Introduction

In the fast-paced world of electronics, understanding PCB manufacturing is crucial for anyone involved in the design and production of electronic devices. But what is PCB manufacturing, and why does it matter? This introduction will guide you through the essentials of PCB manufacturing, the intricate processes involved, and the significant role that PCB manufacturers play in bringing electronic innovations to life.

Understanding PCB Manufacturing Essentials

PCB stands for Printed Circuit Board, a foundational element in virtually all electronic devices. The intricacies of PCB manufacturing encompass various techniques and materials that ensure optimal performance and reliability. Whether you're a seasoned engineer or a curious hobbyist, grasping these essentials can empower you to make informed decisions about your projects.

Exploring the PCB Manufacturing Process

The journey of creating a printed circuit board begins with meticulous design work before moving into fabrication and assembly processes. Understanding how each step contributes to the final product is key; from etching copper layers to soldering components, every detail matters in achieving quality results. By exploring the PCB manufacturing process, you can appreciate not only the technical skills involved but also how these boards support everything from smartphones to industrial machinery.

The Role of PCB Manufacturers

Who manufactures PCBs? The answer lies in a diverse industry filled with specialized companies dedicated to producing high-quality printed circuit boards tailored to various applications. These manufacturers are essential partners for businesses looking to develop reliable electronic products while navigating complexities such as cost management and regulatory compliance. Choosing the right PCB manufacturer in the USA can significantly impact your project's success by ensuring timely delivery and adherence to quality standards.

What is PCB Manufacturing?

PCB manufacturing, or printed circuit board manufacturing, is the intricate process of creating the backbone of electronic devices. It involves designing, fabricating, and assembling various components onto a substrate that provides electrical connections. Understanding what PCB manufacturing entails is crucial for anyone involved in electronics, from hobbyists to large-scale manufacturers.

Definition and Overview

At its core, PCB manufacturing refers to the development of a printed circuit board (PCB), which serves as a platform for connecting electronic components in devices ranging from smartphones to industrial machinery. The process begins with designing the circuit layout using specialized software, followed by fabricating the physical board using various materials like fiberglass and copper. This combination of design and material science makes PCB manufacturing a fascinating field that blends creativity with engineering precision.

Importance in Electronics Industry

The importance of PCB manufacturing in the electronics industry cannot be overstated; it serves as the foundation upon which modern technology stands. Every electronic device relies on PCBs to function effectively, making them essential for everything from consumer gadgets to critical medical equipment. Without efficient PCB manufacturers, innovation would stall, as these boards are integral not only for performance but also for ensuring reliability and safety in electronic applications.

Key PCB Manufacturing Techniques

There are several key techniques employed in PCB manufacturing that cater to different design requirements and complexities. Standard methods include subtractive processes like etching and additive techniques such as screen printing. For more complex designs requiring high-density interconnections or multilayer configurations, advanced methods like laser drilling and HDI (High-Density Interconnect) technology come into play—each technique tailored to meet specific needs within the industry.

Common PCB Manufacturing Techniques

Standard PCB Fabrication Methods

Standard PCB fabrication methods are the backbone of most electronic devices today. These techniques include processes like etching, drilling, and lamination, which transform raw materials into functional printed circuit boards (PCBs). For anyone wondering what does PCB stand for?, it refers to printed circuit board—a critical component in virtually every electronic device we use.

The etching process involves removing unwanted copper from a laminated board to create conductive pathways for electrical signals. Drilling allows for precise holes that accommodate components and connections, while lamination bonds layers of material together for added strength and functionality. Each of these standard methods plays an integral role in ensuring that PCBs meet industry standards and specifications.

Advanced Techniques for Complex Designs

As technology advances, so do the demands placed on PCB manufacturers to produce more intricate designs. Advanced techniques such as multi-layer stacking and blind/buried vias allow designers to create compact boards with complex circuitry that standard methods can't achieve efficiently. These innovations are particularly beneficial in industries like aerospace or telecommunications where space is at a premium.

Another exciting development in advanced PCB manufacturing is the use of flexible materials that enable bendable circuits—ideal for wearable technology or devices requiring unique form factors. Furthermore, high-frequency PCBs are designed specifically for applications needing superior signal integrity at GHz frequencies, showcasing how far we’ve come from basic designs. Understanding these advanced techniques helps businesses select the right approach based on their project requirements.

Comparison of Techniques and Their Applications

When comparing standard fabrication methods with advanced techniques in PCB manufacturing, it's essential to consider their applications carefully. Standard methods are generally more cost-effective and suitable for simpler designs or high-volume production runs where consistency is key—perfect if you’re looking into how much does PCB manufacturing cost? On the other hand, advanced techniques may involve higher costs but provide enhanced performance capabilities necessary for specialized applications.

For instance, if you're developing consumer electronics that require mass production without intricate design features, standard methods will likely suffice—making them an ideal choice among many PCB manufacturers in the USA focusing on efficiency and output volume. In contrast, if your project involves cutting-edge technology with unique specifications requiring flexibility or multi-layer designs, investing in advanced techniques may be worth every penny spent.

Ultimately, understanding both standard and advanced techniques empowers businesses to make informed decisions about who manufactures PCBs tailored to their needs while ensuring quality throughout both fabrication and assembly processes.

Who Manufactures PCBs?

Major PCB Manufacturers in the Industry

In the realm of PCB manufacturing, several giants dominate the scene. Companies like Jabil, Flextronics, and Foxconn are well-known for their extensive capabilities and global reach. These manufacturers not only produce PCBs but also offer integrated solutions that cater to various industries, making them indispensable players in electronics.

What does PCB stand for? It stands for Printed Circuit Board—a vital component that connects electronic components through conductive pathways etched onto a non-conductive substrate. With increasing demand for high-quality PCBs, many manufacturers have adopted advanced technologies to enhance production efficiency and quality control measures.

The competition among these major players drives innovation and cost-effectiveness in PCB manufacturing processes. As a result, they continually invest in research and development to stay ahead of industry trends while ensuring they meet customer needs effectively.

Bensun Technology’s Role in PCB Production

Bensun Technology is an emerging name worth noting within the realm of PCB manufacturing. With a focus on quality and precision, this manufacturer has carved out a niche by specializing in both standard and complex designs tailored to client specifications. Their commitment to using state-of-the-art equipment ensures that every printed circuit board meets stringent industry standards.

What is PCB manufacturing without mentioning Bensun's unique offerings? They provide quick turnaround times without compromising quality—a crucial factor for businesses that require rapid prototyping or low-volume production runs. Additionally, Bensun Technology emphasizes customer collaboration throughout the design process to ensure optimal results aligned with client expectations.

For those wondering how much does PCB manufacturing cost at Bensun? The pricing models are competitive yet transparent; clients can expect fair rates based on complexity and volume while receiving top-notch service throughout their projects.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer can feel overwhelming given the multitude of options available today. It’s essential first to assess your specific needs—whether you require high-frequency boards or multilayer designs—and then filter manufacturers accordingly based on their expertise in those areas. Prioritizing quality assurance procedures during production will also help ensure reliability once your product hits the market.

When considering potential partners like Bensun Technology or other reputable firms within the USA, don’t overlook factors such as lead times and communication responsiveness as well! A good relationship with your chosen manufacturer can significantly influence project outcomes positively over time.

Lastly, always compare quotes from different manufacturers before making your final decision; this enables you to gauge pricing structures effectively while ensuring you're getting value for your investment in pcb assembly services as well as overall production costs related to pcb manufacturing.

PCB Assembly Process Explained

The PCB assembly process is a critical phase in the overall PCB manufacturing journey, transforming bare printed circuit boards into fully functional electronic devices. This stage involves the meticulous placement of components, soldering, and testing to ensure that every aspect of the design works seamlessly. Understanding this process can help you appreciate the intricate world of electronics and the importance of selecting a reliable PCB assembly manufacturer.

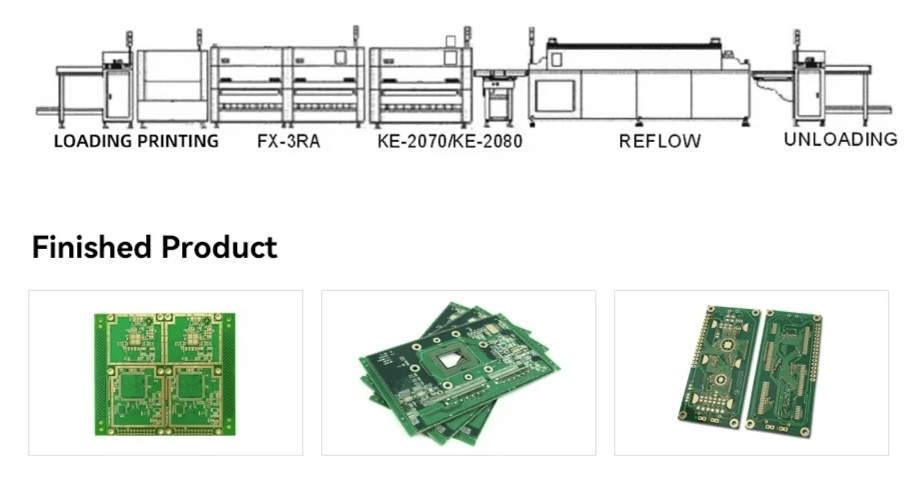

Steps in PCB Assembly

The steps involved in PCB assembly begin with preparing the bare board, which has been created through various PCB manufacturing techniques. Once ready, components are placed on the board using methods like surface mount technology (SMT) or through-hole technology (THT). After placement, soldering follows—either through reflow for SMT or wave soldering for THT—culminating in thorough testing to ensure functionality and reliability.

Once assembled, PCBs undergo several quality checks to verify that all components are correctly placed and functioning as intended. This step is crucial because even minor errors can lead to significant issues down the line. Finally, completed assemblies are often packaged for shipment or further integration into larger systems.

Importance of PCB Assembly Manufacturers

PCB assembly manufacturers play a pivotal role in bringing electronic designs to life by ensuring high-quality assembly processes that meet industry standards. Their expertise not only guarantees that your product functions reliably but also helps reduce time-to-market by streamlining production workflows. When selecting a PCB manufacturer in the USA, it's essential to consider their experience and capabilities in handling complex designs and high-volume production runs.

Moreover, these manufacturers often provide additional services such as prototyping and design assistance, making them invaluable partners throughout your project lifecycle. Choosing a reputable PCB assembly manufacturer can significantly impact your project's success by ensuring consistent quality and adherence to deadlines. With so many options available today, understanding who manufactures PCBs becomes vital for any electronics business looking to thrive.

Quality Control in PCB Assembly

Quality control is an indispensable part of the PCB assembly process—ensuring that each unit meets stringent performance criteria before it leaves the factory floor. Various techniques such as Automated Optical Inspection (AOI) and X-ray inspection help identify defects early on, preventing costly reworks later on in production cycles. By implementing robust quality control measures, manufacturers can maintain high standards while also optimizing costs related to returns or repairs.

In addition to visual inspections and automated testing systems, some manufacturers conduct functional tests under real-world conditions to validate performance further. This level of scrutiny not only enhances reliability but also builds trust with clients who depend on their products for critical applications. Ultimately, investing time and resources into quality control during PCB manufacturing ensures long-term satisfaction for both manufacturers and end-users alike.

How Much Does PCB Manufacturing Cost?

When diving into the world of PCB manufacturing, one burning question often arises: how much does PCB manufacturing cost? The answer isn’t straightforward, as costs can vary significantly based on several factors. Understanding these factors is crucial for businesses looking to budget effectively for their electronic projects.

Factors Influencing PCB Costs

Several key elements influence the costs associated with PCB manufacturing. First and foremost, the complexity of the design plays a pivotal role; intricate designs with multiple layers or specialized materials will typically incur higher costs. Additionally, the volume of PCBs being manufactured can affect pricing—bulk orders often lead to discounts, while smaller batches may result in higher per-unit costs.

Another significant factor is the choice of materials used in production. High-quality substrates or specialized finishes can drive up expenses considerably. Furthermore, geographical location matters; a PCB manufacturer in the USA may have different pricing structures compared to those overseas due to labor and regulatory differences.

Lastly, turnaround time is an important consideration; expedited services usually come at a premium price. By understanding these various factors influencing PCB costs, companies can make informed decisions that align with their budget and project requirements.

Understanding Pricing Models

Navigating through pricing models in PCB manufacturing can feel like deciphering a secret code at times. Typically, manufacturers offer different pricing structures based on quantity, complexity, and lead time—so it’s essential to know what you need before reaching out for quotes. Most manufacturers provide tiered pricing: lower prices for larger orders and higher prices for smaller quantities or more complex designs.

Moreover, some manufacturers might include additional fees for services like prototyping or assembly—a vital aspect if you’re considering hiring a dedicated PCB assembly manufacturer to streamline your production process. It’s also wise to inquire about hidden fees like tooling charges or shipping costs that could inflate your final bill unexpectedly.

Understanding these various pricing models allows businesses to select a manufacturer that aligns best with their specific needs while avoiding any nasty surprises down the road when it comes time to pay up!

Cost Comparison of Different Manufacturers

When shopping around for PCB manufacturing services, comparing costs between different manufacturers is crucial—but it’s not just about finding the cheapest option available! Each manufacturer brings unique strengths and weaknesses to the table that go beyond mere numbers on a quote sheet. For example, while one company may offer lower rates upfront, they might lack experience in producing high-quality boards suitable for complex applications.

Additionally, consider customer service quality and support when evaluating potential partners; after all, good communication can save you time—and money—in resolving issues during production runs! Some well-known manufacturers may charge more but provide superior reliability and support throughout your project lifecycle.

In conclusion, conducting thorough research into various manufacturers helps ensure you choose not only based on cost but also on quality and service—essential components of successful PCB manufacturing endeavors!

Conclusion

In wrapping up our exploration of PCB manufacturing, it's clear that this process is not just a technical necessity but a cornerstone of modern electronics. Understanding what PCB manufacturing encompasses—from design to assembly—allows businesses and hobbyists alike to make informed decisions about their projects. The insights gained here equip you with the knowledge needed to navigate the complex world of printed circuit boards effectively.

Key Takeaways on PCB Manufacturing

PCB manufacturing is an intricate process that combines various techniques to create reliable electronic components. What does PCB stand for? It stands for Printed Circuit Board, which serves as a foundation for connecting electronic components in devices ranging from smartphones to industrial machinery. Knowing how much PCB manufacturing costs can significantly impact project budgets, making it essential for anyone involved in electronics to grasp these financial aspects.

Choosing the Best PCB Manufacturer in USA

When it comes to selecting a PCB manufacturer in the USA, there are several factors to consider, including quality, cost, and turnaround time. Who manufactures PCBs? The answer varies widely; from large-scale firms specializing in high-volume production to smaller companies focused on custom designs. Evaluating potential manufacturers based on their experience and capabilities ensures you find a partner who aligns with your specific needs.

Future Trends in PCB Manufacturing Techniques

The landscape of PCB manufacturing is continuously evolving, driven by advancements in technology and increasing demand for more complex designs. Future trends may include innovations such as flexible PCBs and enhanced automation processes that promise greater efficiency and lower costs. As we look ahead, staying informed about these trends will be crucial for anyone involved in the electronics industry wanting to remain competitive.