Introduction

In the world of electronics, the efficiency of circuit board production can make or break a project. Enter the pick and place SMT machine, a pivotal player in the realm of printed circuit assembly (PCA). These machines automate the process of placing components on PCB circuit boards, significantly enhancing speed and accuracy while reducing labor costs.

Understanding Pick and Place SMT Machines

A pick and place SMT machine is designed to streamline the assembly process of electronic components onto circuit boards. By utilizing advanced technology, these machines can accurately position thousands of components per hour, ensuring that even the most intricate designs are executed flawlessly. This level of precision not only speeds up production but also minimizes defects in PCB assembly, making it an essential tool for manufacturers.

Importance of Affordable Options

While high-end models boast impressive features, affordable options for pick and place SMT machines are crucial for small to medium-sized businesses looking to compete in a crowded market. Cost-effective solutions allow companies to invest in quality equipment without breaking the bank, ultimately improving their bottom line. Moreover, having access to budget-friendly machines enables more businesses to enter the field of circuit board production, fostering innovation and diversity within the industry.

Overview of Available Models

The market offers a variety of models tailored to different needs and budgets when it comes to pick and place SMT machines. From entry-level options perfect for startups to advanced systems designed for high-volume production, there’s something for everyone. In this landscape filled with choices, understanding which model aligns with your specific requirements is key to achieving successful PCB assembly outcomes.

What is a Pick and Place SMT Machine?

In the realm of modern electronics, the pick and place SMT machine stands as a pivotal player in circuit board production. These machines are designed to automate the placement of components onto printed circuit boards (PCBs), significantly enhancing efficiency and accuracy in PCB assembly. By utilizing advanced robotics and sophisticated software, they ensure that each part is positioned correctly, minimizing human error and maximizing output.

Definition and Functionality

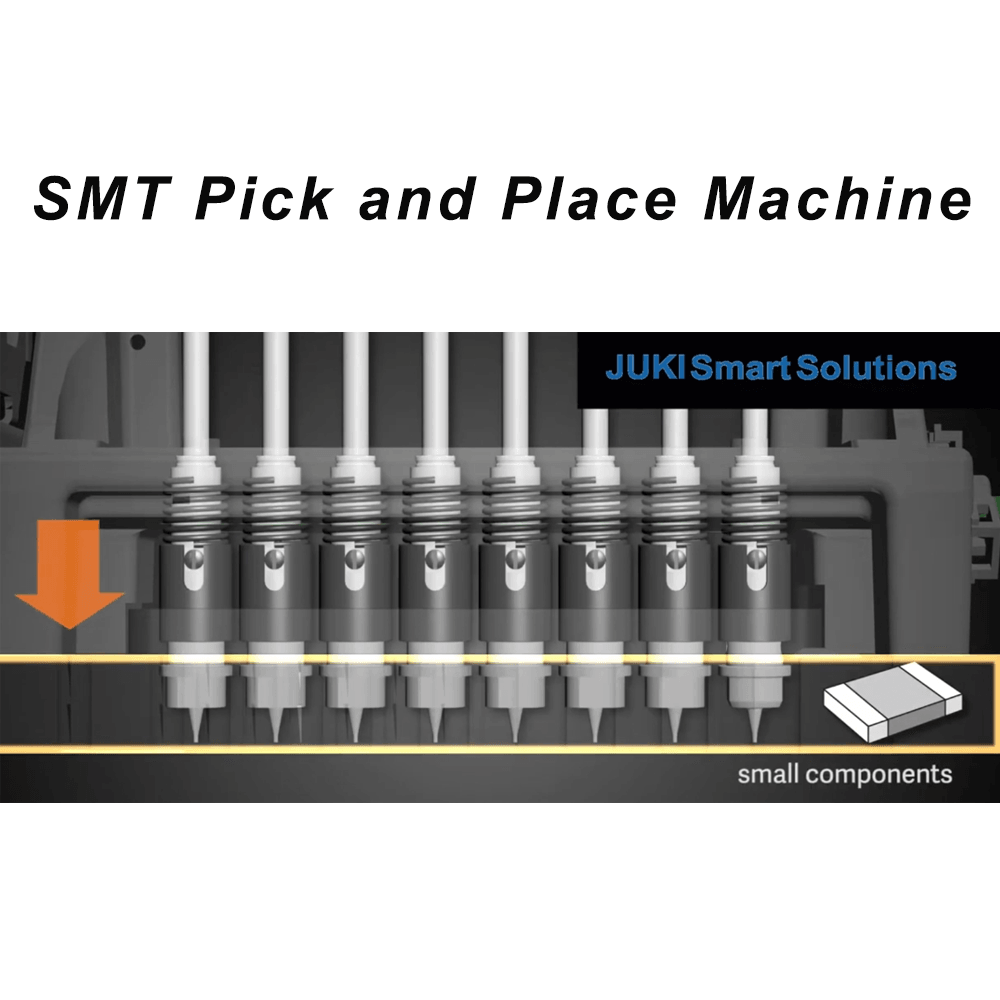

A pick and place SMT machine is essentially a robotic system that picks up electronic components from a designated area and places them onto a PCB at high speed. These machines operate using vision systems to identify component types and positions, ensuring precise placement during circuit card assembly. Their functionality allows for rapid production cycles, making them indispensable in industries where time-to-market is crucial.

Applications in Circuit Board Production

The applications of pick and place SMT machines extend across various sectors involved in circuit board production. From consumer electronics to automotive applications, these machines are utilized to assemble PCBs that power everything from smartphones to electric vehicles. Additionally, their versatility means they can handle a wide range of components, including surface mount devices (SMDs) commonly used in printed circuit assembly.

Advantages for PCB Assembly

The advantages of employing a pick and place SMT machine for PCB assembly are manifold. Firstly, they drastically increase the speed of production compared to manual methods; this not only accelerates manufacturing but also reduces labor costs associated with traditional assembly processes. Secondly, their precision ensures high-quality outcomes with minimal defects—an essential factor when producing complex PCB circuit boards that require exact specifications for functionality. Lastly, automation through these machines enhances scalability; businesses can easily ramp up production as demand increases without compromising quality or efficiency.

Budget-Friendly Models for PCB Production

When it comes to budget-friendly models for PCB production, finding the right pick and place SMT machine can feel like searching for a needle in a haystack. Fortunately, there are several affordable options available that don’t skimp on quality or performance. In this section, we’ll explore Bensun Technology’s offerings and compare them with other models on the market.

Bensun Technology's Offerings

Bensun Technology has made a name for itself in the realm of circuit board assembly with its range of cost-effective pick and place SMT machines. Their models are designed specifically for printed circuit assembly, ensuring high precision and speed without breaking the bank. With features tailored to enhance efficiency in PCB board production, these machines are perfect for small to medium-sized businesses looking to optimize their circuit card assembly processes.

The standout model from Bensun is known for its user-friendly interface, allowing operators—whether seasoned pros or newbies—to navigate easily through complex tasks. Additionally, these machines boast impressive capabilities like multi-functional placement heads that can handle various component sizes, making them versatile tools in any PCB assembly line. In short, Bensun’s offerings provide an excellent balance of affordability and robust functionality.

Comparing Prices and Features

When comparing prices and features among budget-friendly pick and place SMT machines, it’s essential to look beyond just the price tag. Many entry-level models may seem appealing due to their lower costs but could compromise on critical aspects such as speed or accuracy during circuit board production. Therefore, taking a closer look at specifications—like placement speed (components per hour) and accuracy (in millimeters)—is crucial when evaluating which machine best suits your needs.

Bensun's models typically fall within a competitive price range while offering features that rival more expensive counterparts from other brands. For instance, while some brands may charge extra for advanced software capabilities or additional tooling options, Bensun often includes these as standard features in their packages. This means you get more bang for your buck without sacrificing quality or performance during printed circuit assembly.

Cost vs. Performance Analysis

Analyzing cost versus performance is vital when investing in a pick and place SMT machine dedicated to PCB production. While it might be tempting to go with the cheapest option available, this approach can lead to higher long-term costs due to inefficiencies or frequent repairs during circuit card assembly processes. Instead, focusing on machines that offer reliable performance at reasonable prices will ensure smoother operations down the line.

In practice, many users have reported that investing slightly more upfront in a reliable model results in significant savings over time through reduced downtime and enhanced output quality during PCB board production tasks. By examining user reviews alongside technical specifications from brands like Bensun Technology versus competitors’ offerings can help illuminate which machines deliver optimal value without compromising on essential features required for effective printed circuit assembly processes.

Key Features to Consider

When selecting a pick and place SMT machine for circuit board production, there are several key features that can significantly impact the efficiency and quality of your PCB assembly process. Understanding these features will help you make an informed decision tailored to your production needs. Let’s delve into speed and precision, size considerations, and ease of use.

Speed and Precision in Circuit Card Assembly

Speed is crucial in modern circuit card assembly, as faster production times can lead to increased output and reduced costs. A high-speed pick and place SMT machine ensures components are placed accurately on the PCB circuit board without delays, optimizing the entire printed circuit assembly process. Precision is equally important; even minor misalignments during placement can lead to defects, affecting the overall quality of the PCB board production.

Incorporating advanced technology like vision systems enhances both speed and accuracy, allowing machines to adapt quickly to different component sizes and types. This capability not only improves throughput but also minimizes rework associated with misplaced components in circuit board assembly. Ultimately, investing in a machine that balances speed with precision will yield better results in your PCB assembly operations.

Size and Footprint for Production Space

The physical size of a pick and place SMT machine is another critical consideration for those engaged in PCB board production. Depending on your available workspace, you may need a compact model that doesn’t compromise on performance or features essential for effective printed circuit assembly. Assessing the footprint of various machines ensures that they fit seamlessly into your existing workflow without causing bottlenecks.

Additionally, larger machines might offer more capabilities but could require significant floor space or specialized setups. Balancing size with functionality allows businesses to optimize their production line while accommodating future growth or changes in manufacturing processes related to circuit card assembly. Remember that an efficient layout can enhance productivity while maintaining an organized workspace.

Ease of Use and Maintenance

User-friendliness is paramount when considering a pick and place SMT machine for your PCB assembly line; after all, complex machinery should not hinder productivity or require extensive training sessions for operators! Look for machines with intuitive interfaces that simplify setup processes while providing clear instructions for operation—this reduces downtime significantly during shifts dedicated to printed circuit assembly tasks.

Moreover, maintenance plays a vital role in ensuring longevity and consistent performance from any equipment used in circuit board production. Machines designed with easy access points allow operators to perform routine checks without hassle or specialized tools; this keeps them running smoothly over time while reducing operational disruptions linked to unexpected breakdowns.

Investing time upfront into understanding these key features will pay dividends down the line as you streamline your PCB assembly processes effectively!

Recommended Brands to Explore

Each manufacturer offers unique features and advantages that cater to different aspects of PCB assembly. In this section, we’ll delve into Bensun Technology's offerings, other notable brands in the market, and what users have to say about their experiences.

Bensun Technology's Reliable Machines

Bensun Technology has carved a niche for itself in the realm of affordable pick and place SMT machines designed specifically for efficient circuit card assembly. Their machines are known for high precision and speed, which significantly enhances the quality of printed circuit assembly (PCA). With an emphasis on user-friendly designs, Bensun’s equipment is ideal for both small-scale operations and larger PCB board production lines.

One of the standout features of Bensun’s offerings is their ability to handle a variety of components seamlessly, making them versatile tools for any PCB assembly task. Additionally, they provide excellent customer support and maintenance services that ensure your circuit board production runs smoothly without any hiccups. If you’re looking for reliability paired with affordability in a pick and place SMT machine, Bensun Technology should be at the top of your list.

Other Notable Brands in the Market

While Bensun Technology stands out, several other brands also offer impressive pick and place SMT machines worth considering. Companies like Yamaha Motor Corp., Juki Corporation, and Panasonic are renowned for their advanced technology in circuit board assembly equipment. Each brand brings its own strengths; Yamaha is celebrated for its innovative automation solutions while Juki focuses on maximizing speed without sacrificing accuracy.

Panasonic offers robust options with extensive customization capabilities that can cater to specific needs within printed circuit assembly processes. These brands not only provide high-quality machines but also come equipped with advanced software solutions that streamline PCB board production workflows. By comparing these notable manufacturers alongside Bensun Technology, you can find a machine that meets your specific requirements in terms of performance and budget.

User Experiences and Reviews

User experiences play a crucial role in understanding how effective a pick and place SMT machine truly is during real-world applications like circuit card assembly or PCB production tasks. Many users rave about Bensun Technology's machines due to their ease of setup and operation; even those new to PCB assembly often find them intuitive to use. Reviews frequently highlight consistent performance levels across various types of components used during printed circuit assembly.

On platforms dedicated to electronics manufacturing discussions, users often share how switching to certain brands has improved their efficiency dramatically while reducing error rates during production runs. Feedback on automation features shows that many operators appreciate how these innovations simplify traditional processes involved in circuit board production—saving time while boosting output quality. Overall, diving into user reviews provides valuable insights into what you can expect from different models as you navigate through your options.

Future Trends in SMT Machines

The landscape of PCB assembly is evolving rapidly, driven by technological advancements and market demands. As manufacturers seek to optimize circuit board production, innovations in pick and place SMT machines are at the forefront. These developments not only enhance efficiency but also improve the quality of printed circuit assembly.

Innovations Affecting PCB Board Production

Innovative technologies are reshaping the way we approach circuit card assembly. For instance, machine vision systems have become increasingly sophisticated, allowing for real-time inspection and adjustments during the production process. This enhances accuracy and reduces errors in PCB circuit board assembly, ensuring that each component is placed precisely where it needs to be.

Additionally, advancements in software integration mean that modern pick and place SMT machines can adapt to various designs with ease. This flexibility is crucial for manufacturers dealing with diverse product lines or rapid prototyping needs in circuit board production. Overall, these innovations contribute significantly to streamlining operations and boosting productivity in PCB assembly.

The Role of Automation in Assembly

Automation is no longer just a trend; it's a necessity for efficient circuit board assembly processes. With the rise of Industry 4.0, smart factories equipped with interconnected machinery are becoming commonplace. In this environment, pick and place SMT machines play a vital role by automating labor-intensive tasks involved in printed circuit assembly.

These automated systems not only speed up production but also minimize human error, leading to higher quality outputs in PCB board production. Moreover, automation allows for better tracking of production metrics and inventory management, ensuring a seamless workflow from start to finish. As more companies embrace automation, the demand for advanced pick and place SMT machines will undoubtedly continue to grow.

Sustainable Practices and Eco-Friendly Solutions

Sustainability is becoming increasingly important across all industries, including PCB assembly processes involving pick and place SMT machines. Manufacturers are now focusing on eco-friendly practices such as reducing waste during circuit card assembly and using recyclable materials whenever possible. This shift not only benefits the environment but can also lead to cost savings over time.

Furthermore, advancements in energy-efficient technologies mean that modern pick and place SMT machines consume less power while maintaining high performance levels during printed circuit assembly tasks. Companies embracing these sustainable practices often find themselves more competitive as consumers increasingly favor environmentally responsible brands in their purchasing decisions related to PCB board production.

By integrating sustainability into their operations, manufacturers can ensure they remain relevant while contributing positively to global efforts toward environmental preservation.

Conclusion

In the fast-paced world of circuit board production, making informed choices regarding pick and place SMT machines is crucial for success. The right machine can significantly enhance your efficiency in PCB assembly, leading to higher quality products and reduced production times. By understanding the various options available, you can select a model that meets your specific needs without breaking the bank.

Making Informed Choices for PCB Assembly

When it comes to circuit card assembly, knowledge is power. Evaluating features such as speed, precision, and ease of use will help you choose the best pick and place SMT machine for your operation. Additionally, considering user reviews and expert insights can guide you toward making an informed decision that supports your goals in printed circuit assembly.

The Balance of Quality and Affordability

Finding a balance between quality and affordability in PCB board production is essential for any business looking to thrive in a competitive market. While budget-friendly models are available, it’s vital to ensure they don’t compromise on performance or reliability during circuit board assembly. By carefully comparing costs against features, you can secure a pick and place SMT machine that delivers both value and excellence.

Embracing Innovation in Circuit Board Assembly

As technology evolves, embracing innovation becomes key to staying ahead in PCB circuit board production. New advancements in automation are transforming how we approach circuit card assembly, making processes faster and more efficient than ever before. Sustainable practices also play a significant role; integrating eco-friendly solutions into your operations not only benefits the planet but enhances your brand's reputation as well.