Introduction

In the ever-evolving world of electronics, ensuring the longevity and reliability of devices is paramount. One effective solution for achieving this is through the use of conformal coating, a protective layer that shields PCB circuit boards from environmental factors. Understanding the benefits and applications of circuit board coating not only enhances product durability but also contributes to overall performance in various industries.

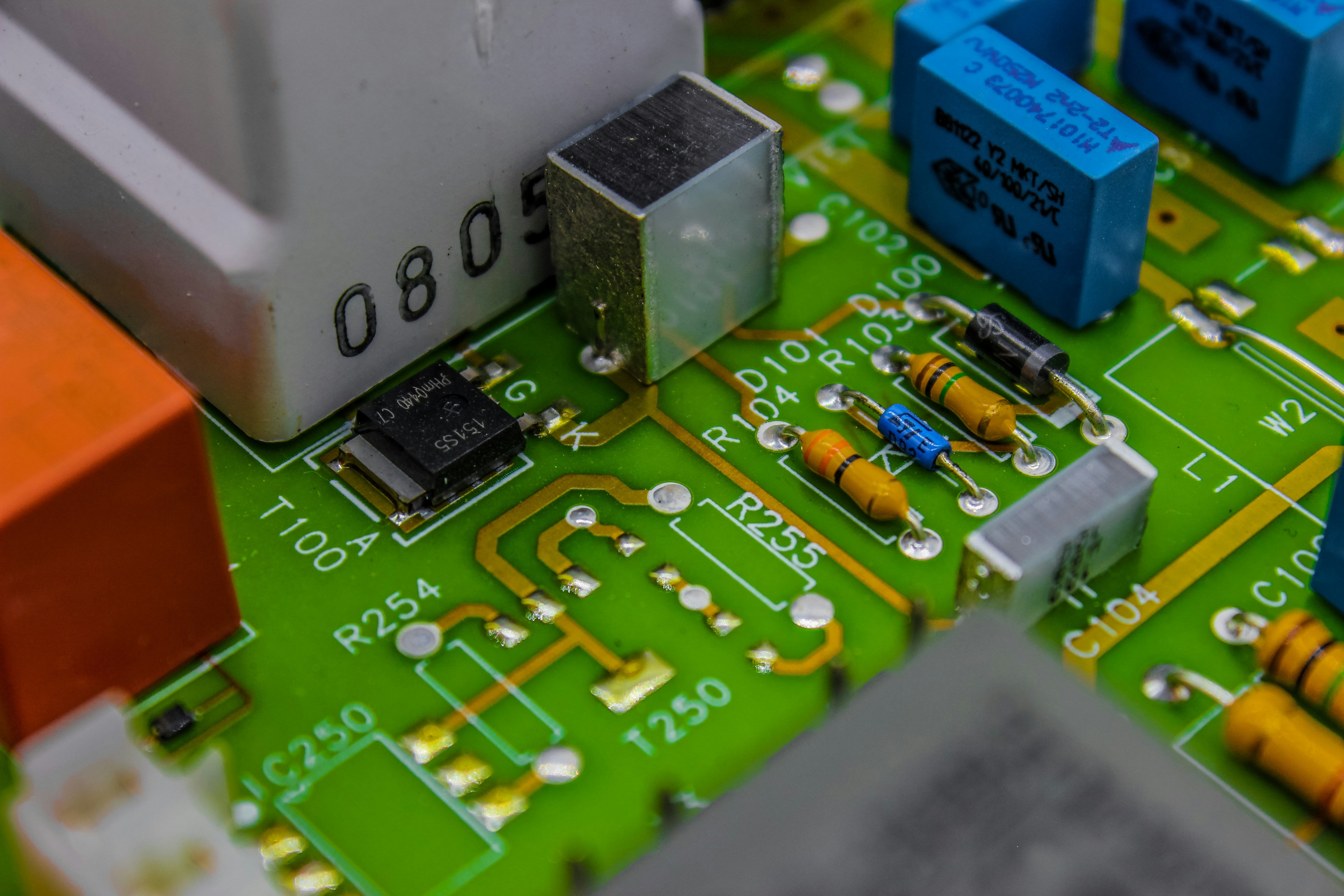

Understanding Conformal Coating Benefits

Conformal coating serves as a vital line of defense for PCB printed circuit boards, protecting them from moisture, dust, chemicals, and temperature fluctuations. This layer provides enhanced environmental resistance, which is crucial in preventing corrosion and short-circuiting that can occur due to exposure to harmful elements. Moreover, the application of conformal coating can significantly extend the lifespan of electronic components, making it a cost-effective choice for manufacturers looking to improve their product reliability.

Types of Conformal Coating Materials

When it comes to selecting a conformal coating for your circuit PCB board, there are several materials available with distinct properties suited for different applications. Common types include acrylics, polyurethanes, silicones, and epoxy coatings—each offering unique advantages depending on environmental conditions and performance requirements. By understanding these materials' characteristics, manufacturers can make informed decisions about which circuit board coating will best protect their PCB circuit boards.

Applications of Conformal Coating in Industries

Conformal coatings find widespread application across various industries including automotive, aerospace, consumer electronics, and medical devices. In these sectors where reliability is non-negotiable, using a quality conformal coating ensures that sensitive electronic components remain operational even under challenging conditions. As technology continues to advance and devices become more compact and intricate, the role of effective circuit board coatings becomes increasingly critical in maintaining functionality over time.

What is Conformal Coating?

Conformal coating refers to a protective layer applied to printed circuit boards (PCBs) to shield them from environmental hazards. This coating conforms to the contours of the underlying components, providing a barrier against moisture, dust, chemicals, and temperature fluctuations. By understanding its definition and purpose, we can appreciate how vital it is for the longevity and reliability of PCB circuit boards.

Definition and Purpose

At its core, conformal coating is a thin polymeric film that adheres to the surface of electronic components on a circuit board. Its primary purpose is to protect sensitive electronic parts from various environmental conditions that could lead to failure or degradation over time. By creating this protective layer, manufacturers ensure that their PCB circuit boards can withstand challenging operating environments without compromising performance.

Importance in Circuit Board Protection

The importance of conformal coating in circuit board protection cannot be overstated; it plays a crucial role in enhancing the durability of PCB printed circuit boards. Environmental factors such as humidity, dust, and corrosive substances can wreak havoc on uncoated electronics, leading to short circuits or complete failures. With a proper circuit board coating in place, manufacturers can significantly reduce maintenance costs and increase product reliability across various industries.

Types of Circuit Board Coatings

There are several types of coatings available for PCB circuits, each offering unique benefits tailored for specific applications. Common materials include acrylics, polyurethanes, silicones, and epoxies—each with distinct properties suited for different environments and performance requirements. Understanding these options allows manufacturers to choose the right conformal coating that best meets their needs while ensuring optimal protection for their circuit PCB boards.

How Conformal Coating Works

Conformal coating plays a critical role in enhancing the durability and reliability of circuit board assemblies. By providing a protective layer over PCB printed circuit boards, it shields sensitive electronic components from environmental factors such as moisture, dust, and chemicals. Understanding how this application process unfolds is essential for anyone involved in electronics manufacturing or maintenance.

The Application Process

The application process of conformal coating involves several key steps to ensure optimal coverage and effectiveness on the circuit board. Initially, the PCB circuit board must be thoroughly cleaned to remove any contaminants that could interfere with adhesion. Once prepped, various methods such as spraying, brushing, or dipping can be employed to apply the coating conformal evenly across all surfaces of the circuit board.

After applying the conformal coating, it’s essential to inspect for any missed spots or bubbles that could compromise protection. A meticulous approach ensures that every nook and cranny of the PCB printed circuit board is covered adequately. This attention to detail during the application process significantly contributes to the overall effectiveness of the coating.

Curing Methods Explained

Once applied, curing methods come into play to solidify the conformal coating on your circuit PCB board. There are several techniques available including air drying, heat curing, and UV curing—each with its own advantages depending on production needs. Heat curing accelerates polymerization through elevated temperatures while UV curing utilizes ultraviolet light for quick hardening; both methods enhance adhesion and durability.

Understanding these curing processes is crucial because improper curing can lead to issues like peeling or insufficient protection against environmental stressors. The choice of method often depends on production speed requirements and material compatibility with specific types of coatings used on PCB circuits. Ultimately, proper curing ensures that your conformal coating performs effectively over time.

Effects on PCB Reliability

The impact of conformal coating on PCB reliability cannot be overstated; it acts as a formidable barrier against potential hazards that threaten electronic components' functionality. By protecting against moisture ingress and corrosive elements, conformal coatings significantly extend the lifespan of a pcb circuit board under challenging conditions. Additionally, they help maintain electrical performance by preventing short circuits caused by contaminants.

Moreover, enhanced reliability translates into reduced maintenance costs and improved overall performance for devices utilizing coated PCBs in various industries—from automotive to aerospace applications. As technology evolves and devices become increasingly compact yet complex, ensuring reliable operation through effective coatings becomes paramount for manufacturers looking to stay competitive in today’s market landscape.

Benefits of Using Conformal Coating

When it comes to protecting PCB circuit boards, conformal coating is a game changer. This protective layer offers several benefits that enhance the durability and reliability of electronic components. By applying a suitable circuit board coating, manufacturers can ensure their products withstand various environmental challenges.

Enhanced Environmental Resistance

One of the standout advantages of conformal coating is its ability to enhance environmental resistance for circuit PCB boards. Whether it's humidity, dust, or corrosive chemicals, these coatings provide a barrier that keeps harmful elements at bay. The result? A significant reduction in potential failures and malfunctions caused by environmental factors.

Moreover, conformal coatings can also protect against thermal cycling and mechanical stress that often plague PCB printed circuit boards in demanding applications. This resilience not only safeguards the integrity of the circuit board but also maintains performance over time. In industries where reliability is paramount, such as automotive and aerospace, enhanced environmental resistance is non-negotiable.

Improved Longevity of PCB Circuit Boards

Another compelling reason to consider conformal coating is its contribution to the improved longevity of PCB circuit boards. By providing a protective layer, these coatings help prevent wear and tear that could lead to premature failure. As electronic devices become more compact and complex, ensuring the longevity of each component becomes increasingly crucial.

Additionally, with reduced exposure to moisture and contaminants, the lifespan of coated PCBs can be significantly extended compared to uncoated alternatives. This means fewer replacements and repairs over time—an attractive proposition for manufacturers looking to optimize costs while maintaining quality standards. Ultimately, investing in high-quality conformal coating translates into longer-lasting products for end-users.

Cost-Effective Protection for Electronics

Cost-effectiveness is often a deciding factor when selecting protective measures for electronic components like PCB printed circuit boards. Conformal coatings offer an economical solution by reducing maintenance costs associated with failures due to environmental damage or wear over time. By preventing corrosion and other forms of degradation, these coatings save companies money in both repairs and replacements.

Furthermore, implementing a reliable coating conformal strategy can lead to increased production efficiency—less downtime means more productivity overall! When considering the long-term benefits versus initial investment costs, it's clear that conformal coatings represent an excellent return on investment for businesses across various sectors. So why not give your electronics the protection they deserve?

Choosing the Right Conformal Coating

Selecting the right conformal coating for your circuit board can feel like a daunting task, but it doesn't have to be. With a variety of options available, understanding the specific needs of your PCB circuit board is crucial for optimal performance and longevity. Factors such as environmental conditions, desired durability, and application methods should guide your decision-making process.

Factors to Consider

When choosing a conformal coating, you must consider several key factors. First and foremost is the environment in which the PCB printed circuit board will operate; exposure to moisture, chemicals, or extreme temperatures can significantly impact performance. Additionally, think about the type of components on your circuit PCB board—some coatings may not adhere well to certain materials or may interfere with component functionality.

Another important factor is the application method you plan to use for the coating conformal process. Some coatings are better suited for spray applications while others work best with dip or brush techniques. Finally, consider curing times and methods; some coatings require heat curing while others cure at room temperature, affecting production timelines.

Popular Coating Materials Overview

There are several popular materials used in circuit board coating that cater to diverse needs in various industries. Polyurethane coatings are favored for their excellent moisture resistance and flexibility, making them ideal for applications exposed to harsh environments. Silicone coatings offer great thermal stability and are often chosen for their ease of application and removal when repairs are necessary.

Acrylic coatings provide good protection against humidity and dust but may not withstand harsh chemicals as well as other materials do. Epoxy coatings are known for their toughness and durability but can be more challenging to remove if repairs on the PCB circuit board become necessary. Understanding these options allows you to make an informed choice based on your specific requirements.

Role of Bensun in Coating Solutions

Bensun stands at the forefront of providing high-quality conformal coating solutions tailored specifically for diverse industries' needs. Their extensive range of products ensures that whether you're working with a delicate PCB printed circuit board or a robust industrial application, there's an optimal solution available just for you. With Bensun's expertise in selecting suitable materials and offering guidance throughout the application process, achieving effective protection through circuit board coating has never been easier.

Moreover, Bensun emphasizes customer education by providing resources that help clients understand how different factors influence their choices in conformal coating selection—making them not just suppliers but partners in ensuring quality PCB circuits perform reliably over time.

Common Challenges with Conformal Coating

While conformal coating offers numerous benefits for protecting PCB circuit boards, it is not without its challenges. Understanding these common obstacles can help manufacturers and engineers ensure effective application and optimal performance of their circuit board coatings. Addressing these issues proactively can lead to enhanced reliability of the final product.

Application Difficulties

One of the primary challenges with conformal coating is ensuring uniform application across all surfaces of the PCB printed circuit board. Factors such as component density, geometry, and accessibility can complicate the coating process, leading to uneven coverage or missed areas entirely. Additionally, achieving the right thickness is crucial; too thin a layer may not provide adequate protection while too thick a layer can lead to problems like cracking or peeling.

Another significant hurdle is selecting the appropriate application method for specific environments and requirements. Techniques such as spraying, dipping, or brushing each have their own advantages and drawbacks depending on the intricacies of the circuit PCB board design. Ensuring that technicians are well-trained in these methods can mitigate application difficulties significantly.

Lastly, environmental factors during application must also be considered; temperature and humidity levels can affect how well the conformal coating adheres to surfaces. Fluctuations in these conditions may result in improper curing or adhesion issues that compromise the integrity of the circuit board coating. Thus, maintaining an optimal environment during application is key to achieving high-quality results.

Potential Performance Issues

Even after successful application, conformal coatings can present performance issues that affect PCB reliability over time. One common concern involves moisture entrapment beneath the coating layer; if any moisture remains trapped during curing, it could lead to corrosion or electrical failures down the line. This underscores why thorough cleaning before applying any circuit board coating is vital.

Moreover, some coatings may not perform well under extreme conditions such as high temperatures or exposure to chemicals found in certain environments. If a PCB circuit board operates outside its intended specifications—like being exposed to solvents—it could compromise both functionality and longevity of electronic components coated with less resilient materials. Thus, selecting a suitable conformal coating material tailored for specific applications becomes essential for maintaining performance standards.

Lastly, compatibility between different materials used on a printed circuit board poses another challenge; certain coatings might react adversely with solder masks or other components on the PCB circuit board itself. Such reactions could lead to delamination or other detrimental effects that ultimately diminish overall product quality and reliability over time.

Solutions for Effective Coating

To tackle these challenges effectively requires a strategic approach rooted in best practices for applying conformal coatings on PCB circuits confidently and consistently. First off, conducting thorough surface preparation cannot be overstated—this includes cleaning components meticulously prior to applying any type of conformal coating so as to eliminate contaminants that could hinder adhesion.

In addition, utilizing automated dispensing systems can enhance precision during application processes while reducing human error associated with manual techniques like brushing or spraying—ensuring even distribution across complex geometries found on modern PCB printed circuit boards becomes much easier this way! Moreover, investing in training programs focused on proper techniques will empower technicians with knowledge needed for overcoming common hurdles encountered during applications regularly.

Finally—and perhaps most importantly—conducting rigorous testing after application ensures that any potential issues are identified early before they escalate into larger problems down the road! Implementing environmental testing procedures helps confirm whether chosen materials withstand real-world conditions effectively while providing peace-of-mind regarding long-term durability expected from quality conformal coatings applied correctly.

Conclusion

In summary, conformal coating is a crucial aspect of ensuring the longevity and reliability of PCB circuit boards. Understanding the types of circuit board coatings available and their applications can significantly enhance the performance of electronic devices, making them more resilient against environmental factors. This protective layer not only shields sensitive components but also extends the lifespan of the entire circuit PCB board.

Key Takeaways on Conformal Coating

Conformal coating serves as an essential barrier for PCB printed circuit boards, providing protection against moisture, dust, and other contaminants. By selecting the appropriate coating conformal material, manufacturers can optimize their products for specific environments and operational conditions. Ultimately, investing in quality conformal coating translates to improved reliability and decreased maintenance costs for circuit board applications.

Future Trends in Circuit Board Coating

As technology continues to evolve, we can expect advancements in circuit board coatings that offer enhanced performance characteristics such as greater flexibility and improved thermal resistance. Innovations in materials science may lead to eco-friendly options that reduce environmental impact while maintaining high levels of protection for PCB circuits. Furthermore, automation in the application process could streamline production lines, making conformal coating even more accessible for manufacturers worldwide.

Resources for Further Learning on PCB Technology

To deepen your understanding of conformal coatings and their impact on PCB technology, consider exploring industry publications such as IPC's technical standards or attending relevant trade shows focused on electronics manufacturing. Online platforms like webinars from leading experts provide valuable insights into emerging trends in circuit board coatings and best practices for application techniques. Additionally, websites dedicated to electronics engineering often feature articles discussing recent advancements related to circuit board coating technologies.