Introduction

In the world of electronics, understanding the intricacies of PCB assembly and fabrication is crucial for anyone looking to bring a project to life. Whether you're developing a new gadget or enhancing an existing device, knowing the differences between these processes can significantly impact your project's success. This overview aims to clarify the roles of PCB manufacturing and assembly, helping you navigate this essential aspect of electronics.

Understanding PCB Assembly and Fabrication

PCB assembly refers to the process where electronic components are mounted onto a printed circuit board (PCB), creating a functional circuit card assembly. On the other hand, PCB fabrication involves creating the actual board itself from raw materials, setting the stage for assembly. Both processes are integral to producing reliable electronic products, but they each serve distinct functions in the overall workflow.

Why It Matters for Your Project

Choosing between PCB fabrication and assembly can influence cost, timeline, and ultimately, product quality. A clear understanding of these processes will enable you to make informed decisions that align with your project's specific needs and goals. By recognizing how PCB manufacturing and assembly work together, you can streamline development and enhance efficiency.

Overview of Key Differences

While both PCB fabrication and assembly are essential components in electronics production, they differ significantly in their focus and execution. Fabrication deals with material selection and board design, while assembly emphasizes component placement and soldering techniques. This distinction is vital when selecting a suitable PCB assembly manufacturer or deciding on your project's direction regarding pcb fab and assembly services.

What is PCB Assembly?

PCB assembly is a critical component of the electronics manufacturing process, where individual electronic components are mounted on a printed circuit board (PCB) to create a functional circuit card assembly. This process transforms raw materials into fully operational electronic devices, bridging the gap between design and functionality. Understanding PCB assembly and its intricacies can significantly impact the success of your project.

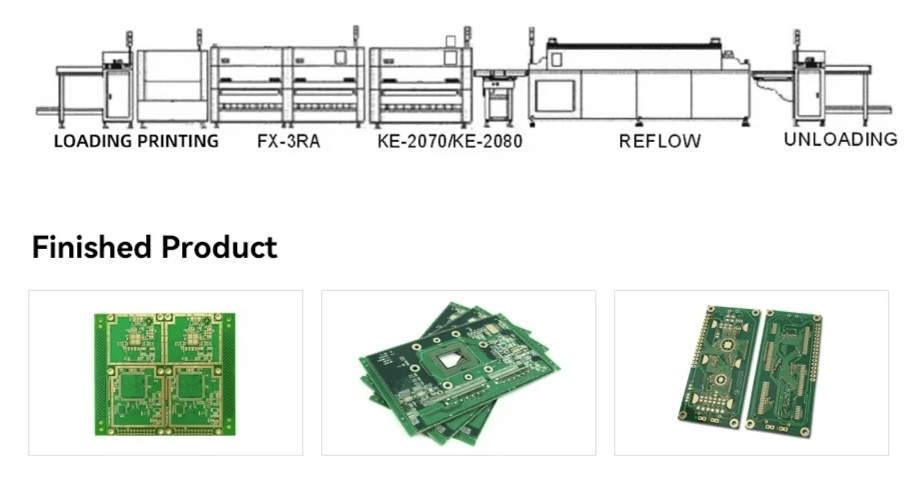

Definition and Process Overview

At its core, PCB assembly involves attaching various electronic components, such as resistors, capacitors, and integrated circuits, onto a pre-fabricated PCB. The process begins with surface mount technology (SMT) or through-hole technology (THT), where components are soldered onto the board using automated machines or manual techniques. Once assembled, the boards undergo testing to ensure they meet quality standards before being integrated into larger systems.

The entire pcb manufacturing and assembly process can be broken down into several key stages: component placement, soldering, inspection, and testing. Each stage plays an essential role in ensuring that the final product operates reliably in its intended application. By understanding these steps in detail, you can better appreciate how they contribute to high-quality circuit card assemblies.

Key Components and Techniques

In pcb fabrication and assembly, several key components come into play that determine both performance and reliability. These include passive components like resistors and capacitors as well as active components such as microcontrollers and sensors. Techniques like pick-and-place for component placement and reflow soldering for securing connections are essential to achieving precision during the assembly process.

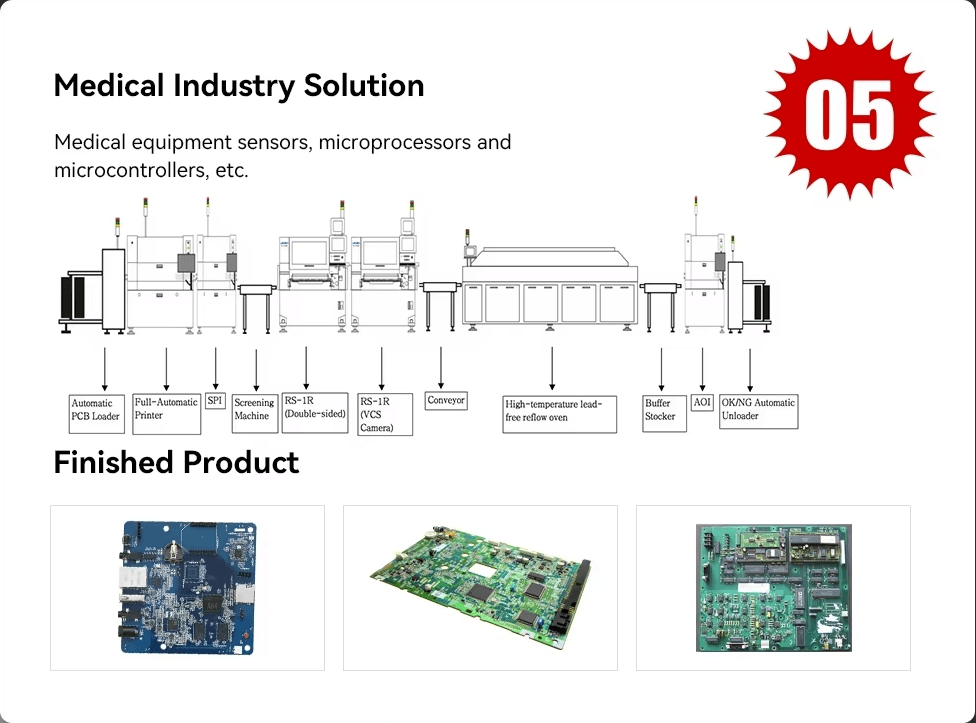

Additionally, advanced technologies such as automated optical inspection (AOI) help identify defects early in production—ensuring that only high-quality products reach customers' hands. The use of specialized equipment during pcb manufacturing assembly not only enhances efficiency but also minimizes human error throughout the process. These innovations contribute significantly to producing reliable circuit card assemblies that meet industry standards.

Role of a PCB Assembly Manufacturer

A pcb assembly manufacturer plays a pivotal role in transforming design concepts into tangible products ready for market distribution. They manage everything from sourcing components to executing complex assembly processes while adhering to strict quality control measures throughout each phase of production. By partnering with an experienced manufacturer specializing in pcb fab and assembly services, businesses can leverage their expertise to streamline operations.

Moreover, these manufacturers often provide valuable insights regarding material selection for optimal performance based on specific project requirements—be it cost-effectiveness or advanced capabilities needed for high-tech applications like IoT devices or medical equipment. Their extensive knowledge of both pcb fabrication assembly processes allows them to offer tailored solutions that align with client needs while maintaining compliance with industry regulations.

In summary, understanding what constitutes effective PCB assembly is vital for anyone involved in electronics projects today—a well-executed process ensures reliable products capable of performing under various conditions while meeting customer expectations.

What is PCB Fabrication?

PCB fabrication is the foundational process in creating printed circuit boards (PCBs), which serve as the backbone of electronic devices. This stage involves transforming raw materials into functional circuit boards that can later be populated with components during the PCB assembly phase. Understanding this process is crucial for anyone involved in PCB manufacturing and assembly, as it sets the stage for quality and performance.

Breakdown of the Fabrication Process

The fabrication process begins with designing a schematic that outlines how the circuit will function. Once the design is finalized, it’s translated into a layout that dictates where copper traces will be etched on a substrate material, typically fiberglass or epoxy resin. Afterward, layers of copper are laminated onto these substrates, followed by etching away excess copper to create precise circuit paths—this intricate dance of technology and craftsmanship ensures that your circuit card assembly operates flawlessly when it reaches its final destination.

Differences in Materials Used

In PCB fabrication, various materials are utilized depending on the intended application and performance requirements of the board. Common materials include FR-4 (a glass-reinforced epoxy laminate) for standard applications and more specialized substrates like Rogers or Teflon for high-frequency designs. These differences significantly affect not only cost but also thermal stability and electrical performance, making it essential to choose wisely when considering your options in PCB fabrication assembly.

Importance of PCB Fabrication and Assembly

PCB fabrication plays an indispensable role in ensuring that electronic devices function correctly; without properly fabricated boards, even the best components would struggle to perform optimally. The synergy between PCB fabrication and assembly cannot be overstated; both processes must align seamlessly to ensure reliability and efficiency throughout production cycles. By investing time into understanding these processes, you can better appreciate how choosing a reputable PCB assembly manufacturer can impact your project’s success dramatically.

The Relationship Between PCB Assembly and Fabrication

Understanding the relationship between PCB assembly and fabrication is crucial for anyone involved in electronics manufacturing. While they are distinct processes, they are interdependent and play vital roles in bringing circuit boards to life. By recognizing how these two elements work together, you can streamline your project and ensure optimal results.

How They Work Together

PCB fabrication lays the groundwork for circuit card assembly by creating the bare board that will eventually house electronic components. This initial step involves etching copper layers onto a substrate to form the necessary circuitry, which is then followed by the assembly process where components are soldered onto the board. In essence, without effective PCB fabrication, there would be no platform for PCB assembly and manufacturing to take place.

Moreover, both processes require meticulous planning and coordination to ensure that specifications align perfectly. The integration of PCB fab and assembly can lead to improved communication between teams, allowing for quicker adjustments if issues arise during production. Ultimately, this collaboration enhances efficiency and reduces potential delays in bringing your product to market.

Workflow from Fabrication to Assembly

The workflow from PCB fabrication to assembly typically follows a structured path that begins with design files being converted into physical boards through various fabrication techniques. Once the bare PCBs are produced, they undergo inspection before moving on to the circuit card assembly phase where components like resistors, capacitors, and ICs are placed on the boards. This seamless transition from one stage to another is essential in maintaining quality throughout both processes.

After fabrication is complete, it's crucial that manufacturers adhere strictly to timelines so that assembled boards can be tested promptly before shipping them out. Efficient workflows not only save time but also help manage costs associated with PCB manufacturing and assembly projects. When both stages are synchronized effectively, it leads to higher-quality products delivered within tighter deadlines.

Benefits of Integrated PCB Manufacturing Assembly

One of the most significant advantages of integrated PCB manufacturing assembly is cost efficiency; combining these processes often results in lower overall expenses compared to handling them separately. Manufacturers can optimize their supply chain management by reducing material waste while benefiting from bulk purchasing opportunities for components used in both fabrication and assembly phases. Additionally, having an integrated approach allows for better inventory control which further minimizes overhead costs.

Another benefit lies in quality assurance; when a single manufacturer handles both PCB fabrication assembly tasks, it ensures consistency across all stages of production—leading to fewer defects or discrepancies in final products. Enhanced communication channels enable rapid feedback loops which facilitate quick resolutions if any issues arise during either process or testing phases after assembly completion.

In conclusion, understanding how PCB assembly and manufacturing work hand-in-hand will empower you as a project manager or engineer involved in electronics design or production efforts while ensuring top-notch results at competitive prices.

Key Differences Between Assembly and Fabrication

Understanding the key differences between PCB assembly and fabrication is crucial for any electronics project. While both processes are essential in creating a functional printed circuit board, they serve distinct purposes and involve different methodologies. This section will explore cost considerations, timelines, and quality control measures that differentiate PCB fabrication assembly from PCB manufacturing assembly.

Cost Considerations

When it comes to costs, PCB assembly and manufacturing can vary significantly based on several factors. Typically, the expenses associated with circuit card assembly tend to be higher due to labor-intensive processes such as soldering components onto the fabricated board. On the other hand, PCB fabrication primarily involves material costs and equipment usage, making it generally less expensive than full-scale pcb manufacturing and assembly.

However, it's essential to consider that while initial costs may seem lower for PCB fabrication alone, the overall project budget should account for both stages of production—fabrication followed by assembly. If you opt for a dedicated pcb assembly manufacturer that offers integrated services, you might find cost efficiencies that could benefit your bottom line significantly. Ultimately, understanding these cost dynamics will help you allocate your project budget more effectively.

Timeline and Lead Times

The timelines associated with PCB fabrication and assembly can also differ quite dramatically. Generally speaking, pcb fab and assembly processes can take longer because they require multiple steps—from designing the layout to fabricating the board before assembling components onto it. If you're working on a tight schedule or need rapid prototypes or low-volume production runs, it's crucial to factor in these lead times when planning your project.

For instance, while a straightforward PCB fabrication might take only a few days depending on complexity and materials used, adding circuit card assembly into the mix could extend this timeline considerably—especially if custom components are involved or if there are delays in sourcing parts. Therefore, when considering your project's timeline needs alongside cost considerations in pcb manufacturing assembly practices becomes vital for meeting deadlines without compromising quality.

Quality Control Measures in PCB Fab and Assembly

Quality control is another critical area where differences between pcb fabrication assembly and circuit card assemblies become apparent. Each stage of production has its own set of quality assurance protocols designed to ensure that every aspect meets industry standards before moving on to the next phase of development. In general terms, quality control during PCB fabrication focuses more on ensuring that boards are free from defects like shorts or open circuits before they reach the assembly stage.

Conversely, during circuit card assembly processes like soldering or component placement—quality checks often include visual inspections as well as automated testing methods such as AOI (Automated Optical Inspection). These measures help catch errors early on so that any issues can be rectified before final testing occurs post-assembly—a critical step in assuring product reliability once it hits consumers' hands. Understanding these quality control measures ensures you choose a reputable provider who prioritizes excellence throughout both stages of production.

Choosing the Right Service: Assembly vs. Fabrication

When embarking on a project that involves electronics, understanding whether to focus on PCB assembly or fabrication is crucial. Each process serves a unique purpose and has its own set of requirements that impact the overall success of your circuit card assembly. By carefully evaluating your project's specific needs, you can make an informed decision that aligns with your goals.

Factors to Consider for Your Project

Several factors come into play when deciding between PCB manufacturing and assembly services. First, consider the complexity of your design; intricate layouts may necessitate specialized skills in both fabrication and assembly processes. Additionally, budget constraints are essential; while PCB fabrication may have lower upfront costs, the total expense can increase significantly if subsequent assembly services are required.

Another critical factor is timeline—how quickly do you need your product? If you're racing against the clock, opting for a manufacturer offering integrated PCB fab and assembly might be wise, as it streamlines production time significantly. Lastly, assess the volume of PCBs needed; high-volume projects often benefit from manufacturers who specialize in bulk pcb manufacturing assembly to reduce costs per unit.

When to Opt for Assembly Services

Choosing to utilize pcb assembly services makes sense when you have pre-fabricated PCBs ready for component placement or when your design requires complex components that demand precision during installation. If you're working with surface mount technologies (SMT) or through-hole components, professional circuit card assembly ensures that each piece fits perfectly and functions as intended without any hitches.

Moreover, if you lack the necessary equipment or expertise in-house for assembling electronic components onto PCBs, outsourcing this task can save time and resources while enhancing quality control measures during production. Ultimately, opting for dedicated PCB assembly manufacturers allows you to focus on other aspects of your project while ensuring high-quality outcomes.

Understanding Your Specific Needs

Understanding your specific needs is paramount when navigating between pcb fabrication and assembly options. Take a moment to reflect on what your end product requires: Are there unique specifications or certifications necessary? Does it involve sensitive components that require careful handling?

Furthermore, consider future scalability—will this project evolve into larger batches or more complex designs? By thoroughly assessing these factors before making a decision between pcb manufacturing and assembly services, you'll ensure that every aspect aligns with both current demands and future aspirations.

Conclusion

In the world of electronics, understanding the distinctions between PCB assembly and fabrication is crucial for the success of your projects. PCB manufacturing and assembly are two integral processes that ensure your circuit card assembly meets performance standards and reliability. While PCB fabrication focuses on creating the physical board, PCB assembly involves placing components onto these boards to create functional electronic devices.

Recap of PCB Assembly and Fabrication Differences

PCB fabrication is primarily concerned with producing the bare circuit boards, including selecting materials and creating layers that form the foundation of any electronic device. In contrast, PCB assembly takes those fabricated boards and populates them with electronic components, effectively bringing your designs to life. Recognizing these differences helps you navigate through your project requirements more effectively—whether you need a simple PCB fab and assembly or a complex setup involving multiple layers.

Importance of Selecting the Right Manufacturer

Choosing the right manufacturer for your PCB fabrication and assembly is paramount for ensuring quality and efficiency in production. A reputable PCB assembly manufacturer will not only have experience in both processes but also provide insights into optimizing costs and timelines for your project needs. With so many options available in the market, aligning with a reliable partner can significantly impact the outcome of your circuit card assembly.

How Bensun Technology Can Help Your Project

Bensun Technology stands out as a leader in the realm of PCB manufacturing assembly, offering comprehensive services that cover both fabrication and assembly under one roof. Our expertise ensures that whether you require intricate designs or high-volume production runs, we can deliver exceptional results tailored to your specifications. By choosing Bensun Technology as your partner in pcb fabrication assembly, you gain access to cutting-edge technology, skilled professionals, and unwavering support throughout your project lifecycle.