Introduction

In the fast-paced world of electronics, the chip mounter plays a pivotal role in the efficiency and quality of PCB manufacturing. These machines are essential for placing various PCB board components with precision, ensuring that every part of a PCB board is correctly positioned for optimal performance. As integrated chip technology continues to evolve, understanding how chip mounters contribute to this process becomes increasingly important.

Understanding the Role of Chip Mounters

Chip mounters, often referred to as pick and place machines, are specialized devices designed to automate the assembly process in PCB manufacturing. They accurately place integrated chips and other components onto printed circuit boards at high speeds, transforming raw materials into functional electronic devices. By eliminating manual labor and enhancing placement accuracy, chip mounters significantly streamline production lines.

Importance of Quality in PCB Manufacturing

Quality assurance is paramount in PCB manufacturing because even minor defects can lead to malfunctioning products or costly recalls. Chip mounters ensure that each component is placed with precision, reducing the likelihood of errors that could compromise device functionality. This focus on quality not only enhances product reliability but also builds trust with customers who depend on these intricate systems.

Enhancing Efficiency in Production Lines

The integration of advanced chip mounter technology into production lines leads to remarkable improvements in efficiency and output rates. With their ability to rapidly assemble parts of a PCB board while maintaining accuracy, these machines minimize downtime and maximize throughput. As manufacturers strive for faster turnaround times without sacrificing quality, investing in state-of-the-art chip mounters becomes essential for staying competitive in the market.

What is a Chip Mounter?

Chip mounters are essential machines in the world of PCB manufacturing, transforming the way we assemble integrated circuits and components on a printed circuit board (PCB). These clever devices automate the placement of PCB board components with precision, ensuring that everything fits snugly and functions optimally. By utilizing advanced technology, chip mounters enhance efficiency in chip manufacturing processes while maintaining high standards of quality.

Definition and Functionality

A chip mounter, often referred to as a pick and place machine, is designed to accurately position various parts of a PCB board onto its surface. Its primary function is to streamline the assembly process by rapidly placing components such as resistors, capacitors, and integrated chips onto PCBs with remarkable speed and accuracy. This automation not only reduces manual labor but also minimizes human error, which can be detrimental to the overall quality of PCB manufacturing.

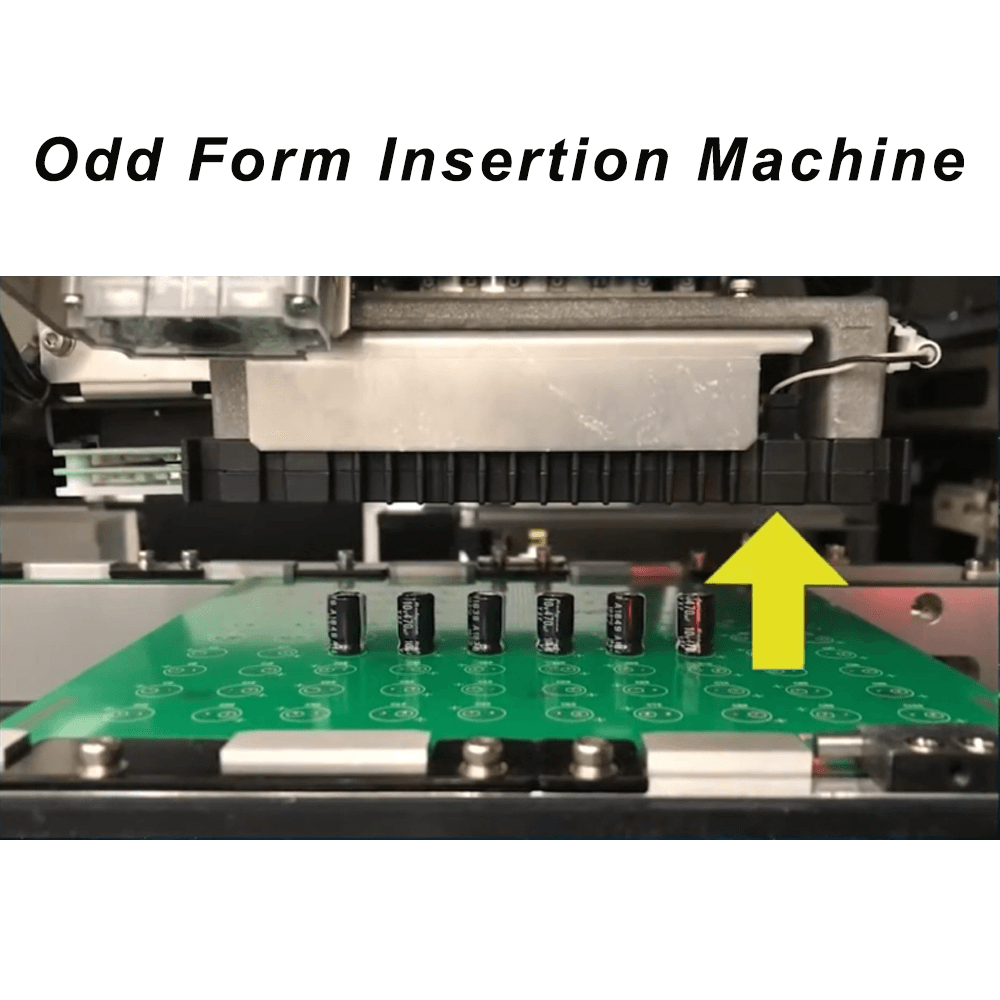

Types of Chip Mounters

There are several types of chip mounters available on the market today, each tailored for specific production needs. From high-speed models designed for mass production to more versatile machines that can handle smaller batches or different types of components, there's a chip mounter for every scenario. Additionally, some machines specialize in handling integrated chips or system on a chip designs, which require precise placement due to their compact nature.

Key Features to Look For

When selecting a chip mounter for your PCB manufacturing needs, several key features should be prioritized to ensure optimal performance. First and foremost is placement accuracy; look for machines that offer high precision in positioning PCB board components to minimize defects during assembly. Other important aspects include speed capabilities—how many components can it place per hour—and compatibility with various component sizes and types including integrated chips used in modern electronics. Moreover, consider user-friendly interfaces that make programming and operation straightforward; after all, even the best pick and place machine is only as good as its operator!

The Impact of Chip Mounters on Production

Chip mounters play a pivotal role in the efficiency and effectiveness of PCB manufacturing. By automating the placement of various components on printed circuit boards (PCBs), these machines significantly enhance production speed while maintaining high standards of quality. Their ability to handle integrated chips and other parts of a PCB board with precision makes them indispensable in modern manufacturing environments.

Speeding Up PCB Manufacturing

The introduction of chip mounters has revolutionized the pace at which PCB manufacturing can occur. Traditional methods, often reliant on manual labor, are slow and prone to errors, whereas automated pick and place machines can place thousands of components per hour with remarkable speed. This acceleration not only meets market demands for rapid turnaround but also allows manufacturers to scale their operations without compromising quality.

Accuracy in Placing PCB Board Components

When it comes to placing PCB board components, accuracy is paramount, especially as designs become more intricate with integrated chip technologies. Chip mounters utilize advanced vision systems that ensure each component is placed precisely where it needs to be, reducing the likelihood of defects that could lead to costly reworks or failures down the line. This level of precision enhances the reliability of end products, particularly those utilizing system on a chip designs that require tight tolerances.

Reducing Waste in Chip Manufacturing

Waste reduction is an often-overlooked benefit brought by chip mounters in the realm of chip manufacturing. By optimizing component placement and minimizing errors during assembly, these machines help reduce scrap materials and lower costs associated with excess inventory or faulty products. Moreover, efficient use of materials aligns well with sustainability goals within the industry, making chip mounters not just a smart investment but also an environmentally friendly choice.

Integrated Chips and Their Relevance

Integrated chips, often referred to as ICs, play a pivotal role in modern electronics, particularly in the realm of PCB manufacturing. These chips combine various electronic components into a single package, streamlining the design and functionality of devices. By integrating multiple functions, they reduce the number of individual parts of a PCB board required, leading to more efficient designs and enhanced performance.

Explanation of Integrated Chip Technology

Integrated chip technology encapsulates an array of electronic circuits within a compact form factor. This technology allows for improved performance and reliability by minimizing the physical space needed for components while maximizing functionality. As chip manufacturing processes evolve, integrated chips have become vital in producing smaller, faster, and more energy-efficient devices.

Importance in System on a Chip Designs

System on a Chip (SoC) designs represent the pinnacle of integrated chip technology by incorporating all necessary components onto a single chip. This approach not only reduces production costs but also enhances speed and efficiency in PCB manufacturing since fewer discrete parts are required to achieve complex functionalities. With SoCs dominating various applications—from smartphones to IoT devices—understanding their relevance is crucial for anyone involved in designing or using PCB board components.

Compatibility with Pick and Place Machines

The compatibility between integrated chips and pick and place machines is essential for efficient assembly processes in chip manufacturing. These machines are designed to accurately position tiny components on PCBs, making them indispensable when working with integrated chips that require precise placement due to their small size and intricate designs. Ensuring that your chip mounter can handle these advanced ICs effectively can significantly enhance production speed while maintaining high-quality standards.

Choosing the Right Chip Mounter

Selecting the right chip mounter is crucial for optimizing your PCB manufacturing process. With various options available, understanding what factors to consider can make all the difference in achieving efficiency and quality. From speed and accuracy to compatibility with integrated chips, each aspect plays a vital role in ensuring that your production line runs smoothly.

Factors to Consider in Selection

When choosing a chip mounter, several factors come into play that can significantly impact your operations. First, consider the speed of the machine; faster chip mountings mean quicker turnaround times for PCB board components. Additionally, accuracy is paramount—look for machines that boast high precision in placing parts of a PCB board to minimize defects and waste during chip manufacturing.

Another important factor is compatibility with integrated chips and system on a chip designs. As technology evolves, you want a pick and place machine that can handle various component sizes and types without compromising efficiency or quality. Lastly, think about maintenance requirements; machines that are easier to service can save you time and money down the line.

Bensun Technology’s Offerings

Bensun Technology stands out in the market by offering an impressive range of chip mounters designed to meet diverse production needs. Their models are engineered for high-speed performance while maintaining exceptional accuracy when placing PCB board components. With features tailored for both integrated chips and traditional designs, Bensun ensures you have flexibility on your production line.

Moreover, Bensun's commitment to innovation means their machines are equipped with advanced technology like real-time monitoring systems that enhance operational efficiency. This not only helps reduce waste during chip manufacturing but also contributes to sustainability efforts within PCB manufacturing practices. By investing in Bensun Technology’s offerings, companies can benefit from reliable equipment tailored for modern challenges.

Comparing Different Brands and Models

When it comes time to compare different brands and models of chip mounters, it's essential to evaluate them based on specific criteria relevant to your needs. Look at user reviews and case studies highlighting performance metrics such as placement accuracy rates and speed benchmarks across various types of integrated chips or system on a chip applications.

Additionally, consider how well each model integrates with existing systems like pick and place machines you may already have in operation; seamless integration can significantly streamline workflows in PCB manufacturing environments. Lastly, don’t forget about customer support—brands that offer robust service agreements often provide peace of mind when investing in new equipment.

The Future of Chip Manufacturing

The landscape of chip manufacturing is poised for remarkable transformation, driven by technological advancements and evolving market demands. As we look to the future, innovations in chip mounter technology are set to redefine how we approach PCB manufacturing. With integrated chips becoming more complex and compact, the role of efficient pick and place machines will be crucial in meeting these new challenges.

Innovations in Chip Mounter Technology

Chip mounters are evolving with features that enhance speed and precision, essential for modern PCB board components. Advanced automation and artificial intelligence are being integrated into these machines, allowing them to adapt to different types of integrated chips seamlessly. This innovation not only boosts production rates but also increases accuracy in placing parts of a PCB board, significantly reducing errors during assembly.

Furthermore, the introduction of multi-functional chip mounters is gaining traction; these machines can handle various tasks such as soldering and inspection within a single unit. This versatility is particularly beneficial in high-volume production environments where efficiency is paramount. As manufacturers continue to push the boundaries of what chip mounters can do, we can expect an exciting era of enhanced productivity and quality control.

Trends in PCB Manufacturing Practices

In tandem with advancements in chip mounter technology, several trends are emerging within the realm of PCB manufacturing that reflect a shift towards greater efficiency and integration. One notable trend is the increasing adoption of system on a chip (SoC) designs which integrate multiple functions into a single unit, thus minimizing space on PCBs while maximizing performance capabilities. This trend necessitates more sophisticated pick and place machines that can accurately handle smaller components without compromising quality.

Another significant trend is the move towards modular design practices that allow for easier upgrades and repairs within electronic devices. Manufacturers are recognizing that flexible design not only enhances product longevity but also aligns with consumer demand for sustainability—an increasingly important factor across industries today. These trends indicate a future where adaptability will be key to success in PCB manufacturing.

Sustainability in the Production Process

Sustainability has become an essential pillar driving change within chip manufacturing processes, including those involving chip mounters. As environmental concerns rise globally, manufacturers are exploring eco-friendly materials for both integrated chips and parts of a PCB board to reduce their carbon footprint during production. Innovations such as lead-free soldering techniques further exemplify this commitment to greener practices.

Moreover, energy-efficient pick and place machines are being developed that consume less power while maintaining high output levels—an attractive proposition for manufacturers looking to cut costs without sacrificing quality or performance. By prioritizing sustainable practices throughout the entire production process, companies not only contribute positively to environmental conservation but also enhance their brand reputation among increasingly eco-conscious consumers.

Conclusion

In the ever-evolving landscape of PCB manufacturing, chip mounters have emerged as indispensable tools that streamline processes and enhance quality. They ensure that integrated chips are placed accurately on PCB board components, which is crucial for the performance of modern electronics. As we look to the future, understanding the significance of these machines in chip manufacturing becomes paramount.

Key Takeaways on Chip Mounting

Chip mounting is not just a technical process; it’s an art form that combines speed, accuracy, and precision. With advancements in pick and place machine technology, manufacturers can now achieve unparalleled efficiency in placing parts of a PCB board. The integration of system on a chip designs further emphasizes the need for high-quality chip mounters that can handle complex layouts with ease.

The Role of Bensun Technology in the Industry

Bensun Technology stands at the forefront of innovation in chip mounting solutions, offering reliable equipment tailored to meet diverse manufacturing needs. Their commitment to quality ensures that each chip mounter optimally supports integrated chip applications while maximizing production line efficiency. By providing state-of-the-art machinery and expert support, Bensun Technology plays a pivotal role in shaping the future of PCB manufacturing.

Investing in Reliable Equipment for Success

Investing in a robust chip mounter is crucial for any company looking to excel in chip manufacturing. Quality equipment not only enhances productivity but also reduces waste and improves overall output quality—key factors for staying competitive in today’s market. As technology continues to advance, prioritizing reliable machinery will be essential for businesses aiming to thrive amidst growing demands.