Introduction

In the fast-paced world of electronics, boosting your SMT efficiency today is not just a goal; it’s a necessity. As the demand for high-quality printed circuit assembly (PCA) continues to surge, manufacturers must adapt and innovate to remain competitive. This introduction sets the stage for understanding how PCB assembly and manufacturing can be streamlined through technology and best practices.

Boost Your SMT Efficiency Today

To truly enhance your PCB manufacturing and assembly processes, it’s essential to focus on efficiency from the ground up. This involves examining every step of circuit card assembly, from design through to final inspection. By implementing effective strategies today, you can significantly reduce production times while maintaining high standards in quality.

Understanding PCB Assembly Fundamentals

At its core, PCB fabrication and assembly involves multiple intricate steps that transform raw materials into functional electronic assemblies. Understanding these fundamentals is crucial for anyone involved in the PCB manufacturing assembly process. Each phase—whether it's soldering components or testing finished boards—plays a vital role in ensuring that your PCB assembly board meets performance expectations.

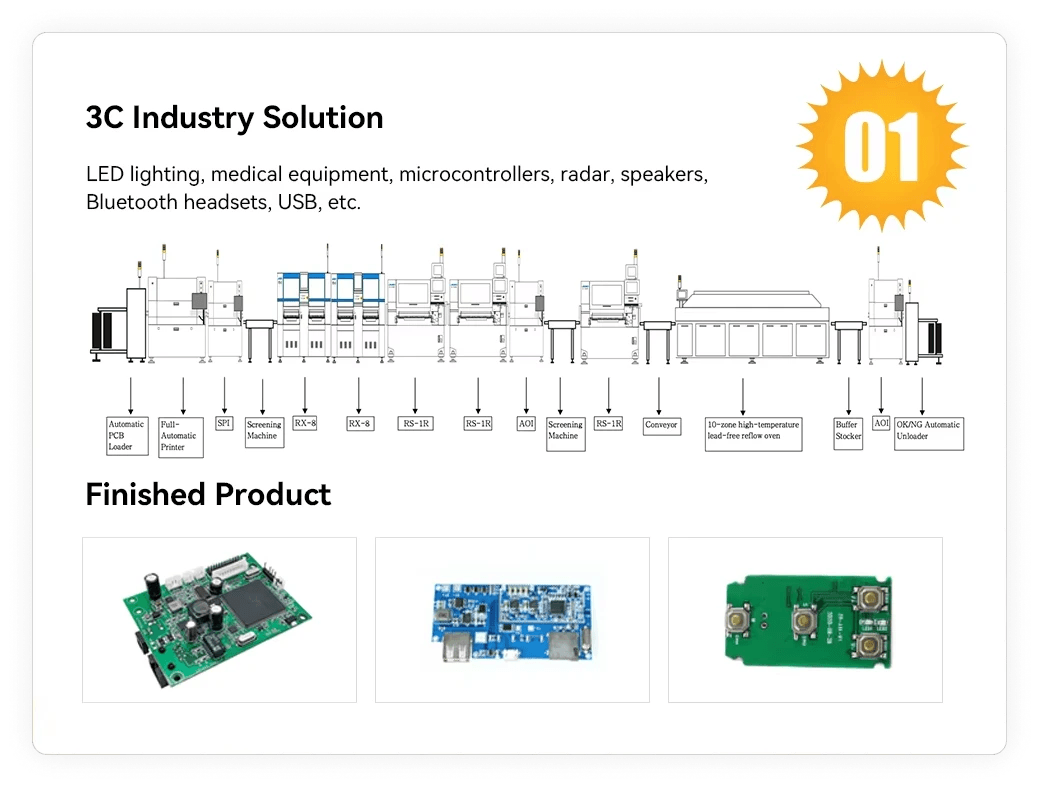

The Role of Technology in PCB Manufacturing

Technology has revolutionized the landscape of PCB manufacturing and assembly, offering tools that enhance precision and productivity. From advanced pick-and-place machines to automated inspection systems, leveraging these technologies can lead to remarkable improvements in circuit card assembly efficiency. Embracing these innovations not only streamlines operations but also positions your business at the forefront of industry advancements.

Streamlining Your PCB Assembly Process

In the fast-paced world of PCB manufacturing and assembly, streamlining your processes is crucial for maintaining competitiveness and efficiency. By refining your approach to printed circuit assembly, you can enhance productivity, reduce costs, and improve overall quality. This section explores essential strategies for optimizing your PCB assembly board operations.

Implementing Lean Manufacturing Techniques

Lean manufacturing techniques are all about maximizing value while minimizing waste in the PCB fabrication and assembly process. By adopting principles such as just-in-time production, continuous improvement, and value stream mapping, you can create a more efficient workflow that significantly reduces lead times in circuit card assembly. The goal is to focus on what truly adds value to your customers while eliminating unnecessary steps that slow down production.

One effective way to implement lean techniques is through regular team training sessions that emphasize problem-solving skills and encourage innovative thinking among employees involved in PCB manufacturing and assembly. Empowering staff to identify inefficiencies fosters a culture of continuous improvement that can lead to remarkable gains in productivity over time. Ultimately, incorporating lean practices not only enhances the speed of your printed circuit assembly but also boosts employee morale as they see their contributions making a tangible impact.

Importance of Workflow Optimization

Workflow optimization is vital for achieving seamless operations in PCB manufacturing assembly. A well-organized workflow ensures that each stage of the process runs smoothly, from initial design through final inspection of the pcb assembly board. By analyzing each step carefully and identifying bottlenecks or redundancies, you can streamline operations to enhance overall efficiency.

Utilizing software tools designed for workflow management can provide valuable insights into how tasks are performed within your facility. These tools allow you to visualize processes clearly and make data-driven decisions regarding resource allocation and task prioritization in printed circuit assembly tasks. With an optimized workflow, you’ll find that not only does production speed increase but also error rates decrease significantly—leading to higher quality outcomes in your pcb fabrication and assembly efforts.

Reducing Waste in PCB Assembly

Waste reduction is a key component of any successful strategy aimed at enhancing efficiency in pcb manufacturing and assembly processes. Whether it’s excess materials, time lost during transitions between stages or defects caused by poor handling practices—waste comes in many forms during printed circuit assembly operations. Identifying these waste sources allows companies to implement targeted strategies for their elimination.

One practical approach involves conducting regular audits of inventory management systems used during circuit card assembly processes; this helps ensure that materials are utilized effectively without excessive overstocking or spoilage occurring on-site at any given time! Additionally, fostering an environment where employees feel comfortable reporting inefficiencies or suggesting improvements creates a proactive culture focused on waste reduction throughout all aspects of pcb manufacturing assemblies—a win-win situation!

Selecting the Right SMT Equipment

When it comes to optimizing your PCB assembly process, selecting the right SMT equipment is crucial. The efficiency of your printed circuit assembly can significantly impact the overall quality and speed of production. Investing in reliable machinery not only enhances performance but also ensures that your circuit card assembly meets industry standards.

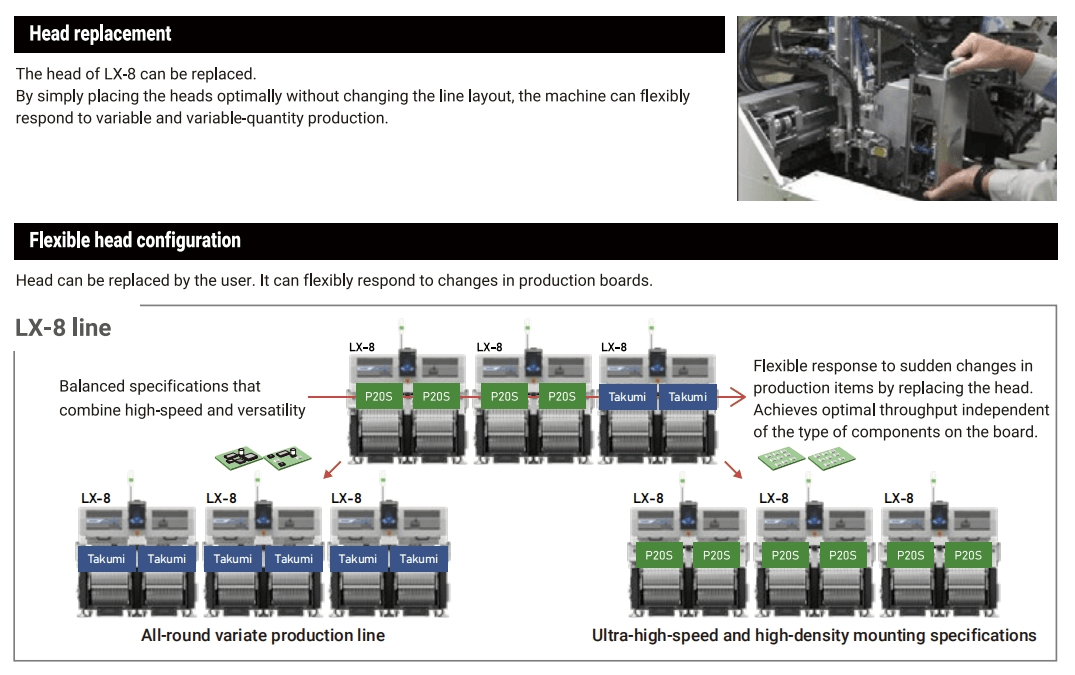

Evaluating JUKI Pick and Place Machines

JUKI pick and place machines are renowned for their precision and reliability in PCB manufacturing and assembly. These machines excel at placing components accurately on the PCB assembly board, minimizing errors that could lead to costly rework. By evaluating various models, you can find a JUKI machine that aligns perfectly with your production needs, ensuring seamless integration into your existing PCB fabrication and assembly workflow.

The advanced features of JUKI machines include high-speed operation and smart software capabilities, which allow for real-time adjustments during the manufacturing process. This adaptability is essential in today’s fast-paced environment where demand for quick turnaround times is high. Ultimately, incorporating a JUKI pick and place machine can elevate your PCB manufacturing assembly to new heights of efficiency.

Visual Inspection Machines for High Quality

In the realm of PCB manufacturing, quality assurance is paramount; this is where visual inspection machines come into play. These devices are designed to scrutinize every aspect of printed circuit assemblies, identifying defects that might escape human eyes during manual inspections. By implementing automated visual inspection systems, you ensure that each circuit card assembly meets stringent quality standards before reaching customers.

The integration of these machines into your workflow not only enhances product reliability but also reduces the likelihood of returns due to defects—saving both time and money in the long run. Furthermore, many modern visual inspection systems utilize advanced imaging technology to provide detailed analysis reports that can inform future improvements in the PCB fabrication and assembly process. In essence, investing in high-quality visual inspection machines is a step toward achieving excellence in PCB assembly smt.

Benefits of Advanced Reflow Ovens

Advanced reflow ovens play a pivotal role in ensuring optimal soldering conditions during PCB manufacturing and assembly processes. These ovens use precise temperature profiles tailored to different types of solder paste used on your PCBs, ensuring effective melting without damaging sensitive components or substrates on the pcb assembly board. The result? A robust bond between components that enhances overall product durability.

Moreover, modern reflow ovens often come equipped with features like data logging capabilities which allow manufacturers to monitor performance over time—helping identify trends or issues before they escalate into larger problems within the production line. This proactive approach leads to better resource management while minimizing waste throughout pcb fabrication and assembly operations. Embracing advanced reflow technology ultimately paves the way for smoother workflows in your pcb manufacturing assembly endeavors.

Effective Design for DFM and DFA

Designing for manufacturability (DFM) and design for assembly (DFA) are crucial steps in optimizing the efficiency of PCB manufacturing and assembly. By incorporating these principles early in the design phase, engineers can significantly reduce production costs, minimize errors, and enhance product quality. Understanding how to effectively implement DFM and DFA can lead to smoother workflows in circuit card assembly and ultimately result in superior printed circuit assembly outcomes.

Integrating Design for Manufacturing Principles

Integrating DFM principles into your PCB manufacturing and assembly process is all about collaboration between design teams and manufacturing personnel. This collaboration ensures that the design accommodates the capabilities of the manufacturing processes, reducing complications during PCB fabrication and assembly. Key considerations include selecting appropriate materials, minimizing part counts, and designing components that are easy to source, all of which contribute to a more efficient workflow in the PCB assembly board.

When engineers prioritize manufacturability from the start, they help avoid costly redesigns later on. For instance, simplifying complex geometries or using standard components can lead to significant reductions in production time during circuit card assembly. Ultimately, embracing DFM not only enhances efficiency but also fosters a culture of quality throughout the entire PCB manufacturing process.

Enhancing Design for Assembly Strategies

Designing with assembly in mind is equally important as it directly impacts how easily components can be placed onto a PCB assembly board during production. Effective DFA strategies focus on minimizing handling time by ensuring that parts are oriented correctly for pick-and-place operations while considering accessibility for soldering processes. This attention to detail not only streamlines workflow but also enhances overall productivity during printed circuit assembly.

Moreover, implementing modular designs can simplify repairs or upgrades down the line while making it easier to assemble multiple variants of a product without extensive rework on each version. The use of clear labeling on components also aids operators during circuit card assembly by reducing confusion and potential errors when assembling devices at high speed. In this way, enhancing DFA strategies leads to improved efficiency across all stages of PCB fabrication and assembly.

Common Pitfalls in Printed Circuit Assembly

Despite best efforts at integrating DFM and DFA principles into your processes, pitfalls can still arise that hinder effective PCB manufacturing and assembly practices. One common issue is neglecting thermal management considerations early on; if heat-generating components are not properly spaced or cooled within their designs, they may lead to failures post-assembly or even complicate soldering processes during production runs.

Another frequent challenge involves overlooking component placement density; cramming too many parts into a small area might seem efficient initially but often results in increased difficulty during soldering or inspection phases later down the line—defeating any initial cost savings achieved through high-density layouts! Lastly, failing to engage with manufacturers early enough often leads designers down paths that create unnecessary complexities rather than streamlined solutions throughout both pcb fabrication and assembly stages.

The Importance of Quality Control

In the world of PCB manufacturing and assembly, quality control is the backbone that supports reliability and performance. Without robust quality measures, even the most advanced printed circuit assembly can fall short of expectations, leading to costly errors and delays. Implementing effective quality control processes ensures that every circuit card assembly meets stringent standards, ultimately fostering customer trust and satisfaction.

Setting Up Robust Inspection Protocols

Establishing robust inspection protocols is crucial for maintaining high-quality standards in PCB assembly and manufacturing. These protocols should encompass various stages of production, from initial material inspection to final product testing, ensuring that defects are caught early in the process. A well-structured inspection protocol not only enhances product reliability but also reduces rework costs associated with faulty printed circuit assemblies.

Incorporating a mix of manual and automated inspections can create a comprehensive approach to quality assurance in PCB fabrication and assembly. By training staff on these protocols, manufacturers can cultivate a culture of quality that permeates throughout the entire production line. Ultimately, investing time in developing effective inspection protocols pays off by minimizing defects and maximizing efficiency.

Utilizing Automated Visual Inspection

Automated visual inspection (AVI) has revolutionized the way PCB manufacturing and assembly processes ensure quality control. By utilizing advanced imaging technology, AVI systems can detect defects much faster than human inspectors while maintaining a high level of accuracy. This technology is particularly beneficial for complex pcb assembly boards where minute discrepancies may lead to significant operational issues down the line.

Moreover, integrating AVI into your workflow allows for real-time monitoring of production quality, enabling immediate corrective actions when necessary. This proactive approach not only saves time but also enhances overall productivity by reducing downtime caused by manual inspections or errors in circuit card assemblies. As automated visual inspection continues to evolve, it becomes an indispensable tool for achieving excellence in PCB fabrication and assembly.

Addressing Common Quality Issues in PCB Assembly

Addressing common quality issues in PCB assembly requires diligence and attention to detail throughout the manufacturing process. Frequent problems such as solder joint failures or misaligned components can jeopardize the functionality of printed circuit assemblies if not properly managed. By identifying these issues early on through rigorous testing protocols and automated inspections, manufacturers can significantly reduce their impact on overall product performance.

It's essential to analyze root causes behind recurring defects—whether they stem from equipment malfunctions or design flaws—to implement effective corrective measures proactively. Continuous improvement initiatives focused on addressing these challenges will foster a culture committed to excellence within your organization’s pcb manufacturing assembly processes. Embracing this mindset not only elevates product quality but also strengthens relationships with customers who rely on your circuit card assemblies.

Continuous Improvement in PCB Manufacturing

In the fast-paced world of PCB manufacturing and assembly, continuous improvement is not just a buzzword; it’s a necessity. By focusing on refining processes and enhancing quality, companies can stay competitive while ensuring that their printed circuit assembly meets the highest standards. Let’s delve into some key strategies that can help elevate your PCB fabrication and assembly game.

Utilizing Feedback Loops for Process Enhancement

Feedback loops are invaluable in the realm of pcb assembly smt, allowing teams to identify bottlenecks and inefficiencies in real-time. By actively seeking input from operators and engineers involved in circuit card assembly, manufacturers can make informed decisions that lead to significant improvements. Implementing regular review meetings ensures that insights are captured and acted upon, creating a culture of continuous enhancement within pcb manufacturing.

Moreover, integrating customer feedback into the process helps tailor products more closely to market needs. This two-way communication fosters innovation while also streamlining workflows in pcb manufacturing and assembly. Ultimately, an effective feedback loop not only enhances product quality but also boosts team morale as everyone feels their contributions matter.

Training and Development for Staff

Investing in training and development for staff is crucial for any successful pcb fabrication and assembly operation. A well-trained workforce is more adept at handling complex tasks associated with printed circuit assembly, leading to fewer errors and increased efficiency. Regular workshops on new technologies or methodologies ensure that employees remain engaged while keeping skills sharp.

Moreover, fostering an environment where employees are encouraged to share knowledge can lead to unexpected breakthroughs in processes related to pcb manufacturing assembly. Cross-training staff across different roles promotes versatility, enabling teams to adapt quickly when challenges arise during production runs. As a result, this approach not only optimizes workflow but also cultivates a sense of camaraderie among team members.

Leveraging Data Analytics in PCB Production

Data analytics has become a game-changer in the world of pcb manufacturing and assembly by providing actionable insights from vast amounts of production data. Utilizing advanced analytics tools allows manufacturers to track performance metrics effectively, identifying trends that may indicate potential issues before they escalate into costly problems during circuit card assembly processes. This proactive approach minimizes downtime while maximizing output quality.

Additionally, data-driven decision-making enables companies to fine-tune their operations continuously based on real-world performance rather than guesswork or outdated practices related to pcb fabrication and assembly. With predictive analytics capabilities, businesses can anticipate demand fluctuations or supply chain disruptions more accurately—allowing them to adjust production schedules accordingly without compromising quality or delivery timelines for their customers’ needs.

In conclusion, embracing these strategies will not only enhance your overall efficiency but also position your organization as a leader within the competitive landscape of pcb assembly smt operations.

Conclusion

As we wrap up our exploration of PCB assembly and manufacturing, it’s important to recognize the key strategies that can significantly enhance your efficiency. Emphasizing lean practices, effective design principles, and robust quality control measures will not only streamline your printed circuit assembly process but also elevate the overall quality of your circuit card assembly. By staying informed about technological advancements and continuously improving your operations, you can ensure that your PCB manufacturing and assembly processes remain competitive in an ever-evolving market.

Key Takeaways for PCB Efficiency

To boost efficiency in PCB fabrication and assembly, consider implementing lean manufacturing techniques that reduce waste while maximizing productivity. Streamlining workflow optimization is crucial; it allows for a smoother transition from PCB design to production, ultimately enhancing the performance of your pcb assembly board. Additionally, investing in high-quality SMT equipment is vital—machines like JUKI pick and place systems can dramatically improve accuracy and speed in printed circuit assembly.

Future Trends in PCB Manufacturing

Looking ahead, several trends are shaping the future of PCB manufacturing assembly. The integration of automation and advanced data analytics will allow manufacturers to achieve unprecedented levels of precision and efficiency in their processes. Moreover, as the demand for miniaturized electronics grows, innovations in materials and design methodologies will play a pivotal role in driving advancements within the realm of circuit card assembly.

Partnering with Bensun for Success

To navigate these trends successfully, partnering with a reliable provider like Bensun can make all the difference in optimizing your pcb manufacturing processes. With their expertise in both pcb fabrication and assembly as well as cutting-edge technology solutions tailored to meet specific needs, Bensun positions itself as a valuable ally on your journey toward enhanced operational excellence. Together, you can tackle challenges head-on while staying ahead of industry shifts—making sure that your business not only survives but thrives.