Introduction

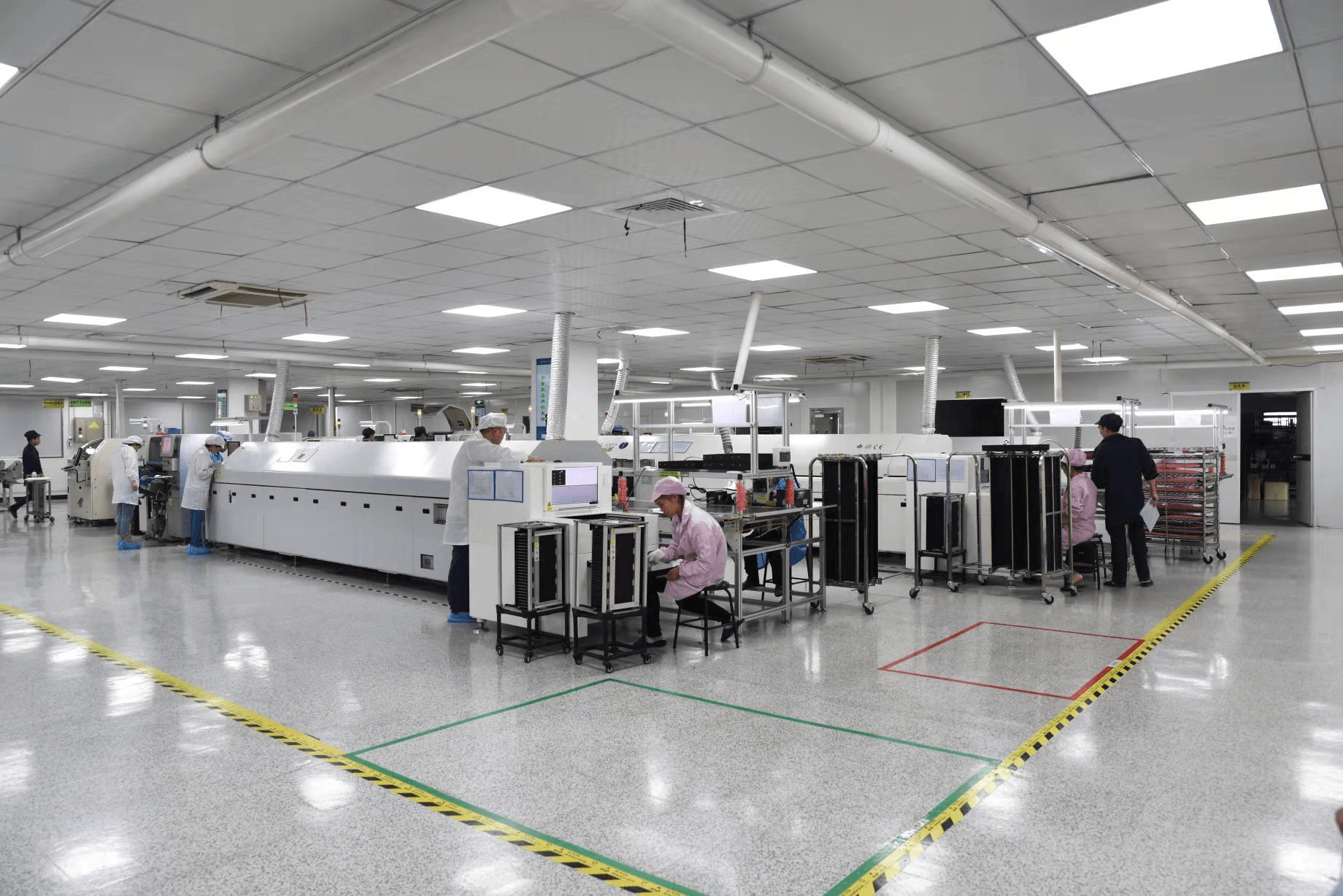

In today's fast-paced manufacturing environment, the choice of machinery can be a game changer, especially when it comes to chip mounters. China chip mounter machine factories have gained a stellar reputation for producing high-quality automated machines that cater to various production needs. Investing in these advanced pick and place machines not only enhances efficiency but also ensures precision in assembling electronic components.

Why Choose a China Chip Mounter Machine

Choosing a china chip mounter machine means opting for reliability and affordability without compromising on quality. These machines are designed to meet the demands of modern manufacturing processes, offering features that enhance productivity and reduce operational costs. With an array of options available, manufacturers can find the perfect machine pick and place solution tailored to their specific requirements.

The Role of Automated Machines in Manufacturing

Automated machines play a pivotal role in streamlining production lines across various industries, particularly in electronics manufacturing. By integrating automatic machines into their operations, companies can significantly increase output while minimizing human error and labor costs. This shift towards automation is not just a trend; it's an essential evolution for any competitive machine manufacturing company aiming to thrive in the global market.

Overview of Bensun Technology

Bensun Technology stands out among china chip mounter machine factories with its commitment to innovation and customer satisfaction. Known for its state-of-the-art automated machines, Bensun offers a diverse range of products including advanced pick and place machines and efficient PCB ovens designed for optimal performance. Their customer-centric approach ensures that clients receive tailored solutions that meet their unique production challenges while maintaining high standards of quality.

Understanding the Importance of Chip Mounters

In the world of electronics manufacturing, chip mounters play a pivotal role in ensuring efficiency and precision. These machines automate the process of placing electronic components onto printed circuit boards (PCBs), which is essential for creating reliable and functional devices. With the rise of automation, many manufacturers are turning to advanced solutions from China chip mounter machine factories to enhance their production capabilities.

What is a Chip Mounter?

A chip mounter, often referred to as a pick and place machine, is an automated device designed for placing surface-mount devices (SMDs) onto PCBs with remarkable accuracy. This technology has evolved significantly, allowing for faster processing speeds and higher placement densities than manual methods could ever achieve. In today’s fast-paced environment, relying on a machine manufacturing company that specializes in these machines can make all the difference in meeting production demands.

The essence of a chip mounter lies in its ability to handle various component sizes and types while maintaining high levels of precision. By utilizing sophisticated vision systems and alignment technologies, these automatic machines ensure that each component is placed exactly where it needs to be on the PCB. This capability not only reduces errors but also minimizes waste—an essential factor for any modern manufacturing process.

Key Benefits of Automated Machines

Automated machines like chip mounters bring numerous benefits that can transform production lines into efficient powerhouses. First and foremost, they significantly increase throughput by reducing cycle times; what once took hours can now be accomplished in mere minutes with an automated solution from reputable china chip mounter machine factories. This boost in efficiency allows manufacturers to meet tight deadlines while maintaining quality standards.

Another key advantage is consistency; automated processes eliminate human error, leading to uniformity across large batches of products. For machine companies looking to scale operations or improve product reliability, investing in automated machines becomes not just beneficial but essential. Furthermore, these machines often come equipped with advanced features such as real-time monitoring and data analytics capabilities that enhance operational oversight.

Lastly, adopting automation reduces labor costs over time by lessening reliance on manual assembly workers while allowing them to focus on more complex tasks that require human intervention. As industries continue evolving toward smart manufacturing practices, integrating automated solutions will remain vital for staying competitive.

The Technology Behind Pick and Place Machines

The technology behind pick and place machines has advanced tremendously over recent years, incorporating cutting-edge features that streamline operations further than ever before. At their core are high-speed robotic arms equipped with suction cups or grippers designed specifically for handling delicate electronic components without damage—a crucial aspect when dealing with sensitive parts from leading machine manufacturing companies.

These machines utilize sophisticated software algorithms capable of optimizing placement strategies based on various factors like component type or board layout—ensuring optimal performance during every production run! Additionally, many modern pick and place systems incorporate artificial intelligence (AI) techniques which allow them to learn from previous placements improving accuracy over time.

Moreover, compatibility with other equipment such as PCB ovens enhances overall workflow efficiency within factories specializing in electronics assembly processes—creating seamless integration across multiple stages of production lines! As manufacturers invest more into these technologies offered by china chip mounter machine factories worldwide; we can expect increased innovation shaping future trends within this dynamic field.

Bensun Technology: Leading the Charge

Bensun Technology stands out in the competitive landscape of China chip mounter machine factories, offering a diverse range of products designed to meet the needs of modern manufacturing. Their portfolio includes state-of-the-art pick and place machines, automatic machines, and advanced PCB ovens that streamline production processes. By embracing innovation and quality, Bensun has positioned itself as a trusted machine manufacturing company dedicated to enhancing efficiency in various industries.

Overview of Bensun Technology's Offerings

Bensun Technology provides an impressive array of automated machines tailored for different manufacturing requirements. Their pick and place machines are engineered for precision and speed, ensuring that components are accurately placed on PCBs with minimal waste. Additionally, their automatic machines offer seamless integration into existing systems, making them an ideal choice for manufacturers looking to upgrade their production capabilities without extensive overhauls.

Strengths of a Machine Manufacturing Company

What sets Bensun apart from other machine companies is its commitment to quality and innovation in every aspect of its operations. The company employs rigorous testing protocols to ensure that each machine meets high standards before it reaches customers, reinforcing its reputation as a reliable supplier among China chip mounter machine factories. Furthermore, Bensun's experienced engineering team continuously explores new technologies to enhance their product offerings, ensuring they stay ahead in the rapidly evolving market.

Customer-Centric Approach to Production

At the heart of Bensun Technology's success is its unwavering focus on customer satisfaction. The company collaborates closely with clients to understand their specific needs and challenges in order to provide tailored solutions that optimize production efficiency. This customer-centric approach not only fosters long-term relationships but also enables Bensun to adapt quickly to changing market demands while maintaining its status as a leading player among machine manufacturing companies.

Exploring the Landscape of China Chip Mounter Machine Factories

The landscape of China chip mounter machine factories is bustling with innovation and competition. As the demand for high-quality automated machines rises, several key players have emerged to dominate the market. Understanding these companies and their offerings can significantly impact your procurement decisions.

Key Players in the Chinese Market

In the realm of chip mounters, a few machine manufacturing companies stand out due to their advanced technology and customer service. Brands like Bensun Technology, Hanwha Techwin, and Juki are recognized for producing reliable pick and place machines that cater to various manufacturing needs. These manufacturers not only focus on automation but also prioritize quality control, ensuring that each automatic machine meets rigorous standards.

Comparing Quality and Price Among Suppliers

While some suppliers offer competitive pricing, it’s essential to evaluate the long-term benefits of investing in higher-quality automated machines that promise durability and efficiency. A well-constructed machine pick and place can save you costs related to maintenance and downtime in the long run.

The Growing Demand for PCB Ovens

As the electronics industry evolves, so does the need for complementary equipment like PCB ovens alongside chip mounters. The increasing complexity of printed circuit boards (PCBs) drives manufacturers to seek reliable solutions that enhance production efficiency. Consequently, many china chip mounter machine factories are expanding their product lines to include these essential devices, recognizing their vital role in modern manufacturing processes.

Types of Machines for Different Needs

When it comes to manufacturing, the right type of machine can make all the difference. In the realm of chip mounters, understanding the distinctions between automatic and automated machines is crucial for optimizing production processes. Each type offers unique features that cater to different operational needs, particularly in bustling environments like those found in China chip mounter machine factories.

Features of Automatic vs. Automated Machines

Automatic machines are designed to perform specific tasks without requiring constant human intervention, making them ideal for repetitive processes. These machines often focus on speed and efficiency, which is essential in high-demand settings like those operated by leading machine manufacturing companies. On the other hand, automated machines incorporate advanced technology such as sensors and AI algorithms to adapt their operations based on real-time data, offering greater flexibility in production lines.

In a world where precision is paramount, automated machines tend to excel due to their ability to minimize errors and enhance overall quality control. This feature makes them particularly appealing for companies looking to maintain high standards while scaling production. For instance, a pick and place machine can be programmed not just for speed but also for accuracy, ensuring that every component is placed correctly on a PCB.

Ultimately, choosing between an automatic or an automated machine depends on your specific manufacturing needs and budget constraints. Companies exploring options from various china chip mounter machine factories should weigh these features carefully before making a decision that suits their operational goals.

Selecting the Right Machine Pick and Place

Choosing the right pick and place machine involves evaluating several factors that align with your production requirements. First off, consider the types of components you will be handling; some machines are better suited for smaller components while others can handle larger ones with ease. Additionally, think about throughput rates—how many units you need per hour—and whether your selected machine can keep pace with those demands.

Another critical aspect is the level of automation desired; fully automated systems may come with higher initial costs but can lead to significant long-term savings through increased efficiency and reduced labor costs at your factory floor. It's also wise to assess compatibility with existing systems; integrating new machinery into current workflows without disruption is key for maintaining productivity levels.

Lastly, don’t overlook support services offered by various suppliers when selecting your pick and place machine; reliable after-sales support can make or break your experience with any machinery from china chip mounter machine factories or other suppliers globally. Investing time upfront into this selection process ensures smoother operations down the line.

Importance of Compatibility with Existing Systems

Compatibility is often an overlooked yet vital aspect when introducing new equipment into any manufacturing setup—especially when dealing with complex systems like those found in china chip mounter machine factories. A seamless integration minimizes downtime during transitions while ensuring that new machinery works harmoniously with existing equipment such as PCB ovens or other assembly line tools already in use.

When assessing compatibility, consider not only mechanical dimensions but also software interfaces; modern pick and place machines may require specific software updates or additional programming capabilities that align with legacy systems present in your facility. This alignment helps avoid potential disruptions caused by mismatched technologies during operation cycles—a scenario no company wants to face!

Moreover, working closely with a reputable machine company allows you access not just to high-quality equipment but also expert guidance on achieving optimal compatibility across all facets of production machinery used within your organization’s ecosystem—ensuring you’re not just investing money but investing wisely towards future growth potential!

Maximizing Efficiency with Machine Manufacturing Solutions

In the fast-paced world of electronics manufacturing, efficiency is paramount. The right equipment, particularly from reputable China chip mounter machine factories, can significantly streamline production processes. By investing in top-notch automatic machines and automated machines, manufacturers can enhance their output while maintaining high quality.

Streamlining Production Processes with the Right Equipment

Selecting the appropriate machinery is crucial for optimizing production workflows. Automatic machines and machine pick and place systems are designed to reduce manual labor and minimize human error, paving the way for smoother operations. When sourced from reliable machine manufacturing companies like Bensun Technology, these machines can seamlessly integrate into existing setups, enhancing overall productivity.

Moreover, incorporating advanced features in pick and place machines allows for greater flexibility in handling various component sizes and types. This adaptability not only supports diverse production needs but also helps manufacturers respond swiftly to market demands. As a result, companies can achieve faster turnaround times without compromising on quality or precision.

Case Studies of Successful Implementations

Numerous case studies highlight how companies leveraging technology from China chip mounter machine factories have transformed their operations. For instance, a leading electronics manufacturer implemented an automated machine that increased their assembly line speed by 30%. This shift not only improved output but also reduced labor costs significantly.

Another example involves a medium-sized firm that integrated a state-of-the-art PCB oven into their production process alongside upgraded pick and place machinery. The result was a more efficient thermal management system that enhanced soldering quality while cutting down on defects by nearly 25%. These success stories emphasize the importance of choosing the right equipment from trusted sources to maximize operational efficiency.

Future Trends in SMT/MI Production

The landscape of surface mount technology (SMT) and manufacturing integration (MI) is rapidly evolving, driven by advancements in automation and smart technologies. With increasing demand for precision and speed, future trends indicate a shift towards more sophisticated automated machines equipped with AI capabilities for real-time monitoring and adjustments during production processes.

China chip mounter machine factories are at the forefront of this evolution, continuously innovating to meet industry needs while ensuring cost-effectiveness through competitive pricing strategies. Additionally, as sustainability becomes increasingly critical in manufacturing practices, we can expect more energy-efficient designs in both automatic machines and PCB ovens that align with eco-friendly initiatives.

In conclusion, staying ahead in SMT/MI production requires embracing these trends while making informed choices about equipment procurement from reputable machine companies like Bensun Technology.

Conclusion

In the fast-paced world of electronics manufacturing, investing in quality machines is not just a choice; it's a necessity. The right equipment, particularly from reputable china chip mounter machine factories, can significantly enhance production efficiency and product quality. By choosing top-tier automatic and automated machines, companies can ensure they stay competitive in an ever-evolving market.

The Value of Investing in Quality Machines

When it comes to manufacturing, the phrase you get what you pay for rings especially true. Quality machines from established machine manufacturing companies not only improve precision but also reduce downtime and maintenance costs. For businesses looking to scale up production, investing in reliable pick and place machines or PCB ovens is crucial for achieving long-term success.

Bensun Technology's Commitment to Excellence

Bensun Technology stands out among machine companies by prioritizing innovation and customer satisfaction above all else. Their commitment to excellence is evident in their range of advanced automated machines designed to meet diverse production needs. With a focus on continuous improvement and adaptation, Bensun ensures that their offerings remain at the forefront of industry standards.

Making Informed Choices in Chip Mounter Procurement

Navigating the landscape of chip mounter procurement can be daunting with so many options available from various china chip mounter machine factories. To make informed choices, businesses should consider factors such as compatibility with existing systems and specific production requirements when selecting a machine pick and place solution. By taking the time to evaluate suppliers thoroughly, manufacturers can secure equipment that will serve them well for years to come.