Introduction

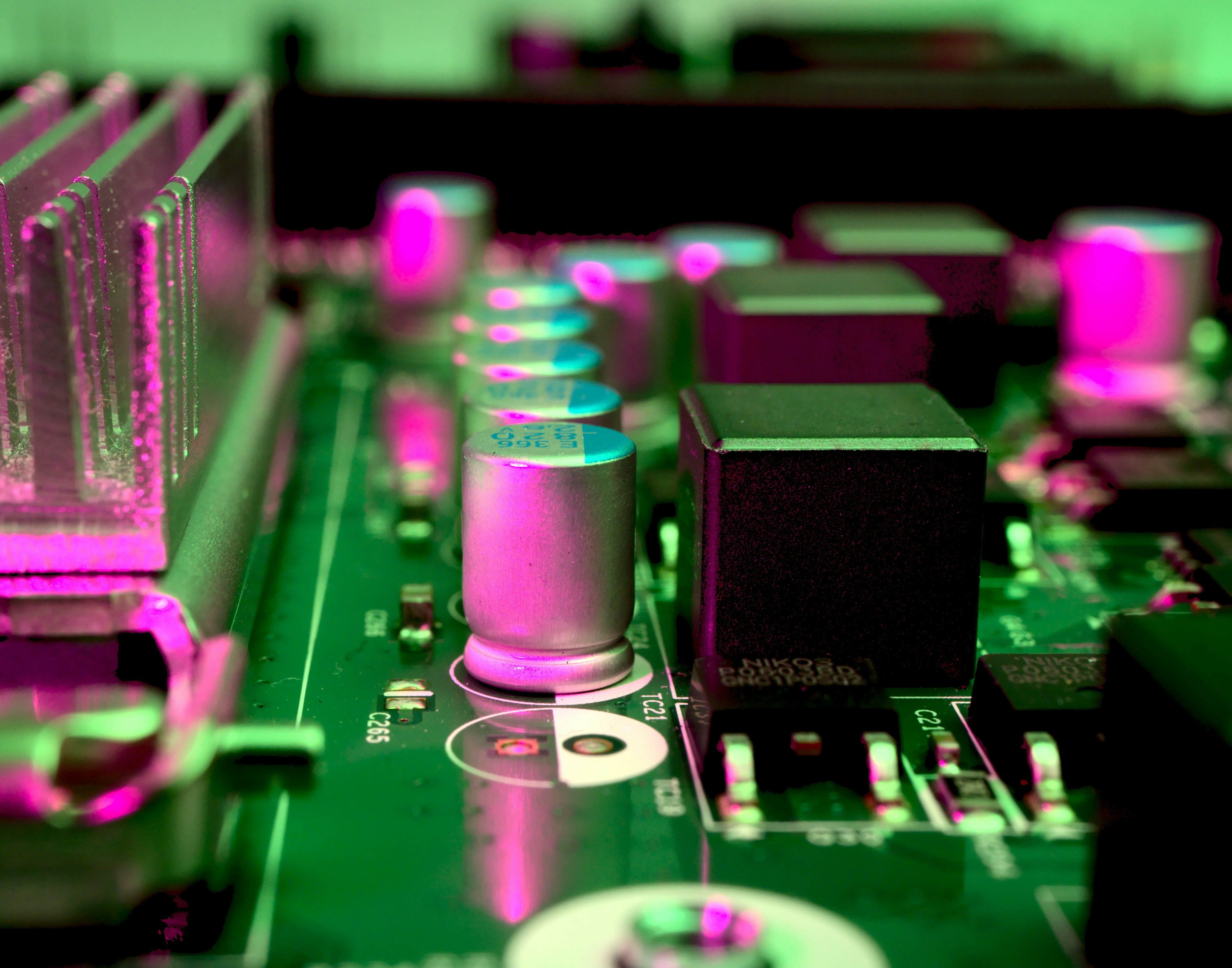

In the ever-evolving world of electronics, SMD surface mount devices have become a cornerstone of modern design and manufacturing. These compact electronic components are pivotal in enhancing the efficiency and functionality of circuit boards, enabling designers to create smaller, more powerful electronic devices. As technology advances, understanding SMD technology is crucial for anyone involved in PCB manufacturing or assembly.

Understanding SMD Surface Mount Devices

SMD surface mount devices are specialized electronic components designed for mounting directly onto the surface of a PCB assembly board, rather than through holes as with traditional components. This innovative approach allows for a denser arrangement of components on circuit boards, leading to more compact and efficient designs. By utilizing SMD technology, engineers can optimize space while maintaining performance in their electronic devices.

Benefits of Using SMD Technology

One significant advantage is the reduced size and weight that SMD components offer compared to their through-hole counterparts, making them ideal for portable applications. Additionally, the automated processes in PCB assembly involving surface mount devices lead to faster production times and lower manufacturing costs.

Key Applications of SMD Components

SMD components find their way into countless applications across various industries due to their versatility and performance advantages. They play a critical role in consumer electronics like smartphones and laptops, where space is at a premium yet reliability is essential. Moreover, these electronic components are increasingly used in automotive systems and medical devices, showcasing their importance across diverse sectors reliant on advanced circuit board technologies.

What Are SMD Surface Mount Devices

Understanding what SMD surface mount devices are is crucial for anyone involved in electronics today. These compact components are designed to be mounted directly onto the surface of printed circuit boards (PCBs), eliminating the need for through-hole technology. This approach not only saves space but also enhances the performance and reliability of electronic devices.

Definition and Overview

SMD surface mount devices are electronic components that adhere directly to the surface of a circuit board, making them a staple in modern PCB assembly. Unlike traditional components that require leads to pass through holes in the board, SMDs utilize small pads for connection, allowing for more efficient use of space. This design is particularly advantageous in compact electronic devices where every millimeter counts.

The integration of SMD technology has revolutionized PCB manufacturing by enabling higher component density, which translates into smaller and more powerful electronic devices. With advancements in soldering techniques and automated assembly processes, manufacturers can produce intricate designs with ease. Consequently, SMDs have become essential for powering everything from smartphones to industrial machinery.

Different SMD Package Types

SMDs come in various package types tailored to specific applications and requirements within electronic components. Common packages include Chip Resistors (0805, 0603), Chip Capacitors, Diodes (SOD-123), and Integrated Circuits (QFN or BGA). Each type offers distinct advantages regarding size, heat dissipation, and electrical performance.

For instance, a QFN package provides excellent thermal conductivity while maintaining a low profile—ideal for power supplies where heat management is critical. Similarly, BGAs allow for high pin count connections without increasing board size significantly. Understanding these different package types is essential when selecting the right smd surface mount device for your project.

Importance in Modern Electronics

The importance of SMDs in modern electronics cannot be overstated; they play a pivotal role in enhancing device functionality while minimizing size and weight. As consumer demand grows for sleek gadgets packed with features, manufacturers rely on these compact components to meet those expectations efficiently. Furthermore, SMD technology supports advanced functionalities such as faster signal processing and improved energy efficiency.

In power supplies specifically, using surface mount devices enables more effective circuit designs that can handle higher loads without compromising performance or reliability. Additionally, their compatibility with automated PCB assembly processes streamlines manufacturing workflows—reducing costs while maintaining high quality standards across production runs. Ultimately, embracing smd technology is key to staying competitive in an ever-evolving electronics landscape.

Popular SMD Surface Mount Device Types

When it comes to SMD surface mount devices, a variety of electronic components play crucial roles in modern circuit board designs. Each type of component has its unique characteristics and applications, making them essential for manufacturing efficient electronic devices. Understanding these popular SMD types can help you make informed choices during PCB assembly and manufacturing processes.

Resistors and Capacitors

Resistors and capacitors are the bread and butter of any circuit board, serving vital functions in controlling current flow and storing energy, respectively. In the realm of SMD technology, these components come in compact sizes that save valuable space on the PCB assembly board while delivering excellent performance. The use of surface mount resistors and capacitors allows engineers to design more intricate electronic devices without compromising on functionality or reliability.

SMD resistors are available in various resistance values and power ratings, making them versatile for different applications. Similarly, surface mount capacitors can be found in diverse dielectric materials like ceramic or tantalum, each offering distinct advantages depending on the specific needs of power supplies or signal processing circuits. By integrating these small yet powerful components into your designs, you ensure that your electronic devices operate smoothly while maximizing efficiency.

Diodes and Transistors

Diodes and transistors form the backbone of modern electronics by controlling voltage levels and amplifying signals within circuit boards. These SMD surface mount devices have evolved over time to become smaller yet more powerful, allowing for greater functionality in compact spaces. Their ability to manage electrical signals effectively makes them indispensable in various applications ranging from simple power supplies to complex integrated circuits.

Surface mount diodes come in various types such as Schottky diodes for fast switching applications or Zener diodes for voltage regulation tasks. On the other hand, transistors can be found as BJTs (Bipolar Junction Transistors) or MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors), each catering to different operational needs within an electronic device's circuitry. With their compact design, these SMD components facilitate efficient heat dissipation while minimizing signal loss across PCB assembly boards.

Integrated Circuits and Connectors

Integrated circuits (ICs) represent a pinnacle achievement in electronics by combining multiple functions into a single chip—think brainpower packed into tiny packages! These SMD surface mount devices are available in various configurations such as microcontrollers or operational amplifiers tailored for specific tasks within electronic devices. Their integration not only saves space but also enhances performance by reducing interconnect lengths on the PCB assembly board.

Connectors also play a critical role alongside ICs by ensuring reliable connections between different parts of an electronic device’s circuitry. Surface mount connectors offer robust solutions that withstand mechanical stress while maintaining high-frequency signal integrity—perfect for today’s demanding applications like telecommunications or consumer electronics. By strategically selecting appropriate ICs and connectors during PCB manufacturing processes, engineers can optimize their designs for both performance and scalability.

The Role of SMD in Power Supplies

When it comes to power supplies, SMD (Surface Mount Device) technology plays a pivotal role in enhancing the efficiency and compactness of electronic devices. These electronic components are vital for converting and regulating power within various applications, from consumer electronics to industrial machinery. By utilizing SMD components on circuit boards, designers can achieve higher performance while saving valuable real estate.

SMD Components in Power Supply Circuits

SMD components are integral to modern power supply circuits, offering a range of functionalities that traditional through-hole devices simply can’t match. Resistors, capacitors, inductors, and integrated circuits are commonly found as surface mount devices in these applications. Their small size allows for denser layouts on PCB assembly boards, which is crucial for meeting the demands of today’s compact electronic devices.

Moreover, SMD technology enables better thermal management within power supplies by reducing the distance between heat-generating components and heat sinks. This helps maintain optimal operating temperatures and prolongs the lifespan of electronic components. As a result, engineers often prefer SMD solutions when designing high-efficiency power supply circuits.

Advantages of SMD Technology in Power Supplies

The advantages of using SMD technology in power supplies are numerous and compelling. For starters, surface mount devices allow for automated PCB manufacturing processes that significantly increase production speed and precision compared to manual assembly methods. This automation not only reduces labor costs but also minimizes human error during assembly.

Additionally, the smaller footprint of SMD components leads to lighter weight designs without sacrificing performance or reliability. This is particularly beneficial for portable electronic devices where space is at a premium. Furthermore, enhanced electrical performance characteristics—such as lower parasitic inductance—make them ideal for high-frequency applications common in modern power supplies.

Best Practices for SMD Power Supply Design

Designing effective power supplies with SMD technology requires adherence to several best practices that ensure optimal functionality and reliability. First and foremost is proper layout design; keeping traces short minimizes resistance and inductance which can affect overall performance negatively. Engineers should also pay close attention to component placement on the PCB assembly board to promote efficient heat dissipation.

Another critical aspect involves selecting appropriate soldering techniques tailored specifically for surface mount devices—whether reflow or wave soldering—to ensure reliable connections without damaging sensitive electronic components during assembly processes. Quality control measures should be implemented rigorously throughout PCB manufacturing to catch any defects early on before they compromise device performance.

Lastly, testing under various conditions is essential; this includes thermal cycling tests that simulate real-world operating environments to validate design robustness over time. By following these best practices, designers can create robust power supply systems using advanced smd surface mount device technology that meets the needs of modern electronics.

PCB Assembly Techniques for SMD Devices

The assembly of SMD (Surface Mount Device) components on a PCB (Printed Circuit Board) requires precise techniques to ensure optimal performance and reliability of electronic devices. Understanding the various methods for placing and soldering these tiny electronic components is crucial in modern PCB manufacturing. With the right approach, manufacturers can enhance the quality and efficiency of their circuit board assembly processes.

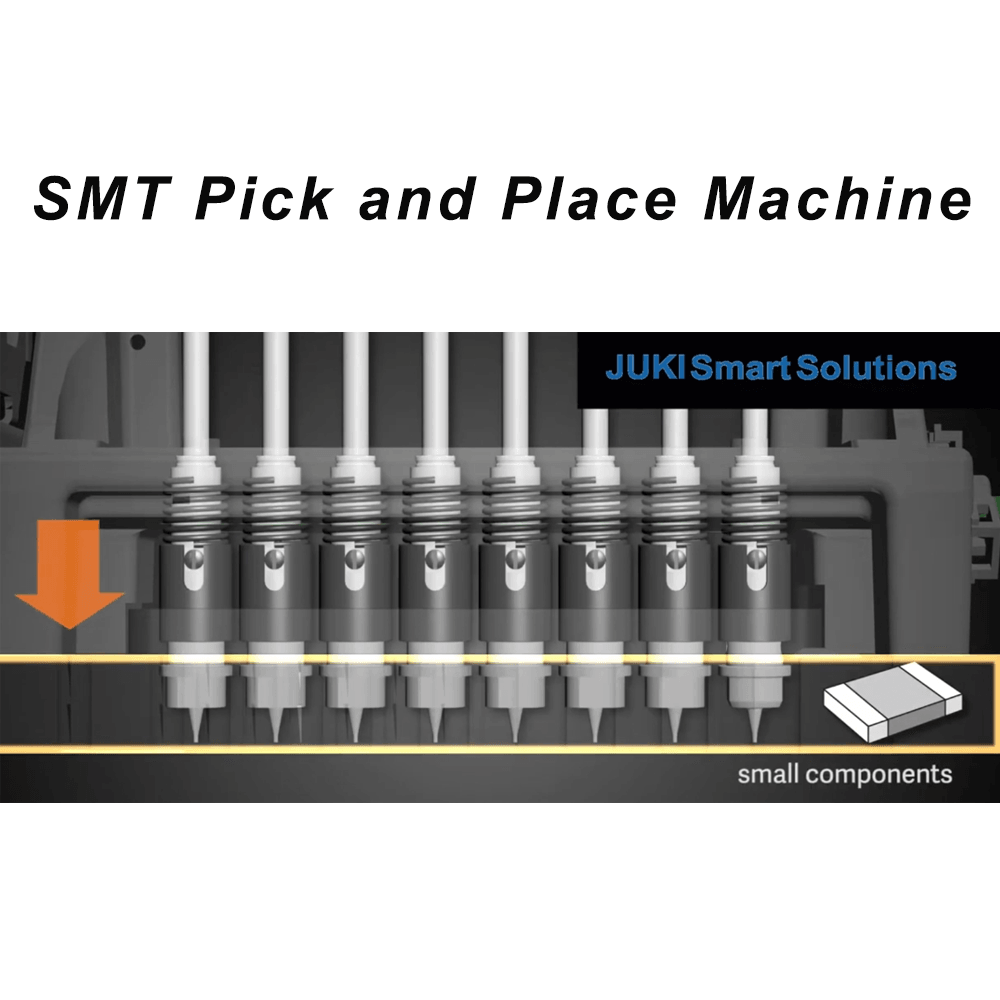

SMD Placement Methods

When it comes to placing SMD components on a PCB assembly board, precision is key. Automated pick-and-place machines are widely used to accurately position these small devices on the circuit board, significantly reducing human error and speeding up production times. Additionally, manual placement techniques may still be employed for prototypes or low-volume runs, ensuring that every smd surface mount device is correctly aligned before soldering.

Another popular method involves using adhesive to temporarily hold components in place before soldering, which can be particularly useful for larger boards with complex layouts. This technique allows for adjustments during assembly without compromising the integrity of the connections later on. Ultimately, choosing the right placement method depends on factors such as production volume, component size, and design complexity.

Soldering Techniques for SMD Components

Soldering techniques play a pivotal role in ensuring that smd surface mount devices are securely attached to the PCB. Reflow soldering is one of the most common methods used in high-volume production; it involves applying solder paste to pads on the circuit board and then heating it in an oven until it melts and forms strong joints with the electronic components. This technique not only provides reliable connections but also minimizes thermal stress on sensitive parts.

For smaller batches or prototypes, hand soldering might be preferred due to its flexibility. Using a fine-tipped soldering iron allows technicians to work precisely around delicate electronic components without damaging them or creating shorts between adjacent pads. Regardless of the chosen method, proper temperature control is vital to avoid overheating any part of your power supplies or other sensitive electronic devices during this process.

Quality Control in PCB Assembly

Quality control is essential throughout every stage of PCB manufacturing involving smd surface mount devices; it ensures that each component functions as intended within electronic devices. Regular inspections during assembly help catch defects early—before they escalate into costly issues down the line—by checking alignment, solder quality, and overall aesthetics of each circuit board produced.

Automated optical inspection systems have become increasingly popular for detecting faults such as insufficient solder joints or misplaced components quickly and accurately at high speeds. Implementing rigorous testing procedures post-assembly can further verify that power supplies and other critical circuits operate flawlessly under various conditions before reaching end-users’ hands. By prioritizing quality control measures within your pcb assembly processes, you can significantly enhance reliability while minimizing waste.

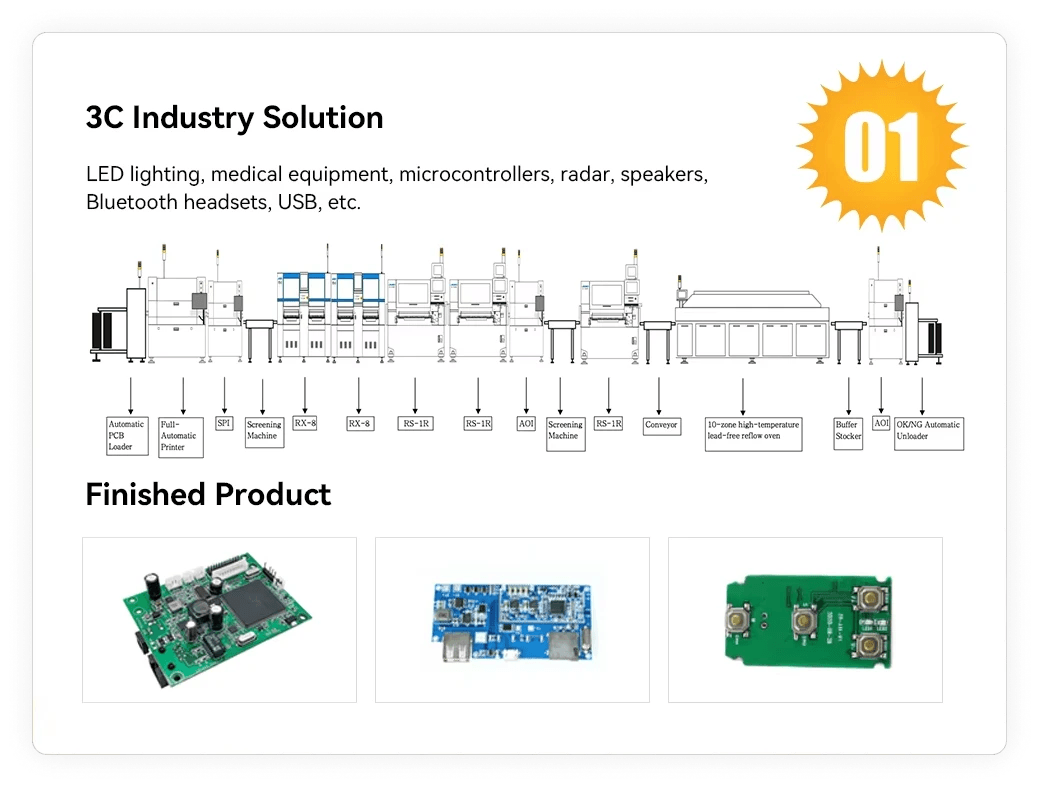

Bensun Technology in SMD Manufacturing

Bensun Technology stands at the forefront of SMD manufacturing, offering advanced solutions that enhance the production of surface mount devices. With a commitment to innovation and efficiency, Bensun provides state-of-the-art equipment designed specifically for the assembly and testing of electronic components. This ensures that every circuit board produced meets the highest standards of quality and reliability.

Overview of Bensun's Equipment

The equipment used by Bensun for SMD manufacturing is a blend of cutting-edge technology and precision engineering. Their automated pick-and-place machines are capable of handling a wide range of surface mount devices, ensuring accurate placement on PCB assembly boards. Additionally, Bensun employs reflow ovens that guarantee optimal soldering conditions, crucial for maintaining the integrity of electronic devices.

With features like real-time monitoring and adaptive control systems, Bensun's equipment not only increases production speed but also enhances overall quality assurance in PCB manufacturing. This combination allows manufacturers to scale their operations while effectively managing costs associated with SMD component production. As a result, companies can focus on innovation rather than worrying about the intricacies of assembly processes.

Benefits of Bensun's Online Dual Platform

Bensun’s online dual platform revolutionizes how businesses approach SMD production and management. By integrating both design and manufacturing processes into one seamless interface, it simplifies communication between engineers and manufacturers regarding electronic components specifications. This leads to faster turnaround times for prototypes and ultimately accelerates time-to-market for new electronic devices.

Moreover, this platform allows users to track progress in real-time, making it easier to manage inventory levels for various surface mount device types used in power supplies or other applications. The transparency offered by this system fosters better collaboration among teams involved in PCB assembly projects, ensuring that everyone is on the same page throughout the manufacturing journey.

Innovations in SMD Production with Bensun

Bensun is continuously pushing boundaries with innovations aimed at enhancing SMD production efficiency while maintaining high-quality standards. One notable advancement is their use of AI-driven analytics to predict potential issues during the assembly process before they escalate into costly problems. This proactive approach not only saves time but also reduces waste associated with defective electronic components.

Additionally, their commitment to sustainability has led them to develop eco-friendly materials and processes that minimize environmental impact during PCB manufacturing without compromising performance or reliability. By embracing such innovations, Bensun not only sets itself apart as a leader in SMD technology but also contributes positively towards a greener future for electronics.

Conclusion

In the ever-evolving landscape of electronics, SMD surface mount devices are at the forefront, driving innovation and efficiency. As technology advances, we can expect SMD components to become even smaller, more powerful, and increasingly integrated into a wider array of applications. The future trends in SMD technology will likely focus on enhancing performance while reducing costs, making these electronic components indispensable for next-generation electronic devices.

Future Trends in SMD Technology

Looking ahead, the future of SMD surface mount devices is bright and full of promise. We anticipate advancements in miniaturization techniques that will allow for even more compact circuit board designs without sacrificing functionality or reliability. Additionally, developments in materials science may lead to new types of electronic components that offer improved thermal management and energy efficiency—key factors for modern power supplies.

Importance of SMD in Electronic Devices

SMD technology is crucial for the development of contemporary electronic devices across various industries. These surface mount devices enable manufacturers to create smaller and lighter products while maintaining high performance levels—a significant advantage in today's competitive market. Furthermore, their role in power supplies cannot be overstated; efficient energy management is vital for everything from smartphones to industrial machinery.

How to Choose the Right SMD for Your Project

Selecting the right SMD surface mount device involves considering several factors tailored to your specific needs. First and foremost, evaluate the electrical characteristics required by your project—this includes voltage ratings, capacitance values, or resistance levels based on your circuit board design. Additionally, consider the physical dimensions and package types available; ensuring compatibility with your PCB assembly board is essential for seamless integration into your final product.