutting-edge technology into their designs, Bensun ensures that clients receive top-notch support in managing their electronic component storage cabinet supplier requirements while enhancing operational efficiency.

PCB Cooling Buffer Machine Explained

In the fast-paced world of electronics manufacturing, the PCB cooling buffer machine plays a pivotal role in maintaining the integrity of electronic components post-reflow. Designed to rapidly cool printed circuit boards (PCBs), this machine ensures that delicate electronic parts do not suffer from thermal stress, which can lead to defects and failures. By integrating this technology into their production lines, electronics manufacturers can enhance overall product quality and reliability.

Functionality and Design

The PCB cooling buffer machine operates by employing advanced cooling techniques that efficiently dissipate heat from freshly soldered PCBs. Its design typically includes a series of fans or air jets strategically positioned to provide uniform cooling across the entire surface area of the boards. This functionality is crucial for preserving sensitive electronic components, as uneven cooling can result in warping or cracking, ultimately compromising the performance of electronic products.

Moreover, these machines are often custom-designed to fit seamlessly within existing SMT lines, allowing for easy integration without disrupting workflow. The compact design ensures that they occupy minimal floor space while maximizing efficiency in handling multiple boards simultaneously. With a focus on ergonomic operation and user-friendly controls, operators can easily monitor and adjust settings for optimal performance.

Key Features and Benefits

One standout feature of modern PCB cooling buffer machines is their ability to offer precise temperature control throughout the cooling process. This precision reduces the risk of thermal shock on electronic components, which is essential for maintaining high-quality standards in electronics manufacturing. Additionally, many models come equipped with energy-efficient systems that minimize power consumption while still delivering effective cooling capabilities.

Another benefit lies in their ability to improve production throughput by decreasing cycle times between reflow soldering and subsequent processes such as inspection or assembly. By ensuring that PCBs are cooled quickly yet safely, manufacturers can keep up with demand without sacrificing quality—an important consideration for any distributor of electronic components looking to stay competitive in today's market.

Furthermore, investing in a reliable PCB cooling buffer machine translates into fewer defects arising from overheating issues during production runs. This reduction not only enhances product reliability but also decreases costs associated with rework or scrap materials—benefits every electronics manufacturer aims for when optimizing their operations.

Impact on Production Efficiency

The impact of incorporating a PCB cooling buffer machine into an SMT line cannot be overstated; it serves as a critical link between various stages of production. By facilitating rapid yet controlled cooling after reflow processes, these machines help streamline workflows significantly within electronics manufacturing facilities. As a result, manufacturers experience improved turnaround times on projects while maintaining stringent quality assurance measures across all electronic products produced.

Additionally, having an efficient PCB cooling system allows companies to scale their operations more effectively; they can handle larger batches without fear of compromising quality due to overheating concerns related to sensitive electronic parts vendors’ specifications or requirements. This scalability is vital for growth-oriented businesses aiming to expand their customer base while ensuring consistent delivery standards.

Lastly, successful implementations demonstrate that investing in top-tier equipment like PCB cooling buffer machines leads directly to enhanced operational efficiency—transforming how companies approach both production planning and execution within an increasingly competitive landscape filled with numerous distributors of electronic components vying for market share.

Benefits of Adequate Cooling After Reflow

In the world of electronics manufacturing, effective cooling after the reflow process is not just a luxury; it’s a necessity. Proper cooling ensures that electronic components reach their optimal performance and longevity, ultimately impacting the quality of the final product. As we delve into the benefits of adequate cooling, we’ll see how it plays a pivotal role in safeguarding investments in electronic parts and systems.

Preventing Damage to Electronic Components

One of the most critical advantages of proper cooling is its ability to prevent damage to sensitive electronic components. Rapid temperature changes can lead to thermal shock, causing cracks or other physical damage that may not be immediately visible but can compromise functionality over time. By employing effective cooling solutions from reliable distributors of electronic components, manufacturers can safeguard their investments and ensure that their products remain intact during storage and handling.

Moreover, when electronic components are cooled gradually after reflow, it allows for uniform thermal distribution across all parts. This uniformity minimizes stress points that could lead to failure later in an electronic product's lifecycle. For electronics manufacturers looking to enhance quality control, investing in adequate cooling systems is a proactive approach that pays dividends down the line.

Enhancing Product Reliability

Reliability is paramount in the competitive landscape of electronics manufacturing; customers expect products that perform consistently over time. Adequate cooling after reflow significantly contributes to this reliability by ensuring that solder joints solidify correctly without defects like cold solder joints or voids. With reliable connections between electronic parts assured through proper cooling techniques, manufacturers can confidently market their products as high-quality solutions.

Additionally, enhanced reliability translates directly into customer satisfaction and brand loyalty for electronics manufacturers. When consumers trust that their devices won’t fail unexpectedly due to poor manufacturing processes, they’re more likely to return for future purchases or recommend those products within their networks. Thus, ensuring adequate cooling becomes not just a technical requirement but also a strategic advantage for any distributor of electronic components aiming for long-term success.

Reducing Defect Rates

Defect rates are often a thorny issue in production lines; even minor flaws can lead to significant losses when it comes time for inspection or testing stages. Implementing efficient PCB cooling solutions helps reduce these defect rates by promoting uniform heat dissipation throughout the assembly process—an essential factor during reflow soldering where precision is key. Electronics manufacturers who prioritize post-reflow cooling will find themselves with fewer rejected units and lower overall production costs.

Furthermore, reduced defect rates contribute positively to supply chain efficiency as well; fewer defective units mean less waste and better utilization of resources such as labor and materials associated with producing electronic products. By choosing high-quality PCB coolers from reputable suppliers—such as an established electronic component storage cabinet supplier—manufacturers can streamline operations while maintaining quality standards across all types of electronic parts they produce or assemble.

In summary, adequate post-reflow cooling isn't merely an operational detail; it's integral to maintaining product integrity and reputation within the industry landscape dominated by fierce competition among vendors supplying various types of electronic components.

Choosing the Right PCB Cooling System

Selecting the right PCB cooling system is crucial for optimizing production processes in electronic manufacturing. With a plethora of options available, electronics manufacturers must carefully evaluate their specific needs, including the types of electronic components being handled and the overall workflow. A well-chosen cooling solution not only enhances product reliability but also contributes significantly to reducing defect rates.

Factors to Consider

When choosing a PCB cooling system, several factors come into play. First and foremost, consider the size and type of electronic components you are working with—different designs may require varying cooling capacities. Additionally, evaluate compatibility with existing SMT lines; a seamless integration will streamline production workflows and minimize downtime.

Another important factor is energy efficiency; systems that consume less power while maintaining optimal performance can lead to significant cost savings over time. Furthermore, think about maintenance requirements—systems that are easy to service can help prevent production hiccups caused by equipment failure. Lastly, consider the reputation of your potential suppliers; collaborating with reliable distributors of electronic components ensures you receive quality products backed by solid support.

Comparing Different Models

With various models on the market, comparing their features is essential for making an informed decision. Start by examining specifications such as cooling capacity, airflow design, and temperature control mechanisms—these aspects directly impact how well a model performs in your specific environment. Also look at user reviews from other electronics manufacturers; real-world experiences can provide valuable insights into reliability and ease of use.

Some models might offer advanced features like programmable settings or automated monitoring systems which can enhance efficiency further. It's also wise to check warranty terms and after-sales support provided by vendors—this can be crucial should any issues arise post-purchase. By carefully weighing these factors against your operational needs, you’ll find a model that fits like a glove.

Leading Suppliers in the Market

In your search for an ideal PCB cooling system, it’s vital to consider leading suppliers known for their quality products and excellent customer service in the realm of electronic parts vendors. Companies like Bensun Technology have established themselves as prominent players in providing innovative solutions tailored for electronics manufacturing needs. They not only supply top-notch equipment but also offer support services that enhance your overall experience.

Don’t overlook other reputable distributors of electronic components who specialize in PCB cooling systems—they often bring unique offerings that could suit niche requirements better than mainstream options. It’s beneficial to engage with multiple suppliers to compare prices and features thoroughly before making a final decision on which system will best meet your needs for efficient cooling post-reflow.

Integration with SMT Lines

Integrating PCB cooling solutions into Surface Mount Technology (SMT) lines is crucial for ensuring a seamless production process. The compatibility of cooling systems with existing SMT machinery can significantly impact the overall efficiency of electronic manufacturing. A well-integrated system not only enhances productivity but also maintains the integrity of electronic components throughout the assembly process.

Importance of Compatibility

When selecting a PCB cooling solution, compatibility with other equipment in the SMT line is paramount. If the cooling system does not align with existing machinery, it can lead to bottlenecks and increased downtime, ultimately affecting production schedules. By partnering with a reputable electronic component storage cabinet supplier, manufacturers can ensure that their cooling systems are designed to fit seamlessly into their workflows, enhancing overall operational efficiency.

Streamlining the Production Workflow

A well-integrated PCB cooling system streamlines the entire production workflow by minimizing interruptions and maintaining optimal temperatures for electronic parts post-reflow. This efficiency allows electronics manufacturers to reduce cycle times and improve output quality, thereby increasing profitability. Furthermore, when electronic parts vendors provide tailored solutions that match specific manufacturing needs, it becomes easier to manage inventory and enhance supply chain operations.

Case Studies of Successful Implementations

Several electronics manufacturers have successfully integrated advanced PCB cooling systems into their SMT lines, showcasing significant improvements in production efficiency. For instance, one leading distributor of electronic components reported a 30% reduction in defect rates after implementing a state-of-the-art cooling solution that aligned perfectly with their existing processes. Another case study highlighted how an innovative approach from an electronic component storage cabinet supplier led to improved thermal management and enhanced reliability of final products, reinforcing the critical role of effective integration in modern electronics manufacturing.

Maintenance and Troubleshooting Tips

Maintaining your PCB cooling system is crucial for optimal performance and longevity. Regular upkeep not only ensures that your equipment runs smoothly but also prevents costly downtime that can affect your production line. By following a structured maintenance routine, you can keep your cooling solutions in top shape, ultimately benefiting electronics manufacturers and their electronic products.

Regular Maintenance Practices

To keep your PCB cooling buffer machine functioning efficiently, regular maintenance practices are essential. Start by checking the coolant levels and ensuring that all components are free from dust and debris; this simple step can significantly enhance the performance of any electronic component storage cabinet supplier's offerings. Additionally, inspect the cooling fans for any signs of wear or obstruction, as these elements play a crucial role in maintaining optimal temperatures for electronic parts.

Another key practice is to perform periodic software updates if applicable, which can improve functionality and address any bugs that may arise over time. Keeping a log of maintenance activities helps track when specific parts were last serviced or replaced, making it easier to schedule future checks. This proactive approach will not only extend the life of your equipment but also ensure consistent quality in your electronic manufacturing processes.

Common Issues and Solutions

Despite best efforts at maintenance, issues may still arise with PCB cooling systems. One common problem is inadequate cooling due to blocked air vents or dirty filters; this can lead to overheating of sensitive electronic components and increased defect rates in production. To resolve this, ensure that all air pathways are clear and replace filters regularly as part of your routine checks.

Another frequent issue involves coolant leaks which can disrupt operations significantly if not addressed promptly. Identifying the source of the leak—whether from hoses or seals—allows you to take corrective action quickly; using high-quality parts from a reliable distributor of electronic components can help prevent such issues in the first place. By being aware of these potential problems and their solutions, electronics manufacturers can maintain smoother operations within their production lines.

Ensuring Longevity of Equipment

The longevity of your PCB cooling system hinges on both proper usage and diligent maintenance practices. Investing in high-quality components from reputable electronic parts vendors ensures durability while minimizing wear over time; after all, nobody wants to deal with frequent breakdowns! Additionally, creating an environment conducive to equipment health—such as controlling humidity levels—can further enhance the lifespan of your machinery.

Training staff on how to operate equipment correctly will also contribute significantly to its longevity; improper handling often leads to unnecessary damage or malfunctioning parts during production runs involving sensitive electronic products. Lastly, keeping an eye on industry trends related to cooling technologies may provide insights into upgrades or replacements that could improve efficiency down the line—a win-win for everyone involved!

Conclusion

In the rapidly evolving landscape of electronic manufacturing, the importance of effective PCB cooling solutions cannot be overstated. As electronics manufacturers strive to meet increasing demands for reliability and efficiency, advancements in cooling technology will play a pivotal role in shaping the future of SMT processes. The right cooling system not only enhances product performance but also safeguards electronic components from potential damage.

Future Trends in PCB Cooling Technology

Looking ahead, we can expect several trends to emerge in PCB cooling technology that will redefine industry standards. Innovations such as advanced thermal management systems and smart monitoring solutions are likely to gain traction among electronics manufacturers seeking to optimize their production lines. Furthermore, greater emphasis on energy efficiency and sustainability will drive the development of eco-friendly cooling options that minimize environmental impact while maintaining high performance.

How Bensun Technology Stands Out

Bensun Technology has established itself as a leader among electronic parts vendors by offering cutting-edge PCB cooling buffer machines tailored for modern manufacturing needs. Their commitment to quality and innovation ensures that clients receive reliable solutions designed to enhance production efficiency significantly. As a trusted distributor of electronic components, Bensun not only provides exceptional products but also invaluable support and expertise throughout the integration process.

Final Thoughts on SMT Efficiency

In conclusion, achieving optimal SMT efficiency hinges on understanding the critical role of adequate cooling systems in protecting electronic products during manufacturing processes. By investing in reliable solutions from reputable suppliers like Bensun Technology, businesses can reduce defect rates and enhance product reliability significantly. Ultimately, embracing these advancements will empower electronics manufacturers to thrive in an increasingly competitive market while ensuring their electronic components remain safe and functional.