Introduction

In the ever-evolving landscape of manufacturing, SMT technology stands out as a pivotal innovation that has transformed production processes across various industries. As companies strive for greater efficiency and precision, understanding what SMT technology is becomes essential for anyone involved in modern production. This introduction sets the stage for exploring how surface mount technology not only enhances manufacturing capabilities but also plays a crucial role in driving competitive advantage.

Understanding SMT Technology in Manufacturing

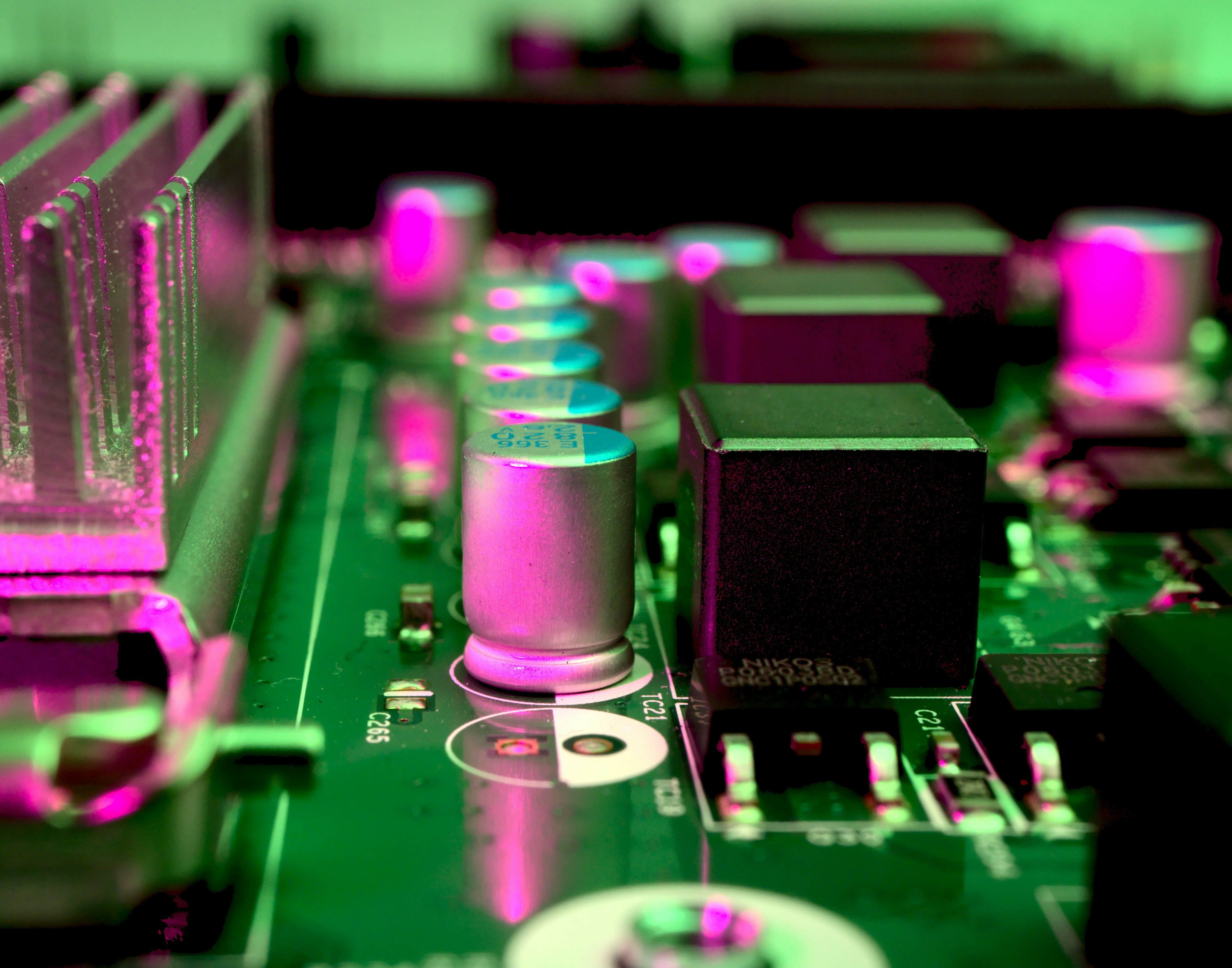

Surface mount technology (SMT) refers to a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional methods that involve inserting components into holes on the PCB, SMT allows for a more compact design and greater flexibility in component placement. By delving into what SMT technology entails, manufacturers can better appreciate its significance in today's fast-paced production environment.

The Shifting Landscape of Modern Production

The manufacturing landscape is undergoing rapid changes driven by technological advancements and increasing consumer demands. As businesses look to streamline operations and reduce costs, they are increasingly turning to SMT technology as a solution that meets these challenges head-on. This shift not only impacts how products are made but also influences the overall efficiency and effectiveness of production lines.

Benefits of Implementing SMT in Factories

Implementing SMT in factories offers numerous benefits that extend beyond mere cost savings. By utilizing this innovative approach, manufacturers can achieve higher production speeds while maintaining quality standards—an essential consideration in today's competitive market. Furthermore, understanding why SMT is used can help businesses identify opportunities for growth and improvement within their operations.

What is SMT Technology?

In the world of electronics manufacturing, SMT technology stands out as a revolutionary method for assembling components onto printed circuit boards (PCBs). This technique allows for the mounting of components directly onto the surface of a PCB, resulting in smaller, lighter, and more efficient electronic devices. Understanding what SMT technology entails is crucial for grasping its impact on modern production processes.

Definition and Overview

So, what is SMT technology? Surface mount technology (SMT) refers to a method where electronic components are placed directly onto the surface of PCBs rather than being inserted through holes as seen in traditional methods. This approach not only enhances design flexibility but also supports higher component density—allowing manufacturers to create compact devices that meet today's consumer demands.

The beauty of SMT lies in its ability to streamline the manufacturing process. With automated machines handling placement and soldering, production lines can operate at remarkable speeds while maintaining high precision. The result? A significant boost in efficiency and a reduction in overall manufacturing costs.

Historical Context of SMT

To fully appreciate what SMT technology is today, it's essential to consider its historical context. The roots of surface mount technology can be traced back to the 1960s when engineers sought ways to improve circuit assembly methods amid growing demands for miniaturization in electronics. Over the decades, advancements in materials and techniques have propelled SMT into mainstream use by the 1980s.

As manufacturers began adopting this innovative approach, they quickly realized that it could drastically reduce assembly times while enhancing performance reliability. Since then, SMT has evolved with new types of components and advanced machinery that facilitate even higher levels of integration on PCBs—a game changer for industries ranging from consumer electronics to aerospace.

Key Components of SMT

Understanding what are the key components involved in SMT is vital for anyone delving into this field. At its core, surface mount technology involves various passive and active components like resistors, capacitors, integrated circuits (ICs), and connectors—all designed specifically for surface mounting applications. These components are typically smaller than their through-hole counterparts due to their unique design characteristics.

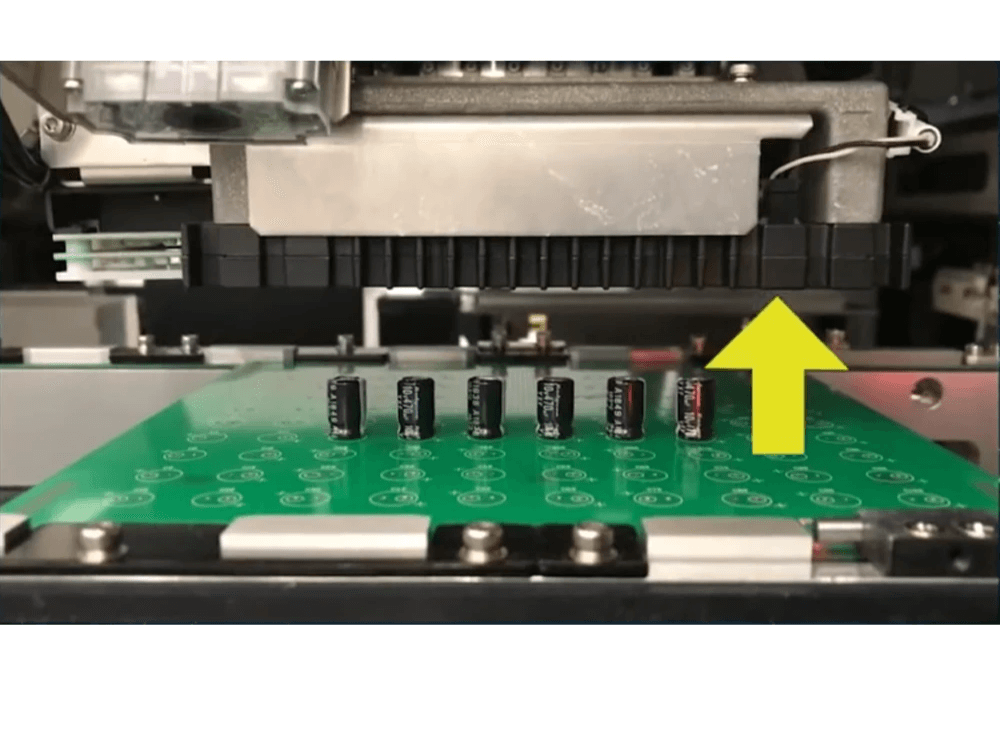

Moreover, specialized equipment plays an integral role in implementing SMT effectively; this includes pick-and-place machines that accurately position components on PCBs before soldering takes place. Additionally, reflow ovens ensure proper soldering by heating up connections uniformly—allowing manufacturers to achieve high-quality results consistently.

As we explore further into this fascinating topic, we will uncover not only what sets PCB apart from SMT but also why numerous industries are increasingly leaning toward this innovative approach—making it clear why understanding these concepts is essential for anyone involved in modern electronics manufacturing.

What is the Difference Between PCB and SMT?

When diving into the world of electronics, understanding the difference between traditional printed circuit boards (PCBs) and surface mount technology (SMT) is crucial. While both serve as fundamental components in electronic devices, their manufacturing processes, cost implications, and applications vary significantly. So, what is SMT technology? It’s a game-changer that has revolutionized how we approach circuit design and assembly.

Manufacturing Process Comparison

The manufacturing process for PCBs typically involves drilling holes for through-hole components, which are then inserted and soldered onto the board. In contrast, SMT technology allows components to be mounted directly onto the surface of the PCB without needing holes, leading to a more compact design. This difference in assembly not only streamlines production but also enhances reliability by reducing potential failure points associated with traditional methods.

In terms of efficiency, SMT offers significant advantages over conventional PCB manufacturing processes. The use of automated pick-and-place machines in SMT allows for faster assembly times compared to manual insertion techniques used for PCBs. Additionally, because components are smaller and lighter in SMT configurations, they can be densely packed on a single board—an essential factor in modern electronics where space is at a premium.

Cost-Effectiveness and Efficiency

Cost-effectiveness is another critical area where surface mount technology shines compared to traditional PCBs. Due to its efficient use of materials and reduced labor costs from automation, manufacturers often find that adopting SMT leads to lower overall production expenses. Moreover, with fewer materials required for soldering connections—thanks to direct mounting—the waste generated during production diminishes significantly.

Efficiency also extends beyond just cost; it includes time savings as well. With faster production cycles afforded by SMT technology, companies can bring products to market more quickly than ever before. This agility not only boosts profitability but also enhances competitiveness in an increasingly fast-paced electronics landscape.

Applications in Modern Electronics

The applications of surface mount technology are vast and varied across industries today—ranging from consumer electronics like smartphones and tablets to industrial equipment and automotive systems. As we explore what is the difference between PCB and SMT further, it's clear that SMT's compactness makes it ideal for devices where size constraints are paramount while still maintaining performance integrity.

Moreover, as electronic devices become more sophisticated with advanced functionalities integrated into smaller packages, manufacturers increasingly rely on SMT due to its flexibility in accommodating diverse component types—from resistors to complex microchips. Understanding why SMT is used helps underscore its significance: it not only meets modern demands but also anticipates future trends towards miniaturization in electronics.

Why is SMT Used?

Surface mount technology (SMT) has become a game-changer in the manufacturing landscape, and it’s not hard to see why. The advantages of SMT technology over traditional methods are numerous, making it the go-to choice for many manufacturers. From improved efficiency to reduced costs, understanding why SMT is used can illuminate its pivotal role in modern electronics.

Advantages Over Traditional Methods

One of the standout advantages of SMT technology is its ability to accommodate smaller components, which leads to more compact circuit designs. Unlike traditional through-hole mounting techniques, SMT allows for higher component density on printed circuit boards (PCBs), optimizing space and enhancing performance. Furthermore, this technology reduces assembly time and labor costs due to its automated processes—an appealing factor for manufacturers looking to streamline operations.

Impact on Production Speed

When considering why SMT is used, one cannot overlook its remarkable impact on production speed. With automated pick-and-place machines capable of placing thousands of components per hour, SMT drastically reduces the time from design to finished product. This acceleration not only meets market demands more effectively but also allows companies to pivot quickly in response to changing consumer preferences.

Quality Improvement Through SMT

Quality is another critical area where surface mount technology shines brightly. By minimizing human error through automation and enhancing solder joint reliability with precise placement, SMT ensures that products meet higher quality standards than those produced using traditional methods. Additionally, continuous advancements in inspection technologies further bolster quality control—making sure that every board meets rigorous specifications before it leaves the factory floor.

What Are the Three Types of SMT?

When diving into the world of SMT technology, it's essential to understand that there are primarily three types of surface mount technology components: Chip, Lead, and Ball Grid Array (BGA). Each type offers unique characteristics and advantages that cater to different manufacturing needs. As we explore these variations, we will also address what is SMT technology and how it fits into modern electronics.

Overview of Types: Chip, Lead, and Ball Grid Array

Chip components are the smallest in size among the three types of SMT. They typically come in rectangular or square shapes and are designed for high-density applications where space is at a premium. On the other hand, Lead components feature leads that extend from the sides or ends of the component; they provide a more robust connection but take up slightly more space than chip components. Lastly, Ball Grid Arrays utilize an array of solder balls beneath the component for electrical connections; this design allows for greater pin counts and improved thermal performance. Understanding these distinctions can help clarify what is the difference between PCB and SMT when considering your production setup.

Applications of Each Type

Chip components are widely used in consumer electronics due to their compact size and efficiency; think smartphones or wearable devices that require small yet powerful parts. Lead components find their niche in applications where durability is key—like automotive electronics—where vibrations might otherwise dislodge smaller chips. Meanwhile, Ball Grid Arrays shine in high-performance computing environments such as servers or gaming consoles, where they facilitate better heat dissipation while accommodating complex circuits with numerous connections.

Selecting the Right Type for Your Needs

Choosing between chip, lead, or ball grid array components requires careful consideration of your specific application requirements. If you're working on a project with limited space but high functionality expectations—like smartwatches—chip components may be your best bet due to their compact nature. Conversely, if you need robust connections capable of handling physical stress (think automotive parts), lead components could be ideal; for high-performance applications demanding both speed and reliability—such as advanced computing systems—ball grid arrays would likely serve you best.

Importance of SMT in Modern Manufacturing

In the rapidly evolving landscape of manufacturing, SMT technology has emerged as a cornerstone for efficiency and innovation. By enabling manufacturers to produce high-quality electronic devices with greater precision, this technology is not just a trend; it's a necessity. As we dive deeper into the importance of SMT in modern manufacturing, we’ll explore how it enhances precision and reliability, reduces facility footprint, and examine a success story from Bensun Technology.

Enhancing Precision and Reliability

One of the primary advantages of SMT technology is its ability to enhance precision and reliability in electronic assembly. Traditional methods often struggle with alignment issues that can lead to defects; however, surface mount technology utilizes automated processes that ensure components are placed accurately on printed circuit boards (PCBs). This level of precision minimizes errors during production and significantly boosts the overall quality of the final product.

Moreover, when discussing what is SMT technology?, it’s essential to highlight its reliance on advanced machinery such as pick-and-place machines that meticulously position components on PCBs. This not only improves yield rates but also allows for more complex designs without compromising reliability. The result? Manufacturers can confidently deliver products that meet stringent industry standards while reducing waste—a win-win for both business and environment.

Reducing Footprint in Production Facilities

Another significant advantage of surface mount technology lies in its ability to reduce the physical footprint required for production facilities. Unlike traditional through-hole components that require larger spaces due to their size and layout needs, SMT components are compact and can be densely packed onto PCBs. This means manufacturers can optimize their floor space while increasing output—an attractive proposition in today’s competitive market.

Additionally, by implementing what is the difference between PCB and SMT?, one quickly realizes that SMT allows for more efficient use of resources within manufacturing plants. With smaller equipment needed for assembly lines, companies can save on overhead costs related to real estate and utilities. Ultimately, embracing surface mount technology leads to streamlined operations where productivity flourishes without unnecessary expansion.

Case Study: Bensun Technology’s Success

To illustrate the transformative power of SMT technology in modern manufacturing, let’s take a closer look at Bensun Technology's journey after adopting this innovative approach. Initially struggling with high defect rates using traditional methods, they turned to surface mount technology as a solution to improve both quality and efficiency in their production processes.

By integrating what are the three types of SMT into their operations—chip resistors/capacitors, leaded devices like transistors, and ball grid arrays—they were able to expand their product offerings while maintaining exceptional standards across all lines. The results were staggering: not only did they see an increase in production speed but also a marked improvement in customer satisfaction due to fewer returns caused by defects.

Conclusion

In wrapping up our exploration of SMT technology, it's clear that this innovative approach is reshaping the landscape of modern manufacturing. As we look toward the future, the evolution of surface mount technology promises even greater efficiencies and capabilities. With advancements in automation and materials, SMT technology is set to become an indispensable part of production processes worldwide.

The Future of SMT Technology

The future of SMT technology appears bright, with ongoing research and development aimed at enhancing its efficiency and versatility. Innovations such as advanced robotics, AI integration, and improved materials are on the horizon, potentially revolutionizing how we understand what is SMT technology? These advancements will not only improve production speed but also lead to higher precision in assembling electronic components.

SMT as a Competitive Advantage

In today's fast-paced market, understanding what is the difference between PCB and SMT can give companies a significant edge over their competitors. By adopting surface mount technology, businesses can reduce production costs while increasing output quality—an unbeatable combination in any industry. Companies leveraging SMT are likely to enjoy enhanced market positioning due to their ability to deliver superior products more efficiently than those relying solely on traditional methods.

Embracing SMT for Sustainable Manufacturing

Sustainability is becoming increasingly vital across all industries, making it essential to consider why is SMT used? Surface mount technology not only minimizes material waste but also allows for smaller product designs—contributing to reduced energy consumption during manufacturing and transportation. By embracing this innovative approach, manufacturers can position themselves as environmentally responsible players in a competitive marketplace while reaping the benefits associated with modern production techniques.