Introduction

In the rapidly evolving world of electronics, understanding SMT (Surface Mount Technology) is crucial for anyone involved in printed circuit assembly. This technology has revolutionized how components are mounted onto PCBs (Printed Circuit Boards), allowing for more compact designs and improved performance. The heart of this process lies in the SMT PCB chip mounter, a device that precisely places surface mount devices (SMDs) onto the PCB, ensuring efficiency and accuracy.

Understanding SMT Technology

SMT technology is a method used to create electronic circuits by mounting components directly onto the surface of PCBs. Unlike traditional through-hole mounting, where components are inserted into holes on the board, SMT allows for a more streamlined design, reducing space and weight while enhancing electrical performance. As a result, modern devices often utilize SMD technology to achieve higher density and functionality on their SMT PCB boards.

The Role of SMT Mounters

SMT mounters play an essential role in the assembly process by automating the placement of SMDs onto PCBs with remarkable precision and speed. These machines are designed to handle various component sizes and types, making them versatile tools in any production line focused on printed circuit assembly. By utilizing an efficient smt mount, manufacturers can significantly enhance their production capabilities while maintaining high-quality standards.

Choosing the Right Supplier

Selecting the right supplier for your SMT PCB chip mounter is critical to ensuring that your production meets industry demands and quality expectations. Factors such as machine reliability, service support, and compatibility with existing systems should be considered when evaluating potential suppliers. With many options available in today's market, making an informed decision can lead to improved efficiency and innovation in your PCB on PCB applications.

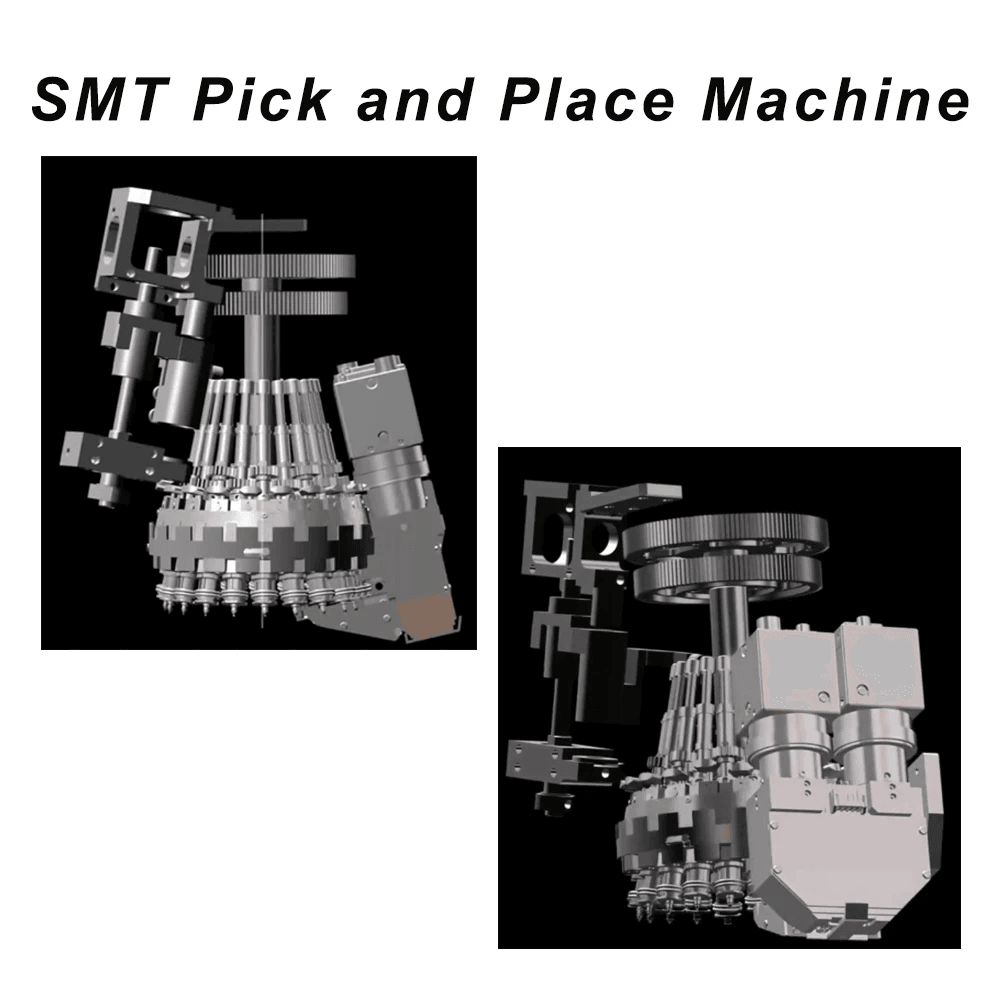

The Basics of SMT PCB Chip Mounters

In the world of electronics, the role of SMT PCB chip mounters is pivotal in the printed circuit assembly process. These machines are designed to place surface mount devices (SMD) onto PC boards with remarkable precision and efficiency. Understanding how they operate and their benefits can significantly enhance your production capabilities.

What is a PCB Chip Mounter

A PCB chip mounter is a specialized machine that automates the placement of SMD components on printed circuit boards (PCBs). Unlike traditional through-hole technology, which requires drilling holes in the board, SMT technology allows for components to be mounted directly onto the surface of the board, making it more efficient and compact. This innovation has revolutionized modern electronics manufacturing, enabling faster assembly times and higher component densities on PCBs.

How SMT Technology Works

SMT technology operates by utilizing a series of steps to ensure accurate placement of SMD components on a PCB. First, solder paste is applied to specific locations on the board using stencils or screen printing methods. Next, the SMT PCB chip mounter picks up each component from a feeder and places it precisely onto the solder paste dots before entering a reflow oven where heat melts the solder, securely attaching each part to the board.

Benefits of Using SMT

The advantages of using SMT for printed circuit assembly are numerous and impactful. For starters, it enables higher circuit density since components can be placed closer together on a smaller area compared to traditional methods—think PCB on PCB capabilities! Additionally, SMT technology offers improved reliability due to fewer mechanical stresses during assembly processes while also reducing costs through less material waste and faster production speeds.

Key Features to Look For in SMT Mounts

When selecting an SMT PCB chip mounter, it's crucial to focus on key features that can significantly impact your printed circuit assembly process. These features ensure that the equipment meets industry standards while enhancing efficiency and productivity. By understanding what to look for, you can make an informed decision that aligns with your specific needs.

Precision and Speed

A high-quality smt pcb chip mounter should deliver exceptional accuracy in placing SMD components on the pc board, reducing the risk of errors during assembly. Additionally, faster placement speeds mean higher throughput, allowing for more efficient production cycles and quicker turnaround times.

Investing in a mount that balances both precision and speed will ultimately enhance your printed circuit assembly process. With advanced technology like vision systems and real-time monitoring, modern SMT mounts can achieve remarkable placement accuracy while maintaining impressive speeds. This combination is essential for meeting the demands of today’s fast-paced electronics market.

Compatibility with SMD Technology

Compatibility with SMD technology is another critical feature to consider when choosing an SMT mount. As electronic devices become more compact and complex, the ability to handle various surface mount devices (SMD) is vital for successful PCB assembly. Ensure that your selected smt pcb chip mounter supports a wide range of SMD sizes and types to accommodate future design changes.

Moreover, compatibility extends beyond just component size; it also includes the ability to work seamlessly with different types of solder paste and substrates used in printed circuit assemblies. A versatile smt mount will allow manufacturers to adapt quickly as new technologies emerge or as design requirements change over time. This flexibility ensures longevity in your investment while keeping you competitive in a rapidly evolving market.

Versatility in PCB Assembly

Versatility plays a significant role in determining the effectiveness of an SMT PCB chip mounter within various applications. An ideal smt mount should be capable of handling multiple configurations, such as single-sided or double-sided assemblies like pcb on pcb designs, without compromising performance or quality. This adaptability allows manufacturers to diversify their product offerings without needing multiple machines.

Furthermore, versatility also encompasses the ability to integrate with other manufacturing processes such as inspection systems or reflow ovens within the printed circuit assembly line. By choosing a multifunctional smt mount, businesses can streamline operations and reduce downtime caused by equipment changes or adjustments between different production runs. Ultimately, this leads to improved efficiency across all aspects of PCB manufacturing.

Top Suppliers in the Market

When it comes to sourcing SMT PCB chip mounters, knowing the top suppliers can significantly impact your production efficiency and quality. The landscape of SMT equipment suppliers is diverse, with each offering unique features that cater to various needs in printed circuit assembly. Let's dive into some key players in this industry, starting with Bensun Technology.

Bensun Technology Overview

Bensun Technology has carved a niche for itself in the realm of SMT PCB boards with its innovative solutions and cutting-edge technology. Known for their precision engineering, Bensun offers a range of SMT mounters that excel in speed and accuracy, making them ideal for high-volume production environments. Their commitment to quality ensures that each smt mount meets rigorous standards, providing reliable performance for SMD technology applications.

In addition to their impressive lineup of smt pcb chip mounters, Bensun also focuses on customer support and tailored solutions for specific industries. This adaptability makes them a go-to choice for companies looking to enhance their printed circuit assembly processes without compromising on quality or efficiency. With a reputation built on trust and technological advancement, Bensun continues to lead the charge in SMT equipment innovation.

Other Notable SMT Equipment Suppliers

While Bensun Technology stands out, there are several other notable suppliers worth considering when searching for an SMT PCB chip mounter. Companies like Yamaha Motor Co., Juki Corporation, and Panasonic also offer competitive options that cater to various needs within the SMD technology space. Each supplier brings its own strengths—Yamaha is renowned for its high-speed placement capabilities while Juki provides excellent flexibility in handling diverse components.

Panasonic’s offerings are particularly noteworthy due to their integration of advanced automation features designed to streamline production lines further. These suppliers not only provide high-quality smt mounts but also emphasize compatibility with newer technologies such as PCB on PCB designs. As such, exploring multiple options allows manufacturers to select equipment that aligns perfectly with their specific requirements.

Comparing Supplier Offerings

When comparing supplier offerings for SMT equipment, several factors should be considered beyond just price points—features like precision, speed, and versatility play crucial roles in determining which smt pcb board will best suit your needs. For instance, while some suppliers may excel at handling standard components efficiently, others might shine when it comes to accommodating complex assemblies involving multiple SMD technologies or intricate pc board designs.

It's essential to evaluate how each supplier's machinery integrates into existing workflows as well; seamless compatibility can lead to significant gains in productivity during printed circuit assembly processes. Additionally, consider after-sales support and warranty terms offered by these companies—reliable service can make all the difference when investing in an expensive piece of equipment like an SMT PCB chip mounter.

By carefully weighing these aspects against your own operational goals and budget constraints, you’ll be better equipped to choose the right supplier who not only meets your immediate needs but also supports future growth within this rapidly evolving industry landscape.

Applications of SMT PCB Boards

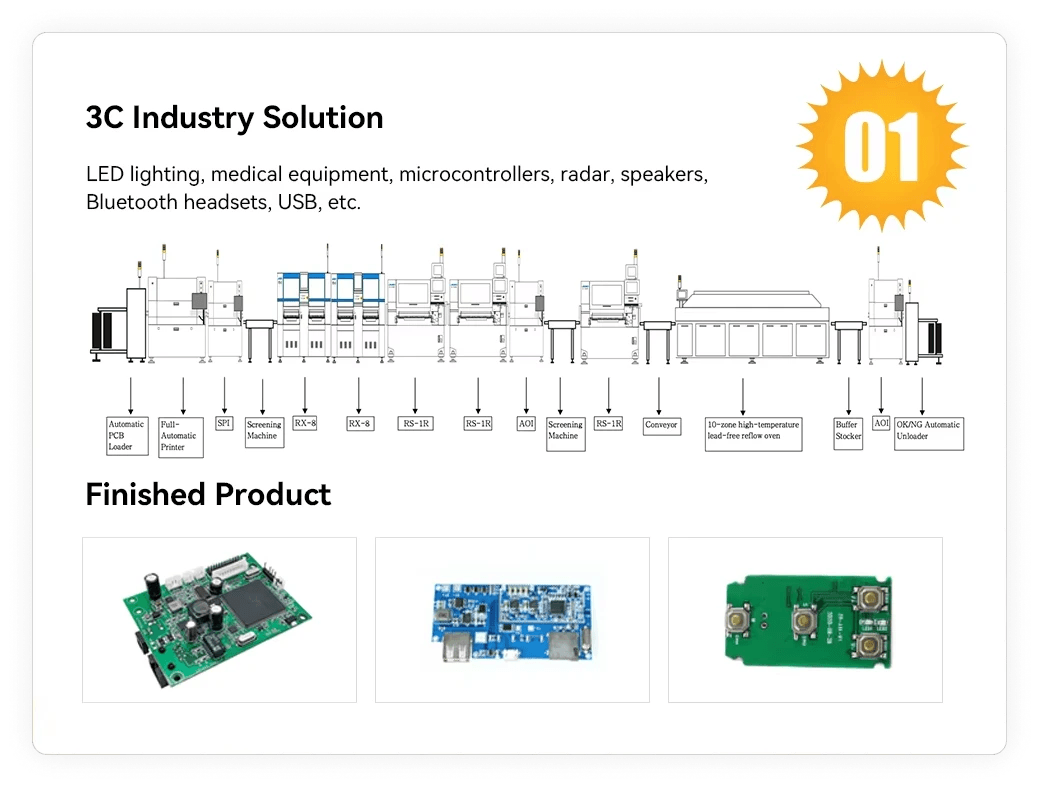

SMT PCB boards have revolutionized the landscape of electronics manufacturing, enabling a wide range of industries to enhance their production processes. From consumer electronics to automotive applications, the versatility and efficiency of SMT technology have made it a staple in modern printed circuit assembly (PCA). As businesses continue to adopt SMD technology, the demand for advanced SMT PCB chip mounters is on the rise.

Industries Utilizing SMT Technology

The adoption of SMT technology spans various industries, including telecommunications, medical devices, and aerospace. In telecommunications, for instance, high-density PCBs are crucial for devices like smartphones and routers that require compact designs without compromising performance. Similarly, in the medical sector, precision is paramount; SMT allows for miniaturized components that can be reliably integrated into life-saving equipment.

Automotive manufacturers also leverage SMT PCB boards to create sophisticated electronic systems that enhance vehicle safety and performance. Features like advanced driver-assistance systems (ADAS) rely heavily on reliable printed circuit assemblies that utilize SMD technology for optimal functionality. With each industry pushing the envelope on innovation, it's clear that SMT technology is not just a trend—it's an essential component driving progress across multiple sectors.

Advancements in Printed Circuit Assembly

Recent advancements in printed circuit assembly techniques have significantly improved the capabilities of SMT PCB chip mounters. Innovations such as automated optical inspection (AOI) and advanced soldering technologies ensure higher accuracy and reduced defects during assembly processes. These enhancements lead to more reliable PC boards that meet stringent quality standards required by today’s markets.

Moreover, manufacturers are increasingly adopting flexible manufacturing systems that allow for rapid changes in production lines tailored to specific needs. This adaptability is crucial as product lifecycles shorten and consumer demands evolve quickly. The continuous improvement in materials used alongside these advancements further enhances performance characteristics like thermal management and electrical conductivity within SMD components.

Innovations in SMD and PCB on PCB

Innovations surrounding SMD technology have paved the way for exciting developments such as PCB on PCB assemblies—where multiple layers of PCBs are stacked together to save space while increasing functionality. This approach not only optimizes real estate but also improves signal integrity among interconnected components within confined spaces typical of modern electronic devices. The ability to integrate complex circuits into compact formats has transformed how engineers design products.

Additionally, advancements in materials science have led to lighter yet stronger substrates suitable for multi-layered assemblies using SMT techniques. As manufacturers embrace these innovations with their smt mounts and chip mounters, we can expect even greater efficiency gains across various applications—from consumer gadgets to industrial machinery requiring robust electronic solutions. Ultimately, these breakthroughs signify a promising future where ingenuity meets practicality through enhanced design capabilities.

Contract Manufacturing and Leasing Options

In the fast-paced world of electronics, businesses often seek ways to optimize their operations without compromising on quality. Contract manufacturing and leasing options for SMT PCB chip mounters provide a flexible solution for companies looking to enhance their printed circuit assembly processes. By leveraging these services, manufacturers can focus on innovation while leaving the complexities of production to specialized partners.

Exploring Contract Processing Services

Contract processing services have become a popular choice for companies aiming to streamline their PCB assembly operations. These services allow businesses to outsource the entire production process or specific components, such as using an SMT mounter for SMD technology integration. This not only reduces overhead costs but also provides access to advanced equipment and expertise that may not be feasible in-house.

Additionally, contract manufacturers often specialize in various industries, ensuring that they are well-versed in the unique requirements of different sectors. Whether it’s automotive, consumer electronics, or medical devices, these providers can tailor their offerings to meet specific needs while using state-of-the-art SMT PCB boards and techniques like PCB on PCB assembly. This level of specialization enhances overall efficiency and product quality.

Benefits of Equipment Leasing

Leasing SMT equipment presents several advantages over outright purchases, particularly for startups or companies with fluctuating demand. First and foremost, leasing allows businesses to access cutting-edge technology without the hefty upfront costs associated with purchasing an SMT PCB chip mounter outright. This means companies can invest more resources into R&D or marketing instead of being tied down by expensive machinery.

Moreover, leasing agreements typically include maintenance and support services from suppliers, ensuring that any issues with the smt mount are quickly resolved without incurring additional expenses. This arrangement provides peace of mind while allowing businesses to adapt quickly to changing market demands or technological advancements in SMD technology and printed circuit assembly processes.

Finally, equipment leasing offers flexibility; businesses can upgrade or change their SMT mounters as needed without being locked into long-term commitments. This adaptability is crucial in today’s rapidly evolving tech landscape where innovations in PC board design and manufacturing processes are constant.

Tailoring Solutions to Industry Needs

One size does not fit all when it comes to SMT solutions; different industries have unique requirements that must be met for successful production outcomes. Therefore, tailoring solutions is essential for optimizing performance within specific applications such as automotive electronics or consumer gadgets utilizing SMD technology on compact PCBs.

By working closely with suppliers who understand these nuances—like those offering contract manufacturing services—companies can ensure that their SMT PCB chip mounters are equipped with features that align perfectly with their operational goals. Customization might involve selecting specific nozzles compatible with various components or integrating advanced software capable of handling complex printed circuit assemblies efficiently.

Furthermore, understanding industry trends enables manufacturers to anticipate future needs better and adapt accordingly through strategic partnerships with suppliers focused on innovation in SMD technology and automation capabilities within the realm of smt mounts used across diverse applications.

Conclusion

In the fast-paced world of electronics manufacturing, enhancing production efficiency with SMT technology is crucial. The integration of SMT PCB chip mounters into printed circuit assembly processes allows for faster and more precise placement of components, ultimately reducing production times and costs. By leveraging advanced SMD technology, manufacturers can achieve higher yields and improved product reliability.

Enhancing Production Efficiency with SMT

SMT PCB chip mounters play a pivotal role in streamlining the assembly process of PC boards. Their ability to handle various SMD components with precision ensures that every piece fits perfectly, minimizing errors during production. Moreover, the speed at which these machines operate allows companies to scale their output without compromising quality, making them indispensable in modern manufacturing.

Future Trends in PCB Assembly

The future of printed circuit assembly is bright, driven by continuous advancements in SMD technology and automation. Innovations such as PCB on PCB designs are gaining traction, allowing for more compact assemblies that save space and enhance performance. As industries evolve, we can expect even more sophisticated SMT solutions that will redefine how we approach electronic design and manufacturing.

Choosing the Right SMT Mounter Supplier

Selecting the right supplier for your SMT PCB board needs is essential for success in today's competitive market. Look for suppliers who not only offer high-quality smt mounts but also provide comprehensive support and service options tailored to your specific requirements. By carefully evaluating potential partners based on their offerings and expertise in SMD technology, you can ensure that your production process remains efficient and effective.