Introduction

In the ever-evolving landscape of electronics manufacturing, the importance of advanced odd form insertion cannot be overstated. This process, which involves placing non-standard components onto printed circuit boards (PCBs), plays a critical role in ensuring that modern devices function seamlessly. With the rise of complex electronic assemblies, understanding ICT insertion and its integration with SMT machines has become essential for manufacturers aiming to stay competitive.

Understanding Advanced Odd Form Insertion

Advanced odd form insertion refers to the specialized technique used for placing irregularly shaped components that cannot be handled by traditional pick & place machines. These components often require precise positioning and solder paste application to ensure reliable connections on PCBs. As electronic devices become more compact and sophisticated, the demand for efficient odd form insertion has surged, making it a vital element in contemporary manufacturing processes.

The Role of SMT Machines in Manufacturing

Surface Mount Technology (SMT) machines are at the heart of modern electronics production, facilitating the assembly of intricate circuit designs with remarkable speed and accuracy. These machines not only handle standard components but also play a crucial role in wave soldering processes that ensure robust connections for both surface-mounted and through-hole parts. By integrating advanced odd form insertion capabilities into their operations, manufacturers can enhance productivity while maintaining high-quality standards.

Overview of Bensun Technology Co., Ltd.

Bensun Technology Co., Ltd. stands out as a leader in providing cutting-edge solutions for SMT needs, specializing in advanced odd form insertion machinery tailored to meet diverse industry demands. With a commitment to innovation and quality, Bensun’s products are designed to integrate seamlessly into existing production lines while optimizing performance across various applications. Their expertise in ICT insertion technology positions them as a trusted partner for manufacturers looking to elevate their assembly processes.

What is Odd Form Insertion?

Odd Form Insertion is a specialized process in the realm of electronics manufacturing, focusing on the placement of components that do not conform to standard shapes or sizes. This technique is crucial for accommodating a variety of odd form components, which are often essential for modern electronic devices. Understanding this process helps manufacturers optimize their production lines and improve overall efficiency.

Defining Odd Form Components

Odd form components are those that deviate from the traditional rectangular or square shapes typically handled by pick & place machines. These can include items like connectors, transformers, or even large capacitors that require unique handling due to their size or shape. The ability to insert these components accurately and efficiently is where advanced SMT machines come into play, ensuring precision and reliability in assembly.

Importance in Modern Electronics

In today's fast-paced electronics landscape, the importance of odd form insertion cannot be overstated. As devices become more compact and sophisticated, the demand for diverse component types increases—making ICT insertion techniques vital for manufacturers aiming to stay competitive. Moreover, incorporating odd form insertion into production processes allows for enhanced functionality and performance in end products.

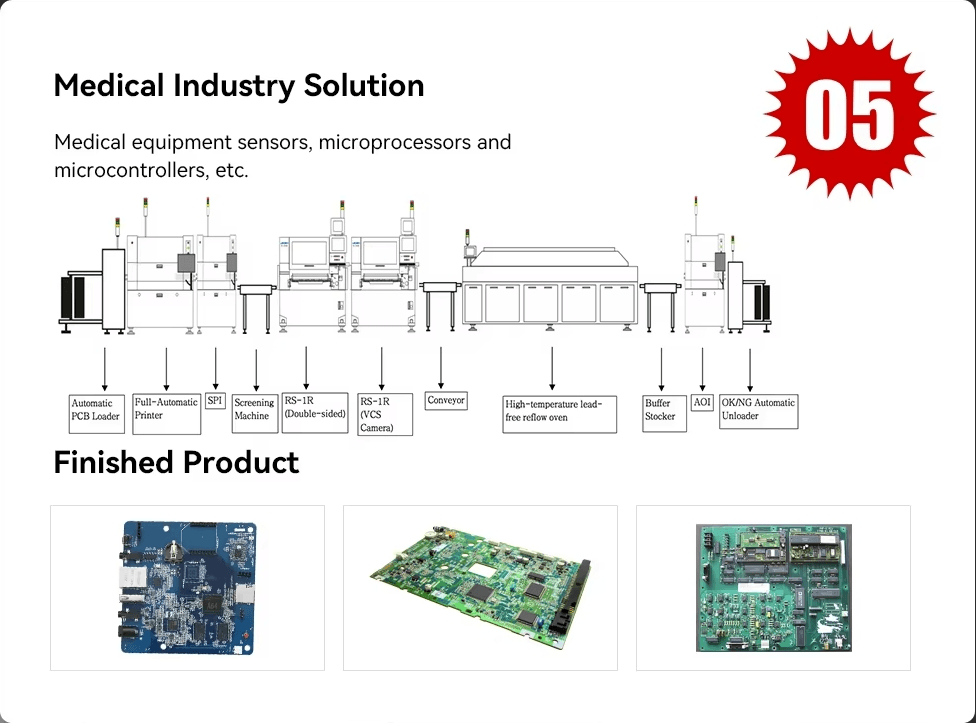

Applications in Various Industries

The applications of odd form insertion span multiple industries including automotive, telecommunications, and consumer electronics. For instance, automotive systems often require various sensors and connectors that fall under the odd form category; thus necessitating specialized SMT machines for effective assembly. Additionally, industries such as medical devices rely heavily on custom configurations of components where wave soldering might also be implemented alongside ICT insertion methods to ensure durability and reliability.

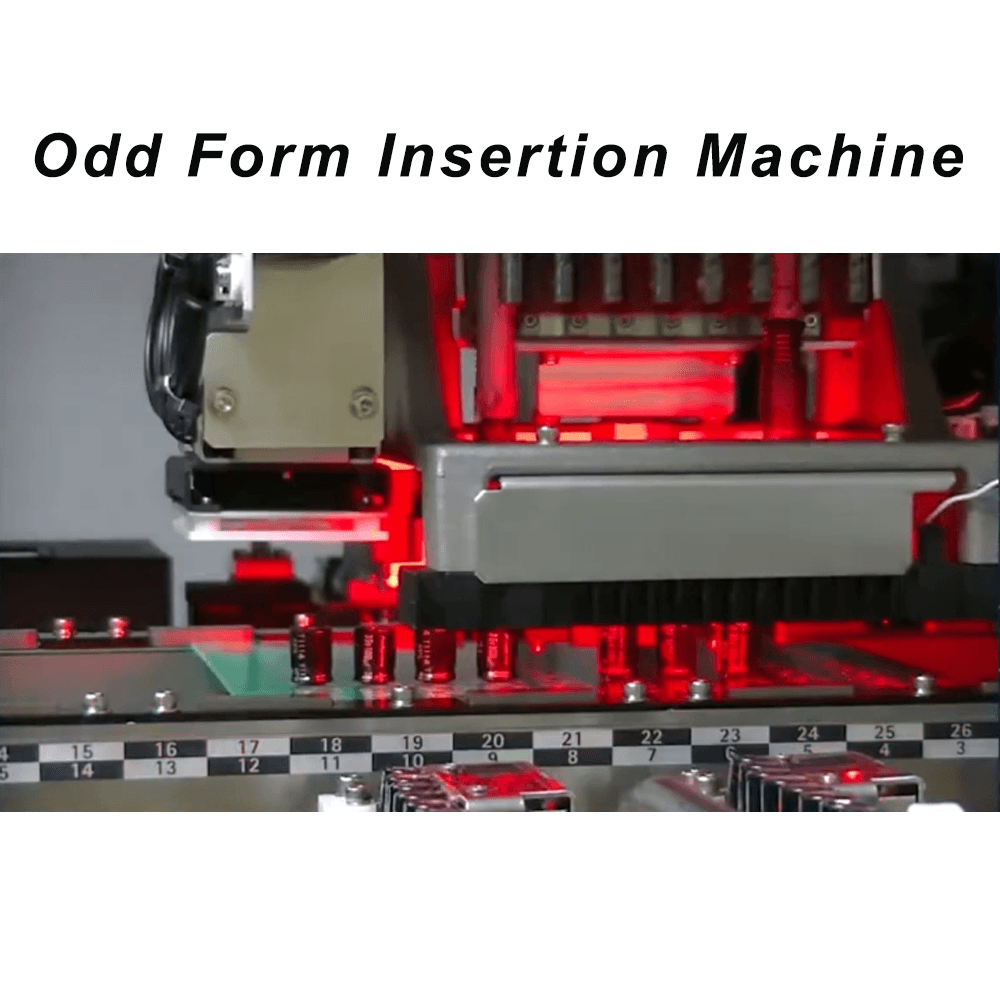

Bensun's Advanced Odd Form Insertion Machine

When it comes to odd form insertion, Bensun Technology Co., Ltd. has taken the lead with its advanced machine that revolutionizes how electronic components are placed on circuit boards. This state-of-the-art equipment is designed to handle various odd form components with precision and efficiency, ensuring that your production line runs smoothly. With features tailored for modern manufacturing needs, Bensun's machine stands out as a top choice for businesses looking to enhance their SMT processes.

Features and Capabilities

Bensun's advanced odd form insertion machine boasts an array of impressive features that set it apart from standard SMT machines. Equipped with high-speed insertion capabilities, it can seamlessly integrate with existing pick & place machines, optimizing the entire assembly process. Additionally, the machine utilizes advanced sensors and software for real-time monitoring and adjustments, ensuring accurate placement of components while minimizing errors associated with wave soldering.

The versatility of this machine allows it to handle a wide range of odd form components—from connectors and transformers to larger capacitors—making it ideal for various applications in electronics manufacturing. With the ability to work alongside traditional SMT solder techniques, Bensun’s technology ensures that all parts are securely attached using solder paste or other bonding methods. This combination of speed, accuracy, and flexibility makes the Bensun insertion machine a game-changer in the industry.

Integration with SMT Processes

Integrating Bensun's advanced odd form insertion machine into your existing SMT setup is straightforward and beneficial for overall production efficiency. The machine is designed to complement traditional pick & place operations by filling in gaps where standard machines may struggle with larger or oddly shaped components. This synergy between different types of SMT machines not only streamlines workflows but also enhances overall output quality.

Furthermore, by utilizing sophisticated software solutions, Bensun ensures seamless communication between its odd form inserter and other equipment on the production line. This integration allows for synchronized operations that minimize downtime while maximizing productivity—a crucial factor in today’s fast-paced manufacturing environment. As industries continue to evolve towards more complex electronic assemblies, having a system that integrates well within an established SMT framework becomes indispensable.

Benefits of Choosing Bensun Technology

Choosing Bensun Technology means investing in cutting-edge solutions tailored specifically for modern electronics manufacturing challenges like ICT insertion tasks. One significant advantage is the reduced need for manual intervention; operators can focus on higher-level tasks rather than micromanaging each component placement thanks to automation features built into our systems. Moreover, our commitment to quality means you’re not just purchasing a piece of machinery—you’re gaining access to support from a team dedicated to keeping your operations running smoothly.

Another benefit lies in cost-effectiveness; by improving accuracy and reducing rework through reliable component placement techniques like those used in wave soldering processes combined with our advanced systems, businesses can enjoy significant savings over time without sacrificing quality or performance standards associated with traditional SMT solder methods. Ultimately, choosing Bensun translates into long-term gains—not just in terms of financial savings but also enhanced reputation through consistent product excellence.

Comparing SMT Machines for Insertion Tasks

In the world of electronics manufacturing, understanding the distinctions between various types of machines is crucial for optimizing production efficiency. When it comes to insertion tasks, two primary contenders often come into play: SMT machines and pick & place machines. Each type has its unique functionalities, strengths, and weaknesses that cater to different aspects of the production process.

Key Differences Between Insertion and Pick & Place Machines

The fundamental difference between insertion machines and pick & place machines lies in their operational focus. While pick & place machines are designed primarily for surface mount technology (SMT) solder applications—placing components onto a PCB with precision—odd form insertion machines specialize in handling components that do not conform to standard shapes or sizes. This makes ICT insertion a critical process where unconventional components are inserted into PCBs efficiently, ensuring that all types of parts can be accommodated without compromising quality.

Moreover, pick & place machines often rely on solder paste application before component placement, while odd form insertion systems may utilize wave soldering techniques post-insertion to secure components firmly onto the board. This distinction is vital when considering the overall workflow in a manufacturing line; integrating both machine types can enhance flexibility and adaptability in production processes.

Advantages of SMT Solder Solutions

One of the standout advantages of utilizing SMT solder solutions is their ability to provide a reliable bond between components and PCBs without excessive manual intervention. With advanced SMT machines equipped with precise dispensing capabilities for solder paste, manufacturers can achieve consistent results every time—a crucial factor when dealing with high-volume production runs. Additionally, these solutions minimize defects associated with manual soldering methods, thus improving yield rates.

Furthermore, incorporating wave soldering alongside advanced odd form insertion techniques allows for efficient thermal management during assembly processes. Wave soldering ensures even heating across all connections while maintaining component integrity; this synergy leads to enhanced durability and performance in electronic devices across various industries—from automotive to consumer electronics.

Investing in Quality for Long-Term Gains

When it comes to choosing machinery for your production line, investing in high-quality SMT machines pays dividends over time. Quality equipment not only improves operational efficiency but also reduces downtime caused by maintenance issues or malfunctions common with lower-tier alternatives. By opting for advanced technologies like those offered by Bensun Technology Co., Ltd., manufacturers can ensure they remain competitive by leveraging cutting-edge features designed specifically for ICT insertion tasks.

Moreover, durable machinery leads to lower total cost of ownership as they require less frequent replacements or repairs compared to cheaper models that might falter under heavy usage conditions. The long-term gains from investing in quality equipment extend beyond mere cost savings; they also include improved product quality and increased customer satisfaction due to fewer defects arising from improper assembly techniques or inadequate bonding methods like poorly applied wave soldering.

The Future of ICT Insertion Technology

The future of ICT insertion technology is poised for exciting advancements, driven by innovations that redefine how we approach electronics manufacturing. As industries increasingly adopt smart technologies, the integration of advanced SMT machines will revolutionize production lines. This evolution will not only enhance efficiency but also improve the overall quality of electronic products.

Innovations on the Horizon

Innovations in ICT insertion technology are set to transform traditional manufacturing processes significantly. One area seeing rapid development is the enhancement of pick & place machines, which are becoming more sophisticated in handling odd form components alongside standard solder paste applications. Additionally, machine SMT capabilities are evolving to incorporate artificial intelligence and machine learning, enabling real-time adjustments for optimal performance during wave soldering processes.

As manufacturers seek greater flexibility and speed, new materials and techniques are emerging to streamline assembly lines further. For instance, advancements in SMT solder formulations promise better adhesion and reliability in challenging environments. Furthermore, the integration of IoT devices within SMT machines allows for predictive maintenance and seamless monitoring of production metrics.

Impact of Automation in Production Lines

The impact of automation on production lines cannot be overstated; it serves as a catalyst for increased productivity and reduced operational costs. By automating tasks traditionally performed by humans, manufacturers can achieve higher precision with their ICT insertion processes while minimizing errors associated with manual labor. The synergy between automated pick & place machines and advanced odd form insertion systems creates a streamlined workflow that ensures timely delivery without compromising quality.

Moreover, automation facilitates a more agile response to market demands by allowing quick adjustments to production schedules based on real-time data analysis. This adaptability is crucial in an era where consumer preferences shift rapidly and require manufacturers to pivot quickly without losing efficiency or incurring excessive costs related to rework or scrap materials. As a result, companies investing in automation technologies stand to gain a significant competitive advantage over those clinging to outdated methods.

Predictions for Industry Growth

Looking ahead, predictions indicate robust growth within the ICT insertion technology sector fueled by ongoing advancements in both hardware and software solutions. The demand for high-quality electronics across various industries—such as automotive, healthcare, and consumer electronics—will drive further investment into state-of-the-art SMT machines capable of accommodating complex assembly requirements seamlessly. Experts forecast that companies embracing these innovations will experience enhanced profitability through improved operational efficiencies and product reliability.

Additionally, as sustainability becomes increasingly critical in manufacturing practices, there will be greater emphasis on eco-friendly materials and processes within ICT insertion technologies. Manufacturers who prioritize sustainable practices while optimizing their use of solder paste will likely capture market share among environmentally conscious consumers seeking responsible products without sacrificing quality or performance.

In conclusion, the future landscape for ICT insertion technology promises exciting possibilities marked by innovation-driven growth opportunities across multiple sectors.

Maintenance Tips for Optimal Performance

Keeping your SMT machines in top-notch condition is essential for ensuring efficient production and minimizing downtime. Regular maintenance not only enhances performance, but it also prolongs the lifespan of your machine, particularly when dealing with complex tasks like ICT insertion. With the right care, your SMT machines can operate seamlessly alongside pick & place machines and wave soldering processes.

Regular Checks for SMT Machines

Routine inspections of your SMT machine are crucial to catching potential issues before they escalate into costly repairs or production delays. Start by checking the solder paste application, ensuring that it’s consistent and free from clogs or discrepancies that could affect assembly quality. Additionally, monitor components like nozzles and feeders regularly; any wear or malfunction can disrupt the delicate balance between precision and speed in your manufacturing process.

Another key aspect is to verify alignment settings periodically to maintain accurate placement of odd form components during ICT insertion tasks. Misalignment can lead to defects that not only waste materials but also require rework—an expense you’d prefer to avoid! By incorporating regular checks into your maintenance routine, you can ensure that your machine SMT performs at its best.

Common Issues and Solutions

Despite regular maintenance, some common issues may arise with SMT machines that require immediate attention. One frequent problem is inconsistent solder paste application, which may lead to poor connections in both traditional and odd form components during assembly processes. If you notice this issue, recalibrating the solder paste dispenser or replacing worn-out parts can often resolve it quickly.

Another common hiccup involves misfeeds from the pick & place machine; this can disrupt workflow significantly during high-volume production runs. To address this issue, ensure that all feeders are properly loaded and calibrated according to specifications—this simple step can save you a world of trouble down the line! Lastly, if you're experiencing frequent errors during wave soldering operations, double-checking temperature settings and flux levels might just be what the doctor ordered.

Importance of Professional Support

While regular checks and DIY fixes are important for maintaining optimal performance in your SMT machines, sometimes professional support is indispensable. Expert technicians have specialized knowledge about complex systems like those used in ICT insertion processes; they can quickly diagnose problems that may not be immediately visible to less experienced operators. Engaging professionals ensures that any intricate issues related to machine SMT operations are addressed effectively without risking further complications.

Moreover, having a dedicated support team means you’ll receive timely updates on best practices for using solder paste efficiently or integrating new technologies into existing setups—keeping you ahead of industry trends! Investing in professional maintenance services ultimately pays off by reducing downtime and enhancing overall productivity across all facets of manufacturing.

Conclusion

In the rapidly evolving landscape of electronics manufacturing, choosing the right partner for your SMT needs is crucial. Bensun Technology Co., Ltd. stands out as a leader in advanced odd form insertion technology, offering machines that not only meet but exceed industry standards. With their commitment to innovation and quality, Bensun ensures that your production lines remain competitive and efficient.

Why Choose Bensun for Your SMT Needs

Their cutting-edge odd form insertion machines are engineered to integrate seamlessly with existing processes like wave soldering and solder paste application. By investing in Bensun's solutions, you gain access to machinery that enhances productivity while reducing operational costs.

The Competitive Edge of Advanced Insertion Machines

Advanced insertion machines from Bensun are designed with features that set them apart from traditional pick & place machines. These SMT machines are capable of handling a wide variety of components, making them versatile for different applications in various industries. The precision and speed offered by these machines not only improve production efficiency but also ensure high-quality solder connections, which are essential for reliable electronic devices.

Looking Ahead: The Future of SMT and Electronics

The future of ICT insertion technology looks promising as automation continues to reshape manufacturing processes worldwide. With ongoing innovations in machine smt capabilities and advancements in software integration, we can expect even greater efficiencies in production lines. As the demand for high-quality electronics rises, investing in superior SMT solder solutions will be vital for businesses looking to thrive in this competitive market.