Introduction

In the fast-evolving world of chip manufacturing, the importance of chip mounters cannot be overstated. These automated machines, often referred to as pick and place machines, play a crucial role in the assembly process by accurately placing components onto printed circuit boards (PCBs). With advancements in technology, modern SMT machinery has transformed how manufacturers approach production efficiency and quality.

Explore the Importance of Chip Mounters

Chip mounters are at the heart of any successful electronics production line. They not only enhance productivity but also ensure precision in placing tiny components that are essential for today's compact devices. Without reliable pick & place machines, manufacturers would struggle to keep up with market demands and maintain high-quality standards.

Understanding Wholesale Pricing Dynamics

Purchasing wholesale chip mounter machine quotes allows companies to benefit from significant cost savings on bulk orders while gaining access to exclusive deals that aren't available through retail channels. This strategic approach not only reduces upfront costs but can also lead to long-term supplier relationships that foster better pricing and service terms.

The Role of Technology in Chip Mounter Solutions

Technology has dramatically reshaped the landscape of chip mounting equipment, making it more efficient and user-friendly than ever before. Modern SMT machines come equipped with advanced features such as real-time monitoring and automated calibration systems that enhance performance while minimizing downtime. As manufacturers increasingly rely on sophisticated machine pick and place capabilities, investing in cutting-edge technology becomes essential for staying competitive in the industry.

Overview of Chip Mounter Machines

In the fast-paced world of chip manufacturing, efficiency and precision are paramount. Enter the chip mounter, a vital piece of equipment that revolutionizes how components are placed onto circuit boards. These machines utilize advanced technology to automate the assembly process, ensuring that every component is accurately positioned for optimal performance.

What is a Chip Mounter?

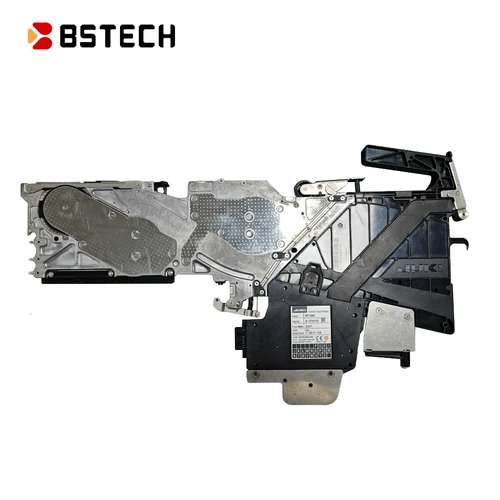

A chip mounter, often referred to as a pick and place machine, is an automated machine designed for assembling electronic components onto printed circuit boards (PCBs). It operates through a series of sophisticated mechanisms that pick up components from a feeder and place them precisely on the PCB. This process significantly enhances production speed and accuracy compared to manual assembly methods, making it an essential tool in modern chip manufacturing.

Key Features of Modern Machines

Modern chip mounters come equipped with several key features that set them apart from their predecessors. High-speed operation capabilities allow these machines to handle large volumes efficiently, while advanced vision systems ensure precise placement accuracy even with tiny components. Furthermore, many machines incorporate flexible software solutions that enable easy programming and adaptation for various production needs—making them indispensable in any SMT (surface-mount technology) machinery lineup.

Types of Chip Mounter Machines Available

When diving into the world of pick & place machines, you'll find a variety tailored for different production scales and needs. There are desktop models ideal for small-scale operations or prototyping environments where space is limited but precision is still required. On the other end of the spectrum are high-capacity automated machines designed for large-scale production lines; these can handle thousands of placements per hour while maintaining impeccable accuracy—perfect for businesses looking to maximize efficiency through wholesale chip mounter machine quotes.

The Benefits of Purchasing Wholesale

Cost Savings on Bulk Orders

One of the most compelling reasons to consider wholesale chip mounter machine quotes is the substantial cost savings associated with bulk purchases. When you buy a pick and place machine in larger quantities, suppliers are often willing to offer discounts that significantly reduce the per-unit price. This allows companies engaged in chip manufacturing to allocate their budgets more effectively while still acquiring high-quality SMT machinery.

Moreover, these savings can be reinvested into other areas of your business, such as enhancing production capabilities or expanding your product line. As you scale up operations with automated machines like pick & place machines, you'll find that reducing overhead costs through wholesale purchasing can lead to increased profit margins over time. In essence, buying wholesale transforms a significant upfront investment into a strategic advantage.

Access to Exclusive Deals

Wholesale purchasing doesn’t just mean lower prices; it often opens doors to exclusive deals that aren’t available for smaller orders. Suppliers frequently roll out promotions or package offers for those who commit to buying multiple units of SMT machines or related equipment. By tapping into these exclusive deals, businesses can secure advanced technology at competitive rates while ensuring they remain ahead in the fast-paced world of chip manufacturing.

Additionally, gaining access to limited-time offers allows companies to stay updated with the latest innovations in pick and place technology without breaking the bank. With every new model released in SMT machinery, there’s an opportunity for businesses that purchase wholesale to stay equipped with cutting-edge tools essential for efficient production processes. Therefore, leveraging exclusive deals not only enhances operational capabilities but also keeps you relevant within an evolving industry landscape.

Long-Term Supplier Relationships

Establishing long-term relationships with suppliers is another pivotal benefit of buying wholesale chip mounter machines. When you consistently order from a particular supplier, you build trust and rapport that can lead to better service and support down the line—especially crucial when dealing with complex equipment like automated machines or SMT machinery. Suppliers appreciate loyal customers and are often more willing to negotiate terms or provide additional support when needed.

Moreover, having a reliable supplier relationship ensures you have consistent access to replacement parts and technical assistance whenever issues arise with your pick & place machine or other equipment used in your chip manufacturing process. This reliability translates into less downtime and greater operational efficiency—a win-win situation! In summary, cultivating long-term partnerships through wholesale purchasing solidifies your supply chain while enhancing overall productivity.

Leading Suppliers in the Market

Bensun Technology Co., Ltd.

Bensun Technology Co., Ltd. is a prominent player in the realm of pick and place machines, specializing in providing high-quality SMT machinery tailored to various manufacturing needs. Their commitment to excellence ensures that clients receive not only top-notch machines but also competitive wholesale chip mounter machine quotes that help businesses save money while maximizing efficiency. With a diverse range of products, including advanced pick & place machines designed for precision and speed, Bensun has positioned itself as a reliable partner in chip manufacturing.

What sets Bensun apart from other suppliers is its focus on technology integration within their smt machine offerings. They employ cutting-edge features that enhance productivity and streamline operations, making them an appealing choice for businesses looking to invest in automated machine solutions. Furthermore, their customer service team works tirelessly to provide accurate quotes and assist clients with any inquiries related to machine pick and place specifications.

In addition to their impressive product lineup, Bensun Technology Co., Ltd. fosters long-term relationships with customers by offering exclusive deals on bulk orders of their chip mounter machines. This approach not only aids companies in reducing costs but also encourages loyalty through consistent support and maintenance services. For those seeking reliable wholesale pricing dynamics combined with innovative technology solutions, Bensun stands out as a go-to supplier in the market.

How to Obtain Accurate Quotes

When diving into the world of chip manufacturing, obtaining accurate quotes for wholesale chip mounter machines is crucial. Variability in quotes can stem from numerous factors, including machine specifications, supplier pricing strategies, and market demand fluctuations. Understanding these elements will help you navigate the waters of purchasing a pick and place machine or any other automated machine with confidence.

Factors Influencing Quote Variability

Several factors can influence the variability of wholesale chip mounter machine quotes. First and foremost is the type of pick & place machine you’re considering; different models come with varying capabilities and price points. Additionally, market conditions can lead to fluctuations in material costs or shipping fees, which directly affect your final quote.

Another key factor is the supplier's pricing strategy; some companies may offer lower initial prices but have hidden fees that inflate overall costs later on. Furthermore, bulk order sizes can also play a role—larger orders might qualify for discounts that smaller purchases do not receive. Lastly, seasonal promotions or changes in demand within the SMT machinery market can impact availability and pricing.

Importance of Specifications in Quotes

The more detailed your requirements—such as speed, accuracy, component size compatibility—the better suppliers can tailor their quotes to meet your needs. This specificity helps avoid misunderstandings that could lead to mismatched expectations regarding performance and cost.

Additionally, clear specifications allow suppliers to highlight features that align with your operational goals, whether you're looking for an automated machine with advanced capabilities or a basic model for simpler tasks. Remember that vague requests often result in generic responses that may not accurately reflect what you truly need for efficient chip manufacturing processes. Thus, investing time upfront in detailing your requirements pays off when it comes to receiving tailored wholesale chip mounter machine quotes.

Requesting Multiple Quotes for Comparison

One effective strategy when searching for the best deal on a pick & place machine is requesting multiple quotes from different suppliers. This practice not only provides insight into competitive pricing but also allows you to gauge variations in service offerings among various SMT machinery vendors. By comparing these wholesale chip mounter machine quotes side by side, you’ll gain a clearer understanding of what constitutes fair pricing based on current market trends.

Moreover, engaging multiple suppliers opens up opportunities for negotiation; knowing what others are offering empowers you during discussions about price reductions or added features at no extra cost. Just be sure to keep track of each quote’s details so you can make informed decisions about which machines best fit your production needs while maximizing value over time.

In conclusion, obtaining accurate quotes requires diligence and attention to detail—factors like variability influences must be understood alongside clear specifications when requesting information from multiple sources within the industry.

Maximizing Your Investment in Chip Mounters

Investing in chip mounters is not just about the initial purchase; it’s about ensuring these machines serve you well over the long haul. By employing effective maintenance strategies, training your staff adequately, and regularly evaluating performance, you can maximize the return on your investment. After all, a well-maintained pick and place machine can significantly enhance productivity in chip manufacturing.

Essential Maintenance Tips for Longevity

Keeping your pick & place machine running smoothly requires regular maintenance to avoid costly downtimes. Simple tasks like cleaning and lubricating moving parts can go a long way in extending the life of your SMT machinery. Additionally, scheduling routine inspections will help identify potential issues before they escalate into major repairs—saving you both time and money while ensuring optimal performance.

Another key aspect of maintenance is keeping up with software updates for your automated machines. These updates often include enhancements that improve efficiency and accuracy during operation, making them essential for staying competitive in the market. Remember to consult wholesale chip mounter machine quotes when considering upgrades or replacements; it could lead to significant savings.

Lastly, consider investing in spare parts that are critical to your chip mounter's operation. Having these on hand will minimize downtime during unexpected failures, allowing you to maintain production schedules without interruption. A proactive approach to maintenance ensures that your machine pick and place operations remain seamless.

Training Staff on New Equipment

When introducing new SMT machines into your production line, proper training is crucial for maximizing their potential. Even the most advanced pick & place machines are only as good as the operators who run them; skilled personnel can make all the difference in efficiency and output quality. Investing time in comprehensive training sessions will empower your staff to utilize features effectively while minimizing operational errors.

Hands-on experience with automated machines can also boost employee confidence and morale, leading to a more productive work environment. Encourage team members to participate in workshops or online courses focused on specific aspects of chip manufacturing technology related to their roles. This knowledge not only enhances their skills but also fosters a culture of continuous improvement within your organization.

Additionally, consider creating an internal resource hub where employees can access manuals, troubleshooting guides, and best practices related to operating new SMT machinery effectively. This resource will serve as an ongoing reference point that supports skill development over time—making it easier for everyone involved when new equipment enters the production landscape.

Evaluating Performance and ROI

To ensure you're getting the most out of your investment in chip mounters, it's essential to regularly evaluate their performance against established benchmarks. Key performance indicators (KPIs) such as throughput rates, defect rates, and overall equipment effectiveness (OEE) provide valuable insights into how well each machine is performing within your production line framework. By analyzing this data consistently, you'll be better positioned to make informed decisions about future investments or adjustments needed for existing equipment.

In addition to quantitative metrics like KPIs, qualitative feedback from operators should not be overlooked when assessing ROI from new SMT machinery purchases or upgrades based on wholesale chip mounter machine quotes received earlier on procurement processes—this insight helps identify areas where improvements may be needed or additional training could enhance productivity further down the line.

Lastly, always keep an eye out for technological advancements that could improve efficiencies further still; innovations within automated machines continue evolving rapidly! Staying updated with industry trends allows you not only leverage cutting-edge solutions but also adapt quickly as market demands change—ensuring sustained success throughout all facets of chip manufacturing operations!

Conclusion

In the fast-paced world of chip manufacturing, understanding the intricacies of chip mounter machines is crucial for any business looking to stay competitive. These automated machines, particularly pick and place machines, are pivotal in ensuring efficiency and precision in production lines. As we wrap up this exploration, let’s highlight some key takeaways that can guide your investment decisions.

Key Takeaways on Chip Mounter Machines

Chip mounter machines are essential tools in modern manufacturing processes, particularly in the realm of surface mount technology (SMT). Their ability to accurately position components ensures high-quality assemblies while minimizing waste and errors. When considering a machine pick and place solution, it's vital to evaluate features such as speed, accuracy, and ease of use to find the best fit for your operational needs.

The Advantage of Wholesale Purchasing

Purchasing wholesale chip mounter machine quotes can lead to significant cost savings for businesses looking to scale their operations. By buying in bulk, companies gain access to exclusive deals that often include additional support or training packages—benefits that enhance overall value. Establishing long-term supplier relationships through wholesale purchasing not only lowers costs but also fosters trust and reliability in sourcing quality SMT machinery.

Final Thoughts on Smart Equipment Investments

Investing in a pick & place machine or other SMT machinery is not just about acquiring new equipment; it’s about future-proofing your operations against industry demands. Proper maintenance and staff training are critical components that ensure longevity and optimal performance from your automated machines. Ultimately, making informed decisions based on accurate quotes will lead you toward maximizing your return on investment while positioning your business for sustained growth.