Introduction

In the fast-paced world of electronics, ensuring the quality and reliability of printed circuit boards (PCBs) is paramount. This is where PCB inspection technology comes into play, offering a range of methods to scrutinize every detail of these essential components. From manual techniques to advanced automated inspection systems, understanding these processes is crucial for manufacturers aiming to maintain high standards.

Understanding PCB Inspection Technology

PCB inspection technology encompasses various methods and tools designed to detect defects in circuit boards before they are put into service. As electronic devices become more complex, the need for precise and reliable inspection solutions has surged, leading to innovations such as Automated Optical Inspection (AOI). These technologies not only enhance accuracy but also streamline production processes by identifying potential issues early on.

Importance of Reliable PCB Inspection

Reliable PCB inspection is critical for ensuring that electronic devices function correctly and safely. Any defects in PCBs can lead to catastrophic failures, costly recalls, and damage to a brand's reputation. By employing effective automated PCB inspection solutions, manufacturers can mitigate risks while maintaining consistent quality across their products.

Overview of Inspection Equipment

The landscape of PCB inspection equipment includes both manual tools and sophisticated automated optical inspection machines tailored for various applications. Manual methods often rely on visual inspections aided by magnifying lenses or other handheld devices; however, they can be time-consuming and prone to human error. In contrast, automated inspection systems leverage advanced imaging technology to provide rapid and accurate assessments of PCBs, making them an indispensable asset in modern manufacturing environments.

Manual Inspection Techniques

In the world of PCB manufacturing, manual inspection techniques still hold a significant place despite the rise of automated inspection systems. These methods allow for hands-on evaluation, providing an immediate sense of quality assurance that can be invaluable in certain contexts. However, as technology advances, the efficiency and accuracy of these manual techniques are often put to the test against their automated counterparts.

Visual Inspection Methods

Visual inspection methods are perhaps the most straightforward approach to PCB evaluation. Operators scrutinize each board for physical defects such as solder issues, component placement errors, and any visible signs of damage. While this technique can be effective for identifying obvious flaws, it heavily relies on human judgment and can lead to inconsistencies—especially when compared to more sophisticated automated optical inspection PCB systems.

Tools for Manual PCB Inspection

To aid in visual inspections, various tools have been developed that enhance the capabilities of human inspectors. Magnifying glasses, microscopes, and specialized lighting equipment can help reveal defects that might otherwise go unnoticed with the naked eye. Despite these advancements in tools, they still cannot match the precision offered by modern automated optical inspection machines which utilize advanced imaging technologies.

Limitations of Manual Inspection

One major limitation of manual inspection is its inherent subjectivity; different inspectors may have varying thresholds for what constitutes an acceptable defect level. Additionally, visual inspections can be time-consuming and labor-intensive—factors that become increasingly problematic in high-volume production environments where speed is crucial. As a result, many manufacturers are turning towards automated PCB inspection solutions to streamline processes and enhance overall quality control.

Automated Inspection Systems

In the fast-paced world of electronics manufacturing, automated inspection systems have become essential for ensuring quality and reliability in printed circuit boards (PCBs). These advanced solutions streamline the inspection process, reducing human error and increasing efficiency. With the rise of automated optical inspection (AOI), manufacturers can now detect defects earlier in the production cycle, saving time and resources.

Advantages of Automated Inspection

Automated inspection offers numerous advantages over traditional manual methods. First and foremost, it significantly increases throughput; machines can inspect hundreds or thousands of PCBs per hour with consistent accuracy. Additionally, automated PCB inspection solutions reduce labor costs and minimize the risk of human error, leading to higher quality products.

Another key benefit is improved data collection capabilities. Automated optical inspection machines can store detailed records of inspections, providing valuable insights into production trends and potential issues. This data-driven approach enhances decision-making processes, allowing manufacturers to make informed adjustments to improve overall efficiency.

Key Features of PCB Inspection Systems

When evaluating a PCB inspection system, several key features should be considered to ensure optimal performance. High-resolution cameras are crucial for capturing detailed images of PCBs during inspections; this enables accurate detection of even the smallest defects. Furthermore, advanced image processing algorithms enhance defect recognition capabilities by quickly analyzing captured images against predefined criteria.

Another important aspect is adaptability; modern automated optical inspection systems must be able to accommodate various PCB designs and sizes without requiring extensive reconfiguration. User-friendly interfaces are also essential for operators to easily set up and monitor inspections while minimizing training time for new staff members.

Lastly, integration capabilities with existing manufacturing processes should not be overlooked. Seamless communication between automated optical inspection machines and other production equipment ensures that any issues detected can be promptly addressed without disrupting workflow.

Leading Brands in Automated Optical Inspection

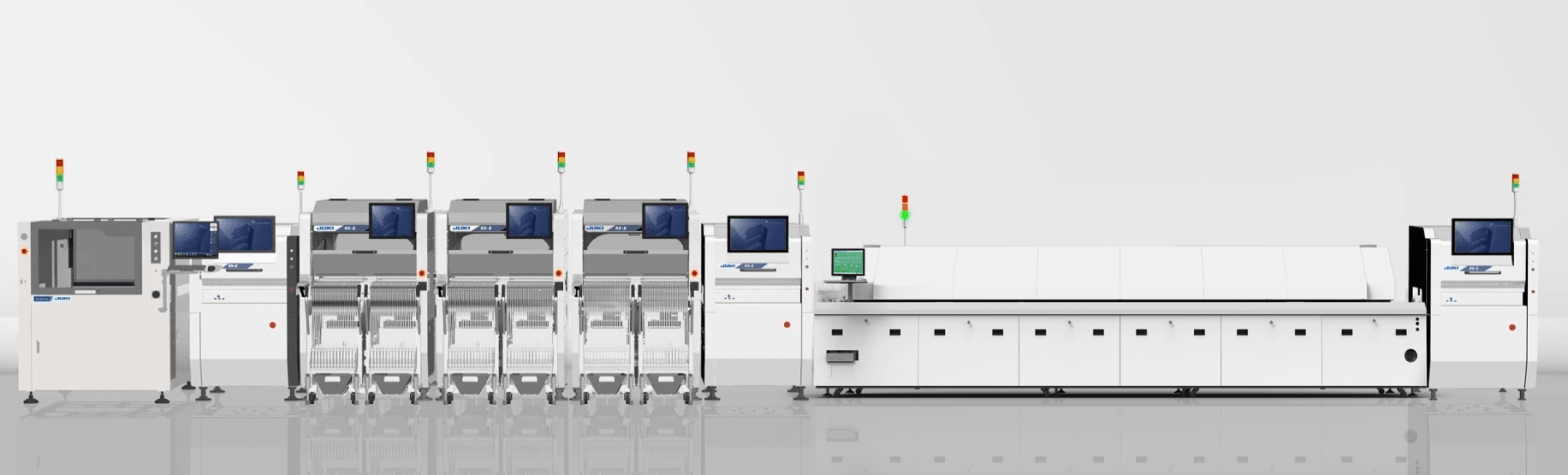

The market for automated optical inspection has seen several leading brands emerge as frontrunners in technology innovation and reliability. Companies like Koh Young Technology are renowned for their precision AOI systems that leverage 3D measurement techniques to provide unparalleled accuracy in defect detection on PCBs. Their commitment to research and development consistently places them at the forefront of automated PCB inspection solutions.

Another notable player is Omron Automation, which offers comprehensive AOI systems that integrate seamlessly into various production lines while providing real-time feedback on product quality. Their focus on user-friendly design ensures that operators can quickly adapt to changing demands without sacrificing efficiency or accuracy.

Lastly, CyberOptics Corporation has gained recognition for its cutting-edge sensors used in their automated optical inspection machines that deliver exceptional speed and precision in detecting solder joint defects on PCBs. As manufacturers continue to seek ways to enhance quality control processes through automation, these leading brands will likely remain pivotal players in shaping the future landscape of PCB inspections.

Automated Optical Inspection PCB

Automated Optical Inspection (AOI) has revolutionized the way we approach PCB inspection, providing a sophisticated alternative to manual methods. By utilizing advanced imaging technology, automated inspection systems can quickly and accurately identify defects in printed circuit boards. This efficiency not only streamlines the inspection process but also enhances overall product quality.

What is Automated Optical Inspection?

Automated Optical Inspection is a non-contact method that employs high-resolution cameras to capture detailed images of a PCB's surface. These images are then analyzed using sophisticated algorithms to detect various defects, such as misalignments, soldering issues, and component placement errors. With the rise of complex electronic devices, Automated Optical Inspection has become essential for ensuring that PCBs meet stringent quality standards.

Role of Automated Optical Inspection Machines

Automated optical inspection machines play a pivotal role in modern manufacturing environments by integrating seamlessly into production lines. They provide real-time feedback on the quality of PCBs being produced, allowing for immediate corrective actions when defects are detected. This capability significantly reduces downtime and waste while ensuring that only high-quality products reach the market.

Benefits of Using Automated Optical Inspection

The benefits of using automated optical inspection are manifold and impactful for manufacturers looking to enhance their processes. First and foremost, these systems offer unparalleled speed and accuracy compared to traditional manual inspections, drastically reducing the time required for quality checks. Additionally, automated PCB inspection solutions minimize human error and variability in inspections—leading to more consistent product quality over time.

Advanced Inspection Techniques

In the realm of PCB inspection, advanced techniques are revolutionizing how manufacturers ensure quality and reliability. As technology progresses, methods like X-ray and laser inspections are becoming more prevalent, offering unique insights that traditional methods simply cannot provide. These advanced inspection systems not only enhance the accuracy of defect detection but also streamline production processes.

X-ray Inspection for PCBs

X-ray inspection is a game-changer in the world of PCB manufacturing, particularly for multilayer boards where internal components can be hidden from view. This technique utilizes high-energy radiation to penetrate layers and reveal any defects such as solder voids or misalignments within the assembly. The beauty of using an automated inspection system with X-ray capabilities lies in its ability to deliver detailed images with pinpoint accuracy, making it an indispensable tool for quality assurance.

One significant advantage of X-ray inspection is its non-destructive nature; boards can be assessed without compromising their integrity. Automated optical inspection PCB systems often complement X-ray techniques by providing surface-level analysis while X-rays delve deeper into internal structures. Thus, manufacturers can achieve a comprehensive overview of their products through integrated automated PCB inspection solutions.

Laser Inspection Methods

Laser inspection methods bring another layer of sophistication to PCB quality control processes. Utilizing focused laser beams, this technique measures various parameters such as height, width, and alignment with exceptional precision. The integration of laser technology in automated optical inspection machines allows for rapid scanning and analysis, significantly reducing the time required for inspections compared to manual approaches.

Moreover, laser inspections are particularly effective at detecting surface irregularities that might go unnoticed during visual checks or even some automated optical inspections. With capabilities to assess both reflective and transparent surfaces accurately, laser systems provide a versatile solution that aligns perfectly with modern manufacturing demands. In conjunction with other automated PCB inspection solutions, these methods help maintain high-quality standards while enhancing operational efficiency.

Comparison of Inspection Techniques

When comparing various PCB inspection techniques—manual visual checks versus advanced automated systems—the differences become strikingly apparent. While manual inspections rely heavily on human judgment and can be prone to errors due to fatigue or oversight, automated systems like those employing X-ray or laser technologies offer unmatched consistency and reliability in defect detection.

Automated optical inspection machines excel at identifying surface defects quickly but might miss issues lying beneath multiple layers—where X-ray shines bright! On the other hand, while laser inspections provide detailed surface analysis with remarkable speed and accuracy, they may not capture certain types of internal flaws that an Automated Optical Inspection PCB system could detect when used together strategically.

In conclusion, each method has its strengths; however, integrating these advanced techniques into a cohesive strategy allows manufacturers to leverage the best aspects from each approach—ensuring top-notch quality control across all stages of production.

Choosing the Right Inspection Solution

Navigating the world of PCB inspection can feel like trying to find a needle in a haystack, especially with the plethora of options available today. Selecting the right inspection solution is crucial for ensuring product quality and reliability. Factors such as technology, cost, and integration capabilities play significant roles in making this decision.

Factors to Consider for PCB Inspection

When considering a PCB Inspection System, several factors should be top of mind. First, assess the complexity of your PCBs; intricate designs may require advanced automated inspection systems that can handle fine details without missing defects. Additionally, consider the volume of production—high-speed manufacturing lines benefit greatly from Automated optical inspection machines that can quickly analyze multiple boards simultaneously.

Cost is another critical factor; while investing in an Automated optical inspection PCB might seem steep initially, it often pays off in reduced error rates and increased efficiency over time. Furthermore, evaluate how user-friendly the system is; an intuitive interface can save training time and ensure quicker adoption by your team. Lastly, think about scalability—can your chosen solution grow alongside your production needs?

Bensun Technology's Inspection Solutions

Bensun Technology offers a suite of Automated PCB inspection solutions designed to meet various industry needs with precision and reliability. Their flagship products include state-of-the-art Automated optical inspection machines that combine high-resolution imaging with intelligent defect recognition algorithms. These systems are not only efficient but also adaptable to different types of PCBs, making them a versatile choice for manufacturers.

One standout feature of Bensun's offerings is their commitment to continuous improvement; regular software updates ensure that users always have access to cutting-edge technology without needing to invest in new hardware frequently. Additionally, their customer support is robust—providing training sessions and troubleshooting assistance ensures that clients get maximum value from their investment in automated inspection systems. With Bensun Technology's solutions at your disposal, achieving high-quality standards becomes a more manageable task.

Integrating Inspection Systems into Production

Integrating an Automated optical inspection system into existing production lines requires careful planning and execution for seamless operation. Start by assessing current workflows; identifying bottlenecks where manual inspections slow down processes will help pinpoint where automation can make the most impact. Next, involve key stakeholders—engineers and operators alike—to gather insights on how best to implement these changes without disrupting productivity.

Once you've selected an appropriate system like those offered by Bensun Technology, develop a phased rollout plan that allows gradual adoption rather than an all-or-nothing approach which could lead to chaos on the factory floor! Training sessions should be scheduled early on so that operators are comfortable with using new technologies before they officially go live within production environments.

Finally, monitor performance metrics post-integration closely; this will provide valuable insights into how well your automated PCB inspection solutions are performing compared to manual methods previously employed. By continuously evaluating effectiveness and making necessary adjustments along the way, you’ll ensure optimal functionality while enhancing overall product quality through rigorous inspections.

Conclusion

In the ever-evolving landscape of electronics manufacturing, the significance of reliable PCB inspection cannot be overstated. From manual techniques to state-of-the-art automated inspection systems, each method plays a crucial role in ensuring product quality. As we’ve explored, a range of PCB Inspection Systems exists to meet diverse needs, with automated optical inspection machines leading the charge in efficiency and accuracy.

Recap of Inspection Techniques

Throughout this discussion, we delved into various PCB inspection techniques that are pivotal in maintaining quality standards. Manual inspection methods rely heavily on human eyes and tools, while automated solutions offer precision and speed that far exceed traditional approaches. Automated optical inspection (AOI) stands out as a game-changer among these techniques, providing real-time analysis and high throughput for manufacturers looking to enhance their production lines.

Future of PCB Inspection Technology

Looking ahead, the future of PCB inspection technology is bright and brimming with potential advancements. The integration of artificial intelligence into automated optical inspection machines promises not only improved defect detection but also predictive analytics for maintenance and performance optimization. As industries continue to embrace automated PCB inspection solutions, we can expect even more sophisticated systems that adapt to evolving manufacturing challenges.

Enhancing Quality with Proper Inspections

Proper inspections are essential for ensuring quality in electronic components, and leveraging advanced technologies can significantly enhance this process. Implementing robust automated inspection systems allows manufacturers to identify defects early on, reducing waste and improving overall efficiency. By investing in cutting-edge Automated Optical Inspection (AOI) technology, businesses can ensure they deliver superior products that meet or exceed customer expectations.