Introduction

In today's fast-paced world, the significance of SMT (Surface Mount Technology) manufacturing cannot be overstated. As electronic devices become more compact and complex, the need for efficient and precise assembly methods grows. Choosing the right SMT mounter supplier is crucial for businesses looking to stay ahead in the competitive landscape of chip manufacturing.

Discover the Importance of SMT Manufacturing

SMT manufacturing revolutionizes how components are assembled onto printed circuit boards (PCBs). By utilizing advanced techniques like machine pick and place, manufacturers can achieve higher precision and efficiency compared to traditional methods. This shift not only enhances product quality but also reduces production costs, making it an essential process for any PCB assembly supplier.

Why Choose BSTECH as Your Supplier

BSTECH stands out among machine vendors as a leading SMT mounter supplier due to our commitment to quality and innovation. Our extensive range of equipment, including state-of-the-art pick and place machines, ensures that you have access to the best technology available. With a customer-centric approach, we tailor our solutions to meet your specific needs in PCB manufacturing.

Your Guide to Advanced SMT Equipment

Navigating the world of SMT equipment can be daunting without proper guidance. At BSTECH, we provide comprehensive insights into our advanced machinery designed for optimal performance in chip manufacturing processes. Whether you're looking for essential machines or auxiliary devices that enhance efficiency, our expertise will help you make informed decisions that drive your business forward.

Understanding SMT Technology

In the rapidly evolving world of electronics, understanding Surface Mount Technology (SMT) is crucial for anyone involved in the manufacturing process. SMT has revolutionized how components are mounted on printed circuit boards (PCBs), leading to more compact designs and enhanced performance. As a leading smt mounter supplier, BSTECH embraces this technology to provide innovative solutions for modern chip manufacturing.

What is SMT Manufacturing?

SMT manufacturing refers to the process of mounting electronic components directly onto the surface of PCBs, rather than through holes as seen in traditional methods. This technique allows for a higher density of components, which is essential for today’s miniaturized devices. With advanced equipment like pick and place machines, machine vendors enable manufacturers to achieve precision and efficiency that was once unimaginable.

The heart of SMT lies in its ability to streamline production while maintaining high quality standards. By using automated processes, PCB assembly suppliers can reduce labor costs and improve turnaround times significantly. This shift towards automation not only enhances productivity but also ensures that manufacturers can meet the growing demand for complex electronics.

The Role of SMT in Electronics

SMT plays a pivotal role in modern electronics by facilitating the creation of smaller, lighter, and more efficient devices. The technology supports various applications ranging from consumer electronics to industrial machinery, making it indispensable across multiple sectors. As chip manufacturing becomes increasingly sophisticated, relying on an experienced smt mounter supplier like BSTECH ensures that businesses stay ahead with cutting-edge solutions.

Moreover, SMT allows for better electrical performance by minimizing parasitic inductance and capacitance associated with traditional through-hole mounting techniques. This results in improved signal integrity and overall device reliability—critical factors in today’s fast-paced market where every millisecond counts. By leveraging advanced PCB manufacturing techniques, companies can innovate without compromising on quality or performance.

Key Benefits of SMT Over Traditional Methods

One of the most significant advantages of SMT over traditional methods is its ability to accommodate smaller component sizes without sacrificing functionality or reliability. This capability allows designers greater flexibility when creating compact devices while maximizing board space effectively. Additionally, machine pick and place technology ensures that even minute components are placed accurately—reducing errors during assembly.

Another key benefit lies in production efficiency; SMT processes typically require fewer manual interventions compared to conventional methods. This reduction leads to shorter lead times and lower production costs—an enticing proposition for any PCB assembly supplier looking to enhance their competitiveness in the market. Furthermore, as industries shift toward sustainability practices, adopting SMT can contribute significantly by optimizing material usage and reducing waste.

In summary, understanding SMT technology is essential for anyone involved in electronics manufacturing today; it offers numerous benefits over traditional approaches while paving the way for future innovations within the industry.

The Range of Equipment Offered by BSTECH

At BSTECH, we pride ourselves on providing a comprehensive range of equipment tailored for the ever-evolving needs of SMT manufacturing. As a leading SMT mounter supplier, our offerings are designed to enhance productivity and precision in PCB assembly processes. Let’s delve into the specifics of our equipment lineup that sets us apart from other machine vendors.

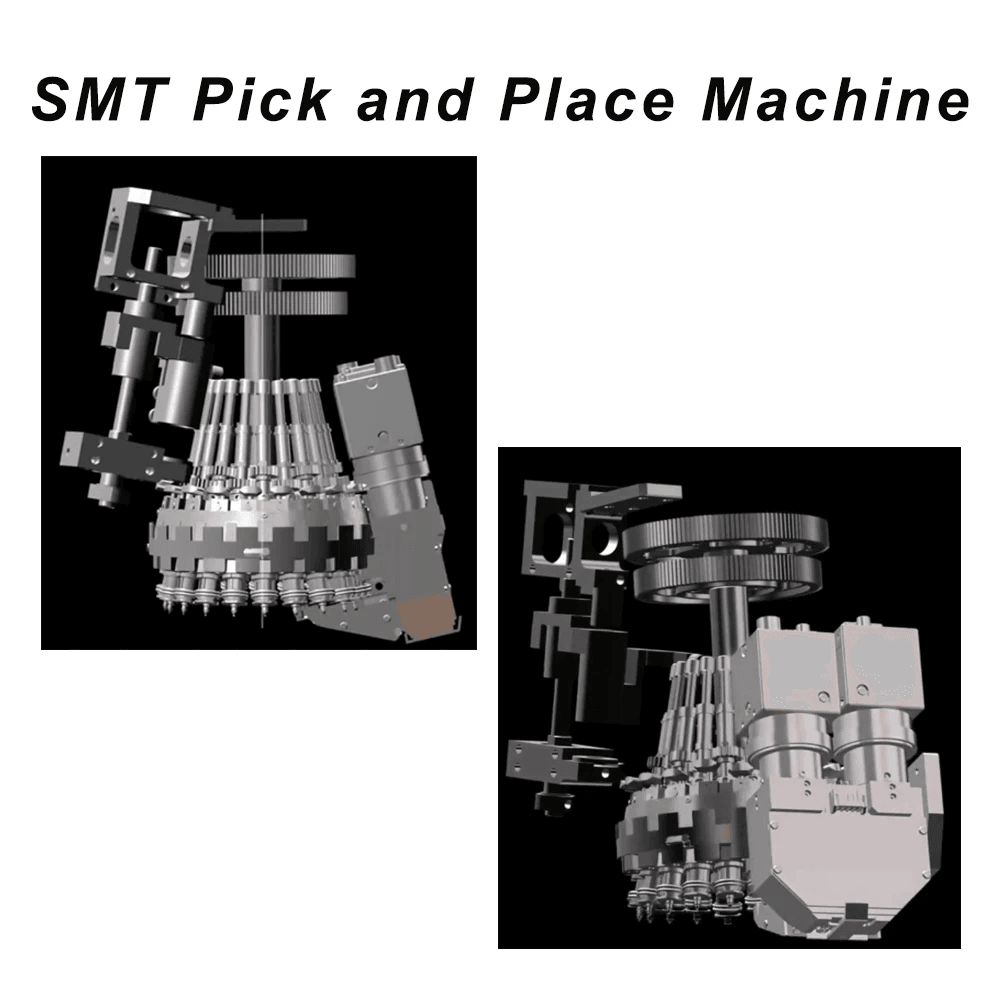

Overview of Pick and Place Machines

One of the cornerstones of our product range is our state-of-the-art pick and place machines. These machines are essential for any PCB assembly supplier looking to streamline their production line while maintaining high accuracy levels. With advanced features such as vision systems and flexible component handling, our pick and place machines ensure that every chip finds its rightful place on the board with unmatched speed.

Moreover, the versatility of our machine pick and place technology allows it to adapt to various component types and sizes, making it ideal for diverse applications in chip manufacturing. This adaptability not only enhances efficiency but also reduces setup times significantly—an essential factor for any manufacturer aiming to stay competitive in today’s fast-paced market. When you choose BSTECH as your SMT mounter supplier, you’re investing in machinery that guarantees reliability and performance.

Essential Machines for PCB Assembly

In addition to our top-notch pick and place machines, we offer a complete suite of essential machines for PCB assembly that cater to all stages of the manufacturing process. From screen printers that apply solder paste with precision to reflow ovens that ensure perfect soldering conditions, each piece plays a critical role in achieving high-quality results. Our equipment is designed with user-friendly interfaces so operators can quickly become proficient without extensive training.

Furthermore, these essential machines work seamlessly together within your production line, enhancing overall workflow efficiency—a crucial advantage when competing against other pcb manufacturing players. By integrating advanced technology into each machine's design, we help you minimize defects while maximizing throughput rates. Trust BSTECH as your go-to pcb assembly supplier; we provide solutions tailored specifically to meet your unique needs.

Auxiliary Devices for Enhanced Efficiency

To complement our primary machinery offerings, BSTECH also provides a selection of auxiliary devices engineered for enhanced efficiency during the SMT process. These devices include conveyors for smooth material handling, inspection systems equipped with AI-driven analytics for quality control, and automated storage solutions that optimize space usage in your facility. Each auxiliary device is designed to work harmoniously with our main machines—ensuring minimal downtime and maximum productivity.

By investing in these auxiliary tools alongside your core equipment like pick and place machines or other smt machinery from us, you can achieve a truly integrated production environment where every element contributes toward operational excellence. With such an extensive range available from one trusted SMT mounter supplier like BSTECH, you can rest assured knowing you're equipped with everything necessary for success in electronics manufacturing.

Why BSTECH is a Leading SMT Mounter Supplier

Customer-Centric Solutions and Flexibility

At BSTECH, we understand that every client has specific requirements when it comes to chip manufacturing processes. That's why our approach is rooted in delivering tailored solutions, whether you need a pick and place machine or other essential machinery for PCB assembly. By prioritizing your needs, we ensure that our offerings adapt seamlessly to your production demands, making us the go-to PCB assembly supplier.

Our flexibility extends beyond just equipment; we also provide options for customization in our smt machines. This means you can get precisely what you need without settling for off-the-shelf solutions that may not fit your operational workflow perfectly. In a world where adaptability is key, BSTECH's customer-centric focus sets us apart from traditional machine vendors.

Comprehensive Support and Services

BSTECH doesn’t just stop at supplying high-quality SMT equipment; we believe in offering comprehensive support throughout your journey with us. From initial consultations on selecting the right pick and place machine to ongoing maintenance and training, our team is dedicated to ensuring your success in PCB manufacturing. This level of service builds long-lasting relationships with our clients who trust us as more than just a supplier but as partners in their growth.

Our support extends into troubleshooting and operational guidance as well, which is crucial for minimizing downtime during production runs. We recognize that effective communication and prompt assistance can make all the difference when you're working on tight deadlines or facing unexpected challenges with smt machines. By choosing BSTECH as your SMT mounter supplier, you gain access to a wealth of resources designed specifically for optimizing efficiency.

Competitive Advantages of Bensun Technology

Bensun Technology isn’t just another name in the industry; it’s synonymous with innovation and reliability in SMT manufacturing solutions. One significant advantage lies in our advanced technology used within our pick and place machines which enhances precision during PCB assembly processes—an essential factor for any successful chip manufacturing operation. Our commitment to continuous improvement means we're always upgrading our technology offerings based on market trends.

Moreover, being part of an extensive network allows us to leverage better pricing on components while ensuring quality remains uncompromised—something many other machine vendors struggle with today due to supply chain issues. This competitive edge translates directly into cost savings for clients who choose us as their preferred pcb assembly supplier while still receiving top-tier equipment designed for longevity and performance.

In summary, when you partner with BSTECH as your SMT mounter supplier, you're not only gaining access to superior machinery but also benefiting from exceptional service tailored specifically around your needs—a combination that's hard to beat!

Contract Manufacturing and Production Line Sales

In the fast-paced world of electronics, partnering with a reliable PCB manufacturing supplier can make all the difference. Choosing the right supplier not only enhances production efficiency but also ensures high-quality results in your chip manufacturing processes. With BSTECH, you gain access to top-tier SMT equipment and expertise that streamline your PCB assembly, enabling you to stay ahead of the competition.

Benefits of Choosing a PCB Manufacturing Supplier

Opting for a dedicated PCB manufacturing supplier like BSTECH comes with numerous advantages. First and foremost, these suppliers provide specialized knowledge and resources that are crucial for effective machine pick and place operations. Additionally, by leveraging their experience in SMT technology, you can significantly reduce production costs while maintaining exceptional quality standards.

Another benefit is the ability to scale production quickly without compromising on quality or timelines. A reputable smt mounter supplier will have established processes in place that facilitate rapid adjustments to meet varying demand levels. This flexibility allows businesses to respond promptly to market changes while ensuring consistent output from their pick and place machines.

Moreover, collaborating with an experienced PCB assembly supplier means gaining access to cutting-edge technology that enhances productivity. These machine vendors often invest in advanced machinery and automation solutions that optimize every stage of the manufacturing process. As a result, your operations become more efficient, leading to faster turnaround times and increased profitability.

Tailored Solutions for Various Client Needs

Every business has unique requirements when it comes to PCB manufacturing, which is why tailored solutions are essential. At BSTECH, we understand that one size does not fit all; thus, we offer customized services designed specifically for diverse client needs within chip manufacturing sectors. Whether you're looking for high-volume production or specialized small-batch runs, our team works closely with you to develop solutions that align perfectly with your objectives.

Our extensive range of equipment includes various models of pick and place machines suited for different types of projects. By discussing your specific needs with our experts, we can recommend the best smt machine configurations that will maximize performance while minimizing waste during the assembly process. This personalized approach ensures you receive not just equipment but also strategic insights tailored for optimal results.

Additionally, our commitment extends beyond just supplying machinery; we aim to build long-lasting partnerships through ongoing support and consultation services tailored precisely for your operational challenges. This customer-centric philosophy distinguishes us as a leading pcb assembly supplier who genuinely cares about helping clients succeed in an ever-evolving marketplace.

Insights on Equipment Leasing Options

Investing in SMT equipment can be daunting due to high upfront costs; however, leasing options offer an attractive alternative for many businesses looking at chip manufacturing investments without breaking the bank. BSTECH provides flexible leasing arrangements designed specifically for companies seeking access to advanced pick and place machines without immediate capital expenditure burdens.

Leasing allows businesses not only cost-effective access but also opportunities for upgrading their machinery as technology evolves rapidly within electronics manufacturing sectors—keeping pace with industry trends has never been easier! Furthermore, this arrangement enables companies to allocate budget resources toward other critical areas such as research or marketing efforts rather than being tied down by heavy equipment purchases.

By choosing leasing options through our reputable smt mounter supplier network at BSTECH, clients benefit from reduced financial risk associated with ownership while still enjoying top-notch performance from state-of-the-art SMT machinery throughout their production lines—ultimately driving growth strategies forward confidently!

The Future of Chip Manufacturing with BSTECH

The landscape of chip manufacturing is evolving rapidly, and BSTECH is at the forefront of this transformation. As a leading SMT mounter supplier, we are committed to innovating our offerings to meet the demands of a fast-paced industry. Our focus on advanced technology ensures that our clients receive cutting-edge solutions for their PCB assembly needs.

Innovations in SMT Machinery

BSTECH is continuously pushing the envelope with innovations in SMT machinery that redefine efficiency and precision in chip manufacturing. Our latest pick and place machines are equipped with state-of-the-art technology, enabling faster placement speeds and improved accuracy, which are essential for modern PCB assembly. By partnering with top machine vendors, we ensure that our equipment remains at the pinnacle of performance and reliability.

Moreover, our commitment to research and development allows us to integrate smart features into our SMT machines, such as real-time monitoring systems that enhance operational oversight. These innovations not only streamline production but also reduce waste—making them indispensable for any serious PCB manufacturing operation. With a focus on future-ready solutions, BSTECH’s machinery stands out as a cornerstone for businesses aiming to thrive in an increasingly competitive market.

Adapting to Industry Trends

The electronics industry is characterized by rapid technological advancements and shifting consumer preferences; hence, adaptability is crucial for success. At BSTECH, we closely monitor industry trends to ensure our products align with market demands while providing exceptional value as your PCB assembly supplier. This proactive approach enables us to offer tailored solutions that cater specifically to emerging challenges faced by manufacturers today.

For instance, as miniaturization becomes more prevalent in chip manufacturing, our pick and place machines have been designed to handle smaller components without compromising speed or accuracy. Additionally, we understand the importance of flexibility; therefore, our equipment can be customized based on specific production requirements or volume fluctuations—an essential feature for any savvy machine pick and place operation looking to stay ahead of the curve.

Sustainability in Electronics Manufacturing

Sustainability has become a hot topic across all sectors—including electronics manufacturing—and BSTECH takes this responsibility seriously as an SMT mounter supplier committed to eco-friendly practices. Our machinery not only focuses on efficiency but also incorporates sustainable technologies aimed at reducing energy consumption during operations. By investing in greener solutions today, we pave the way for a more sustainable future within the chip manufacturing landscape.

Furthermore, we actively promote recycling initiatives within our operations and encourage clients to adopt practices that minimize electronic waste during PCB assembly processes. As part of this commitment, we work closely with machine vendors who share similar values regarding environmental stewardship—ensuring that every piece of equipment meets stringent sustainability guidelines while still delivering top-notch performance.

Conclusion

As we wrap up our exploration of SMT manufacturing and the pivotal role that BSTECH plays in this dynamic industry, it’s clear that making the right choice in an SMT mounter supplier can significantly impact your production efficiency. With a reputation built on quality and innovation, BSTECH stands out among machine vendors by offering a comprehensive range of advanced equipment tailored for PCB assembly. Choosing BSTECH means opting for reliability, cutting-edge technology, and a partner who understands your unique needs in chip manufacturing.

Making the Right Choice with BSTECH

When selecting an SMT mounter supplier, consider not just the machines but also the support that comes with them. BSTECH excels in providing customer-centric solutions that adapt to various client requirements, ensuring every pick and place machine is optimized for performance. The dedication to quality and service makes BSTECH a preferred choice among PCB manufacturing professionals looking to enhance their production lines.

Maximizing Efficiency with Quality Equipment

Investing in high-quality SMT machines is essential for maximizing efficiency in electronics manufacturing. Whether you need a state-of-the-art pick and place machine or auxiliary devices that boost productivity, BSTECH has you covered. By partnering with us, you’re not just acquiring equipment; you’re gaining tools designed specifically to streamline your PCB assembly processes and elevate your overall output.

Partnering for Success in Electronics Manufacturing

In today’s fast-paced electronics landscape, collaboration is key to staying ahead of the curve. By choosing BSTECH as your PCB assembly supplier, you're aligning yourself with a leader committed to innovation and sustainability in chip manufacturing. Together, we can navigate industry trends while ensuring that your production remains efficient and effective—because success is best achieved as partners.