Introduction

Navigating the realm of PCB assembly costs can feel like deciphering a complex puzzle, especially for those new to circuit card assembly. The intricacies of pricing stem from various factors—ranging from materials and labor to technological advancements in PCB manufacturing and assembly. Understanding these elements is crucial for anyone looking to optimize their budget while ensuring quality in their circuit board projects.

Understanding PCB Assembly Costs

PCB assembly costs encompass a wide array of expenses associated with the production and assembly of printed circuit boards. These costs are influenced by multiple variables, including the choice of components, manufacturing techniques, and even the geographical location of production facilities. By grasping how these factors interplay, businesses can make informed decisions that align with their budgetary constraints.

Key Components Affecting Prices

Several key components play a pivotal role in determining the overall price of PCB manufacturing and assembly. The type and quality of materials used are often at the forefront; high-grade components may elevate costs but can also enhance performance and longevity. Additionally, labor rates, technology employed in fabrication processes, and overhead expenses contribute significantly to the final pcb assembly cost.

Strategies for Reducing Costs

Reducing pcb manufacturing assembly costs doesn't have to be an uphill battle; strategic planning can yield significant savings without sacrificing quality. Designing for cost efficiency is one effective approach—considering how layouts affect material use can lead to lower expenses overall. Furthermore, leveraging partnerships with established firms like Bensun Technology can provide bulk purchasing benefits that further decrease circuit board production prices.

Breakdown of PCB Assembly Costs

Understanding the breakdown of PCB assembly costs is crucial for anyone involved in circuit card assembly. By identifying the various components that contribute to these costs, businesses can make informed decisions and optimize their budgets. This section will delve into material expenses, labor fees, and additional charges that together shape the overall pcb manufacturing and assembly price.

Material Expenses

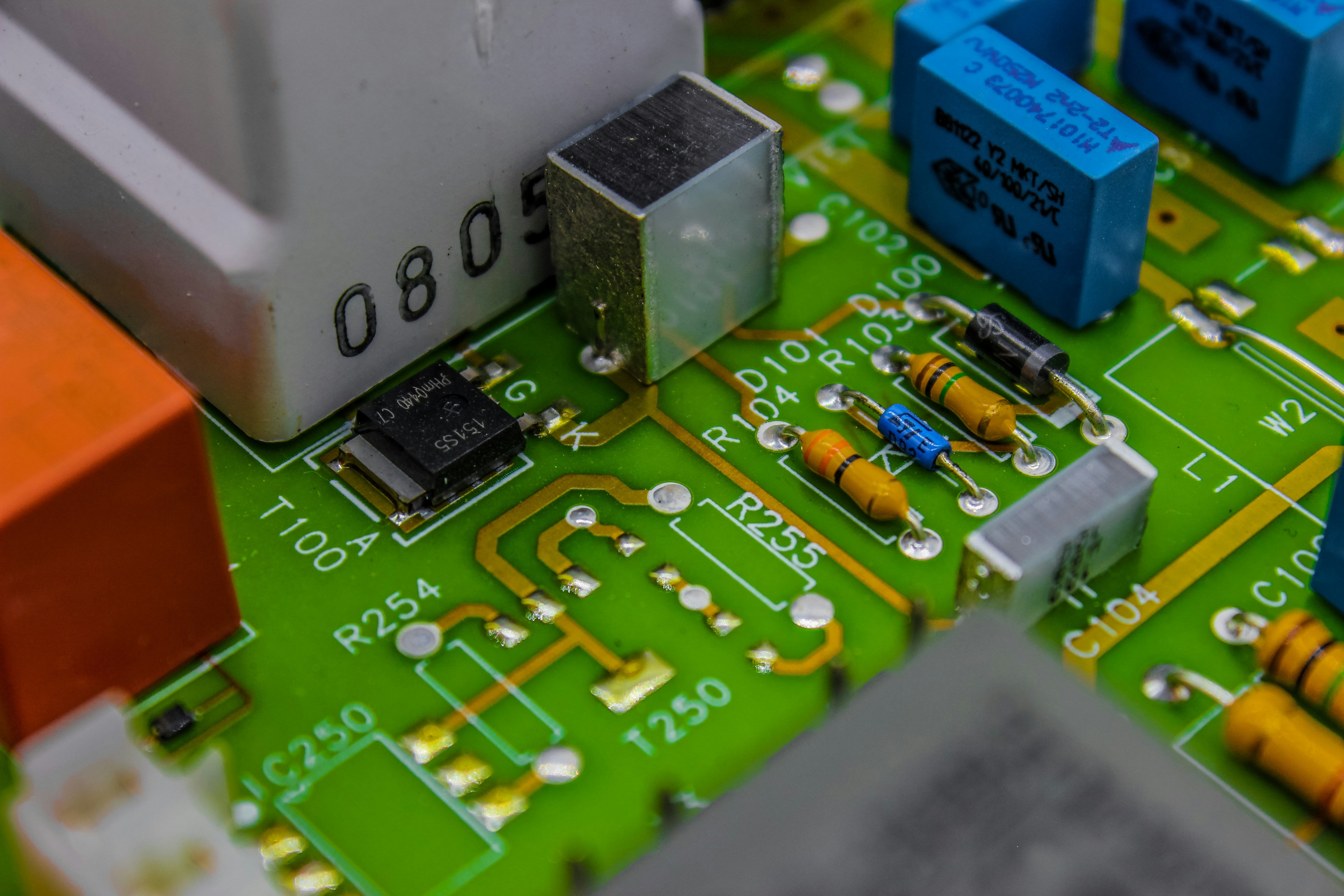

Material expenses are one of the most significant contributors to overall pcb assembly cost. The choice of components used in a circuit board can vary widely in price; from basic resistors to high-end microprocessors, each part impacts the final bill. Additionally, factors like sourcing quality materials and managing supply chain fluctuations can add unexpected costs to your pcb fab and assembly projects.

When selecting materials for your pcb assembly board, consider not just the upfront cost but also longevity and performance. Cheaper components may save money initially but could lead to higher replacement or failure rates down the line. Thus, investing in quality materials can ultimately reduce long-term expenses associated with repairs or replacements in your circuit card assembly.

Labor and Manufacturing Fees

Labor costs play a pivotal role in determining the total expense of pcb manufacturing and assembly. Skilled technicians are required for tasks ranging from soldering components onto a pcb assembly board to rigorous quality checks throughout production. As labor rates fluctuate based on location—whether local or overseas—understanding these fees is essential for accurate budgeting.

Manufacturing fees also vary depending on the complexity of the design and production processes involved in circuit board fabrication. More intricate designs typically require advanced machinery and longer processing times, further driving up costs associated with pcb manufacturing assembly. Therefore, careful planning during the design phase can help streamline production efforts while keeping labor costs manageable.

Overhead and Additional Charges

Overhead charges are often overlooked but significantly influence overall pcb assembly cost calculations. These include expenses like facility maintenance, utilities, equipment depreciation, and administrative salaries that support manufacturing operations behind-the-scenes. Understanding how overhead impacts pricing allows companies to identify areas where they might reduce unnecessary expenditures.

Additionally, there may be other charges related to shipping, handling, or even tariffs if you’re working with overseas suppliers for your circuit card assembly needs. Hidden fees can sneak up on you if not accounted for early on; thus transparency from your manufacturing partner is essential when estimating total project costs involving pcb fab and assembly services. By being mindful of these additional charges upfront, businesses can better navigate their budget constraints without compromising quality.

Price Factors in Circuit Card Assembly

When it comes to circuit card assembly, several price factors come into play that can significantly influence the overall PCB assembly cost. Understanding these factors is crucial for businesses looking to optimize their budgets and achieve the best possible outcomes in their PCB manufacturing and assembly processes. Let’s dive deeper into the key elements that affect pricing.

Component Types and Prices

The type of components used in a circuit board can dramatically impact the PCB assembly cost. High-performance components, such as specialized microcontrollers or high-frequency capacitors, tend to be more expensive than standard parts, which can inflate the overall budget for your circuit card assembly project. Additionally, sourcing rare or hard-to-find components may lead to increased prices due to limited availability and higher shipping costs.

Another consideration is the quantity of components required for your PCB manufacturing and assembly project. Larger orders often allow for bulk purchasing discounts, which can help mitigate some of the expenses associated with component types and prices. However, if you’re working with a small batch size or custom parts, you might find yourself facing higher per-unit costs that could strain your budget.

Lastly, keep in mind that component prices fluctuate based on market demand and supply chain dynamics. Staying informed about trends in component pricing can help you make more strategic decisions when selecting parts for your PCB assembly board.

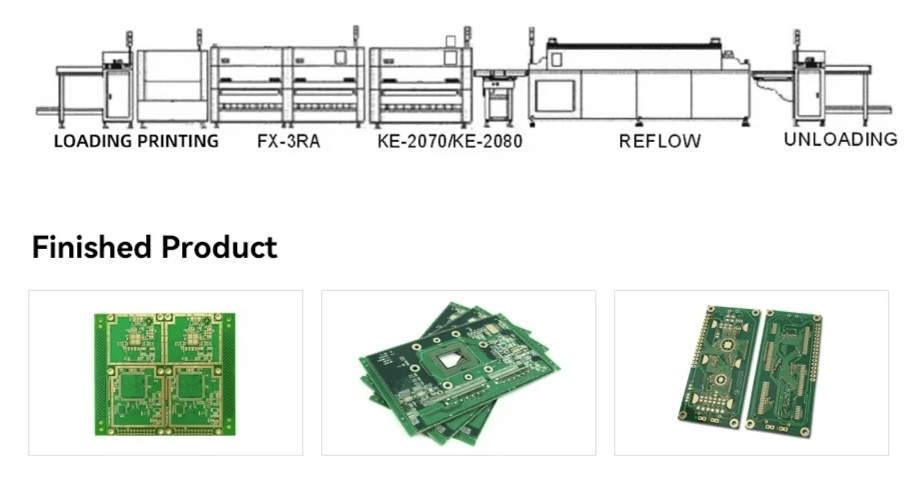

Technology in PCB Manufacturing

The technology employed in PCB manufacturing plays a significant role in determining overall costs associated with circuit card assembly. Advanced technologies such as surface mount technology (SMT) or through-hole technology each have unique implications on both labor and material expenses during the PCB fab and assembly process. While SMT may offer faster production times due to its automated nature, it might require an initial investment in specialized equipment that could raise upfront costs.

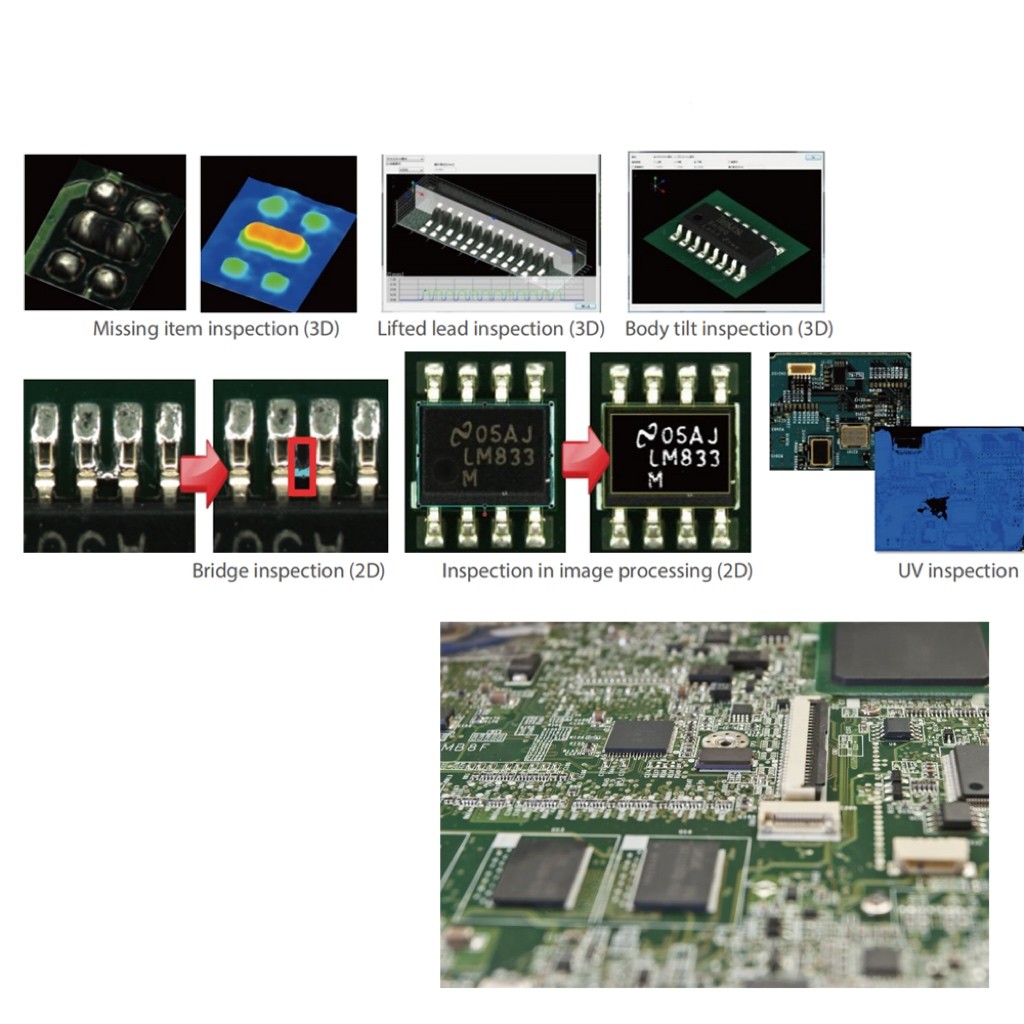

Moreover, innovations like automated optical inspection (AOI) systems enhance quality assurance during production but also add another layer of expense to your manufacturing budget. Investing in cutting-edge technologies may yield long-term savings by reducing defects and rework rates; however, it's essential to weigh these benefits against immediate financial implications when considering your options.

Additionally, staying abreast of emerging technologies within the realm of PCB manufacturing can provide opportunities for cost savings over time as new methods emerge that streamline processes or reduce material usage—ultimately impacting your circuit card assembly expenditures positively.

Scale of Production and Its Impact

The scale of production is a critical factor influencing both unit costs and overall PCB assembly cost effectiveness. Generally speaking, larger production runs tend to lower per-unit expenditures due to economies of scale; this means that while initial setup fees might be higher for smaller batches, spreading those costs across a greater number of units often leads to lower individual prices per circuit board produced.

However, smaller-scale projects might benefit from flexibility at the expense of higher per-unit prices when engaging with PCB manufacturing assemblies designed for low-volume runs or prototypes. In such cases where rapid iterations are necessary—particularly during product development phases—the trade-off between cost efficiency and speed becomes essential when deciding on how best to approach production scaling.

Ultimately, understanding how scale impacts pricing allows businesses to make informed decisions regarding order quantities while balancing immediate needs against long-term financial implications related to their specific circuit card assembly projects.

Navigating PCB Manufacturing and Assembly

Finding the right partner for your PCB manufacturing and assembly can feel like dating in a digital age—there are plenty of options, but choosing the right one is crucial. The ideal PCB manufacturing partner should not only understand your specific needs but also have a proven track record in circuit card assembly. A solid relationship with a reliable partner can significantly influence your overall pcb assembly cost and ensure that your project runs smoothly from start to finish.

Selecting the Right PCB Manufacturing Partner

When searching for a PCB manufacturing partner, consider their experience in both pcb fab and assembly as well as their capability to handle various circuit board types. Look for manufacturers who specialize in the specific technologies you require, whether it’s through-hole or surface mount technology. Additionally, don’t forget to check reviews or testimonials—after all, you want someone who has successfully navigated the challenges of pcb manufacturing and assembly before.

Communication is also key; a responsive manufacturer can help resolve issues quickly, keeping your project on schedule and within budget. Establishing clear lines of communication will help you manage expectations regarding timelines and costs associated with your pcb assembly board. In essence, selecting the right partner is about finding someone who understands both the technical aspects of manufacturing as well as the financial implications tied to those processes.

Importance of Quality Assurance

Quality assurance is paramount when it comes to circuit board production; after all, even minor defects can lead to significant failures down the line. Ensuring that your chosen manufacturer employs rigorous quality control measures will help you avoid costly reworks or product recalls that could inflate your overall pcb assembly cost dramatically. Look for certifications such as ISO 9001 or IPC standards that indicate adherence to high-quality practices in pcb manufacturing assembly.

Moreover, investing time upfront in quality assurance processes might save you money later by ensuring that components are correctly assembled from the get-go. Regular inspections during production can catch potential issues early on—better safe than sorry! This proactive approach not only enhances reliability but also builds confidence in your final product's performance.

Local vs. Overseas Manufacturing Costs

Deciding whether to go local or overseas for your pcb manufacturing and assembly needs involves weighing multiple factors beyond just price tags on paper. While overseas manufacturers often offer lower labor costs which may seem appealing at first glance, consider other hidden costs like shipping fees, longer lead times, and potential language barriers that could complicate communication about circuit card assembly requirements.

On the flip side, working with local manufacturers usually provides faster turnaround times and easier access for quality checks throughout production phases—this can be invaluable when you're racing against tight deadlines! Ultimately, understanding how these factors affect overall pcb fab and assembly costs will empower you to make informed decisions that align with both budget constraints and project timelines.

How to Save on PCB Assembly

When it comes to managing pcb assembly costs, a strategic approach can lead to significant savings. Understanding how each component of the process contributes to the overall expenses is essential for any project manager or engineer. By implementing cost-saving strategies, businesses can optimize their circuit card assembly without compromising on quality.

Designing for Cost Efficiency

Designing for cost efficiency is the first step toward minimizing pcb assembly costs. By simplifying circuit board layouts and reducing the number of components, engineers can streamline manufacturing processes, which ultimately lowers labor and material expenses. Additionally, choosing standard component sizes often leads to better pricing from suppliers, making your pcb manufacturing and assembly more budget-friendly.

Moreover, considering factors like trace width and spacing during design can prevent costly modifications later in the production process. Utilizing design software that highlights potential issues before fabrication can also save time and resources in both pcb fab and assembly phases. Ultimately, a well-thought-out design not only enhances functionality but also ensures that your circuit board remains within budget constraints.

Bulk Purchasing Benefits

Another effective way to cut down on circuit card assembly costs is through bulk purchasing benefits. When components are bought in larger quantities, manufacturers typically offer discounts that can significantly reduce overall material expenses for your pcb manufacturing assembly projects. This strategy not only lowers individual component prices but also minimizes shipping costs per unit.

Additionally, establishing long-term relationships with suppliers can yield even greater savings over time as they may provide exclusive deals or priority service for repeat customers. It’s essential to analyze your projected needs carefully so you don’t over-purchase components that may become obsolete or outdated before use. In short, bulk purchasing effectively leverages economies of scale while ensuring you have enough stock on hand for future projects.

Leveraging Partnerships with Bensun Technology

Leveraging partnerships with companies like Bensun Technology offers another pathway to reduce pcb assembly costs effectively. Through collaboration with established firms specializing in both pcb fabrication and assembly, businesses gain access to advanced technologies and optimized processes that drive down production expenses while maintaining high-quality standards. Bensun’s expertise in efficient circuit board manufacturing allows clients to benefit from their streamlined operations and cost-effective solutions.

Furthermore, partnering with a reliable manufacturer means you’re less likely to encounter unexpected delays or quality issues that could inflate overall project costs later on. Their experience in managing supply chains ensures timely delivery of materials at competitive prices—an invaluable asset when aiming for budget-friendly pcb manufacturing and assembly solutions. Embracing such partnerships ultimately transforms cost-saving measures into long-term strategic advantages.

Understanding PCB Fabrication Processes

When diving into the world of PCB fabrication, it’s essential to recognize the various methods that can significantly influence your overall PCB assembly cost. Each type of circuit board fabrication comes with its own set of advantages and challenges, impacting everything from production speed to material selection. Understanding these processes will empower you to make informed decisions that can lead to substantial savings in your circuit card assembly projects.

Different Types of PCB Fabrication

PCB fabrication can be broadly categorized into several types, including single-sided, double-sided, and multilayer boards. Single-sided PCBs are the most straightforward option, offering a cost-effective solution for simpler electronic devices; however, they may not always meet the needs of more complex applications. On the other hand, double-sided and multilayer boards provide increased functionality but often come with higher pcb assembly costs due to more intricate manufacturing processes and additional materials.

Another factor is the use of rigid vs. flexible PCBs; while rigid boards are standard in many applications, flexible PCBs offer unique advantages in space-constrained designs but can also drive up costs due to specialized manufacturing techniques. Additionally, advanced technologies like HDI (High-Density Interconnect) allow for smaller features and greater component density but may require more sophisticated equipment and expertise in pcb manufacturing and assembly. Ultimately, choosing the right type of PCB fabrication depends on balancing performance requirements with budget constraints.

Innovations Impacting Production Costs

In recent years, innovations in technology have dramatically transformed pcb fab and assembly processes, leading to both reduced production times and lower costs associated with circuit board manufacturing. Automation plays a crucial role here; automated machinery streamlines tasks such as soldering and inspection, which not only enhances precision but also minimizes labor expenses tied to manual operations. Furthermore, advancements in materials—such as lower-cost substrates or eco-friendly options—can help reduce overall pcb assembly cost without compromising quality.

Moreover, software tools for design optimization have emerged as game-changers in reducing waste during production runs; by simulating layouts before physical prototyping begins, companies can avoid costly mistakes that could inflate their circuit card assembly expenses later on. Innovations like 3D printing for rapid prototyping also offer a glimpse into future possibilities where initial design iterations could be tested at a fraction of traditional costs before committing to full-scale production runs in pcb manufacturing assembly environments. Embracing these innovations allows businesses to stay competitive while managing their budgets effectively.

Timeline and Its Effect on Pricing

The timeline associated with PCB fabrication significantly affects pricing structures within the industry; faster turnaround times often come at a premium price point due to expedited shipping fees or prioritized labor allocation during peak periods. If you’re able to plan ahead and allow for longer lead times on your project timelines, you may unlock opportunities for reduced rates on both materials and labor costs associated with circuit board manufacturing processes. This is particularly relevant when considering bulk orders or contracts that allow manufacturers flexibility in scheduling.

Additionally, understanding how different stages of production—from design through testing—impact overall timelines enables better project management strategies that align with budgetary goals related to pcb assembly cost management. For instance, rushing through prototype phases might hinder thorough testing procedures which could lead backtracking later if issues arise post-production—ultimately inflating costs even further down the line during subsequent iterations or repairs needed after initial deployment phases are complete within your circuit card assembly projects.

Conclusion

In the realm of electronics, understanding PCB assembly cost is crucial for any project’s success. Budgeting effectively for PCB manufacturing and assembly can make the difference between a profitable venture and financial strain. By recognizing the various factors that contribute to these costs, businesses can better navigate their expenses and optimize their circuit card assembly processes.

The Importance of Budgeting for PCB Assembly

Budgeting for PCB assembly is not just a good practice; it’s essential for maintaining financial health in your projects. By establishing a clear budget, you can allocate resources wisely across different aspects of circuit board production, from material selection to labor costs. This foresight helps prevent unexpected expenses that could derail your project or lead to compromises in quality.

Making Informed Decisions on Components

Choosing the right components is pivotal when considering PCB assembly cost. Each decision regarding component types and specifications directly influences both the final price and performance of your circuit card assembly. By doing thorough research and consulting with experts in PCB manufacturing and assembly, you can select components that balance cost-efficiency with reliability.

Long-Term Strategies for PCB Assembly Savings

To achieve lasting savings in PCB manufacturing assembly, consider implementing long-term strategies that focus on efficiency and innovation. Designing your pcb assembly board with cost-saving measures in mind—like minimizing complex layouts or opting for standard components—can significantly lower expenses over time. Additionally, building strong partnerships with trusted suppliers like Bensun Technology fosters collaboration that often leads to bulk purchasing benefits, further reducing overall costs associated with circuit board production.