Introduction

In the fast-paced world of electronics, the importance of a well-crafted PCB prototype cannot be overstated. Understanding PCB prototypes is crucial for anyone looking to bring an innovative idea to life, as they serve as the foundation for testing and refining your design before mass production. This introduction will explore key costs associated with PCB prototyping, helping you navigate your budget effectively while defining your specific PCB project needs.

Understanding PCB Prototypes

So, what is a PCB prototype? Simply put, it’s a preliminary version of a printed circuit board that allows engineers and designers to test their concepts and make necessary adjustments before production. A successful PCB prototype can save both time and money in the long run by identifying potential issues early in the development process.

Key Costs in PCB Prototyping

When considering how much does prototype PCB assembly cost, it’s essential to account for various factors such as materials, labor, and manufacturing techniques. Each of these elements contributes significantly to the overall expense of your project, making it vital to plan accordingly. By understanding these key costs upfront, you can better allocate resources and avoid surprises down the line.

Defining Your PCB Project

Before diving into prototyping, it's important to clearly define what is a PCB project for you or your organization. This involves outlining objectives, timelines, and desired outcomes so that everyone involved is on the same page from day one. Knowing how to make PCB prototyping efficient will ensure that you maximize productivity while minimizing costs throughout your project's lifecycle.

What is a PCB Prototype?

When diving into the world of electronics, one term that often pops up is PCB prototype. But what exactly is a PCB prototype? In essence, it’s a preliminary version of a printed circuit board (PCB) used to validate and test designs before mass production. This process not only ensures functionality but also serves as a crucial step in refining your ideas into tangible products.

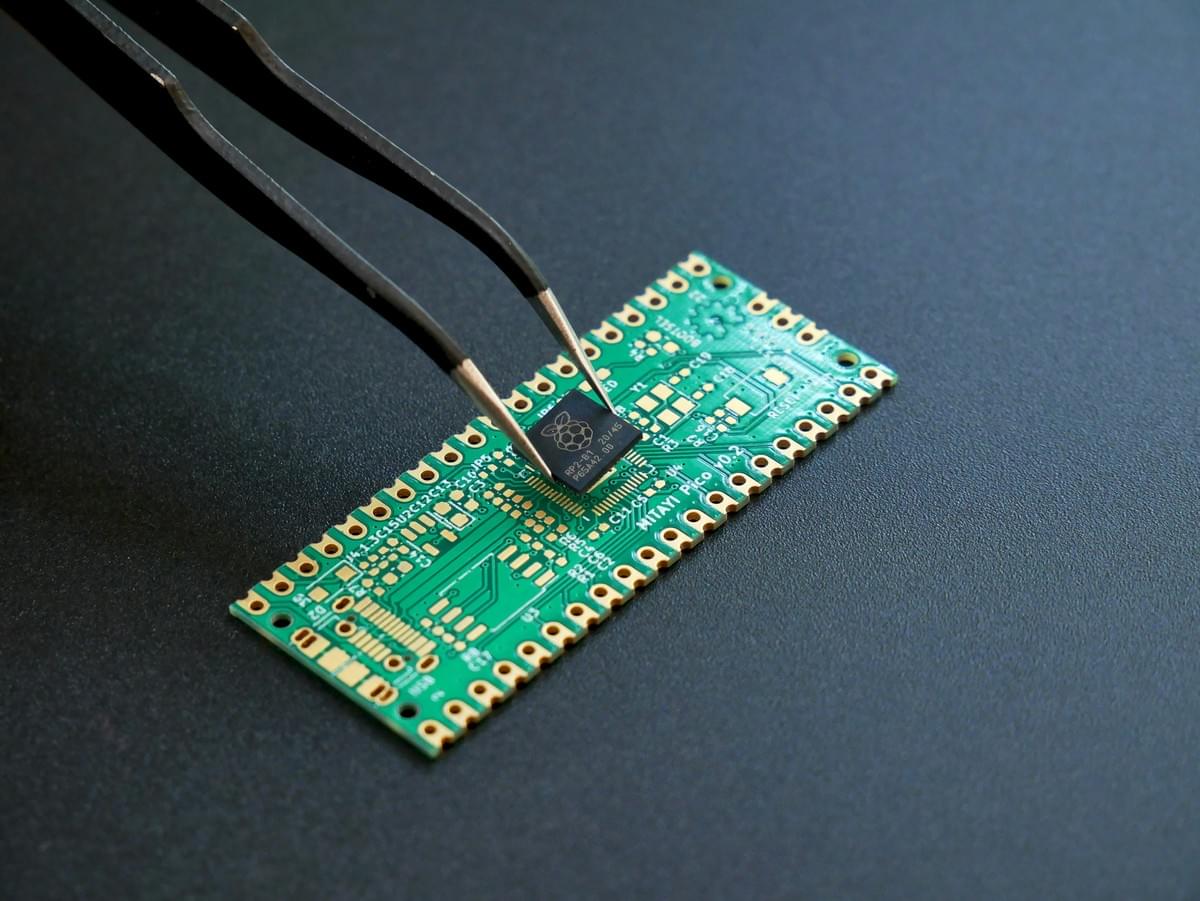

Basics of PCB Prototyping

At its core, PCB prototyping involves creating a small batch of circuit boards based on initial design specifications. These prototypes enable engineers to evaluate the performance and reliability of their designs under real-world conditions. Understanding the basics of PCB prototyping can help you navigate through your own project effectively, ensuring that you avoid common pitfalls along the way.

A well-crafted PCB prototype allows for testing various components and layouts without committing to large-scale production runs. This flexibility can save both time and money in the long run, particularly when addressing design flaws early in the process. Ultimately, mastering the basics of how to make PCB prototyping work for you will set you up for success in your projects.

Importance in Product Development

The importance of PCB prototypes in product development cannot be overstated; they serve as an essential bridge between concept and reality. By testing prototypes, designers can identify issues related to functionality or manufacturability before investing heavily in production costs. This critical phase helps mitigate risks associated with launching new products while fostering innovation.

Furthermore, engaging in thorough testing during this stage allows teams to iterate quickly based on feedback from stakeholders or end-users. It encourages collaboration between engineers and designers, leading to better overall product quality. In short, understanding what is a PCB project entails recognizing how vital prototypes are for refining those projects into viable solutions.

Common Types of PCB Prototypes

There are several common types of PCB prototypes that cater to different needs within the prototyping landscape. The most straightforward type is known as proof-of-concept prototypes; these focus primarily on validating basic functionality without extensive features or aesthetics involved. Then we have functional prototypes which are designed with more complexity and aim to showcase specific functionalities before finalizing designs.

Another popular option includes pre-production prototypes, which closely resemble the intended final product and allow for detailed testing prior to mass manufacturing decisions being made. Each type serves its purpose within various stages of product development—whether it's validating concepts or fine-tuning designs ahead of full-scale production runs—underlining how crucial it is to choose wisely based on project goals.

In conclusion, understanding what is a PCB prototype provides invaluable insight into successful electronic design projects while highlighting their significance throughout product development cycles.

Essential Components for Prototypes

Creating a successful PCB prototype requires careful consideration of several essential components. From selecting the right materials to utilizing effective design tools and adhering to best practices, each aspect plays a crucial role in the prototyping process. Understanding these components can significantly enhance the efficiency and effectiveness of your PCB project.

Choosing the Right Materials

When embarking on your PCB project, one of the first questions that arises is: What is a PCB prototype made of? The choice of materials can affect everything from performance to cost, so it’s essential to consider factors like substrate type, copper thickness, and solder mask options. For instance, FR-4 is a popular choice due to its balance of cost and performance; however, specialized applications might require materials like Rogers or aluminum substrates.

Moreover, how much does prototype PCB assembly cost? This often hinges on material selection; high-performance materials may increase initial costs but provide better durability and functionality in the long run. Therefore, weighing short-term expenses against long-term benefits is vital when choosing materials for your PCB prototype.

Key Design Tools and Software

In today’s digital age, having access to robust design tools is fundamental for crafting an effective PCB prototype. Software such as Eagle, Altium Designer, or KiCAD offers intuitive interfaces that simplify complex designs while ensuring accuracy throughout the prototyping process. These tools not only help visualize your circuit layout but also allow for simulations that can identify potential issues before moving into production.

Understanding how to make PCB prototyping efficient means leveraging these design tools effectively. They often come equipped with libraries of components that save time during the design phase while ensuring you’re using industry-standard parts in your project. By mastering these software solutions, you can streamline your workflow and minimize costly errors down the line.

Best Practices for PCB Layout

A well-executed layout can be the difference between a successful PCB prototype and one riddled with issues. Best practices include maintaining proper spacing between traces and components to avoid interference—especially critical in high-frequency applications where signal integrity is paramount. Additionally, implementing ground planes effectively helps reduce noise and enhances overall performance.

Another key consideration in layout design involves following standard practices regarding power distribution; this ensures that all parts receive adequate voltage without causing overheating or other failures during operation. Remember that neglecting these best practices could lead to increased costs later on—how much does prototype PCB assembly cost if you have to redo it? By prioritizing an optimized layout from the start, you set yourself up for success in both prototyping and eventual manufacturing stages.

How Much Does Prototype PCB Assembly Cost?

When diving into the world of electronics, one question often looms large: how much does prototype PCB assembly cost? The answer isn’t as straightforward as you might hope, as numerous factors come into play. From the complexity of your design to the materials used, understanding these elements can help you better estimate your budget for a PCB project.

Factors Influencing PCB Assembly Costs

Several key factors influence the costs associated with prototype PCB assembly. First and foremost is the complexity of your design; intricate layouts require more time and specialized skills to assemble, thereby increasing costs. Additionally, the choice of materials can significantly impact pricing; high-quality components or unique substrates may raise expenses but could also enhance performance.

Another crucial factor is the volume of PCBs being produced in a single run. Larger quantities often lead to lower per-unit costs due to economies of scale, while small batches might carry higher prices due to setup fees and labor intensity. Finally, turnaround time plays a role; if you need your PCBs assembled quickly, be prepared for expedited service fees that can add up fast.

Comparing Different Manufacturers

When it comes to understanding how much prototype PCB assembly costs, comparing different manufacturers is essential. Not all companies offer the same pricing structures or services; some may provide lower rates but compromise on quality or support. It's vital to evaluate not just cost but also reputation and reliability—after all, a cheap PCB prototype that fails in testing isn’t a bargain at all.

Look for manufacturers who provide transparent quotes detailing each aspect of their service—from design assistance to final assembly—so you can make informed decisions about what fits within your budget for your PCB project. Reviews and testimonials are invaluable here; they give insight into other customers' experiences and whether those manufacturers deliver on their promises.

Bensun Technology's Competitive Pricing

Bensun Technology stands out in the crowded field of PCB manufacturing with its competitive pricing structure tailored specifically for prototype projects. They understand that every penny counts when you're trying to get from concept to reality efficiently without sacrificing quality or speed in your prototyping process. Their transparent approach ensures clients are aware of all costs involved upfront, allowing for better financial planning.

With Bensun Technology’s services, you’re not just getting a low-cost option; you're gaining access to high-quality materials and expert knowledge that streamline production while keeping expenses manageable. Whether you're asking What is a PCB prototype? or How much does prototype PCB assembly cost?—Bensun provides clear answers and reliable solutions designed around your needs.

How to Make PCB Prototyping Efficient

In the fast-paced world of electronics, efficiency in PCB prototyping can be the difference between success and failure. To streamline your design process, minimize delays, and cut costs, it’s essential to focus on effective strategies that enhance productivity. This section will explore how to make PCB prototyping more efficient through streamlined processes, quick turnaround tips, and leveraging specialized services.

Streamlining Your Design Process

To truly grasp what is a PCB prototype? it’s crucial to start with a well-organized design process. Begin by clearly defining your objectives for the PCB project; this will help you avoid unnecessary revisions later on. Utilize design software that allows for easy collaboration among team members, ensuring everyone is on the same page from the outset.

Moreover, adopting modular designs can save time by allowing you to reuse components across different projects. This not only speeds up development but also reduces costs associated with creating entirely new designs from scratch. Streamlining your design process ultimately leads to faster iterations and a more efficient path toward producing your prototype.

Tips for Fast Turnaround

When asking how much does prototype PCB assembly cost? remember that time is often just as valuable as money in the prototyping phase. To achieve a fast turnaround, consider implementing rapid prototyping techniques such as 3D printing or using flexible manufacturing services that can quickly adapt to changes in your design specifications.

Additionally, prioritize communication with all stakeholders involved in the project; clear lines of dialogue can prevent misunderstandings that lead to delays. Establishing deadlines and milestones will also keep everyone accountable and focused on delivering results promptly.

Leveraging Bensun Technology's Services

One of the best ways to make PCB prototyping efficient is by leveraging specialized services like those offered by Bensun Technology. Their expertise in managing various aspects of PCB projects ensures you get high-quality prototypes without breaking the bank or sacrificing speed. With competitive pricing structures and advanced manufacturing capabilities, they provide an invaluable resource for anyone looking to streamline their prototyping efforts.

Bensun Technology also offers consulting services that guide you through common pitfalls associated with prototype development—helping you avoid mistakes before they happen! By utilizing their extensive experience in the field, you’ll find yourself equipped with knowledge on what is a PCB project? and how best to execute it efficiently.

Common Mistakes to Avoid in PCB Projects

When embarking on a PCB project, it's easy to overlook some critical aspects that can lead to costly delays and frustrations. Understanding what is a PCB prototype and the intricacies involved is crucial for success. By recognizing common pitfalls, you can navigate your project more smoothly and efficiently.

Underestimating Time and Budget

One of the biggest blunders in any PCB project is underestimating both time and budget. Many assume that once they have a solid design, the rest will fall into place seamlessly; however, this often isn’t the case. The reality of how much does prototype PCB assembly cost can be shocking if adequate time and resources aren't allocated from the start.

Budgeting for unexpected expenses, such as additional materials or redesigns, is essential for staying on track. Furthermore, rushing through phases of development can lead to mistakes that require even more time—and money—to fix later on. So take a deep breath, plan your timeline wisely, and ensure you have enough funds set aside for those pesky surprises.

Neglecting Testing and Iteration

Another common mistake in PCB projects is neglecting testing and iteration throughout the prototyping phase. Some may think that once they finalize their design, they’re good to go; unfortunately, this mindset can lead to major oversights. What is a PCB prototype without rigorous testing? It’s just an expensive piece of art!

Prototyping should be an iterative process where each version undergoes thorough testing before moving on to the next stage. This not only helps identify flaws early but also allows for refinements based on real-world performance data—making your final product far more reliable. Embrace testing as part of how to make PCB prototyping successful rather than viewing it as an afterthought.

Failing to Communicate with Manufacturers

Effective communication with manufacturers plays a pivotal role in ensuring your PCB project runs smoothly from conception through assembly. Failing to articulate your needs clearly can result in misunderstandings about specifications or features—leading you down a path riddled with frustration. Remember: manufacturers are not mind readers; sharing all relevant details about what you expect from your pcb prototype will save everyone time.

Regular check-ins during production help clarify any potential issues before they escalate into significant problems or delays in delivery timelines—because who wants their project stalled due to miscommunication? Staying engaged also allows you to ask questions about how much does prototype PCB assembly cost at different points during production so there are no surprises when it comes time for payment either!

In conclusion, avoiding these common mistakes can dramatically increase your chances of success in any PCB project while ensuring that you get the most out of what is a PCB prototype experience.

Conclusion

As we wrap up our exploration of PCB prototypes, it's clear that understanding the essentials of what a PCB prototype is can significantly impact your project’s success. From grasping the key costs associated with prototype PCB assembly to recognizing the importance of choosing the right materials and design tools, every detail matters. Prototyping isn’t just a step in product development; it’s the backbone that supports innovation and efficiency.

Recap of PCB Prototype Essentials

To summarize, a PCB prototype serves as a critical tool in validating your designs before mass production. Understanding how much prototype PCB assembly costs helps you budget effectively while selecting the right components and manufacturers can save you time and resources. Remember, best practices in layout design and testing are crucial for ensuring that your final product meets expectations.

Final Thoughts on Prototyping Success

Achieving success in prototyping hinges on thorough planning and execution. The journey of answering questions like “What is a PCB project?” or “How to make PCB prototyping?” leads to better outcomes when approached strategically. Embracing an iterative process allows for adjustments based on testing feedback, ultimately enhancing your product's reliability and performance.

Next Steps for Your PCB Project

Now that you’re equipped with knowledge about PCB prototypes, it’s time to take action! Start by defining your project requirements clearly, then research potential manufacturers who align with your needs—consider factors such as cost and turnaround times when asking “How much does prototype PCB assembly cost?” Lastly, don’t hesitate to reach out for expert assistance; leveraging services like those offered by Bensun Technology can streamline your prototyping efforts significantly.