Introduction

In today's fast-paced manufacturing landscape, the significance of automated inspection cannot be overstated. As industries strive for higher quality and efficiency, optical inspection equipment has emerged as a critical tool in ensuring products meet stringent standards. With the advent of machine vision systems, the revolution in automated optical inspection is transforming how we inspect vision across various sectors.

The Importance of Automated Inspection

Automated inspection is essential for maintaining quality control in production environments, minimizing human error while maximizing throughput. By integrating optical inspection into their processes, manufacturers can identify defects early and reduce waste significantly. Ultimately, this leads to enhanced customer satisfaction and a stronger competitive edge in the marketplace.

How Optical Inspection Equipment Works

Optical inspection equipment utilizes advanced imaging technology to examine products for defects or inconsistencies with remarkable precision. These systems capture high-resolution images that are analyzed by sophisticated algorithms to detect anomalies that may not be visible to the naked eye. By automating this process, companies can achieve consistent results and ensure compliance with industry standards.

The Rise of Machine Vision Systems

The rise of machine vision systems marks a pivotal shift in how industries approach quality assurance and product verification. These systems combine advanced optics with powerful software capabilities to create comprehensive solutions for automated optical inspection tasks. As businesses increasingly adopt these technologies, they are reaping the benefits of improved accuracy and reduced operational costs.

Understanding Automated Optical Inspection

Automated Optical Inspection (AOI) has revolutionized the way industries conduct quality control. By employing advanced optical inspection equipment, manufacturers can detect defects and ensure product integrity with minimal human intervention. This section delves into the key features, benefits, and real-world applications of automated optical inspection systems.

Key Features of Automated Optical Inspection

One of the standout features of automated optical inspection is its ability to deliver high-resolution imaging through sophisticated inspection cameras. These cameras are designed to capture minute details, ensuring that even the tiniest defects are detected during the inspection process. Additionally, machine vision systems integrated into these setups enable rapid image processing and analysis, allowing for real-time feedback and adjustments.

Another critical feature is the versatility of AOI systems; they can be customized to inspect a wide range of products across various industries, from electronics to pharmaceuticals. The flexibility in configuring these systems makes them ideal for different production environments and varying quality standards. Furthermore, automated optical inspection can operate under diverse lighting conditions, enhancing its capability to inspect vision accurately regardless of external factors.

Lastly, user-friendly software plays a pivotal role in automating the inspection process by providing intuitive interfaces for operators. This software not only facilitates easy setup and calibration but also enables data logging and reporting for continuous improvement initiatives. With these key features combined, automated optical inspection stands out as an essential tool for modern manufacturing.

Benefits of Automated Optical Inspection

The benefits of implementing automated optical inspection are manifold and impactful for businesses aiming to enhance their quality control processes. First and foremost, AOI significantly reduces labor costs associated with manual inspections while increasing throughput rates—allowing manufacturers to produce more in less time without sacrificing quality. The precision offered by machine vision systems also leads to higher accuracy in defect detection compared to traditional methods.

Moreover, adopting optical inspection equipment enhances consistency across production lines; every item is subjected to the same rigorous standards regardless of human variability or fatigue factors. This uniformity not only bolsters product reliability but also builds customer trust as companies deliver consistently high-quality goods. Additionally, early detection of defects through automated inspections minimizes waste and rework costs—ensuring that resources are used efficiently throughout the manufacturing process.

Finally, integrating AOI into production workflows provides valuable data insights that can drive continuous improvement initiatives within organizations. By analyzing trends in defect occurrence or identifying recurring issues within specific batches or processes, businesses can make informed decisions on how best to optimize their operations moving forward.

Real-World Applications of Automated Optical Inspection

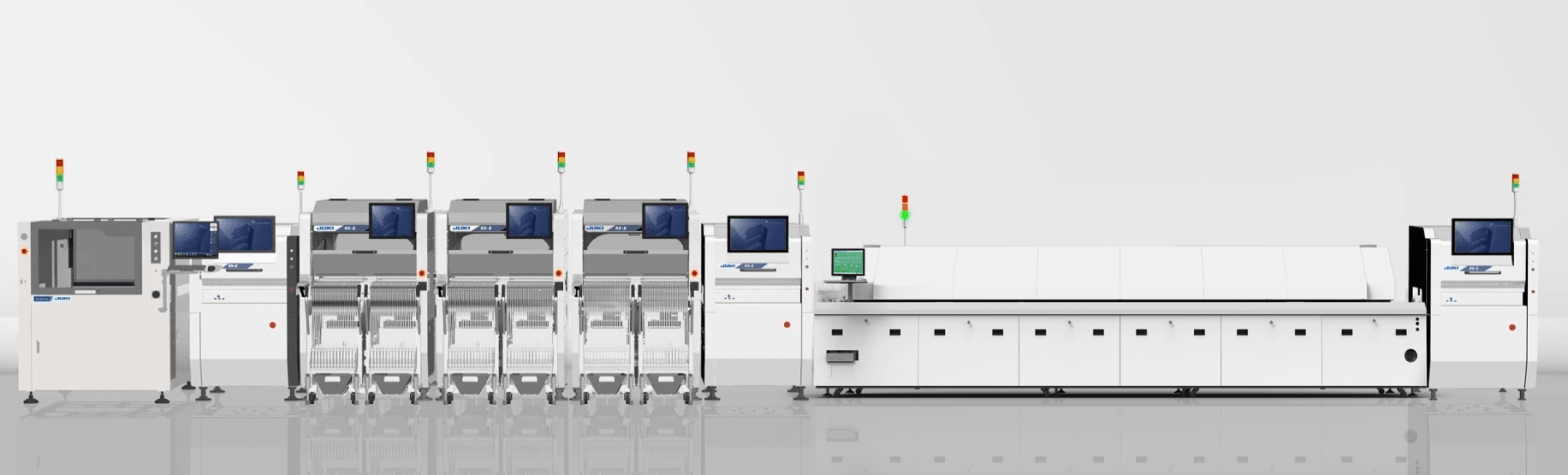

Automated optical inspection finds its application across a multitude of industries where precision is paramount—most notably in electronics manufacturing where components such as circuit boards require meticulous scrutiny for defects like soldering flaws or misalignments. In this sector, AOI serves as a first line of defense against potential failures that could compromise product functionality or safety down the line.

In addition to electronics, pharmaceutical companies utilize automated optical inspection equipment during packaging processes to ensure label accuracy and seal integrity—vital components that directly impact consumer safety and regulatory compliance standards. By employing these advanced vision inspection technologies at various stages in production lines—from raw materials through final packaging—companies can uphold stringent quality assurance measures effectively.

The automotive industry has also embraced AOI technologies for inspecting parts such as sensors or engine components where even minor imperfections could lead to significant performance issues or safety hazards on the road. As automation continues evolving within manufacturing sectors worldwide, expect further innovations within automated optical inspection applications tailored specifically for unique industry needs.

Components of Optical Inspection Systems

In the realm of automated optical inspection, understanding the components of optical inspection systems is crucial for achieving effective results. These systems are built on a foundation of precision tools that work in harmony to ensure quality control and efficiency. By delving into the specifics, we can appreciate how each element contributes to the overall functionality of optical inspection equipment.

Overview of Inspection Cameras

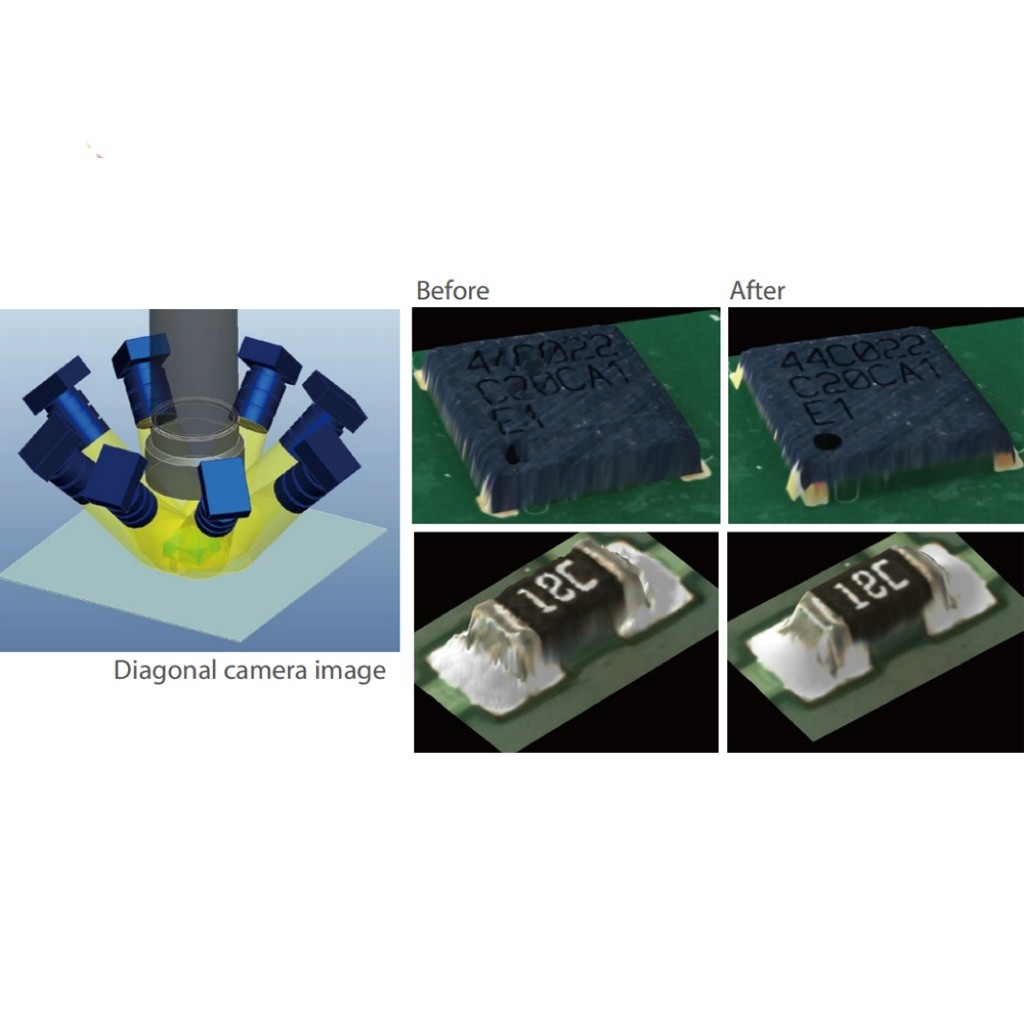

Inspection cameras serve as the eyes of any optical inspection system, capturing high-resolution images that are essential for thorough analysis. These cameras are designed specifically for vision inspection tasks, often featuring advanced sensors and lenses that can detect minute details and defects in products. With capabilities ranging from visible light to infrared imaging, these cameras elevate automated optical inspection by ensuring no flaw goes unnoticed.

The technology behind modern inspection cameras has evolved significantly, allowing them to operate in various environments and conditions while maintaining image clarity. Many models now incorporate features like adjustable lighting and high-speed capture options, enhancing their versatility across different applications. Ultimately, these advancements make inspection cameras indispensable tools within machine vision systems.

Machine Vision Systems Explained

Machine vision systems represent a sophisticated integration of hardware and software designed to automate visual inspections in manufacturing processes. At their core, these systems utilize powerful algorithms alongside high-quality optical inspection equipment to analyze captured images for quality assurance purposes. This combination allows manufacturers to detect defects or irregularities at speeds far exceeding human capabilities.

A typical machine vision system includes not just the inspection cameras but also lighting setups and processing units that work together seamlessly. The ability to process images in real-time enables immediate feedback loops within production lines, drastically reducing waste and improving efficiency rates. As industries continue to embrace automation, machine vision systems will play an increasingly pivotal role in ensuring product integrity through automated optical inspection.

The Role of Software in Optical Inspection

Software is the unsung hero behind successful optical inspections; it transforms raw image data into actionable insights that drive decision-making processes. Advanced software algorithms analyze images captured by inspection cameras, identifying patterns or anomalies with remarkable accuracy—often faster than any human inspector could manage. This capability not only enhances quality control but also streamlines workflows within automated inspection environments.

Moreover, modern software solutions offer user-friendly interfaces that allow operators to customize parameters according to specific needs or product requirements easily. Features such as machine learning enable these programs to adapt over time based on historical data, continuously improving their defect detection capabilities during automated optical inspections. As technology progresses further into AI-driven solutions, the role of software will undoubtedly expand its influence on machine vision systems.

Leading Technologies in Optical Inspection

In the world of optical inspection, innovation reigns supreme, and several companies are pushing the boundaries of what's possible with automated inspection technologies. As industries demand more precision and efficiency, the development of advanced optical inspection equipment has become crucial. Among these pioneers is Bensun Technology, which has made significant strides in enhancing machine vision systems for various applications.

Bensun Technology's Innovations

Bensun Technology stands out for its commitment to developing cutting-edge optical inspection solutions that cater to diverse industries. Their latest automated optical inspection systems integrate high-resolution cameras with sophisticated algorithms to achieve unparalleled accuracy and speed in inspecting products. By focusing on user-friendly interfaces and real-time analytics, Bensun ensures that their optical inspection equipment not only meets but exceeds industry standards.

Moreover, Bensun's innovations extend beyond hardware; they have also invested heavily in software advancements that enhance the capabilities of their inspection cameras. These improvements allow for seamless integration with existing production lines, making it easier for manufacturers to adopt automated systems without major disruptions. With a focus on continuous improvement, Bensun is paving the way for smarter vision inspection solutions that adapt to evolving market needs.

Comparison with Competitors like Cognex and Keyence

When comparing leading players in the optical inspection arena, Cognex and Keyence often come up alongside Bensun Technology as formidable competitors. Cognex has long been recognized for its robust machine vision systems that excel in complex environments; however, its pricing can be a barrier for smaller businesses looking to implement automated inspections. On the other hand, Keyence is known for its user-friendly devices that offer impressive performance but may lack some of the advanced features found in Bensun's offerings.

While both companies have established themselves as leaders in automated optical inspection equipment, they each bring unique strengths to the table. For instance, Cognex’s extensive range of products caters well to high-volume manufacturing settings where speed is critical, while Keyence focuses on versatility across various applications but may not always match Cognex’s speed under pressure. As such, businesses must carefully assess their specific needs when choosing between these options or considering new entrants like Bensun.

Emerging Trends in Vision Inspection Technology

The landscape of vision inspection technology is continually evolving as new trends emerge within automated optical inspection systems. One significant trend is the increasing integration of artificial intelligence (AI) into optical inspection equipment; this allows machines to learn from data patterns over time and improve their accuracy during inspections automatically. Furthermore, AI-driven insights enable manufacturers to anticipate potential defects before they occur—truly a game-changer for quality assurance processes.

Another trend gaining traction is the adoption of 3D imaging technology within machine vision systems—this advancement allows inspectors to capture detailed spatial information about objects being examined. This capability enhances depth perception during inspections and provides more comprehensive data analysis compared to traditional 2D methods alone. As manufacturers look toward future-proofing their operations through innovative solutions like these technologies will play a pivotal role.

Lastly, sustainability remains at the forefront as companies strive towards greener practices; thus incorporating energy-efficient components into optical inspection equipment becomes increasingly important as well—reducing waste while maintaining high levels of productivity remains an essential goal across all sectors involved in manufacturing processes today.

Challenges in Optical Inspection

Automated optical inspection is not without its hurdles, and understanding these challenges is vital for successful implementation. While the technology promises numerous benefits, organizations often encounter common issues that can impede the effectiveness of optical inspection equipment. Additionally, the costs associated with automated inspection and the resistance to change within organizations can complicate matters further.

Common Issues with Automated Inspection

One of the most prevalent challenges in automated optical inspection is ensuring accurate calibration of inspection cameras. If these systems are not calibrated correctly, they may produce inconsistent results, leading to potential defects being overlooked or false positives being flagged. Moreover, lighting conditions can drastically affect the performance of machine vision systems; inadequate or excessive lighting can distort images and compromise the quality of vision inspection.

Another issue lies in the complexity of integrating automated optical inspection into existing production lines. Companies often struggle with aligning new technologies with legacy systems, which can lead to disruptions in workflow and inefficiencies during transition periods. Furthermore, training staff to operate advanced optical inspection equipment poses a significant challenge; without proper training, users may not fully leverage the capabilities of sophisticated automated optical inspection systems.

The Cost of Implementation

Implementing automated optical inspection comes with a hefty price tag that can deter many businesses from adopting this technology. The initial investment in high-quality optical inspection equipment and machine vision systems may seem daunting, especially for small to mid-sized enterprises operating on tight budgets. Beyond purchasing costs, ongoing maintenance and potential upgrades add layers of financial commitment that must be factored into any decision-making process.

However, it’s essential to consider that while upfront costs are significant, they often pale compared to long-term savings achieved through increased efficiency and reduced waste associated with manual inspections. Organizations should conduct thorough cost-benefit analyses before dismissing automated solutions solely based on initial outlays. In many cases, investing in reliable vision inspection technology leads to greater profitability over time as quality assurance improves dramatically.

Overcoming Resistance to Automated Systems

Resistance to adopting machine vision systems often stems from fear of change among employees accustomed to traditional methods of quality control. Many workers may feel threatened by automation as it could imply job displacement or require them to learn new skills quickly—both daunting prospects for anyone entrenched in their routines. To overcome this resistance effectively, companies must foster a culture that emphasizes continuous learning and adaptability while clearly communicating how automated optical inspections enhance rather than replace human roles.

Additionally, providing comprehensive training programs tailored specifically for using new optical inspection equipment will empower employees rather than intimidate them. By demonstrating how these tools simplify tasks and improve outcomes—such as faster defect detection—organizations can alleviate fears surrounding automation’s impact on employment security. Ultimately, engaging employees early on fosters buy-in for technological advancements like automated optical inspections while ensuring smoother transitions toward more efficient processes.

Future of Automated Optical Inspection

The future of automated optical inspection is poised for significant advancements, driven by technological innovations and evolving market demands. As industries increasingly rely on precision and efficiency, optical inspection equipment will become even more integral to quality control processes. With the rise of machine vision systems, we can expect a transformation in how products are inspected and validated.

Predictions for Optical Inspection Equipment

In the coming years, predictions indicate that optical inspection equipment will become more compact and user-friendly while maintaining high performance levels. The integration of smart features such as real-time analytics and enhanced connectivity will allow these systems to seamlessly integrate into existing production lines. Moreover, as industries adopt Industry 4.0 principles, automated optical inspection will evolve to include cloud-based solutions that facilitate data sharing and remote monitoring.

As machine vision systems continue to advance, we can anticipate improvements in image processing capabilities that enhance defect detection accuracy. These innovations will not only reduce false positives but also increase throughput by allowing manufacturers to inspect vision at unprecedented speeds. Ultimately, the future landscape of automated inspection promises a blend of sophistication and simplicity that caters to a wide range of applications.

The Impact of AI on Automated Inspection

Artificial Intelligence (AI) is set to revolutionize the realm of automated optical inspection by enabling systems to learn from data patterns over time. With AI-powered algorithms, inspection cameras can adapt their parameters dynamically based on previous inspections, leading to greater accuracy in identifying defects or anomalies within products. This capability means that machine vision systems can refine their processes continuously, minimizing human intervention while maximizing efficiency.

Furthermore, the integration of AI into optical inspection equipment allows for predictive maintenance capabilities; these systems can alert operators about potential failures before they occur. This proactive approach not only saves time but also reduces costs associated with unexpected downtimes in production lines. As AI technology matures within this domain, we can expect an era where automated optical inspection becomes smarter and more intuitive than ever before.

Sustainability in Inspection Technologies

Sustainability is becoming an essential consideration in the development of new technologies across various sectors, including automated optical inspection. Manufacturers are increasingly looking for ways to reduce waste during production processes while ensuring high-quality outputs through effective inspections using advanced equipment like inspection cameras and machine vision systems. This trend not only benefits companies economically but also aligns with global efforts toward environmental responsibility.

Moreover, sustainable practices are being integrated into the design and manufacturing processes of optical inspection equipment itself; energy-efficient components are now prioritized alongside performance metrics during development stages. Companies adopting these green technologies often find themselves gaining a competitive advantage in markets where consumers favor eco-friendly practices. As sustainability continues to shape industry standards, it’s clear that future advancements in automated optical inspection will prioritize both efficiency and environmental impact.

Conclusion

In the rapidly evolving landscape of manufacturing and quality control, automated optical inspection has emerged as a cornerstone for efficiency and precision. By leveraging advanced optical inspection equipment, businesses can significantly reduce human error while enhancing the accuracy of their processes. As we look to the future, it’s clear that integrating inspection cameras into production lines will be key to maximizing operational efficiency.

Maximizing Efficiency with Inspection Cameras

Inspection cameras are revolutionizing how companies approach quality assurance in their production processes. These devices not only streamline workflows but also provide real-time feedback, allowing manufacturers to quickly identify defects and rectify issues before they escalate. With automated optical inspection systems in place, organizations can achieve unprecedented levels of productivity while ensuring that only top-quality products reach the market.

The Growing Market for Machine Vision Systems

The demand for machine vision systems is on an upward trajectory as industries recognize their value in automating inspection processes. As technology advances, more businesses are investing in optical inspection equipment to stay competitive and meet stringent quality standards. This growing market signifies not just an increase in sales but also a shift towards smarter manufacturing practices that prioritize efficiency and reliability.

Strategies for Adopting Automated Optical Inspection

Adopting automated optical inspection requires a strategic approach to ensure seamless integration into existing workflows. Companies should start with a thorough assessment of their current processes to identify areas where machine vision systems can add value. Training staff on how to effectively use these technologies is equally important; after all, even the best optical inspection equipment is only as good as the people operating it.