Introduction

In the world of electronics, surface mount device soldering has become a cornerstone technique for assembling modern circuit boards. Unlike traditional methods, this process allows components to be mounted directly onto the surface of printed circuit boards (PCBs), streamlining production and enhancing performance. As technology continues to evolve, mastering surface mount soldering is essential for anyone looking to stay competitive in the field.

Understanding Surface Mount Device Soldering

Surface mount device soldering involves attaching electronic components directly onto the surface of a PCB rather than inserting them through holes. This method offers significant advantages, such as reduced size and weight of devices, which is crucial in today's compact electronics landscape. By understanding the nuances of this technique, hobbyists and professionals alike can improve their skills and produce higher-quality assemblies.

Importance of Techniques in Soldering

Soldering techniques are vital in ensuring reliable connections between components and PCBs. Mastery over these techniques can mean the difference between a successful project and a frustrating failure; poor solder joints can lead to malfunction or complete breakdowns. Therefore, investing time in learning proper methods not only enhances your craftsmanship but also boosts confidence when tackling complex projects.

Overview of Essential Soldering Methods

When diving into surface mount soldering, it’s important to familiarize yourself with various essential methods that cater to different needs and applications. Techniques such as reflow soldering, wave soldering, and hand soldering each have their unique benefits depending on your project requirements. Understanding these methods will help you choose the right approach for your specific tasks while making informed decisions about your surface mount soldering kit.

Choosing the Right Surface Mount Solder

When diving into the world of surface mount device soldering, selecting the right surface mount solder is crucial. The quality of the solder can significantly impact both the process and the final product. Understanding what makes a good solder will help you achieve better results in your projects.

Characteristics of Quality Surface Mount Solder

Quality surface mount solder should possess several key characteristics to ensure optimal performance during surface mount soldering. First and foremost, it must have excellent wetting properties, allowing it to flow smoothly onto pads and components for a strong bond. Additionally, a good surface mount solder should exhibit minimal oxidation and have a suitable melting point that aligns with your specific application needs.

Another important factor is the alloy composition; lead-free solders are becoming increasingly popular due to environmental regulations, but they often require higher temperatures for effective joining. Moreover, quality solders come with consistent diameter and flux content, which ensures uniform application and reduces defects during the soldering process. Ultimately, investing in high-quality surface mount solder can save time and prevent headaches down the road.

Comparison of Solder Types

When comparing different types of solders for surface mount applications, you'll encounter various options such as leaded vs. lead-free solders or different alloy compositions like SAC (Tin-Silver-Copper). Leaded solders tend to have lower melting points and better flow characteristics, making them easier to work with; however, they are also less environmentally friendly than their lead-free counterparts.

On the other hand, lead-free solders are often required in many modern electronics due to RoHS compliance but may necessitate adjustments in your heating technique or equipment settings because they generally melt at higher temperatures. Additionally, consider factors like viscosity and flux type when choosing between different types of surface mount solder—these aspects can greatly influence how well your solder adheres during assembly.

Ultimately, understanding these differences will help you make an informed decision on which type best suits your specific needs in surface mount device soldering.

Recommendations for Specific Applications

Selecting the ideal surface mount solder isn't just about personal preference; it should also align with your project's requirements. For general-purpose applications where reliability is key without breaking any environmental regulations, a high-quality SAC alloy would be a solid choice for most hobbyists and professionals alike.

If you're working on projects that require precise control over thermal properties—such as RF applications—it might be best to opt for specialized alloys designed specifically for those conditions. For beginners using a comprehensive surface mount soldering kit that includes various types of fluxes might be beneficial as it allows experimentation while gaining experience in this intricate craft.

In conclusion, carefully considering these recommendations can significantly enhance your experience with surface mount device soldering while ensuring successful outcomes tailored to your unique project demands.

Selecting the Ideal Surface Mount Soldering Kit

Choosing the right surface mount soldering kit can make a world of difference in your soldering projects. The ideal kit should not only contain essential tools but also be tailored to your specific needs, whether you're a beginner or a seasoned pro. With the right kit in hand, you'll find that surface mount device soldering becomes less daunting and much more enjoyable.

Components of a Comprehensive Soldering Kit

A comprehensive surface mount soldering kit typically includes several key components that facilitate effective soldering. First and foremost, you'll need a quality soldering iron with adjustable temperature settings to handle various types of surface mount solder. Additionally, look for kits that include precision tips, tweezers for handling small components, flux pens to improve adhesion, and desoldering braid for correcting mistakes.

Don't forget about accessories like magnifying glasses or microscopes; these tools help you see those tiny connections clearly during the intricate process of surface mount device soldering. A reliable work mat is also crucial to protect your workspace from heat damage while keeping small parts organized and accessible. Finally, ensure that your kit has an anti-static wrist strap to prevent any static discharge from damaging sensitive electronic components.

Top Picks for Beginners and Pros

For beginners venturing into the world of surface mount soldering, kits like the Weller WHS40 are fantastic choices due to their user-friendly design and excellent performance at an affordable price point. This kit provides everything you need without overwhelming you with unnecessary extras—perfect for getting started! On the other hand, pros might prefer something like the Hakko FX-951 which offers advanced features such as rapid heating elements and interchangeable tips suited for various applications.

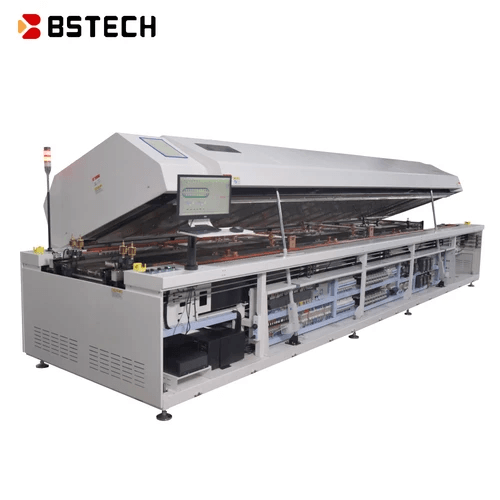

Bensun Technology's Soldering Solutions

Bensun Technology stands out in providing high-quality solutions tailored specifically for surface mount soldering needs. Their kits come equipped with everything from precision tools designed for fine-pitch devices to advanced hot air rework stations that make delicate operations easier than ever before. With Bensun’s commitment to excellence in every product they offer, you can trust their solutions will enhance your experience whether you're new to SMT or looking to refine your skills further.

Moreover, Bensun offers specialized accessories such as premium fluxes and high-quality surface mount solder that cater directly to various applications within electronics assembly—making them an indispensable resource in your toolkit! By choosing Bensun Technology's products, you're not just investing in equipment; you're embracing a partnership aimed at achieving perfection in every project involving surface mount device soldering.

Mastering the Surface Mount Soldering Technique

When it comes to surface mount device soldering, mastering the technique is crucial for achieving reliable connections and high-quality results. This section will guide you through a step-by-step soldering process, highlight common pitfalls to avoid, and introduce essential tools that can make your surface mount soldering experience smoother and more efficient.

Step-by-Step Soldering Process

To begin with, ensure you have a clean workspace equipped with your surface mount soldering kit. Start by preparing your printed circuit board (PCB) by cleaning the pads where the components will be placed; this ensures good adhesion for the surface mount solder. Next, position the component accurately on the PCB pads using tweezers or a vacuum pick-up tool.

Once everything is in place, apply flux to both the component leads and PCB pads; this will help in heat transfer during soldering. Using a hot air rework station or a fine-tipped soldering iron, carefully apply heat to melt the surface mount solder—just enough to create a solid connection without overheating any components. After cooling down, inspect each joint visually for quality assurance before moving on to additional components.

Common Pitfalls and How to Avoid Them

Even seasoned professionals can stumble upon common pitfalls during surface mount device soldering. One major issue is overheating components, which can lead to damage or failure—always keep an eye on temperature settings and use appropriate techniques like preheating when necessary. Another frequent mistake is insufficient flux application; without enough flux, it’s easy for solder not to flow properly onto pads.

Additionally, misalignment of components can be detrimental; take extra time during placement to ensure everything is aligned correctly before applying heat. If you find yourself frustrated with cold joints or weak connections, revisit your technique—ensuring proper heating time and method can save you from costly rework later on.

Tools That Make a Difference

Investing in quality tools can significantly enhance your surface mount soldering experience and outcomes. A well-equipped surface mount soldering kit should include precision tweezers for accurate placement of tiny components as well as a fine-tipped soldering iron for detailed work on small pads. Hot air rework stations are also invaluable for larger assemblies where multiple connections need attention simultaneously.

Moreover, magnification tools such as binocular loupes or digital microscopes allow you to inspect your work closely—important when dealing with intricate designs typical of surface mount technology (SMT). Finally, don’t underestimate the power of good quality fluxes and solders specifically designed for SMT applications; they make all the difference in achieving strong bonds that withstand testing over time.

Surface Mount Soldering vs Through Hole Soldering

When it comes to soldering, the debate between surface mount device soldering and through hole soldering is a hot topic among electronics enthusiasts. Each method has its own set of characteristics that can make one more suitable than the other, depending on the application at hand. Understanding these differences is crucial for anyone looking to master their craft in surface mount soldering.

Key Differences Explained

Surface mount device soldering involves attaching components directly onto the surface of a printed circuit board (PCB), while through hole soldering requires components to be inserted into holes drilled into the PCB. This fundamental difference leads to variations in manufacturing processes, assembly techniques, and even repair methodologies. Additionally, surface mount solder typically allows for a higher density of components on a board compared to their through hole counterparts, making it ideal for compact designs.

Advantages of Surface Mount Technology

One of the most significant advantages of surface mount technology is its ability to accommodate smaller components, which can lead to more compact and lightweight designs. This efficiency not only saves space but also enhances electrical performance due to shorter connection paths and reduced inductance. Furthermore, using a quality surface mount solder often results in improved reliability and performance over time—benefits that are hard to ignore when selecting your preferred method.

When to Use Each Method

Choosing between surface mount soldering and through hole methods largely depends on project requirements such as size constraints and component types. For high-density applications or projects requiring miniaturization, surface mount soldering shines as the go-to choice with its efficient use of space and advanced capabilities. On the other hand, if you’re dealing with larger components or need easier access for repairs or modifications, through hole soldering may be your best bet.

Preheating Techniques for Soldering Success

When it comes to surface mount device soldering, preheating is often the unsung hero that can make or break your soldering success. Properly preheating your components ensures that the solder flows smoothly and adheres properly, reducing the risk of cold joints and other common issues. By elevating the temperature of both the PCB and surface mount solder, you create an ideal environment for a reliable connection.

Importance of Preheating in Soldering

Preheating plays a pivotal role in surface mount soldering by minimizing thermal shock to components during the soldering process. Sudden temperature changes can lead to stress fractures or damage in sensitive electronic parts, which is why gradual heating is essential. Additionally, preheating helps activate flux within the surface mount solder, promoting better wetting and ensuring a stronger bond between components and pads.

Effective Preheating Methods

There are several effective methods for preheating when engaging in surface mount soldering. One popular technique involves using a hot air rework station that evenly distributes heat across the board without risking damage to nearby components. Alternatively, infrared heaters provide a more controlled approach by focusing heat on specific areas while maintaining safety for surrounding elements—perfect for intricate designs where precision matters most.

Bensun’s Advanced Preheating Solutions

Bensun Technology offers advanced preheating solutions tailored specifically for those engaged in surface mount soldering applications. Their state-of-the-art preheaters feature adjustable temperature settings and uniform heat distribution, making them ideal for both beginners using a surface mount soldering kit and seasoned professionals alike. With Bensun’s innovative technology at your fingertips, achieving perfect results becomes not just possible but straightforward—because who doesn’t want to master their craft with ease?

Quality Control Tips for Soldered Devices

Quality control in surface mount device soldering is paramount, ensuring that every connection meets the required standards for functionality and reliability. With the intricacies involved in surface mount soldering, a systematic approach to quality assurance can help prevent defects and maximize performance. By implementing effective strategies and utilizing appropriate tools, you can elevate your soldering game to new heights.

Ensuring Quality in Surface Mount Soldering

To ensure quality in surface mount soldering, start by selecting high-quality surface mount solder that meets industry standards. Proper temperature control during the soldering process is crucial; too hot can damage components while too cool leads to weak joints. Additionally, maintaining a clean work environment free from contaminants will significantly enhance the quality of your connections.

Regular training on best practices for using a surface mount soldering kit can also improve outcomes. Familiarity with the equipment and techniques helps avoid common mistakes that could compromise joint integrity. Ultimately, investing time in mastering these aspects will pay off with more reliable and durable electronic devices.

Testing Methods to Verify Connections

Once you've completed your surface mount device soldering, it's essential to verify the quality of your connections through various testing methods. Visual inspection is often the first step; look for any visible defects such as cold joints or excess solder that could lead to failures down the line. However, visual checks alone may not catch all issues, so consider employing additional testing techniques like continuity tests or X-ray inspections for thoroughness.

Functional testing of assembled devices can reveal whether all components are operating as intended after soldering. This process helps identify any weak links within your circuitry that may have gone unnoticed during assembly. By integrating these testing methods into your workflow, you’ll ensure that each device meets performance expectations before it reaches customers.

Incorporating Visual Inspection Technologies

Automated optical inspection (AOI) systems are particularly effective at detecting defects such as misaligned components or insufficient solder coverage—issues that might be missed by the naked eye during manual inspections. These technologies not only enhance accuracy but also speed up the inspection process significantly.

Furthermore, combining AOI with other advanced imaging techniques like thermal imaging can provide insights into potential problems related to heat dissipation and component integrity post-soldering. As technology continues to evolve, integrating these tools into your workflow becomes increasingly feasible and beneficial for achieving high-quality results consistently in surface mount soldering projects.

Conclusion

In wrapping up our exploration of surface mount device soldering, it’s clear that mastering this technique is essential for anyone working in electronics today. We’ve covered the importance of choosing the right surface mount solder, selecting a quality surface mount soldering kit, and understanding critical techniques to ensure success. With these insights, you’re now equipped to tackle your projects with confidence and precision.

Recap of Essential Soldering Techniques

Throughout this guide, we’ve emphasized several essential soldering techniques that can make or break your projects. From understanding the characteristics of quality surface mount solder to recognizing the differences between surface mount soldering vs through hole methods, each aspect plays a vital role in achieving optimal results. Additionally, we discussed how effective preheating techniques and thorough quality control measures can enhance your overall soldering experience.

Final Thoughts on Surface Mount Soldering

Surface mount soldering is not just a trend; it’s a fundamental skill that every electronics enthusiast should master. The advantages of using surface mount technology are numerous, including smaller component sizes and increased circuit density—ideal for modern applications. As you continue to refine your skills in this area, remember that practice makes perfect; so keep experimenting with different techniques and tools.

The Role of Bensun in Soldering Excellence

Bensun stands out as a leading provider of innovative solutions in the realm of surface mount device soldering. Their comprehensive range of products—from high-quality surface mount solder to advanced soldering kits—ensures that both beginners and seasoned professionals have everything they need at their fingertips. By choosing Bensun, you're not just investing in tools; you're partnering with a brand committed to excellence in every aspect of surface mount soldering.