Introduction

In the fast-paced world of electronics manufacturing, understanding SMT AOI technology is essential for maintaining quality and efficiency. Automated Optical Inspection (AOI) systems play a critical role in ensuring that printed circuit boards (PCBs) meet stringent industry standards. This introduction will explore the significance of AOI in PCB manufacturing and provide an overview of Bensun's cutting-edge JUKI AOI machines.

Understanding SMT AOI Technology

SMT AOI machines are designed to enhance the reliability of electronic assemblies by inspecting them for defects during the production process. But what is AOI in SMT? It refers to a sophisticated method that utilizes high-resolution cameras and advanced algorithms to detect anomalies on PCBs, ensuring that every component is correctly placed and soldered. With the growing complexity of electronic devices, understanding how these automated optical inspection systems work has become increasingly important for manufacturers aiming for excellence.

Importance of AOI in PCB Manufacturing

The importance of Automated Optical Inspection cannot be overstated when it comes to PCB manufacturing. These systems significantly reduce the risk of human error, which can lead to costly rework or product failures down the line. By integrating an SMT AOI machine into their processes, manufacturers can enhance product quality while also improving overall operational efficiency.

Overview of Bensun's JUKI AOI Machines

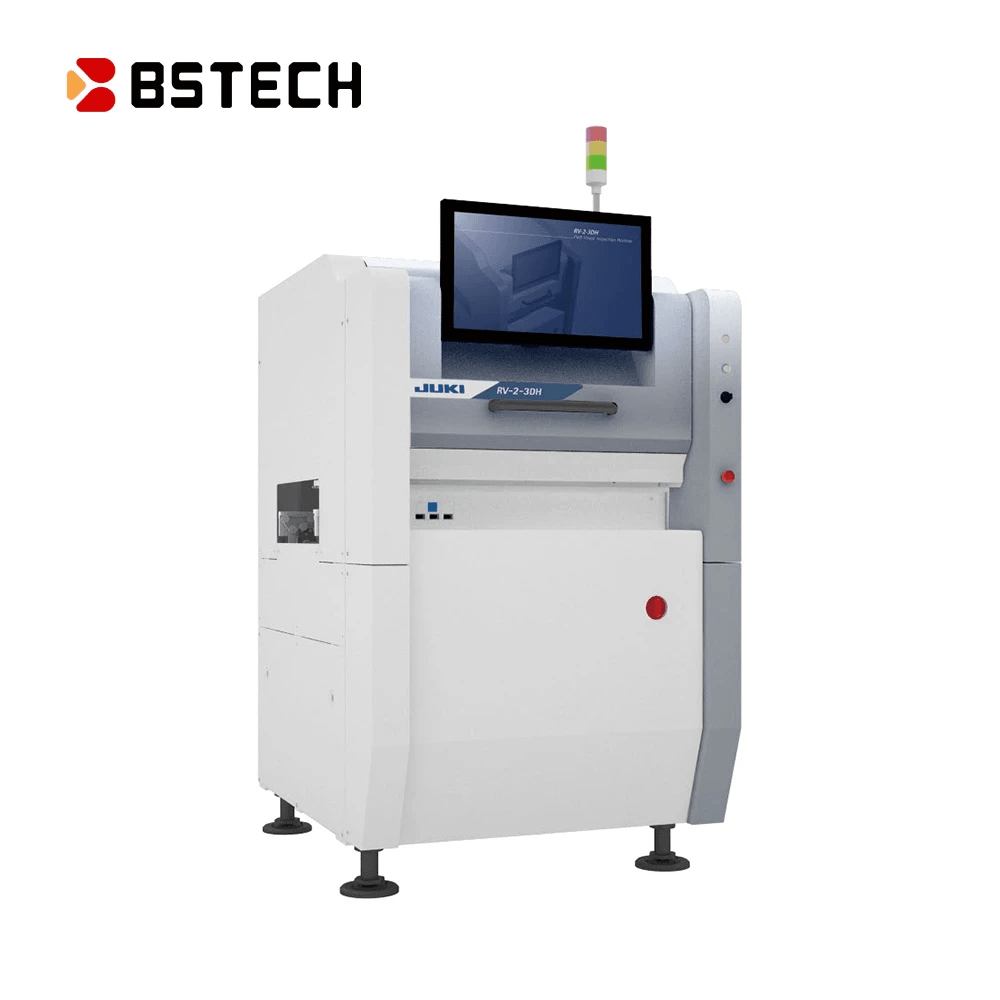

Bensun offers a range of JUKI AOI machines that exemplify state-of-the-art technology in automated optical inspection. Designed with precision and speed in mind, these machines cater to various production needs while delivering exceptional accuracy in defect detection. With Bensun's commitment to innovation and quality, choosing their SMT AOI machine means investing in reliability and performance for your PCB manufacturing operations.

What is AOI in SMT?

When we dive into the world of Surface Mount Technology (SMT), one term that pops up frequently is AOI, or Automated Optical Inspection. This technology plays a pivotal role in ensuring the quality and reliability of printed circuit boards (PCBs). Understanding what AOI is in SMT helps manufacturers maintain high standards and meet customer expectations.

Definition of Automated Optical Inspection

Automated Optical Inspection (AOI) systems are sophisticated machines designed to inspect PCBs during the manufacturing process. They utilize high-resolution cameras and advanced image processing algorithms to detect defects such as misaligned components, soldering issues, or missing elements on a board. In essence, an AOI machine acts like a vigilant eye, ensuring that every PCB meets strict quality criteria before it moves further along the production line.

Role of AOI in Quality Control

The role of AOI in quality control cannot be overstated; it serves as a crucial checkpoint in the manufacturing process. By identifying defects early on, an SMT AOI machine minimizes the risk of faulty products reaching customers and reduces costly rework or recalls down the line. This proactive approach not only enhances product reliability but also boosts overall efficiency by streamlining workflows and reducing downtime.

Benefits of Implementing AOI

Implementing Automated Optical Inspection systems offers numerous benefits for PCB manufacturers looking to enhance their production capabilities. First and foremost, these systems improve defect detection rates significantly compared to manual inspections, leading to higher quality outputs. Moreover, investing in an AOI system can result in long-term cost savings by decreasing labor costs and minimizing waste—after all, preventing problems is far cheaper than fixing them later!

How Does an AOI Machine Work?

Automated Optical Inspection (AOI) systems are the unsung heroes of PCB manufacturing, ensuring that every component is in its rightful place. By utilizing advanced imaging technology, these machines inspect the surface of printed circuit boards (PCBs), identifying defects and ensuring quality control. So, how exactly does this intricate dance of technology unfold? Let’s dive into the key components, workflow, and technologies behind these remarkable machines.

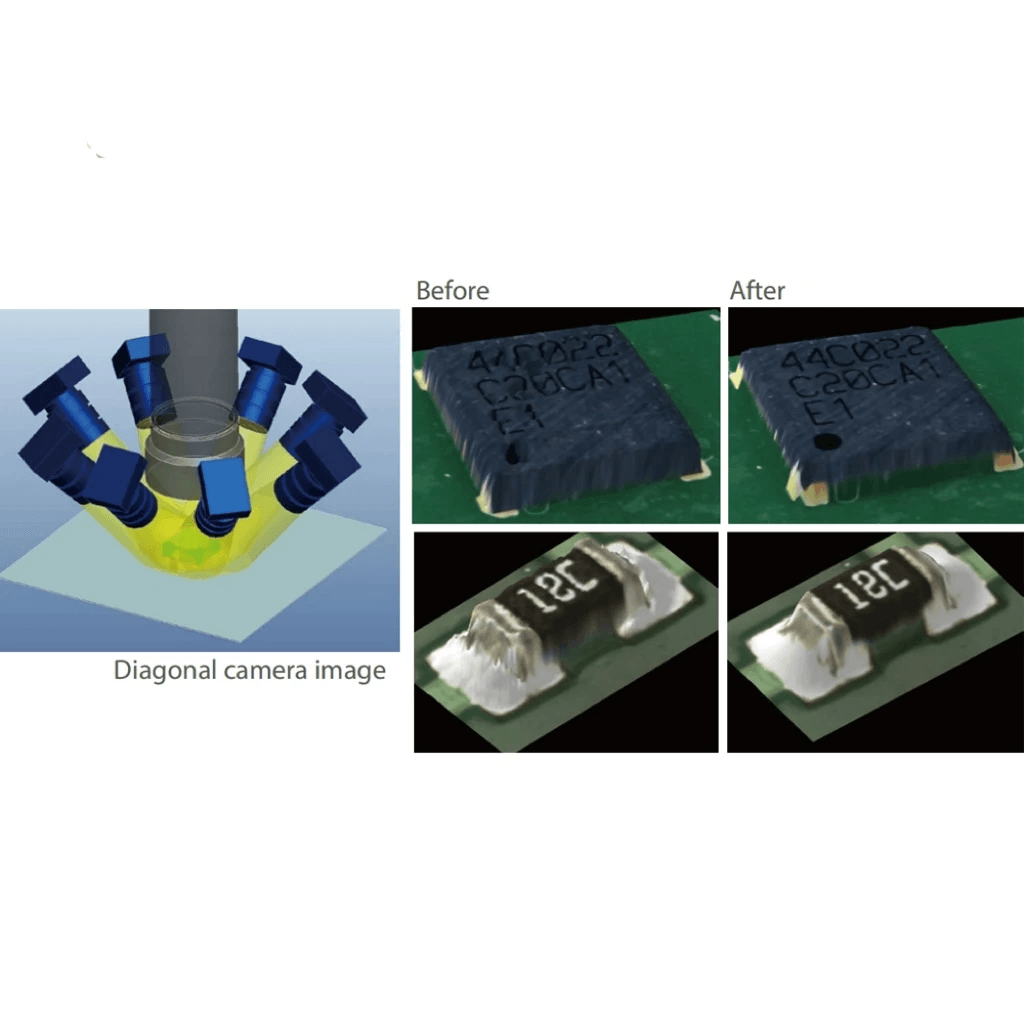

Key Components of AOI Systems

At the heart of every SMT AOI machine lies a sophisticated array of components designed for precision and efficiency. The primary elements include high-resolution cameras that capture detailed images of the PCBs, powerful lighting systems to illuminate the boards evenly, and robust software algorithms for analyzing images against predefined criteria. These components work in harmony to detect discrepancies such as missing components or incorrect placements—essentially acting as a vigilant eye throughout the manufacturing process.

Additionally, many Automated Optical Inspection Systems (AOI) feature conveyor systems that transport PCBs through inspection zones seamlessly. This integration allows for high-speed inspections without compromising accuracy or quality—a critical factor when considering how much an AOI system costs versus its value in preventing costly errors down the line. Ultimately, understanding these key components is crucial for appreciating how effectively an AOI machine operates within a production line.

Workflow in Automated Optical Inspection

The workflow in automated optical inspection is a well-orchestrated sequence that maximizes efficiency while minimizing human error. Initially, each PCB enters the SMT AOI machine on a conveyor belt where it is positioned precisely under high-resolution cameras equipped with advanced lighting systems. Once aligned correctly, the inspection process begins automatically; images are captured and analyzed at lightning speed to identify any potential defects.

After capturing images, sophisticated software compares them against a set of predefined standards to determine if each component meets quality specifications. If discrepancies are detected—such as missing parts or misalignments—the system flags these issues for review by operators or automatically rejects defective boards from further processing. This streamlined workflow not only enhances productivity but also significantly reduces rework costs associated with faulty PCBs.

Technologies Behind AOI Machines

The technologies behind automated optical inspection are nothing short of impressive and represent some of the most cutting-edge advancements in manufacturing today. Modern SMT AOI machines utilize various imaging techniques including 2D and 3D inspections to provide comprehensive assessments of PCB integrity. While 2D imaging focuses on capturing flat representations of components on a board's surface, 3D imaging adds depth perception—allowing for more accurate detection of solder joint integrity and component height variations.

Moreover, artificial intelligence (AI) has begun to play an increasingly vital role in enhancing the capabilities of Automated Optical Inspection Systems (AOI). With AI-driven algorithms capable of learning from previous inspections and adapting detection parameters accordingly, these machines can continuously improve their accuracy over time—a game-changer when considering what an AOI machine operator needs to keep up with industry standards! As technology evolves further, we can expect even more innovative features to emerge within this essential sector.

What Does AOI Machine Stand For?

Deciphering AOI Acronyms

AOI stands for Automated Optical Inspection. This technology plays a crucial role in ensuring quality control during PCB manufacturing processes. By utilizing an SMT AOI machine, manufacturers can detect defects that might otherwise go unnoticed, such as misaligned components or soldering issues.

The acronym signifies more than just a fancy term; it embodies a shift towards automation and precision in quality assurance. Understanding what AOI means is essential for grasping its importance in modern electronics manufacturing. For those asking What is AOI in SMT?, it’s clear that this technology has become indispensable.

The Significance of Optical Inspection

Optical inspection is vital because it allows manufacturers to maintain high-quality standards while minimizing human error. Automated Optical Inspection Systems (AOI) utilize advanced cameras and algorithms to scan PCBs for defects at incredible speeds and accuracy levels. This not only saves time but also enhances overall production efficiency.

With an increasing demand for reliable electronic devices, incorporating automated optical inspection into your production line becomes non-negotiable. The significance of optical inspection lies in its ability to catch potential issues early on, thereby reducing costly rework later in the manufacturing process. In essence, an effective smt aoi machine can be your best friend when it comes to quality assurance.

Connection Between AOI and SMT

The connection between AOI and SMT is as strong as peanut butter and jelly—each enhances the other’s effectiveness! Surface Mount Technology (SMT) involves attaching electronic components directly onto the surface of PCBs, which increases density and performance but also introduces potential errors during assembly. That's where an automated optical inspection system shines.

By integrating an SMT AOI machine into your workflow, you can ensure that each component is placed correctly and that solder joints are reliable before moving on to further stages of production. This synergy between SMT processes and automated optical inspection not only boosts productivity but also significantly lowers defect rates—keeping both manufacturers and customers happy!

In summary, understanding what does an AOI machine stand for helps clarify its pivotal role within PCB manufacturing ecosystems today.

How Much Does an AOI System Cost?

The price of an AOI system can vary widely based on features, technology, and manufacturer reputation, making it essential to know what influences these costs. Understanding how much an AOI system costs is crucial for businesses looking to invest in quality control solutions in PCB manufacturing.

Factors Influencing AOI System Pricing

Several key factors influence the pricing of an SMT AOI machine, including its capabilities and specifications. For instance, machines equipped with advanced imaging technologies or higher resolution cameras typically command a higher price due to their enhanced inspection capabilities. Additionally, the level of automation—whether the machine is fully automated or semi-automated—can significantly impact costs; fully automated systems tend to be more expensive but offer greater efficiency in production lines.

Another important factor is the support and service offered by the manufacturer, which can include training for operators and ongoing maintenance packages. These services add value but also contribute to the overall cost of ownership for an Automated Optical Inspection system. Lastly, market demand and technological advancements can also affect pricing; as new models are released with cutting-edge features, older models may see price reductions.

Cost Comparison of Different Models

When comparing different models of AOI machines, it's essential to look at both entry-level options and high-end systems tailored for specific needs in PCB manufacturing. Entry-level SMT AOI machines might start at a few thousand dollars but may lack some advanced functionalities that higher-end models offer. In contrast, premium models equipped with sophisticated algorithms for defect detection could range from tens of thousands to even hundreds of thousands of dollars.

For example, while a basic model might suffice for simple inspections on less complex boards, more intricate designs may require advanced features such as 3D inspection capabilities or real-time data analytics that justify their higher price tag. Ultimately, businesses must weigh their specific needs against budget constraints when deciding which model best fits their operational requirements.

Value Proposition of Bensun JUKI AOI Machines

Bensun's JUKI AOI machines stand out in terms of value proposition within the competitive landscape of Automated Optical Inspection systems. These machines are designed not only for efficiency but also deliver exceptional accuracy in detecting defects during the PCB manufacturing process—essentially ensuring that your product meets quality standards before reaching customers' hands. The combination of cutting-edge technology and robust customer support makes Bensun's offerings particularly appealing.

Furthermore, investing in a Bensun JUKI AOI machine means you’re getting a reliable partner that understands your operational challenges and provides tailored solutions accordingly. With competitive pricing compared to other high-end brands without compromising on performance or support services, Bensun positions itself as a leader in delivering effective SMT AOI machine solutions that enhance productivity while minimizing errors.

What is an AOI Machine Operator?

An AOI machine operator plays a pivotal role in the realm of Automated Optical Inspection Systems (AOI) within the PCB manufacturing process. These professionals are responsible for ensuring that the SMT AOI machines are functioning optimally and delivering accurate inspections. With the increasing reliance on automated optical inspection, understanding what an AOI machine operator does is essential for maintaining quality control in production.

Skills Required for AOI Operation

To excel as an AOI machine operator, a diverse skill set is necessary. First and foremost, operators must possess a solid understanding of what AOI in SMT entails, including how to interpret inspection results accurately. Additionally, technical skills related to operating and troubleshooting SMT AOI machines are crucial, as operators frequently encounter issues that require quick problem-solving abilities.

Moreover, attention to detail is paramount; even the tiniest defects can lead to significant issues down the line. Familiarity with software used in Automated Optical Inspection can also give operators an edge, enabling them to analyze data effectively and make informed decisions regarding quality control processes. Lastly, good communication skills foster collaboration with team members and ensure smooth operations throughout production.

Daily Responsibilities of an AOI Operator

The daily responsibilities of an AOI operator involve a blend of technical tasks and quality assurance duties. Operators begin their day by setting up the SMT AOI machine for inspections based on production requirements. This includes calibrating equipment settings according to specific PCB designs and ensuring that all parameters align with industry standards.

Throughout the day, operators run inspections on various PCBs, monitoring output closely for any discrepancies or defects detected by the automated optical inspection systems (AOI). When anomalies arise, it’s up to them to investigate further—this could mean adjusting settings or even performing minor repairs on machinery if needed. In addition to these hands-on tasks, documentation is key; operators must maintain records of inspection results for traceability and compliance purposes.

Importance of Training and Certification

Training and certification are vital components in developing competent AOI machine operators who can navigate complex systems effectively. Given that technology continues evolving rapidly in areas like automated optical inspection, ongoing education ensures that operators remain updated on best practices and new features within their SMT AOI machines.

Certification programs not only enhance individual skills but also boost overall team confidence in handling sophisticated equipment—this translates into fewer errors during inspections and ultimately leads to higher product quality levels across manufacturing lines. Furthermore, companies often prefer hiring certified individuals as it reflects a commitment to professionalism within their workforce.

In conclusion, understanding what an AOI machine operator does helps underscore their value within PCB manufacturing environments utilizing Automated Optical Inspection Systems (AOI). By honing essential skills through training and certification programs while managing daily responsibilities effectively, these professionals play a critical role in maintaining high-quality standards.

Conclusion

In the fast-paced world of PCB manufacturing, understanding the role of Automated Optical Inspection Systems (AOI) is crucial for ensuring high-quality products. AOI technology not only enhances quality control but also streamlines production processes, making it an indispensable tool in the industry. As we’ve explored, Bensun's JUKI AOI machines stand out as reliable solutions for achieving precision and efficiency in SMT operations.

Key Takeaways on AOI in PCB Manufacturing

To wrap up our discussion on what is AOI in SMT?, it’s clear that Automated Optical Inspection plays a pivotal role in maintaining quality standards throughout the manufacturing process. The implementation of an smt aoi machine can significantly reduce defects and improve overall yield rates, making it a vital investment for any PCB manufacturer. Moreover, understanding how much does an AOI system cost? is essential for businesses looking to enhance their production capabilities without breaking the bank.

Future Trends in Automated Optical Inspection

As technology continues to evolve, future trends in automated optical inspection are leaning towards greater integration with artificial intelligence and machine learning. These advancements will enable smt aoi machines to not only detect defects more accurately but also predict potential issues before they arise. Additionally, the growing demand for miniaturization and increased complexity in PCBs means that the importance of skilled operators will rise; hence knowing what is an AOI machine operator? becomes increasingly relevant.

Why Choose Bensun for SMT AOI Solutions

When considering which Automated Optical Inspection Systems (AOI) to invest in, Bensun's offerings stand out due to their innovative design and user-friendly interface. With competitive pricing structures that address how much does an AOI system cost?, Bensun ensures that businesses get excellent value without compromising on quality or performance. Ultimately, choosing Bensun means opting for reliability and expertise that can elevate your PCB manufacturing process to new heights.