Introduction

In the fast-paced world of manufacturing and production, ensuring quality is not just a goal; it’s a necessity. Vision inspection equipment has emerged as a critical tool in this quest for quality control, enabling businesses to detect defects and ensure that products meet stringent standards. With advancements in technology, various types of inspection systems have been developed, each tailored to specific needs, from optical inspection to automatic visual inspection systems.

Understanding Vision Inspection Equipment

Vision inspection equipment refers to advanced systems that utilize cameras and imaging software to analyze products for quality assurance. These tools can identify imperfections that might be invisible to the naked eye, making them invaluable in industries where precision is paramount. By leveraging optical inspection technology, manufacturers can automate their processes and enhance their overall efficiency.

Importance of Quality Control Processes

Quality control processes are essential for maintaining product integrity and customer satisfaction. In today’s competitive market, even minor defects can lead to significant losses in revenue and reputation; thus, implementing robust quality checks is crucial. Vision inspection plays a vital role here by providing real-time feedback through automated inspection solutions that help catch errors before they escalate.

Key Types of Inspection Technologies

The realm of vision inspection boasts a variety of technologies designed for different applications—each with its unique strengths. Optical inspection equipment often includes high-resolution cameras and sophisticated software algorithms capable of performing detailed analyses quickly and accurately. Meanwhile, automatic inspection systems integrate these capabilities with robotics and AI, streamlining production lines while ensuring top-notch quality control.

Basics of Vision Inspection

In the world of quality control, vision inspection stands out as a pivotal technology that enhances the reliability and efficiency of manufacturing processes. This method utilizes advanced vision inspection equipment to detect defects, ensuring products meet stringent quality standards. By integrating optical inspection techniques into production lines, companies can significantly reduce errors and improve overall output.

Definition and Overview of Vision Inspection

Vision inspection refers to the process of using optical systems and cameras to examine products for flaws or inconsistencies during manufacturing. This technique leverages sophisticated algorithms and imaging technologies to analyze items in real-time, providing immediate feedback on quality issues. Essentially, vision inspection acts as a vigilant eye that monitors production flows, ensuring that only top-notch products make it to market.

How Vision Inspection Works

At its core, vision inspection operates by capturing images of products through high-resolution cameras integrated with optical inspection equipment. These images are then processed using advanced software algorithms that compare them against predefined quality criteria. The automatic visual inspection system can quickly identify defects such as scratches, misalignments, or color discrepancies—allowing for swift corrective actions before products reach consumers.

Benefits of Implementing Vision Inspection

The advantages of implementing vision inspection are multifaceted and significant for any manufacturing operation. First and foremost, it enhances product quality by reducing human error associated with manual inspections; this leads to lower return rates and increased customer satisfaction. Moreover, automated inspection technologies streamline production processes by providing consistent monitoring without fatigue—freeing up human resources for more complex tasks while maintaining high standards in optical inspection outcomes.

Optical Inspection Equipment Explained

In the realm of quality control, optical inspection equipment plays a pivotal role in ensuring that products meet stringent standards. These devices utilize advanced imaging technologies to detect defects and verify product integrity, making them indispensable in various industries. With the rise of automation, understanding the different types of optical inspection devices and their applications has never been more crucial.

Different Types of Optical Inspection Devices

Optical inspection devices come in various forms, each tailored for specific applications within vision inspection equipment. Common types include cameras, laser scanners, and 2D/3D vision systems. Each device harnesses unique technologies to capture images or data that facilitate automatic visual inspections, ensuring that even the smallest defects are identified swiftly and accurately.

For instance, high-resolution cameras are often used for surface inspections where detail is paramount, while laser scanners excel at measuring dimensions with precision. Additionally, 3D vision systems can assess complex geometries and contours that traditional methods might miss. By integrating these diverse optical inspection technologies into an automatic inspection framework, manufacturers can enhance their quality control processes significantly.

Key Features of Optical Inspection Equipment

When evaluating optical inspection equipment, several key features stand out as essential for effective performance in quality control settings. First and foremost is resolution; higher resolution allows for more detailed image capture and defect detection in visual inspections. Coupled with speed and processing power, these features enable rapid assessments without compromising accuracy.

Another critical feature is adaptability; many modern optical inspection devices can be configured to meet specific production line requirements or product characteristics. This flexibility enhances their utility across various industries—from electronics to food production—where different standards apply. Furthermore, user-friendly interfaces simplify operation and integration into existing automatic visual inspection systems.

Real-World Applications of Optical Inspection

The real-world applications of optical inspection are vast and varied, showcasing its versatility across multiple sectors. In manufacturing environments like automotive or electronics assembly lines, visual inspections help ensure components meet safety regulations by detecting flaws before products reach consumers. Similarly, in pharmaceutical industries, optical inspection equipment verifies packaging integrity to prevent contamination or mislabeling.

Moreover, food processing plants employ these technologies to maintain hygiene standards by inspecting packaging seals or identifying foreign objects within products—a vital step for consumer safety! As companies increasingly adopt automated solutions for quality assurance tasks using vision inspection equipment like this one mentioned above; the trend towards efficiency while maintaining high-quality standards continues to grow.

Automatic Inspection Systems Unveiled

In the world of quality control, automatic inspection systems are game-changers. These systems leverage advanced technology to conduct thorough assessments of products without human intervention. By utilizing a combination of vision inspection equipment and sophisticated algorithms, they ensure that every item meets stringent quality standards.

What Constitutes an Automatic Inspection System

An automatic inspection system typically involves a blend of hardware and software designed for real-time evaluation. At its core, it employs vision inspection equipment equipped with cameras and sensors that capture detailed images of products as they pass through the production line. The software then analyzes these images using optical inspection techniques to detect defects or deviations from specified criteria.

These systems can be tailored for various applications, from simple visual checks to complex multi-dimensional assessments. They often integrate with existing manufacturing processes, allowing for seamless operation without disrupting workflow. With the ability to operate continuously and at high speeds, automatic visual inspection systems significantly enhance productivity while maintaining high-quality output.

Integrating Automatic and Visual Inspection Systems

The integration of automatic inspection systems with traditional visual inspection methods creates a robust framework for quality assurance. By combining human oversight with automated processes, industries can achieve greater accuracy in identifying defects while also speeding up the inspection cycle. This hybrid approach allows operators to focus on more complex issues that require human judgment while routine inspections are handled by automated solutions.

Moreover, integrating these systems means that data collected during inspections can be analyzed more comprehensively, leading to insights that inform future production strategies. Automated inspections can flag recurring issues or trends in product quality, enabling proactive measures before problems escalate into larger concerns. As such, companies benefit not only from improved efficiency but also from enhanced decision-making capabilities regarding their optical inspection processes.

Advantages of Automation in Quality Control

The advantages of incorporating automation into quality control processes are manifold and impactful. First and foremost, automated inspection significantly reduces the likelihood of human error—an essential factor when precision is paramount in manufacturing environments where even minor flaws can lead to substantial losses or safety hazards. Additionally, these systems operate at speeds far exceeding manual inspections; thus, they can handle higher volumes without sacrificing accuracy.

Another key benefit is cost efficiency over time; although initial investments in advanced vision inspection equipment may seem daunting, the long-term savings realized through reduced labor costs and increased throughput often justify this expenditure quickly. Furthermore, automated solutions provide consistent results regardless of external factors like fatigue or distraction that might affect human inspectors’ performance levels over time. Ultimately, embracing automation in optical inspections not only streamlines operations but also fosters a culture of continuous improvement within organizations dedicated to maintaining high-quality standards.

Spotlight on Automated Inspection Technologies

In the realm of quality control, automated inspection technologies have revolutionized the way industries ensure product integrity and compliance. These systems utilize advanced algorithms and high-resolution imaging to detect defects that the human eye might miss, making them indispensable in modern manufacturing. As competition intensifies across various sectors, businesses are increasingly adopting these solutions to enhance productivity and maintain high standards.

Types of Automated Inspection Solutions

Automated inspection solutions come in various forms, each tailored to specific needs within production lines. From automatic visual inspection systems that assess product quality in real-time to more specialized optical inspection equipment designed for intricate components, these technologies cater to diverse applications. Additionally, some systems integrate machine learning capabilities, allowing them to adapt and improve their defect detection over time.

One popular type of automated inspection solution is the 2D and 3D vision inspection equipment that captures detailed images of products from multiple angles. This technology is particularly effective in industries like electronics and automotive manufacturing where precision is paramount. Moreover, there are also inline inspection systems that operate seamlessly within existing production processes, ensuring minimal disruption while maximizing efficiency.

Innovators in Automated Inspection Equipment

The landscape of automated inspection equipment is dotted with innovative companies pushing the boundaries of what's possible in quality control technology. Industry leaders such as Cognex and Keyence have made significant strides with their cutting-edge vision inspection equipment that combines speed with accuracy. These innovators are not only enhancing traditional optical inspections but also developing new methods for automatic inspections that leverage artificial intelligence.

Another noteworthy player is Bensun Technology, which has carved out a niche by focusing on user-friendly automated visual inspection systems tailored for various industries. Their commitment to research and development has led to breakthroughs in defect recognition algorithms that can identify even the most subtle inconsistencies in products. As competition heats up, these companies are setting benchmarks for others by consistently delivering reliable solutions that meet evolving market demands.

Enhancing Efficiency with Automated Inspection

Implementing automated inspection technologies can significantly enhance operational efficiency across manufacturing processes. By reducing reliance on manual inspections, companies can streamline workflows while minimizing human error—an essential factor when dealing with high-volume production environments where consistency is key. Furthermore, integrating automatic visual inspection systems allows businesses to achieve faster throughput without compromising on quality standards.

Additionally, these technologies provide valuable data analytics capabilities that help manufacturers identify trends and potential issues before they escalate into costly problems. With real-time feedback from optical inspection equipment, organizations can make informed decisions about process improvements or necessary adjustments promptly. Ultimately, investing in automated inspection not only boosts productivity but also fosters a culture of continuous improvement within organizations striving for excellence.

Bensun Technology: A Leader in Inspection Solutions

When it comes to vision inspection equipment, Bensun Technology stands out as a prominent player in the industry. Their advanced optical inspection machines are designed to enhance quality control processes across various sectors. With a focus on innovation and efficiency, Bensun is redefining the standards of visual inspection.

Overview of Bensun's Visual Inspection Machines

Bensun's visual inspection machines incorporate cutting-edge technology to provide reliable and accurate results in quality assurance. These devices utilize sophisticated optical inspection methods that ensure every product meets stringent quality standards. By integrating automatic visual inspection systems, Bensun enhances the speed and precision of inspections, making them an invaluable asset for manufacturers.

Applications of Bensun Equipment in Various Industries

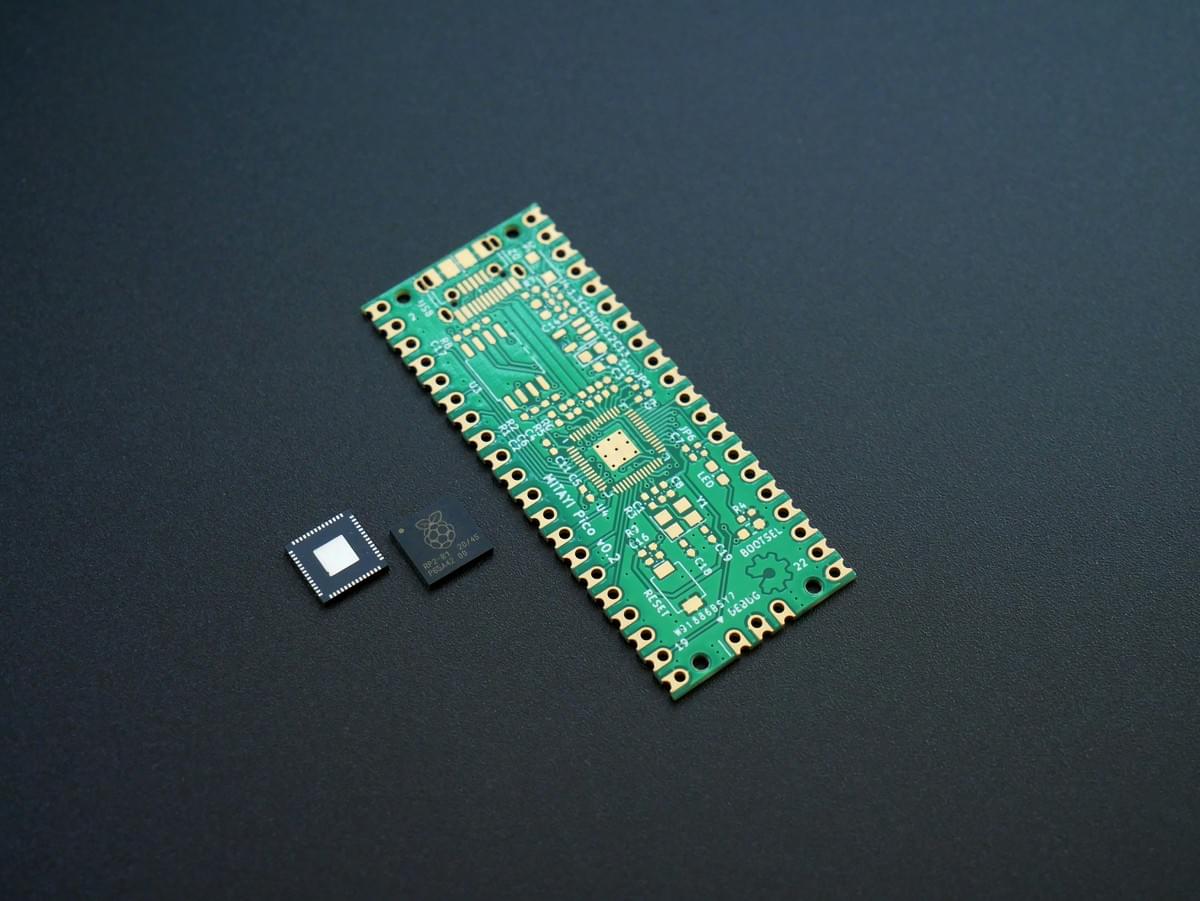

Bensun's equipment finds applications across a multitude of industries, including electronics, automotive, pharmaceuticals, and food processing. In electronics manufacturing, for instance, their automated inspection solutions detect defects on circuit boards with unparalleled accuracy. Similarly, in the automotive sector, optical inspection equipment ensures that components meet safety regulations before they leave the production line.

Why Choose Bensun for Quality Control Needs

Choosing Bensun for your quality control needs means opting for reliability and excellence in vision inspection technology. Their commitment to innovation ensures that clients receive state-of-the-art automated inspection solutions tailored to their specific requirements. With a proven track record of enhancing efficiency and reducing waste through effective optical inspection processes, Bensun is undoubtedly a leader in the realm of vision inspection equipment.

Conclusion

In wrapping up our exploration of vision inspection equipment, it’s evident that the future holds exciting advancements in this field. As industries continue to prioritize quality control, we can expect innovations that enhance the efficiency and accuracy of optical inspection processes. The integration of artificial intelligence and machine learning into automatic inspection systems will likely redefine standards for visual inspection across various sectors.

The Future of Vision Inspection Equipment

The future of vision inspection equipment is poised for remarkable growth, driven by technological advancements and increasing demand for precision in manufacturing. Enhanced algorithms and smarter sensors will improve the capabilities of optical inspection tools, enabling them to detect even the most minute defects with unparalleled accuracy. As industries evolve, so too will the automatic visual inspection systems that support them, ensuring products meet rigorous quality standards.

Maximizing Quality with Optical Inspection Technology

Maximizing quality through optical inspection technology requires a strategic approach to integrating these tools into existing production lines. By leveraging advanced optical inspection equipment, companies can significantly reduce error rates and enhance product consistency. This not only boosts customer satisfaction but also minimizes waste and operational costs—making a compelling case for investing in high-quality vision inspection solutions.

Investing in Automated Inspection for Success

Investing in automated inspection is not just about keeping pace with competition; it's about leading the charge toward excellence in quality control. Companies that adopt automated inspection technologies stand to gain substantial advantages, including faster production times and improved accuracy in defect detection through automatic visual inspections. With the right vision inspection equipment at their disposal, businesses can ensure they are well-equipped to meet future challenges head-on.