Introduction

In the rapidly evolving world of electronics manufacturing, the SMT (Surface Mount Technology) chip mounter landscape plays a pivotal role in ensuring high-quality production. With an increasing demand for precision and efficiency, selecting the right SMT chip mounter supplier has become more critical than ever. This decision not only impacts production timelines but also affects overall product quality and operational costs.

Overview of SMT Chip Mounter Landscape

The SMT chip mounter market is characterized by diverse suppliers offering a range of factory equipment that caters to various manufacturing needs. From automatic machines designed for high-speed assembly to specialized soldering machines that ensure optimal performance, the options are vast. As technology advances, manufacturers are increasingly integrating sophisticated pick and place machines into their operations to enhance productivity and accuracy.

Importance of Choosing the Right Supplier

Choosing the right supplier for your SMT chip mounter is crucial for maintaining competitive advantage in a crowded marketplace. A reliable factory equipment supplier will not only provide quality machines but also offer ongoing support and maintenance services that can save time and money in the long run. Additionally, working with a reputable supplier ensures access to cutting-edge technology, such as AOI (Automated Optical Inspection) machines, which can significantly improve quality control processes.

Key Features to Look for in Manufacturers

When evaluating potential manufacturers for your SMT chip mounter needs, several key features should be prioritized. First and foremost is their production scale and flexibility; you want a partner capable of adapting to changing demands without compromising on quality or speed. Furthermore, robust quality control processes should be non-negotiable—after all, even the best parts machine won’t deliver results if it’s not backed by stringent testing protocols.

Leading SMT Chip Mounter Suppliers

In the competitive landscape of SMT chip mounter suppliers, Bensun Technology stands out as a comprehensive solution provider. With a focus on innovation and quality, they offer a wide range of factory equipment that meets the diverse needs of electronics manufacturers. Their products include advanced soldering machines, automatic machines, and parts machines designed to enhance efficiency and precision in production lines.

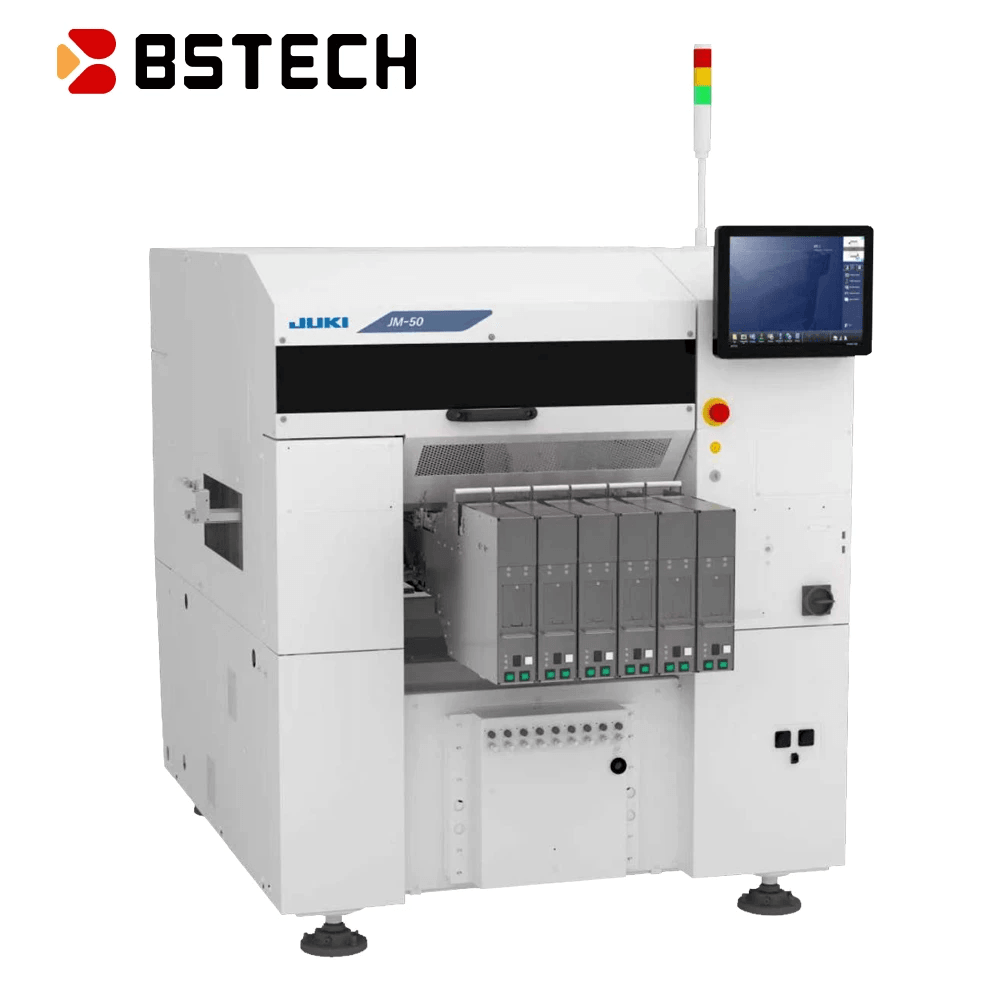

Bensun Technology: A Comprehensive Solution

Bensun Technology has carved its niche as a premier smt chip mounter supplier by delivering cutting-edge solutions tailored for modern manufacturing demands. Their flagship offerings include state-of-the-art pick and place machines that ensure accurate component placement with minimal downtime. Moreover, Bensun’s commitment to integrating advanced AOI (Automated Optical Inspection) machines enhances quality assurance throughout the assembly process.

What sets Bensun apart from other factory equipment suppliers is their emphasis on customization and flexibility. They understand that every production line is unique; thus, they provide options for machine pick and place configurations to suit specific operational requirements. This adaptability not only maximizes productivity but also allows manufacturers to stay ahead in an ever-evolving market.

Furthermore, Bensun Technology remains at the forefront of technology trends with their investments in automation and robotics within their product line-up. Their automatic machines are designed not just for speed but also for precision, reducing errors that could lead to costly rework or product failures. As industries move towards smart factories, Bensun’s innovative approach positions them as a leader among SMT chip mounter suppliers committed to enhancing operational efficiencies.

Evaluating Manufacturing Capabilities

When selecting an SMT chip mounter supplier, evaluating their manufacturing capabilities is crucial to ensure they meet your production needs. A supplier's ability to scale production and adapt to changing demands can significantly impact your operational efficiency. Additionally, understanding their quality control processes and customization options can help you make a more informed decision.

Production Scale and Flexibility

The production scale of an SMT chip mounter supplier determines how well they can cater to both large-scale operations and smaller, specialized tasks. Suppliers with a flexible manufacturing setup can quickly adjust their output based on your requirements, whether you need high-volume runs or limited batches for niche projects. Look for factory equipment suppliers that offer automatic machines capable of accommodating various sizes and types of components, ensuring seamless integration into your existing processes.

Quality Control Processes

Quality control is non-negotiable when it comes to choosing the right SMT chip mounter supplier. Robust quality assurance processes should be in place to monitor every stage of production, from the initial assembly of parts machines to the final inspection using AOI machines (Automated Optical Inspection). Suppliers who prioritize quality will not only enhance the reliability of your products but also reduce costly rework or recalls in the long run.

Customization Options for Specific Needs

In today's competitive market, one-size-fits-all solutions rarely cut it; hence, customization options are vital when choosing an SMT chip mounter supplier. Whether you require specific features on a pick and place machine or unique configurations for soldering machines, a capable supplier should be able to tailor their offerings accordingly. This level of flexibility ensures that your manufacturing process aligns perfectly with your operational goals while maximizing efficiency.

Technology Trends in SMT Machinery

The landscape of SMT machinery is undergoing a significant transformation, driven by technological advancements that enhance efficiency and precision. Suppliers of SMT chip mounters are increasingly integrating cutting-edge automation and robotics into their offerings, making these machines more capable than ever. This evolution not only streamlines production processes but also ensures higher accuracy in component placement.

Advancements in Automation and Robotics

Automation has become the backbone of modern SMT chip mounters, with suppliers focusing on creating machines that can operate with minimal human intervention. Automatic machines equipped with advanced robotics can handle complex tasks such as loading components, soldering, and quality inspection seamlessly. For instance, pick and place machines now feature sophisticated robotic arms that improve speed and precision while reducing the likelihood of errors during assembly.

Moreover, factory equipment suppliers are continually innovating to enhance the flexibility of their products. This means that manufacturers can easily adapt their lines to accommodate different types of parts machines without extensive downtime or reconfiguration. As a result, businesses can respond more swiftly to market demands while maintaining high-quality standards.

Integration of AI in Chip Mounting

Artificial Intelligence (AI) is playing an increasingly pivotal role in the operation of SMT machinery, particularly in chip mounting processes. Suppliers are now equipping soldering machines with AI algorithms that analyze real-time data to optimize placement accuracy and speed. This integration allows for predictive maintenance schedules, minimizing machine downtime and enhancing overall productivity.

Additionally, AI-driven systems can learn from previous production runs to continuously improve performance metrics across various parameters like speed and error rates. The incorporation of AI into AOI (Automated Optical Inspection) machines further ensures quality control by enabling instant feedback on defects or misalignments during production cycles. As a result, manufacturers benefit from reduced waste and enhanced reliability in their output.

The Rise of Smart Factories

The concept of smart factories is reshaping the manufacturing landscape as companies leverage connected technologies to create more responsive production environments. Suppliers are now offering solutions that enable seamless communication between different types of machinery—including pick and place machines—allowing for real-time adjustments based on production needs. This interconnectedness enhances operational efficiency by ensuring all components work harmoniously together.

Moreover, smart factories utilize data analytics to monitor performance metrics continuously, allowing managers to make informed decisions quickly about resource allocation or process improvements. By investing in such technology from reputable SMT chip mounter suppliers, businesses position themselves at the forefront of industry innovation while maximizing their competitive advantage.

In conclusion, staying abreast of these technology trends is crucial for any manufacturer looking to thrive in today’s dynamic market environment where every detail counts—from selecting the right soldering machine to implementing fully automated systems capable of driving growth.

Geographic Insights: Where to Buy

When it comes to sourcing SMT chip mounters, understanding geographic dynamics is crucial. Different regions offer unique advantages in terms of supplier capabilities, availability of factory equipment suppliers, and local regulations that can impact supply chains. This section delves into why Bensun stands out as a pivotal industry hub and how regional regulations shape the landscape for purchasing essential machinery like soldering machines and pick and place machines.

Exploring Bensun as an Industry Hub

Bensun has emerged as a notable industry hub for SMT chip mounter suppliers, attracting businesses looking for reliable factory equipment suppliers. This region boasts a concentration of advanced manufacturing facilities specializing in automatic machines, parts machines, and cutting-edge pick and place machines. The synergy between various manufacturers fosters innovation and ensures that clients have access to the latest technology in machine pick and place solutions.

Moreover, Bensun's strategic location facilitates efficient logistics networks, enabling quick delivery times for essential components like AOI machines. Companies can benefit from reduced lead times while enjoying competitive pricing due to the region's robust supply chain ecosystem. As a result, businesses seeking high-quality SMT chip mounters find Bensun offers not just products but also valuable partnerships that enhance their operational efficiency.

The Impact of Regional Regulations on Supply

Regional regulations play a significant role in shaping the landscape of SMT machinery procurement. Depending on local laws governing manufacturing standards and environmental practices, factory equipment suppliers may face different compliance requirements that affect production capabilities and costs. For instance, regions with stringent regulations may drive up prices for soldering machines or automatic machines due to increased compliance costs.

On the flip side, areas with more lenient regulations might allow quicker market entry for new technologies such as advanced parts machines or innovative pick and place machines. Businesses must navigate these regulatory waters carefully to ensure they align with both their operational needs and legal obligations while maintaining product quality through effective quality control processes. Understanding these nuances can empower companies to make informed decisions when selecting an SMT chip mounter supplier that aligns with their long-term goals.

Costs and Investment Considerations

When diving into the world of SMT chip mounters, understanding costs and investment considerations is crucial for any business looking to enhance its manufacturing capabilities. The initial price tag can often seem daunting, especially when evaluating various factory equipment suppliers. However, a well-informed decision can lead to significant long-term benefits that outweigh the upfront costs.

Understanding Price Structures

The price structures of SMT chip mounter suppliers vary widely based on several factors, including machine specifications, production capacity, and technological advancements. For instance, a basic pick and place machine might come at a lower cost compared to an advanced automatic machine equipped with AI capabilities. Understanding these nuances allows businesses to budget effectively while ensuring they select a soldering machine that meets both current needs and future scalability.

Moreover, it's essential to consider additional costs associated with parts machines and maintenance services when evaluating overall investment in SMT machinery. Some suppliers may offer bundled packages that include training or support services, which can impact the total expenditure significantly. Therefore, being aware of all potential expenses helps manufacturers avoid unexpected financial surprises down the line.

Balancing Quality and Cost

Striking the right balance between quality and cost is vital when choosing an SMT chip mounter supplier. While it might be tempting to opt for cheaper options available in the market, sacrificing quality can lead to increased downtime and higher defect rates in production. Investing in high-quality machinery like an AOI machine ensures reliability and precision during assembly processes.

Additionally, many factory equipment suppliers offer tiered pricing based on the features included in their machines; this allows businesses to customize their investments according to specific operational needs without compromising on quality. It’s also worth noting that some automatic machines come with enhanced features that justify their higher price points through improved efficiency and reduced labor costs over time. Ultimately, a judicious approach towards balancing these elements will pay dividends in productivity.

Long-term Value of Investing in Technology

Investing in advanced technology such as automated pick and place machines or sophisticated soldering machines should not just be viewed through the lens of immediate cost but rather as a strategic long-term investment for growth potential. As industries evolve rapidly due to technological advancements, having state-of-the-art equipment positions companies favorably against competitors who may still rely on outdated methods.

Furthermore, modern SMT machinery often leads to better product quality due to enhanced accuracy during assembly processes—this translates into fewer returns or warranty claims over time which can save substantial amounts of money for manufacturers. Ultimately, recognizing the long-term value embedded within these investments encourages businesses not only to improve their current operations but also prepares them for future challenges within an ever-changing market landscape.

Conclusion

In the ever-evolving landscape of electronics manufacturing, finding the perfect SMT chip mounter supplier is crucial for businesses aiming to enhance efficiency and quality. The right factory equipment supplier can make all the difference in production capabilities, especially when it comes to investing in advanced machinery like pick and place machines or automatic machines. By carefully evaluating options based on technology trends and customization capabilities, manufacturers can secure a competitive edge.

Finding the Perfect SMT Chip Mounter Supplier

Choosing an SMT chip mounter supplier involves more than just comparing prices; it’s about aligning with a partner that understands your specific needs. Look for suppliers who offer comprehensive solutions, including soldering machines and AOI machines, ensuring that every aspect of your production line is covered. A good match will not only provide high-quality parts machines but also deliver exceptional customer support throughout your journey.

The Role of Innovation in SMT Manufacturing

Innovation is at the heart of modern SMT manufacturing, driving improvements in automation and efficiency across the board. Suppliers that leverage cutting-edge technologies like AI integration and smart factory concepts are setting new standards for what’s possible in chip mounting processes. As businesses adopt these advancements, they’ll find that their productivity increases significantly while also reducing error rates associated with manual processes.

Future Outlook for the Chip Mounter Industry

The future outlook for the chip mounter industry is bright as demand continues to grow alongside technological advancements. With a focus on automation and smarter manufacturing processes, we can expect significant developments in machine pick and place technology as well as enhanced functionalities within existing equipment like soldering machines. As companies invest wisely in their production capabilities through reliable suppliers, they will be well-positioned to thrive amidst changing market dynamics.