Introduction

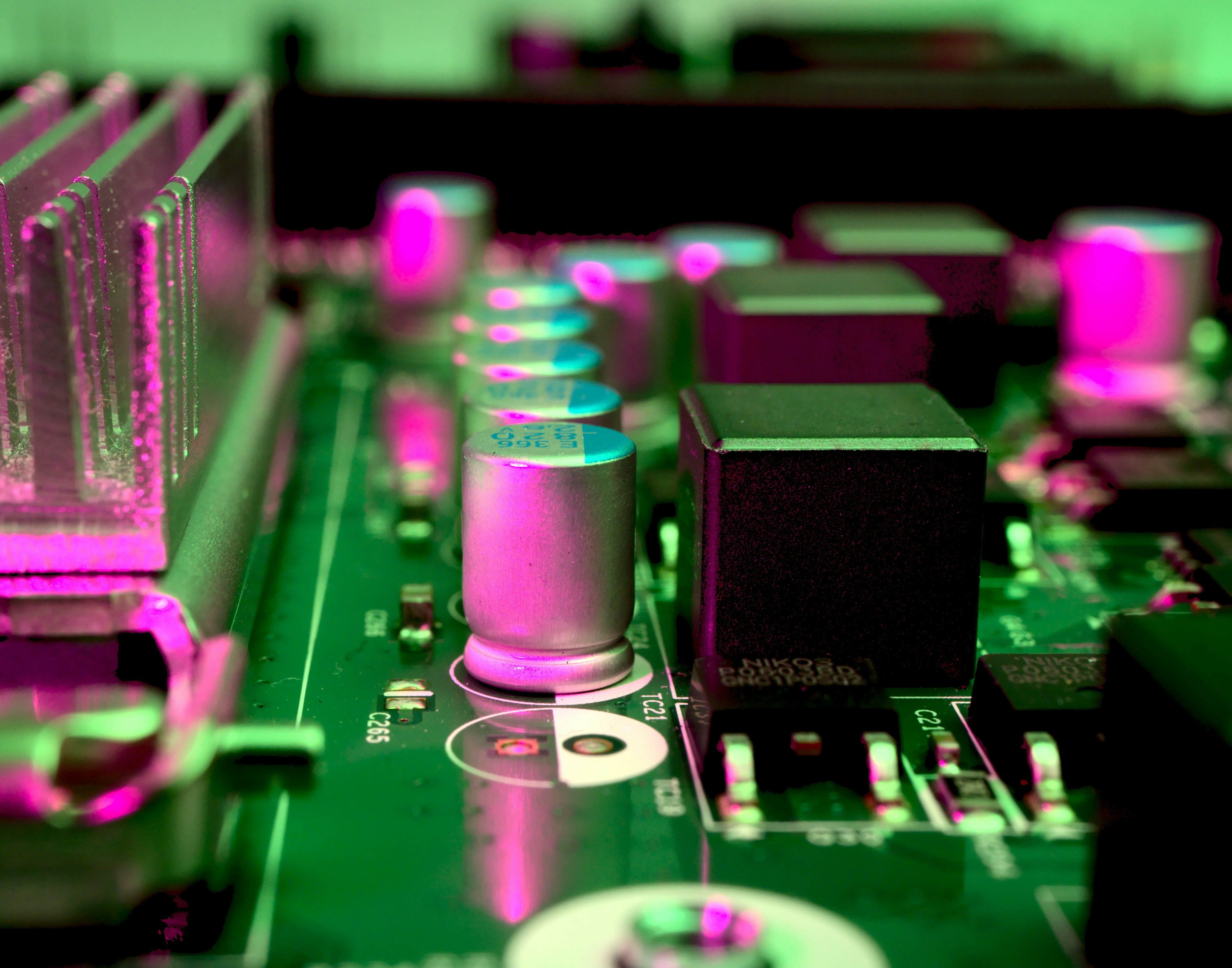

In the ever-evolving landscape of electronics, surface mount devices (SMD) have emerged as a pivotal component in printed circuit assembly (PCA). Their compact design and efficiency have revolutionized how electronic components are integrated into circuit boards, making them indispensable in modern electronic devices. Understanding SMD is crucial for anyone involved in PCB manufacturing and circuit board manufacturing, as they significantly enhance performance while reducing size.

Understanding Surface Mount Devices

Surface mount devices are specialized electronic components designed to be mounted directly onto the surface of a circuit board. Unlike traditional through-hole components that require drilled holes for installation, SMDs offer a more streamlined approach to PCB assembly. This innovative mounting technique not only saves space but also allows for automated production processes that increase efficiency and reduce costs.

The Role of SMD in PCB Manufacturing

The role of SMD in PCB manufacturing cannot be overstated; they enable manufacturers to create smaller, lighter, and more complex circuit boards than ever before. As electronic devices become more compact and feature-rich, the demand for surface mount technology continues to grow. Consequently, understanding how SMD integrates into the overall process of circuit board manufacturing is essential for optimizing production workflows and meeting market demands.

Benefits of Using SMD Components

Using surface mount device components offers numerous benefits that appeal to both designers and manufacturers alike. Firstly, their small size allows for higher component density on circuit boards, facilitating more intricate designs without compromising performance. Additionally, SMDs typically provide better electrical performance due to shorter lead lengths and reduced parasitic capacitance—key factors in today’s high-speed electronic devices.

What are Surface Mount Devices?

Surface mount devices (SMDs) represent a revolutionary shift in the design and manufacturing of electronic components. These compact devices are designed to be mounted directly onto the surface of a printed circuit board (PCB), allowing for more efficient use of space and improved performance in electronic devices. By eliminating the need for holes in the circuit board, SMDs facilitate higher density circuit board manufacturing, which is essential in today’s ever-shrinking electronic landscape.

Definition and Purpose

A surface mount device is an electronic component that is soldered onto the surface of a PCB rather than inserted through holes, as traditional components do. This mounting method not only saves space but also enhances electrical performance by reducing lead lengths, which can improve signal integrity. The primary purpose of SMDs is to enable more compact and efficient designs in modern electronics, catering to the demand for smaller, lighter, and more powerful electronic devices.

Differences from Through-Hole Components

The main difference between surface mount devices and through-hole components lies in their mounting techniques and physical attributes. While through-hole components require drilled holes on the PCB for insertion, SMDs feature flat leads or pads that sit flush against the board's surface. This fundamental distinction allows for greater miniaturization in printed circuit assembly, making SMDs particularly advantageous for high-density applications where space is at a premium.

Additionally, SMDs typically offer better performance due to shorter electrical paths that reduce inductance and resistance compared to their through-hole counterparts. This makes them ideal for high-frequency applications commonly found in advanced electronics such as smartphones and computers. Overall, this shift towards surface mount technology has redefined circuit board manufacturing processes across various industries.

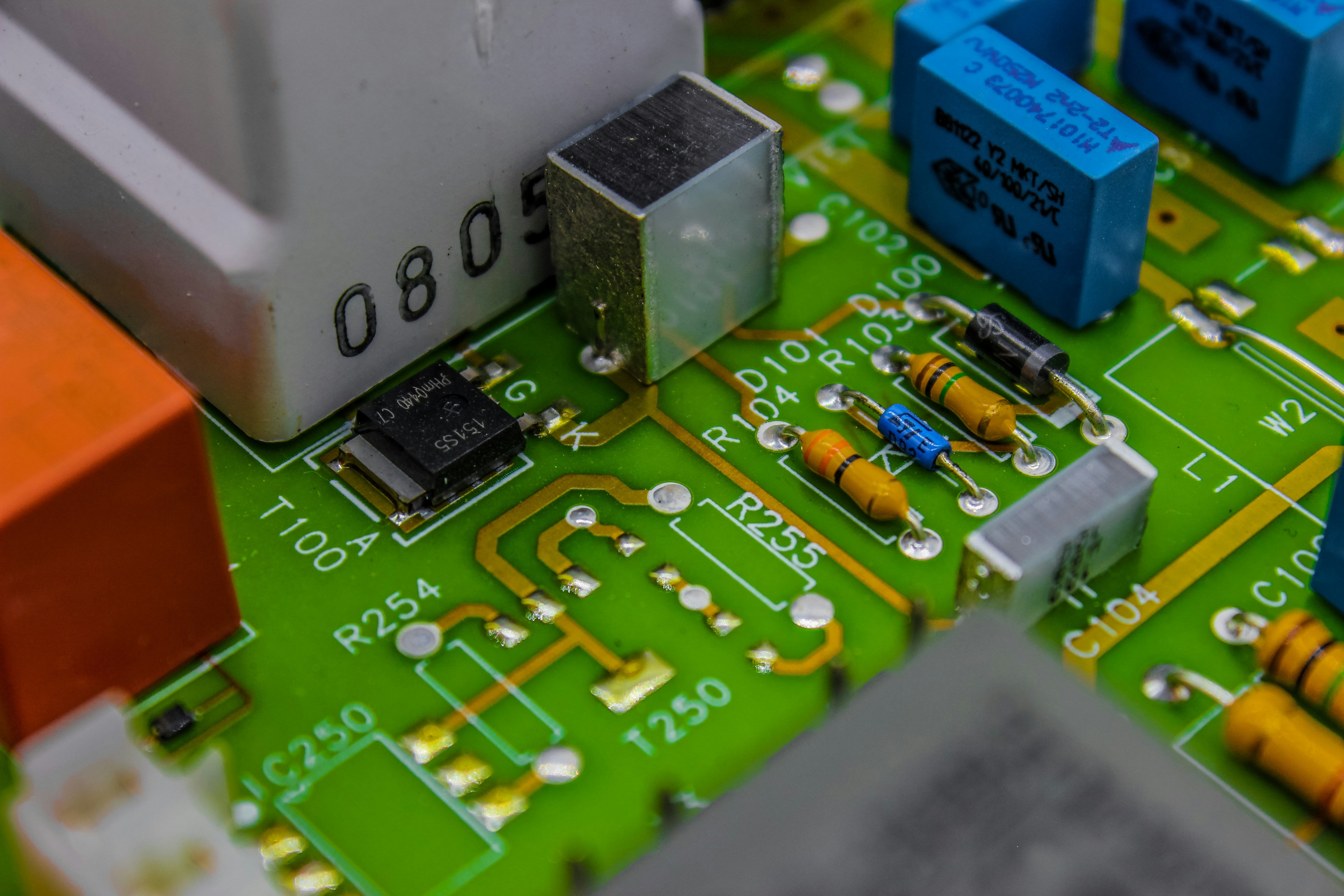

Popular Types of SMD Components

There’s a diverse array of popular types of surface mount devices used in modern electronics today. Resistors and capacitors are among the most common SMD components, serving vital roles in controlling current flow and storing energy within circuits. Integrated circuits (ICs), diodes, inductors, and transformers also play critical roles—enabling everything from simple logic functions to complex power management systems.

In consumer electronics like smartphones or tablets, you’ll often find an assortment of these SMD components working together seamlessly on a single PCB to deliver enhanced functionality while conserving space. Furthermore, automotive technology increasingly relies on specialized SMD types tailored for durability under extreme conditions—ensuring reliability where it matters most. As industries continue to innovate with new electronic devices requiring advanced features packed into smaller footprints, understanding these popular types of surface mount devices becomes crucial for engineers involved in PCB assembly.

Key Electronic Components in SMD

When it comes to surface mount devices (SMD), several key electronic components play crucial roles in enhancing the functionality and efficiency of printed circuit assemblies (PCBs). Understanding these components is essential for anyone involved in circuit board manufacturing, as they significantly impact the performance of electronic devices. Let's dive into a few of the most important SMD components that are integral to modern PCB assembly.

Resistors and Capacitors

Resistors and capacitors are foundational elements found in nearly every surface mount device configuration. Resistors control the flow of electric current, ensuring that other components receive the correct voltage. Capacitors, on the other hand, store and release electrical energy, playing a vital role in stabilizing power supply fluctuations within electronic devices.

In SMD applications, both resistors and capacitors are available in compact sizes that fit perfectly on circuit boards without taking up excessive space. This miniaturization allows for denser layouts while maintaining high performance levels—essential for today's advanced PCB manufacturing processes. Additionally, their reliability contributes to overall circuit stability, making them indispensable for robust printed circuit assemblies.

Integrated Circuits and Diodes

Integrated circuits (ICs) are perhaps the stars of surface mount technology; they house multiple electronic components within a single package, drastically reducing size while increasing functionality. ICs can perform complex tasks like signal processing or data storage—all while maintaining a small footprint on a circuit board. Coupled with diodes, which allow current to flow in one direction only, these components create efficient pathways for electrical signals.

The integration of ICs into SMD designs revolutionizes how we approach electronics; they enable intricate functionalities without requiring extensive real estate on PCBs. Diodes also protect circuits from voltage spikes and reverse polarity issues—ensuring longevity and reliability in various electronic devices. Together, these components exemplify how modern PCB assembly techniques can optimize performance while minimizing space constraints.

Inductors and Transformers

Inductors and transformers complete our lineup of key electronic components used in surface mount devices by managing energy transfer within circuits effectively. Inductors store energy in a magnetic field when electrical current passes through them; this characteristic is particularly beneficial for filtering applications within power supplies or radio frequency circuits found on many PCBs today.

Transformers serve an equally important purpose by stepping up or stepping down voltage levels as needed—a critical function for adapting power requirements across different sections of an electronic device’s circuitry. Both inductors and transformers come in compact designs suitable for SMD applications, allowing manufacturers to create more efficient layouts during printed circuit assembly processes without sacrificing performance or reliability.

Surface Mount Device Applications

Surface mount devices (SMDs) have revolutionized the landscape of electronic components, finding their way into various applications across multiple industries. Their compact size and efficient performance make them ideal for modern electronic devices, especially as PCB manufacturing evolves to meet the demands of increasingly sophisticated technology. Let’s explore how SMDs are making waves in consumer electronics, automotive technology, and industrial equipment.

Use in Consumer Electronics

Consumer electronics are perhaps the most visible application of surface mount devices. From smartphones to laptops, these electronic devices rely heavily on SMDs for their compactness and reliability. The integration of surface mount components allows for slimmer designs and enhanced functionality without compromising performance, making them a staple in printed circuit assembly.

In addition to saving space on circuit boards, SMDs contribute significantly to energy efficiency in consumer electronics. With advancements in PCB manufacturing techniques, manufacturers can now incorporate more features while keeping power consumption low. This balance is crucial as consumers increasingly demand longer battery life and higher performance from their gadgets.

Moreover, the rapid pace of innovation in consumer electronics means that product lifecycles are shorter than ever before. This necessitates efficient circuit board manufacturing processes that can accommodate quick turnarounds without sacrificing quality or reliability—something that SMDs excel at providing.

Role in Automotive Technology

The automotive industry is undergoing a technological revolution where surface mount devices play an integral role. Modern vehicles are packed with electronic components that enhance safety features, navigation systems, and entertainment options—all relying on SMD technology for optimal performance. As cars become more connected with smart technologies, the need for reliable and compact circuit boards has never been greater.

Surface mount devices contribute not only to functionality but also to weight reduction in vehicles—a critical factor for fuel efficiency and overall performance. By utilizing SMDs in printed circuit assemblies within automotive applications, manufacturers can develop lighter yet robust systems that meet stringent safety standards without adding unnecessary bulk.

Furthermore, as electric vehicles (EVs) gain popularity, the demand for advanced electronic control units increases dramatically. These units often utilize complex circuitry made possible by SMD technology; thus ensuring that they remain competitive within this rapidly evolving market is essential.

Applications in Industrial Equipment

Industrial equipment also benefits immensely from the use of surface mount devices due to their durability and reliability under harsh conditions. In factories where precision matters most—from robotics to automation systems—SMDs ensure seamless operation of critical machinery by providing robust connections on circuit boards even when exposed to vibrations or temperature fluctuations.

The trend towards smart manufacturing is further fueled by advancements in PCB assembly techniques that incorporate sophisticated sensors powered by surface mount components. These sensors enable real-time monitoring and data collection which enhances operational efficiency across various industrial processes—a game changer for manufacturers looking to optimize productivity while minimizing downtime.

Additionally, as industries strive towards sustainability goals through automation and intelligent systems integration, SMDs play a pivotal role by enabling smaller footprints while delivering high-performance outputs necessary for modern industrial demands—reinforcing their importance across diverse applications beyond traditional uses.

The PCB Assembly Process

When it comes to the world of electronics, the PCB assembly process is where the magic happens. Printed circuit assembly (PCA) involves a series of carefully orchestrated steps that transform raw materials into functional electronic devices. This process not only integrates various electronic components onto a circuit board but also ensures everything works seamlessly together.

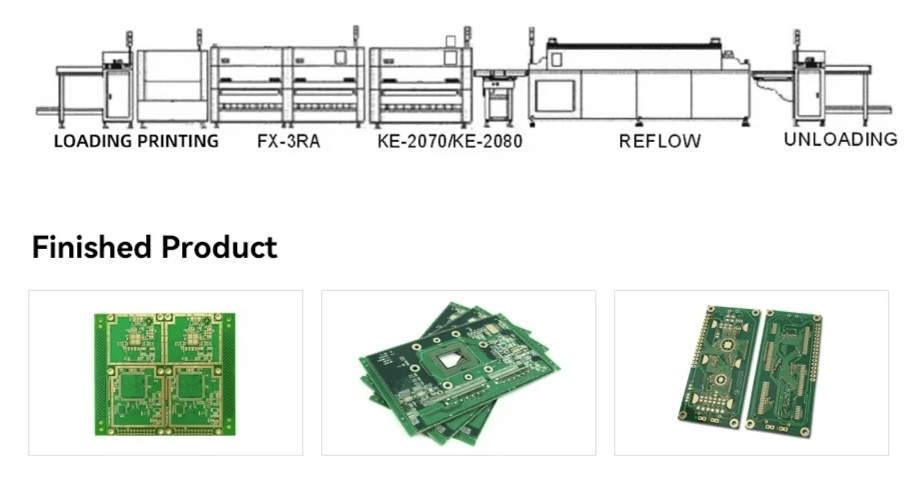

Overview of PCB Manufacturing

PCB manufacturing begins with designing the layout of the circuit board, which includes placing surface mount devices (SMDs) and other components in a way that optimizes space and functionality. Once the design is finalized, materials like copper-clad laminates are used to create layers that form electrical connections. This layered approach allows for intricate designs that can accommodate complex circuits essential for modern electronic devices.

After layering, processes such as etching and drilling are employed to carve out pathways for electrical signals. These pathways connect various electronic components on the circuit board, ensuring efficient power distribution and signal integrity. Finally, soldering techniques are applied to secure surface mount devices and through-hole components in place, completing the assembly stage.

Importance of SMD in Circuit Board Production

Surface mount devices have revolutionized circuit board production by allowing for higher component density and smaller footprints compared to traditional through-hole technology. This reduction in size opens up new possibilities for designing compact electronic devices without sacrificing performance or functionality. In today’s fast-paced tech landscape, where miniaturization is key, SMDs play an indispensable role in meeting consumer demands.

Moreover, SMDs facilitate automated assembly processes that enhance production speed and efficiency during printed circuit assembly operations. These advancements lead to reduced manufacturing costs while maintaining high-quality standards across various applications—from consumer electronics to automotive technology. Consequently, integrating SMDs into circuit board manufacturing has become a staple practice across industries.

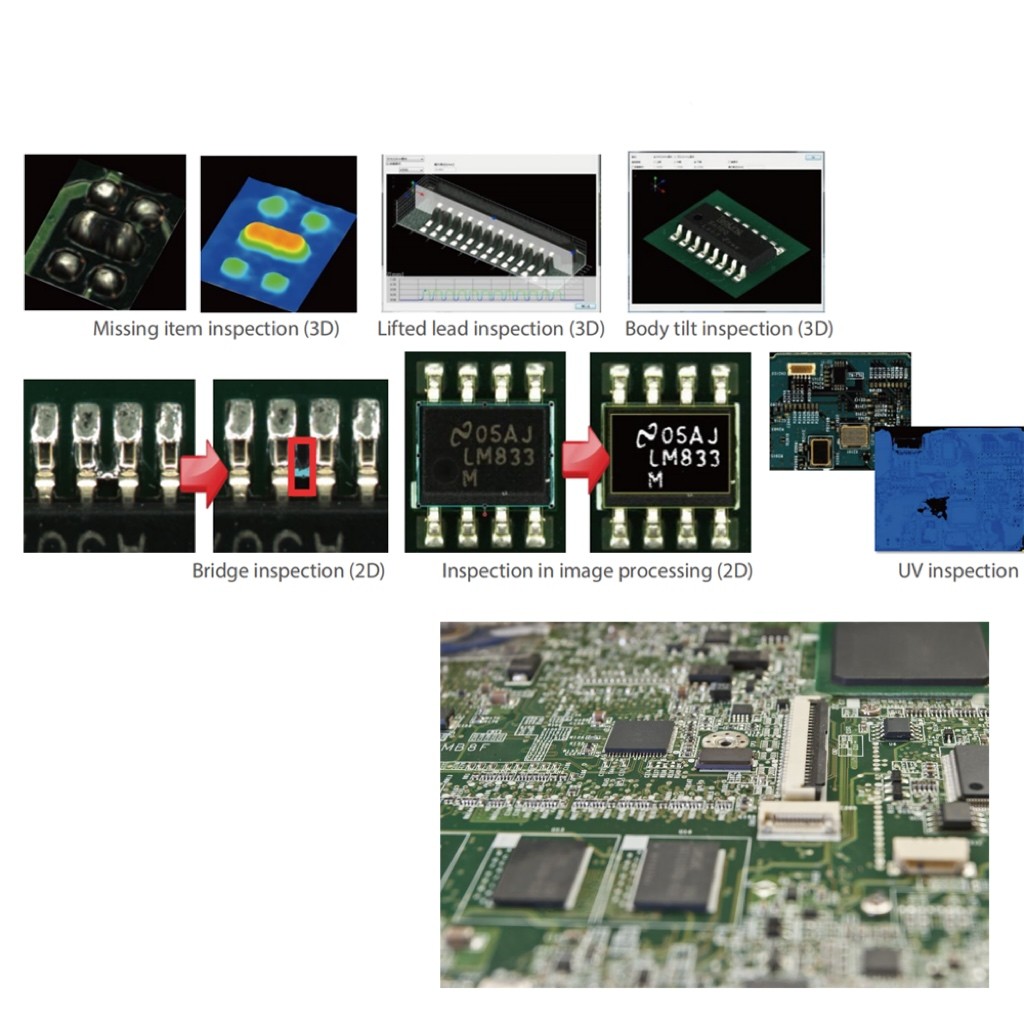

Quality Control in PCB Assembly

Quality control is paramount in PCB assembly to ensure reliability and performance of electronic components within any device. Rigorous testing procedures are implemented at various stages of production to identify potential defects or issues before they escalate into larger problems down the line. Techniques such as Automated Optical Inspection (AOI) help verify correct placement of surface mount devices on printed circuit boards.

Additionally, functional testing ensures that each assembled circuit board operates according to specifications under real-world conditions. By employing thorough quality control measures throughout the PCB manufacturing process, manufacturers can minimize failures and enhance product longevity—crucial factors for maintaining customer satisfaction in an increasingly competitive market.

In conclusion, understanding every aspect of the PCB assembly process—from initial design through quality assurance—is vital for anyone involved in electronics production today.

Choosing the Right SMD Components

Selecting the right surface mount device (SMD) components is crucial for ensuring the performance and reliability of your printed circuit assembly (PCA). With a plethora of electronic components available, making informed choices can significantly impact your circuit board's functionality. This section will guide you through essential factors to consider, recommendations from Bensun Technology, and common pitfalls to avoid.

Factors to Consider

When choosing SMD components, several factors come into play that can affect both the design and production of your circuit board. First and foremost is the component size; smaller devices can save space but may be harder to handle during assembly. Additionally, consider the electrical specifications such as voltage ratings and tolerance levels, which must align with your electronic devices' requirements for optimal performance.

Another critical aspect is compatibility with existing PCB manufacturing processes. Ensure that selected SMD components are suitable for automated assembly methods commonly used in printed circuit assembly. Finally, take into account lead time and availability; sourcing components that are readily available can prevent costly delays in your circuit board manufacturing timeline.

Recommendations from Bensun Technology

Bensun Technology offers a wealth of knowledge when it comes to selecting SMD components tailored to your project needs. They recommend starting with well-known brands that offer reliable quality assurance; this reduces risks associated with component failure during operation. Additionally, their team suggests using simulation software to model how different electronic components will interact within your design before committing to physical prototypes.

For specific applications like consumer electronics or automotive technology, Bensun provides insights into trending components that meet industry standards while ensuring durability and efficiency. Their extensive catalog includes high-performance resistors, capacitors, integrated circuits, and more—each designed for optimal compatibility in various PCB assembly processes.

Common Mistakes to Avoid

Choosing SMD components isn't without its challenges; many engineers fall into common traps that could easily be avoided with a little foresight. One prevalent mistake is overlooking thermal management; failing to account for heat dissipation can lead not only to performance issues but also premature failure of electronic devices over time. Always check thermal specifications alongside electrical ratings when selecting surface mount devices.

Another frequent error is neglecting future scalability; opting for low-cost or obsolete parts might save money initially but could hinder upgrades or repairs down the line as technology evolves rapidly in PCB manufacturing environments. Lastly, don’t underestimate the importance of thorough documentation—missing data sheets or incorrectly interpreted specifications can result in costly rework during circuit board manufacturing.

Conclusion

As we wrap up our exploration of surface mount devices (SMDs) and their pivotal role in printed circuit assembly (PCA), it’s clear that these components are at the heart of modern electronic devices. Innovations in SMD technology continue to push the boundaries of what’s possible in circuit board manufacturing, making devices smaller, faster, and more efficient. The advantages that SMDs offer not only streamline the PCB assembly process but also enhance performance across a myriad of applications.

Innovations in SMD Technology

Recent advancements in surface mount device technology have revolutionized how electronic components are designed and integrated into circuit boards. For instance, the development of miniaturized SMDs has allowed for denser layouts on PCBs without compromising performance or reliability. Additionally, innovations like automated soldering techniques and improved materials are enhancing the durability and efficiency of these components, ensuring they can withstand the demands of modern electronic devices.

Future Trends in PCB Manufacturing

Looking ahead, several trends are shaping the future landscape of PCB manufacturing. The rise of IoT (Internet of Things) continues to drive demand for smaller yet more powerful surface mount devices that can fit into compact designs while maintaining connectivity and functionality. Furthermore, sustainability is becoming a priority; manufacturers are increasingly focusing on eco-friendly materials and processes to reduce waste during circuit board production while meeting regulatory standards.

How Bensun Technology Supports Your Needs

At Bensun Technology, we understand that choosing the right electronic components is crucial for successful PCB assembly and overall project success. Our expertise ensures you receive high-quality surface mount devices tailored to your specific needs while avoiding common pitfalls associated with circuit board manufacturing. With our commitment to innovation and quality control in every step of the PCB assembly process, we empower you to turn your ideas into reality seamlessly.