Introduction

In the fast-paced world of electronics manufacturing, having a trusted supplier is not just beneficial; it's crucial for your success. A reliable China SMT mounter supplier can make all the difference in your production efficiency and product quality. With the right partner, you can streamline your operations and ensure that your pick and place machine delivers optimal results.

The Crucial Role of a Trusted Supplier

Choosing a dependable supplier is like selecting the right foundation for a house; without it, everything else may crumble. A reputable china smt mounter supplier offers not only high-quality machinery but also invaluable support throughout the production process. When you invest in machines such as pick & place or PCB ovens from a trusted source, you're investing in peace of mind.

How SMT Mounting Impacts Your Business

Surface Mount Technology (SMT) has revolutionized electronics manufacturing by enhancing efficiency and precision. The effectiveness of your line SMT directly influences production speed and accuracy, which can either propel your business forward or hold it back. By utilizing advanced SMT machines like pick and place machines, manufacturers can reduce errors and increase output, ultimately impacting their bottom line positively.

What Makes a Reliable China SMT Mounter Supplier

Identifying what constitutes reliability in a china smt mounter supplier involves examining their track record in quality assurance and customer service. A trustworthy partner should provide comprehensive solutions tailored to your needs, including machine pick and place options that suit various project requirements. Moreover, they should offer ongoing support to help you integrate their equipment seamlessly into your existing production lines while ensuring maximum uptime for all machines involved.

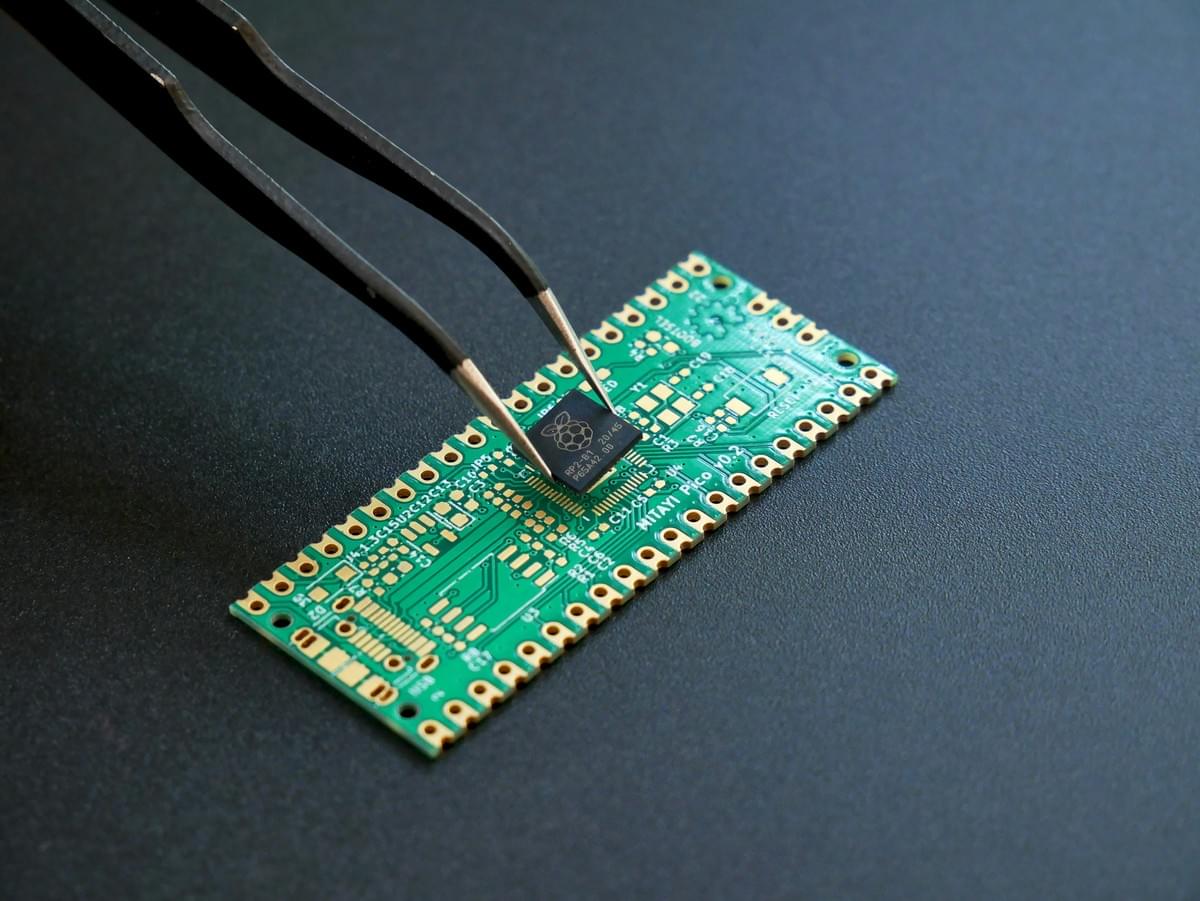

Understanding the Basics of SMT

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, providing a method for mounting electronic components directly onto the surface of printed circuit boards (PCBs). This technology streamlines production processes, allowing for higher component density and improved performance. With a reliable China SMT mounter supplier, businesses can leverage these advancements to enhance their manufacturing capabilities.

What is Surface Mount Technology?

At its core, Surface Mount Technology (SMT) involves placing components on PCBs without the need for through-holes, which was standard in earlier technologies. This approach not only saves space but also allows for faster assembly processes using machines like pick and place machines. By adopting machine pick and place systems, manufacturers can achieve precise placements that are crucial for modern electronic devices.

The rise of SMT has led to a significant reduction in size and weight of electronic products while improving performance and reliability. As devices become smaller yet more powerful, understanding SMT becomes essential for businesses seeking to stay competitive in the market. The efficiency gained from utilizing advanced SMT machinery can often be traced back to choosing a reputable China SMT mounter supplier.

Key Components of SMT Machinery

SMT machinery consists of several key components that work together harmoniously to ensure efficient production lines. At the heart of these systems is the pick & place machine, which automates the placement of components onto PCBs with remarkable speed and accuracy. Other essential elements include solder paste printers, reflow ovens like PCB ovens, and inspection systems that guarantee quality control throughout the production process.

Each component plays a vital role in maintaining high productivity levels while minimizing errors during assembly. For instance, integrating a reliable machine smt setup with advanced software enhances operational efficiency by providing real-time data analysis and troubleshooting capabilities. A well-rounded understanding of these key components is crucial when selecting your preferred china smt mounter supplier.

The Importance of Quality in SMT

Quality assurance in Surface Mount Technology cannot be overstated; it directly impacts product reliability and customer satisfaction. Choosing high-quality SMT machinery from a trusted china smt mounter supplier ensures that every component is placed accurately without defects or misalignments. This focus on quality not only reduces manufacturing errors but also enhances overall production efficiency.

Investing in superior equipment such as pick & place machines or PCB ovens leads to long-term benefits by decreasing operational costs associated with rework or product failures. Additionally, maintaining strict quality standards fosters trust among clients who depend on your products’ performance in their applications. Ultimately, prioritizing quality within your line smt setup will yield dividends as you build your reputation within the industry.

Why Choose a China SMT Mounter Supplier

The combination of competitive pricing and high-quality products makes Chinese suppliers particularly appealing for companies looking to enhance their production lines. With a focus on innovation and efficiency, these suppliers provide the essential tools needed to stay ahead in the fast-paced electronics industry.

Competitive Pricing and Quality Products

One of the most significant advantages of partnering with a China SMT mounter supplier is the affordability without sacrificing quality. These suppliers offer machine pick and place solutions that are not only budget-friendly but also meet international standards for reliability and performance. Companies can invest in advanced equipment like pick and place machines, ensuring their production lines remain efficient while keeping costs low.

Moreover, the pricing strategy employed by Chinese manufacturers often allows businesses to scale operations without breaking the bank. By choosing a reputable supplier from China, you can access top-tier SMT machines that deliver exceptional value for your investment. This balance between cost-effectiveness and quality is crucial for any business aiming to thrive in today's competitive market.

Access to Advanced Technology

China has become synonymous with technological advancement, particularly in manufacturing sectors like surface mount technology (SMT). By opting for a China SMT mounter supplier, companies gain access to cutting-edge machinery equipped with features that enhance productivity and precision. These suppliers continuously invest in research and development, resulting in state-of-the-art pick & place machines that streamline assembly processes.

The integration of smart technology into machine SMT ensures that manufacturers can keep pace with evolving industry demands. For instance, many modern PCB ovens produced by these suppliers incorporate automated functions that optimize temperature control during soldering processes. This level of sophistication not only improves product quality but also reduces operational downtime—an essential factor for any successful production line.

Diverse Product Range

Another compelling reason to choose a China SMT mounter supplier is their extensive range of products tailored to various manufacturing needs. Whether you're looking for high-speed pick and place machines or specialized PCB ovens, you’ll find an impressive selection designed to meet diverse requirements within the electronics sector. This variety allows companies to customize their production lines (line SMT) according to specific project demands.

Additionally, many Chinese suppliers offer flexible solutions that cater to both small-scale operations and large industrial facilities alike. The ability to source different types of machinery from one trusted provider simplifies procurement processes while ensuring compatibility across all equipment used in your assembly line. With such diversity at your fingertips, it's easier than ever to adapt your manufacturing capabilities as market trends shift.

The Benefits of a Good Pick and Place Machine

This essential piece of equipment significantly enhances the efficiency of production lines by automating the placement of components on PCBs. With the right machine, your manufacturing process can run like a well-oiled machine, allowing you to meet deadlines and increase output without sacrificing quality.

Efficiency in Production Lines

A reliable pick and place machine can dramatically boost efficiency in your SMT line. By automating the component placement process, these machines reduce manual labor and minimize the time spent on each PCB assembly. This means that with a good china smt mounter supplier providing top-notch machines, you can produce more units in less time, ultimately lowering costs and increasing profitability.

Moreover, an efficient pick & place system integrates seamlessly into existing production lines, allowing for quick adjustments between different projects or product types. This flexibility is crucial for manufacturers looking to adapt to market demands without extensive downtime. Investing in a high-quality machine SMT not only improves productivity but also enhances your ability to respond swiftly to changing customer needs.

Precision in Component Placement

Precision is paramount when it comes to PCB assembly, and this is where an advanced pick and place machine shines. These machines are designed to accurately position components on the board with minimal deviation from specified locations. When sourced from a reputable china smt mounter supplier, you can expect exceptional precision that reduces misalignment issues often seen with manual placements.

This level of accuracy not only ensures higher quality assemblies but also allows for tighter tolerances in design specifications. Consequently, manufacturers can incorporate smaller components into their designs without worrying about placement errors impacting functionality or performance. Ultimately, investing in precision-focused machinery like this will enhance your product’s reliability and reputation in the market.

Reducing Manufacturing Errors

One of the most significant advantages of using an advanced pick & place machine is its ability to reduce manufacturing errors significantly. Automated systems minimize human error associated with manual assembly processes—think misplaced components or incorrect orientations that lead to costly rework or scrapped boards! With technology evolving rapidly within SMT machinery, modern machines are equipped with sophisticated sensors that ensure every component is placed correctly.

Additionally, integrating these machines into your line SMT operations means fewer mistakes translate directly into savings on materials and labor costs over time. The reduction of errors also leads to improved customer satisfaction as products leave your facility ready for action without defects or delays caused by assembly issues. Choosing a reliable china smt mounter supplier ensures that you receive equipment capable of consistently delivering high-quality results.

Essential Features of SMT Machines

When it comes to selecting the right SMT machines for your production line, understanding their essential features is paramount. The right combination of speed, flexibility, and integration capabilities not only enhances efficiency but also ensures a seamless manufacturing process. This is particularly important when sourcing from a reliable China SMT mounter supplier.

Speed and Productivity

Speed is one of the most critical factors in any manufacturing environment, especially when using a pick and place machine in your line SMT setup. High-speed machines can significantly boost productivity by reducing cycle times and allowing for more components to be placed in less time. When you invest in an efficient machine pick and place system, you're not just buying equipment; you're enhancing your overall workflow.

Moreover, faster production rates mean that you can meet tight deadlines without compromising on quality. A well-optimized PCB oven can complement your SMT machinery by ensuring that soldering processes are equally swift and effective. Ultimately, choosing a machine with superior speed translates directly into increased output and profitability.

Flexibility for Different Projects

Flexibility is another essential feature of modern SMT machines that cannot be overlooked. In today's fast-paced market, manufacturers need to adapt quickly to varying project requirements—whether it's switching between different PCB designs or adjusting component sizes on the fly. A versatile pick & place machine allows you to handle diverse projects without needing extensive reconfiguration or downtime.

This adaptability extends beyond just component placement; it also involves accommodating various types of assemblies within the same production line SMT environment. By choosing an adaptable machine SMT solution from a reputable China SMT mounter supplier, you can ensure that your operations remain agile and responsive to market demands. Ultimately, flexibility leads to innovation and growth opportunities for your business.

Integration Capabilities with Existing Lines

The ability of an SMT machine to integrate seamlessly with existing production lines is crucial for maintaining operational efficiency. When investing in new machinery—such as a state-of-the-art pick and place system—it’s vital that it complements rather than disrupts your current setup. This means looking for machines that offer compatibility with other equipment like PCB ovens or automated inspection systems.

A good China SMT mounter supplier will provide machines designed with integration in mind, ensuring smooth communication between devices while minimizing workflow interruptions. This capability not only saves time during installation but also enhances overall productivity by streamlining processes across multiple stages of assembly. With proper integration capabilities, manufacturers can maximize their existing investments while reaping the benefits of advanced technology.

Bensun Technology: Your Ideal Partner

When it comes to selecting the right china SMT mounter supplier, Bensun Technology stands out as a beacon of reliability and innovation. With a robust portfolio of SMT equipment solutions, they cater to diverse manufacturing needs, ensuring that clients have access to top-notch machinery that can elevate their production capabilities. Whether you're in need of a pick and place machine or a complete line SMT setup, Bensun has you covered.

Comprehensive SMT Equipment Solutions

Bensun Technology offers an extensive range of SMT equipment solutions tailored for various production environments. They specialize in providing high-quality machine pick and place options that enhance efficiency while maintaining precision in component placement. From PCB ovens to advanced SMT machines, their product line is designed to meet the rigorous demands of modern manufacturing processes.

In addition to traditional pick & place machines, Bensun also provides integrated systems that streamline operations across your production line. This means less downtime and more productivity as you harness the full potential of your manufacturing capabilities. With their comprehensive offerings, choosing Bensun as your china SMT mounter supplier ensures you have the right tools for every project.

Flexible Production Line Services

One of the standout features of partnering with Bensun Technology is their commitment to flexible production line services. They understand that each business has unique requirements, which is why they offer customizable solutions tailored specifically for your operational needs. Whether you're scaling up or adjusting for new product lines, their expertise ensures seamless integration with existing systems.

Their flexibility extends beyond just machinery; it includes support services designed to optimize your entire production workflow. By implementing state-of-the-art machine SMT technology alongside tailored configurations, you can expect increased efficiency and reduced operational costs over time. Trusting Bensun means having a partner who adapts alongside your evolving business landscape.

Commitment to Quality and Customer Satisfaction

At the heart of Bensun Technology's operations is an unwavering commitment to quality and customer satisfaction. Each piece of equipment undergoes rigorous testing before reaching clients’ hands, ensuring that every pick and place machine meets industry standards for performance and reliability. Their dedication doesn't end at delivery; ongoing support ensures that any issues are swiftly addressed.

Moreover, by choosing this china SMT mounter supplier, you're not just investing in machinery but also in peace of mind knowing you have a partner focused on your success. Their customer-centric approach fosters long-term relationships built on trust and mutual growth—essential elements in today’s competitive market landscape. With Bensun Technology by your side, expect nothing less than excellence in both products and service.

Conclusion

In the fast-paced world of electronics manufacturing, choosing the right supplier can dramatically elevate your production capabilities. A reliable China SMT mounter supplier brings not only advanced technology but also a commitment to quality that can set your business apart. With the right partner, you can streamline operations and enhance overall efficiency in your production line.

Elevate Your Production with the Right Supplier

Selecting a trusted china smt mounter supplier is essential for achieving operational excellence in your manufacturing processes. The right pick and place machine can transform how components are assembled on PCB boards, leading to improved productivity and reduced errors. By investing in high-quality SMT machines, you ensure that your production line remains competitive and agile in meeting market demands.

The Long-Term Value of Quality SMT Machinery

Quality SMT machinery is not just an expense; it’s a long-term investment that pays dividends over time. When you choose a dependable machine pick and place system or PCB oven from a reputable supplier, you're securing consistent performance and reliability for years to come. This commitment to quality translates into fewer disruptions on the line SMT, ultimately saving you time and money while enhancing product quality.

Trust Bensun Technology for Your SMT Needs

With comprehensive solutions ranging from pick & place machines to flexible production line services, they cater to every aspect of surface mount technology requirements. Trusting Bensun means investing in quality machinery that ensures precision, efficiency, and satisfaction across all your manufacturing processes.