Introduction

In the world of circuit board manufacturing, ensuring the quality and reliability of printed circuit boards (PCBs) is paramount. PCB inspection plays a critical role in identifying defects and ensuring that each PCB circuit board meets stringent industry standards. With various inspection techniques available, manufacturers can choose methods that best suit their production needs, enhancing overall efficiency and product quality.

Importance of PCB Inspection

The importance of PCB inspection cannot be overstated; it acts as a safeguard against potential failures in electronic devices. By employing effective optical inspection techniques, manufacturers can detect issues such as soldering defects, misalignments, or component failures before they escalate into costly problems. Ultimately, thorough inspection processes lead to higher reliability in PCB manufacturing and greater customer satisfaction.

Overview of Inspection Techniques

WFrom manual inspections by trained personnel to advanced automated optical inspection (AOI) systems, the spectrum of options caters to various production scales and complexities in printed circuit board manufacturing. Understanding these techniques helps manufacturers make informed decisions about which methods will yield the best results for their specific needs.

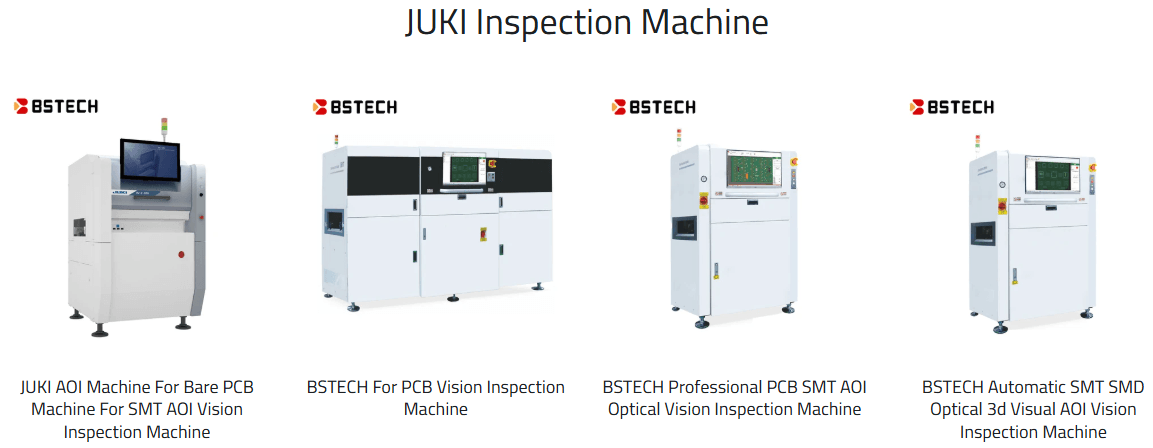

Introduction to Common Equipment

To facilitate effective PCB inspections, a variety of equipment is utilized across the industry. This includes everything from basic visual aids for manual inspections to sophisticated pcb optical inspection equipment designed for automated processes. Familiarity with common tools not only enhances the efficiency of inspections but also ensures that every pcb printed circuit board produced meets high standards for performance and reliability.

PCB Visual Inspection Techniques

Visual inspection is a fundamental step in ensuring the quality and reliability of printed circuit boards (PCBs). With the complexity of modern circuit board manufacturing, having robust inspection techniques is crucial. From manual checks to advanced optical inspection equipment, each method plays a vital role in maintaining high standards in PCB manufacturing.

Manual Inspection for Quality Assurance

Manual inspection remains a cornerstone of quality assurance in PCB manufacturing, allowing skilled technicians to identify defects that machines might overlook. This hands-on approach enables inspectors to examine each pcb circuit board closely, checking for issues like soldering defects, component misalignment, or visual inconsistencies. Though time-consuming, manual inspections provide invaluable insights and can often catch subtle flaws that automated systems may miss.

However, relying solely on human eyes can introduce variability and potential errors due to fatigue or oversight. To combat this, many manufacturers complement manual inspections with optical inspection equipment that enhances accuracy and efficiency. By combining both methods, manufacturers can achieve a balanced approach to ensuring their printed circuit boards meet stringent quality standards.

Benefits of Using PCB Optical Inspection Equipment

PCB optical inspection equipment revolutionizes the way circuit boards are assessed during production. These systems utilize advanced imaging technology to detect defects at a much faster rate than manual inspections alone could achieve. By employing high-resolution cameras and sophisticated algorithms, optical inspection equipment can quickly analyze pcbs for common issues such as missing components or incorrect placements.

One significant advantage of using optical inspection is its ability to maintain consistent quality across large production runs of pcb printed circuit boards. With minimal human intervention required during this process, manufacturers can significantly reduce labor costs while increasing throughput without sacrificing quality. Furthermore, the data collected from these inspections helps inform continuous improvement efforts within the overall pcb manufacturing process.

Role of Bensun Technology in Visual Inspection

Bensun Technology has made significant strides in enhancing visual inspection processes for printed circuit board manufacturing through its innovative solutions. Their state-of-the-art pcb optical inspection equipment integrates seamlessly into existing workflows while providing unparalleled accuracy and speed in defect detection. This not only streamlines operations but also empowers manufacturers with real-time feedback on their production lines.

By leveraging Bensun's expertise in optical inspection technology, companies can ensure their pcbs adhere to strict industry standards while minimizing waste and rework costs associated with flawed products. Additionally, Bensun's commitment to customer support means that users receive ongoing assistance as they navigate the complexities of implementing these advanced systems into their operations. Ultimately, partnering with Bensun enhances overall efficiency and reliability within the realm of PCB visual inspections.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) has revolutionized the landscape of printed circuit board manufacturing, providing an efficient and accurate way to assess the quality of PCB circuit boards. By utilizing advanced imaging technology, AOI systems can detect defects that may go unnoticed during manual inspections. This not only enhances the reliability of the final product but also streamlines the overall PCB manufacturing process.

Understanding AOI Systems

At its core, an AOI system employs high-resolution cameras and sophisticated software algorithms to analyze images of PCB boards. The system captures detailed visuals of each printed circuit board and compares them against predefined standards or templates to identify any discrepancies or faults. This level of precision in optical inspection allows manufacturers to ensure that their PCB printed circuit boards meet stringent quality requirements before they proceed further in the production line.

The integration of AI and machine learning into AOI systems has further improved their capabilities, enabling them to learn from past inspections and adapt to new designs quickly. As a result, these systems can handle complex layouts with ease, making them indispensable tools in modern circuit board manufacturing environments. With real-time feedback, manufacturers can address issues promptly, reducing waste and increasing efficiency.

Key Benefits of AOI in PCB Manufacturing

One of the primary advantages of using AOI in PCB manufacturing is its ability to significantly reduce human error during inspections. Unlike manual inspection methods that rely on human judgment, automated systems provide consistent results with unparalleled accuracy. This reliability ensures that defects are caught early in the production process, minimizing costly rework or product failures down the line.

Another key benefit is speed; AOI systems can inspect PCBs much faster than traditional methods without sacrificing quality. This rapid assessment is crucial for maintaining production schedules and meeting tight deadlines in a competitive market environment where time-to-market is everything. Moreover, by automating optical inspection processes, manufacturers can allocate their skilled labor towards more complex tasks that require human expertise.

Finally, implementing AOI not only enhances product quality but also contributes to lower overall costs associated with warranty claims and customer dissatisfaction due to faulty products. By investing in reliable pcb optical inspection equipment like AOI systems, manufacturers position themselves as leaders in quality assurance within the highly demanding realm of printed circuit board manufacturing.

X-Ray Inspection Techniques

In the world of printed circuit board manufacturing, precision is key, and X-ray inspection techniques have emerged as a vital component of quality control. This method allows manufacturers to see through layers of the PCB circuit board, revealing hidden defects that might otherwise go unnoticed. By utilizing X-ray inspection, companies can ensure the reliability and longevity of their products while reducing the risk of costly recalls.

When to Use X-Ray Inspection

X-ray inspection is particularly useful in scenarios where traditional optical inspection methods fall short. For instance, when dealing with densely populated PCBs or multilayer circuit boards, it becomes essential to verify connections beneath the surface layers—something that optical inspection simply cannot achieve. Furthermore, this technique is invaluable for detecting issues such as solder joint integrity and component placement errors in high-reliability applications like aerospace and medical devices.

Comparing X-Ray Methods and Benefits

There are several methods within X-ray inspection techniques that cater to different needs in PCB manufacturing. 2D X-ray imaging provides a straightforward view but lacks depth perception; on the other hand, 3D X-ray computed tomography (CT) offers a comprehensive view of internal structures without disassembly. While both methods have their merits, 3D CT is increasingly favored for its ability to deliver detailed insights into complex assemblies, making it an excellent choice for high-stakes circuit board manufacturing.

Leading Brands in X-Ray Inspection

When it comes to choosing equipment for PCB optical inspection equipment or advanced X-ray systems, several brands stand out in the industry. Companies like Nikon Metrology and Yxlon are renowned for their cutting-edge technology designed specifically for printed circuit board manufacturing applications. Investing in reputable brands ensures not only superior performance but also reliable support and service throughout your PCB printed circuit board production process.

In-Circuit Testing (ICT)

In-Circuit Testing (ICT) is a crucial method used in the verification of printed circuit boards (PCBs) during the manufacturing process. This technique involves testing individual components on a PCB circuit board while they are still mounted, allowing for early detection of faults or defects. By integrating ICT into the PCB manufacturing workflow, manufacturers can ensure that each component functions correctly before moving on to further assembly or inspection stages.

What is In-Circuit Testing?

In-Circuit Testing is designed to identify issues such as shorts, opens, and incorrect component values in a PCB board after assembly but before final testing. The process typically employs specialized test fixtures that connect to the PCB's test points, allowing for comprehensive analysis of all components and their interconnections. This not only enhances the efficiency of circuit board manufacturing but also significantly reduces the risk of defects slipping through to later stages.

Advantages of ICT for PCB Reliability

One of the primary advantages of In-Circuit Testing is its ability to catch defects early in the production process, which can save manufacturers both time and money by avoiding costly rework later on. Additionally, ICT provides detailed diagnostic information that helps engineers understand potential failure points within a printed circuit board design, improving overall reliability and performance. By ensuring that each component functions as intended before moving forward, manufacturers can bolster quality assurance efforts throughout their PCB manufacturing processes.

Recommended ICT Equipment Providers

When it comes to selecting equipment for In-Circuit Testing, several providers stand out in the industry due to their reputation for quality and innovation. Companies like Keysight Technologies and Teradyne offer advanced ICT solutions tailored for various needs within printed circuit board manufacturing environments. Additionally, Bensun Technology has emerged as a reliable provider of ICT equipment specifically designed to enhance efficiency and accuracy in testing PCBs.

Functional Testing for PCBs

Functional testing is a crucial phase in the lifecycle of printed circuit board manufacturing, ensuring that each PCB board operates as intended under real-world conditions. This type of testing goes beyond simple visual inspections, providing insights into how well the circuit board can perform its designated functions. By identifying potential failures early in the process, manufacturers can save time and costs associated with later-stage rework or product recalls.

The Importance of Functional Testing

The significance of functional testing cannot be overstated; it serves as a final verification step before a PCB is deployed in its intended application. This process evaluates not only the integrity of the PCB circuit board but also its ability to function correctly within an electronic system. Without thorough functional testing, manufacturers risk delivering faulty products that could lead to malfunctions or safety hazards down the line.

Techniques for Effective Testing

To achieve effective functional testing, various techniques are employed depending on the complexity and requirements of the PCB design. One popular method involves using automated test equipment (ATE) that simulates real-world conditions to assess performance metrics accurately. Additionally, integrating optical inspection alongside functional tests can provide a comprehensive view of both physical and operational characteristics, making it easier to pinpoint issues related to both assembly and functionality.

Bensun’s Offerings for Functional Testing

Bensun Technology offers an array of solutions tailored for functional testing in PCB manufacturing, ensuring reliability from prototype through production stages. Their state-of-the-art equipment includes advanced pcb optical inspection equipment designed to complement traditional functional tests by verifying component placement and solder quality simultaneously. With Bensun's commitment to innovation in printed circuit board manufacturing, clients can trust that their PCBs will meet stringent quality standards while also being cost-effective.

Conclusion

In the ever-evolving landscape of printed circuit board manufacturing, the importance of effective inspection techniques cannot be overstated. As technology advances, so do the methods and equipment used for ensuring the quality and reliability of PCB circuit boards. This conclusion will explore future trends in PCB inspection, emphasize the balance between cost and quality, and highlight how partnering with Bensun can elevate your PCB manufacturing processes.

Exploring the Future of PCB Inspection

The future of PCB inspection is poised for transformative changes driven by advancements in technology, particularly in automation and artificial intelligence. Optical inspection systems are becoming increasingly sophisticated, enabling faster and more accurate assessments of printed circuit boards than ever before. As manufacturers seek to enhance efficiency while maintaining high-quality standards, integrating state-of-the-art pcb optical inspection equipment will be essential for staying competitive in a crowded market.

Emerging technologies like machine learning are set to revolutionize how we approach visual inspections in circuit board manufacturing. These innovations will not only improve defect detection rates but also streamline processes that were once labor-intensive and time-consuming. Ultimately, embracing these advancements will allow companies to produce higher-quality PCBs while reducing lead times and operational costs.

Balancing Cost and Quality in Inspection

When it comes to pcb manufacturing, striking a balance between cost-effectiveness and quality assurance is crucial for long-term success. While investing in advanced optical inspection equipment may seem daunting initially, it often pays off by minimizing defects that could lead to costly recalls or rework later on. By implementing rigorous testing protocols such as automated optical inspection (AOI) alongside traditional methods like manual checks, manufacturers can achieve optimal results without breaking the bank.

Moreover, understanding that quality assurance is an investment rather than an expense can shift perspectives within organizations. Companies that prioritize high standards often enjoy enhanced customer satisfaction and loyalty—key ingredients for sustainable growth in today's competitive environment. Thus, finding reliable suppliers who offer robust solutions at reasonable prices becomes essential for any business looking to thrive in printed circuit board manufacturing.

Partnering with Bensun for Your Needs

Bensun Technology stands out as a leader in providing comprehensive solutions tailored specifically for PCB inspection needs across various industries. By offering cutting-edge pcb optical inspection equipment along with expert guidance on best practices, Bensun ensures that clients have everything they need to maintain exceptional quality control throughout their production processes. Moreover, their commitment to innovation means customers can expect continuous improvements aligned with emerging trends.

Choosing to partner with Bensun not only enhances your capabilities but also empowers your organization to adapt quickly as market demands evolve over time. With a diverse range of testing solutions—from AOI systems to functional testing tools—Bensun has positioned itself as a one-stop shop for all things related to printed circuit board manufacturing excellence. By collaborating closely with their team of experts, businesses can confidently navigate the complexities associated with modern PCB inspections while maximizing both performance and profitability.