Introduction

In the fast-paced world of electronics, PCB manufacturing and assembly stand as the backbone of modern technology. From smartphones to sophisticated industrial machines, printed circuit assembly (PCA) and circuit card assembly (CCA) play a pivotal role in ensuring that electronic devices function seamlessly. Understanding the intricacies of PCB assembly and manufacturing is essential for businesses looking to stay competitive in this ever-evolving landscape.

Understanding PCB Manufacturing and Assembly

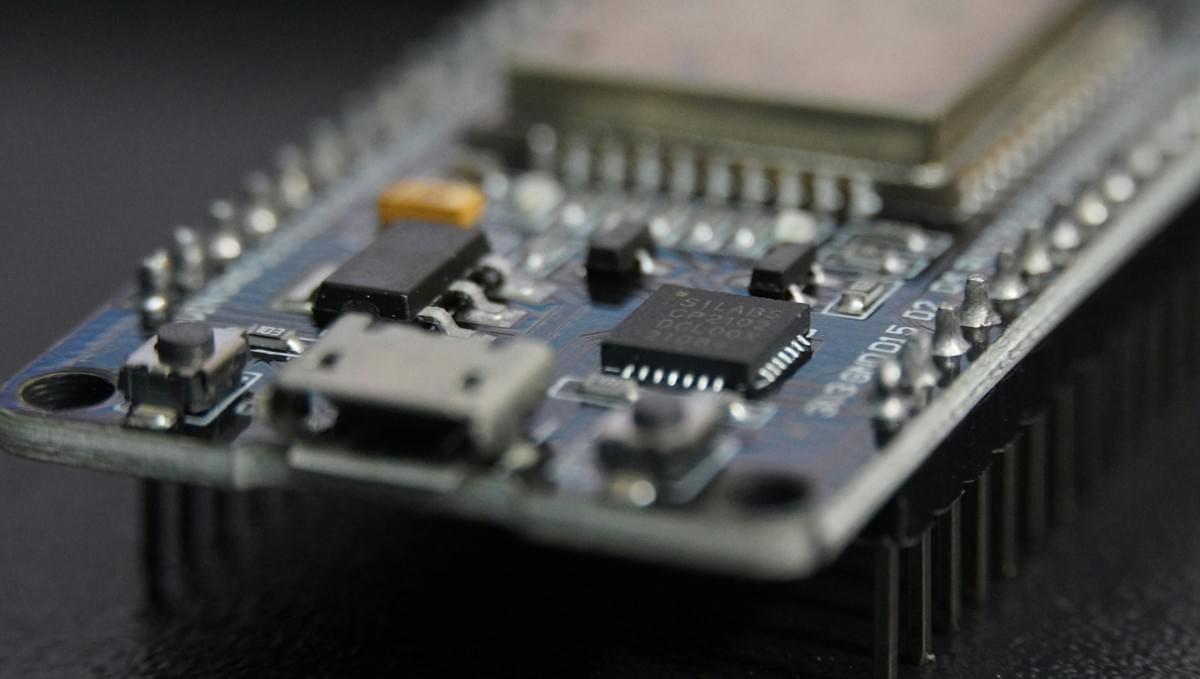

PCB manufacturing involves a complex series of processes that transform raw materials into functional electronic components. This journey begins with designing the circuit boards, followed by etching copper patterns onto substrates and assembling various components through processes like surface mount technology (SMT). The result is a meticulously crafted printed circuit board assembly that meets specific design requirements while ensuring reliability and performance.

The Importance of Quality in PCB Solutions

Quality is paramount in PCB solutions; even minor defects can lead to significant failures in electronics assembly. High-quality PCBs ensure longevity, reduce failure rates, and enhance overall product performance, which is crucial for manufacturers aiming to build trust with their customers. Investing in superior quality PCB board assembly not only safeguards against costly recalls but also elevates a brand's reputation in a crowded marketplace.

Innovations in Circuit Board Technology

The landscape of circuit board technology is rapidly evolving, driven by innovations that enhance efficiency and functionality. Advancements such as flexible PCBs, high-density interconnects (HDI), and integrated passive devices are revolutionizing how we approach electronics assembly. As manufacturers embrace these cutting-edge technologies, they pave the way for more compact designs and increased capabilities within electronic devices.

Overview of PCB Manufacturing Process

The journey of creating a printed circuit board (PCB) is an intricate one, encompassing several key stages that ensure a high-quality final product. From initial design to the final assembly, each phase plays a crucial role in delivering effective circuit board assembly solutions. Understanding these stages is essential for anyone looking to delve into PCB assembly and manufacturing.

Key Stages of PCB Production

The PCB production process begins with designing the layout using specialized software, which translates into a blueprint for the circuit card assembly. This step is followed by printing the design onto a substrate material, typically copper-clad laminate, through techniques such as photolithography or direct imaging. Once the boards are etched and cleaned, they undergo drilling and plating processes that prepare them for components to be mounted during the electronics assembly phase.

After preparing the boards, solder paste is applied precisely to designated areas where components will be placed. This leads us to surface mount technology (SMT), where components are arranged on the board using automated pick-and-place machines—often seen in China PCB assembly operations due to their efficiency and precision. Finally, after placement, reflow soldering solidifies connections before thorough testing ensures that every printed circuit assembly meets stringent quality standards.

Essential Materials Used in PCB Assembly

Materials play an indispensable role in ensuring successful PCB board assembly and overall reliability of electronic devices. The most common substrate used is FR-4—a fiberglass-reinforced epoxy laminate—known for its excellent electrical insulation properties and mechanical strength. Additionally, copper foil serves as conductive pathways while solder masks protect these pathways from environmental factors during manufacturing.

Other essential materials include various types of capacitors, resistors, and integrated circuits that populate the boards during assembly; these components must meet specific standards for performance and durability. In China PCB assembly facilities, sourcing high-quality materials is often streamlined due to established relationships with suppliers who provide reliable components at competitive prices. Ultimately, selecting superior materials contributes significantly to achieving optimal performance in circuit card assemblies.

Quality Control Measures in Production

Quality control measures are critical throughout every stage of PCB manufacturing; they ensure that defects are minimized and reliability standards are upheld across all products produced during electronics assembly processes. One common method involves visual inspections at multiple points in production; trained personnel examine each step—from raw materials to completed PCBs—to catch any inconsistencies early on.

Automated testing methods also play a vital role; techniques like Automated Optical Inspection (AOI) allow manufacturers to detect issues such as misaligned components or insufficient solder joints more efficiently than manual checks alone could achieve. Furthermore, implementing rigorous Final Inspection protocols guarantees that only PCBs meeting specified criteria advance toward shipment—a hallmark of reputable china pcb assembly services committed to excellence.

In conclusion, understanding the overview of PCB manufacturing processes—from key stages through essential materials used down to quality control measures—provides valuable insight into how effective circuit board assemblies come together seamlessly while maintaining high standards throughout production cycles.

Benefits of China PCB Assembly

When it comes to PCB assembly, China stands out as a powerhouse in the electronics assembly industry. The combination of cost-effectiveness, speed, and access to cutting-edge technology makes China a top choice for businesses looking to manufacture printed circuit assemblies and circuit card assemblies. Let's dive deeper into these benefits that make China PCB assembly so appealing.

Cost-Effectiveness of Manufacturing in China

One of the main attractions of choosing China for PCB assembly is its cost-effectiveness. Labor costs are significantly lower than in many Western countries, allowing manufacturers to produce circuit board assemblies at a fraction of the price. This affordability doesn't come at the expense of quality; many Chinese manufacturers invest heavily in technology and skilled labor to ensure that their printed circuit assembly meets international standards.

Moreover, bulk production capabilities in China further drive down costs per unit. When companies scale their production runs with circuit card assembly, they can achieve economies of scale that are hard to match elsewhere. As a result, businesses can save significantly on manufacturing expenses while still delivering high-quality products.

Speed and Efficiency of Production

In today's fast-paced market, speed is essential for staying competitive, and China's PCB assembly sector excels in this regard. With streamlined processes and advanced manufacturing techniques, companies can expect quick turnaround times on their orders without sacrificing quality or precision. Whether it's a small batch or large-scale production run, efficiency is built into every step of the PCB board assembly process.

Furthermore, Chinese manufacturers often operate around the clock with multiple shifts to maximize productivity. This commitment ensures that projects move swiftly from design through production to delivery—ideal for companies needing rapid prototyping or urgent orders in electronics assembly. The ability to quickly adapt to changing demands makes China an invaluable partner for businesses looking to stay agile.

Access to Advanced Technology

China is not just about low costs; it's also at the forefront of technological innovation in PCB manufacturing and assembly processes. Many factories utilize state-of-the-art machinery and automated systems that enhance precision during circuit board assembly operations like surface mount technology (SMT). This access allows companies working with printed circuit assemblies to benefit from high-quality outputs consistently.

Additionally, Chinese manufacturers frequently invest in research and development initiatives aimed at improving manufacturing techniques and materials used in PCB production. By collaborating with these forward-thinking companies, businesses can leverage cutting-edge technologies that may not yet be available elsewhere—keeping them ahead in the competitive landscape of electronics assembly.

In summary, choosing China for your PCB assembly needs offers significant advantages: cost savings without compromising quality, rapid turnaround times due to efficient processes, and access to advanced technologies driving innovation forward.

Bensun Technology: A Leader in Electronics Assembly

When it comes to electronics assembly, Bensun Technology stands out as a premier provider, offering comprehensive solutions that cater to a diverse range of industries. Specializing in PCB assembly and manufacturing, they leverage cutting-edge technology and industry expertise to deliver high-quality circuit board assembly services. With a strong focus on innovation and customer satisfaction, Bensun ensures that each project meets the highest standards of excellence.

Overview of Bensun’s Offerings

Bensun Technology offers a wide array of services within the realm of PCB assembly, including printed circuit assembly (PCA) and circuit card assembly (CCA). Their offerings encompass everything from prototype development to full-scale production runs, making them an ideal partner for businesses looking to streamline their electronics manufacturing process. By providing tailored solutions that meet specific client needs, Bensun has established itself as a leader in the competitive landscape of PCB board assembly.

In addition to traditional services, Bensun also emphasizes rapid turnaround times and cost-effective solutions for clients seeking china PCB assembly options. This approach not only enhances efficiency but also aligns with the growing demand for quick-to-market products in today's fast-paced technological environment. With an unwavering commitment to quality control throughout the PCB assembly process, clients can trust that their projects are in capable hands.

JUKI Machines and Their Impact on Quality

One key factor contributing to Bensun's reputation for excellence is its investment in state-of-the-art JUKI machines for electronics assembly. These advanced machines significantly enhance precision during the PCB board assembly process by ensuring accurate placement of components on the circuit boards. The result is a marked improvement in product quality and reliability—two critical factors that customers prioritize when selecting a manufacturer.

The integration of JUKI technology not only elevates the standard of printed circuit assemblies but also streamlines operations within the facility. By automating various aspects of production, these machines reduce human error while increasing overall output efficiency—a win-win scenario for both Bensun and its clients seeking effective china PCB assembly solutions. As technology continues to evolve, so too does Bensun's commitment to incorporating innovative equipment into their processes.

Custom Solutions for Diverse Industries

Understanding that no two industries are alike, Bensun Technology excels at providing custom solutions tailored specifically for different market needs within electronics assembly. Whether it's automotive applications or consumer electronics, their team collaborates closely with clients to develop unique designs that optimize functionality while adhering to stringent industry standards. This flexibility allows them to cater effectively to niche markets requiring specialized printed circuit assemblies.

Moreover, their expertise extends beyond just manufacturing; they also offer consulting services aimed at optimizing designs for manufacturability (DFM), ensuring that every aspect—from materials selection to production techniques—is carefully considered during development stages. This holistic approach ultimately leads to enhanced performance across all types of circuit card assemblies produced at their facilities—an essential aspect when navigating today's complex supply chains.

As businesses increasingly seek reliable partners who understand both technological advancements and market demands, Bensun remains committed to delivering exceptional quality through innovative practices in china PCB assembly and beyond.

Differences Between PCB Assembly Types

When diving into the world of PCB assembly and manufacturing, it's essential to understand the different types of assemblies available. Each type has its unique characteristics, applications, and benefits that cater to various industry needs. In this section, we will explore printed circuit assembly, circuit card assembly, and the role of surface mount technology (SMT) in PCB board assembly.

Understanding Printed Circuit Assembly

Printed circuit assembly (PCA) is a crucial component in electronics assembly that involves soldering electronic components onto a printed circuit board (PCB). This process is fundamental for creating reliable electronic devices and systems used across various industries. PCA not only ensures that components are securely attached but also optimizes the electrical pathways for efficient performance in applications ranging from consumer electronics to industrial machinery.

In the realm of china pcb assembly, PCA stands out due to its cost-effectiveness and efficiency. The ability to mass-produce PCBs with high precision makes it an attractive option for companies looking to scale their production while maintaining quality. As technology advances, innovations in PCA techniques continue to enhance the reliability and functionality of electronic products.

Circuit Card Assembly Explained

Circuit card assembly (CCA) refers specifically to the integration of multiple PCBs into a single functional unit known as a circuit card or module. This process involves assembling various types of PCBs together with connectors, headers, and other components necessary for connectivity within a device or system. CCA plays an essential role in creating complex electronic systems like computers, telecommunications equipment, and automotive electronics.

One significant advantage of using circuit card assembly is its ability to streamline production processes by combining multiple functions into one cohesive unit. In china pcb assembly factories, CCAs are often produced at remarkable speeds while ensuring strict quality control measures are upheld throughout manufacturing. As industries demand more compact designs with enhanced capabilities, CCA continues to evolve as a vital aspect of modern electronics.

The Role of SMT in PCB Board Assembly

Surface mount technology (SMT) has revolutionized the way PCB board assemblies are manufactured by allowing components to be mounted directly onto the surface of PCBs rather than through holes as seen in traditional methods. This shift enables manufacturers to produce smaller boards with more components packed closely together without compromising performance or reliability—ideal for today’s compact electronic devices.

In china pcb assembly operations, SMT offers numerous advantages including faster production times and reduced material costs due to fewer drilling requirements on boards. Additionally, SMT facilitates automated processes which can significantly improve overall efficiency during electronics assembly projects compared to older techniques like through-hole mounting. As manufacturers seek ways to innovate further while meeting consumer demands for high-performance devices, SMT will undoubtedly play an increasingly pivotal role in shaping future PCB board assemblies.

Future Trends in PCB Manufacturing

The landscape of PCB manufacturing is evolving rapidly, driven by technological advancements and changing market demands. As we look ahead, several trends are poised to reshape the way electronics assembly is approached. From innovations in production techniques to a greater emphasis on sustainability, the future of PCB assembly and manufacturing promises to be both exciting and transformative.

Innovations Reshaping Electronics Assembly

Innovations in electronics assembly are at the forefront of improving efficiency and quality in circuit board assembly. One significant trend is the integration of advanced automation technologies, which streamline operations and reduce human error during printed circuit assembly processes. Additionally, developments in materials science are leading to lighter, more durable substrates that enhance the performance of circuit card assemblies.

Another notable innovation is the rise of 3D printing within PCB manufacturing. This technology allows for rapid prototyping and custom designs that were previously difficult or impossible to achieve with traditional methods. By leveraging these innovations, manufacturers can produce high-quality PCBs faster than ever before while meeting diverse customer needs.

Finally, artificial intelligence (AI) is making its mark on PCB board assembly by optimizing design processes and predictive maintenance schedules. AI algorithms analyze data from previous projects to identify patterns that can improve future production runs. This not only enhances efficiency but also contributes significantly to quality control measures within electronics assembly.

Sustainability in PCB Production

Sustainability has become a vital consideration in modern PCB manufacturing practices as companies seek to minimize their environmental impact. The push towards eco-friendly materials has led many manufacturers to explore alternatives like biodegradable substrates for printed circuit assemblies. These innovations not only reduce waste but also align with global efforts toward greener production methods.

Moreover, energy-efficient practices are being adopted across China PCB assembly facilities as part of a broader commitment to sustainable operations. By investing in renewable energy sources and optimizing resource usage, manufacturers can significantly lower their carbon footprints while maintaining productivity levels in circuit card assembly processes.

Recycling initiatives are also gaining traction within the industry; many companies now focus on reclaiming valuable materials from discarded PCBs for reuse in new products or components. This circular economy approach not only conserves resources but also reflects a growing awareness among consumers about environmental responsibility.

The Rise of Smart Manufacturing

Smart manufacturing is revolutionizing how PCB assembly and manufacturing operate by leveraging IoT (Internet of Things) technology for enhanced connectivity between machines and systems. This interconnectedness allows real-time monitoring of production lines during circuit board assembly, enabling instant adjustments based on performance metrics or quality indicators.

With smart manufacturing comes increased data analytics capabilities that help manufacturers make informed decisions regarding their operations—whether it's optimizing workflow or predicting equipment failures before they occur during printed circuit assembly processes. Such proactive approaches lead to reduced downtime and improved overall efficiency across all stages of production.

Furthermore, smart factories often utilize collaborative robots (cobots) alongside human workers during electronics assembly tasks—creating a harmonious blend between automation and human expertise that drives innovation forward while maintaining high standards for quality control throughout every phase of PCB board assembly.

Conclusion

In the ever-evolving world of electronics, choosing the right partner for PCB solutions can make all the difference. Bensun Technology stands out in the crowded field of PCB assembly and manufacturing, offering innovative solutions tailored to meet diverse industry needs. With a commitment to quality and advanced technology, Bensun is poised to lead in the realm of circuit board assembly.

Why Choose Bensun for PCB Solutions

When it comes to china pcb assembly, Bensun Technology has established itself as a formidable player with an impressive track record. Their state-of-the-art facilities utilize JUKI machines that enhance precision and efficiency in every step of the printed circuit assembly process. By prioritizing customer satisfaction and delivering custom solutions, Bensun ensures that your project is not just completed but excelled.

The Value of Quality PCB Assembly

Quality in pcb assembly and manufacturing cannot be overstated; it directly impacts performance, reliability, and lifespan of electronic devices. By investing in top-notch materials and rigorous quality control measures, companies like Bensun guarantee that each circuit card assembly meets stringent standards. This dedication to excellence translates into fewer defects and higher customer trust—an invaluable asset in today’s competitive market.

Navigating the Future of Electronics Manufacturing

The landscape of electronics assembly is rapidly changing with innovations reshaping how we think about production processes. As sustainability becomes increasingly important, companies are seeking greener methods for pcb board assembly while maintaining efficiency and effectiveness. With advancements like smart manufacturing on the horizon, partnering with leaders like Bensun will help businesses navigate this transformation successfully.