Introduction

In the fast-paced world of electronics manufacturing, understanding insertion machines is crucial for optimizing production processes. These machines play a pivotal role in placing electronic components onto printed circuit boards (PCBs), ensuring that devices function effectively and efficiently. With the rise of automated solutions, selecting the right machine can significantly impact not only productivity but also the overall quality of electronic products.

Understanding Insertion Machines

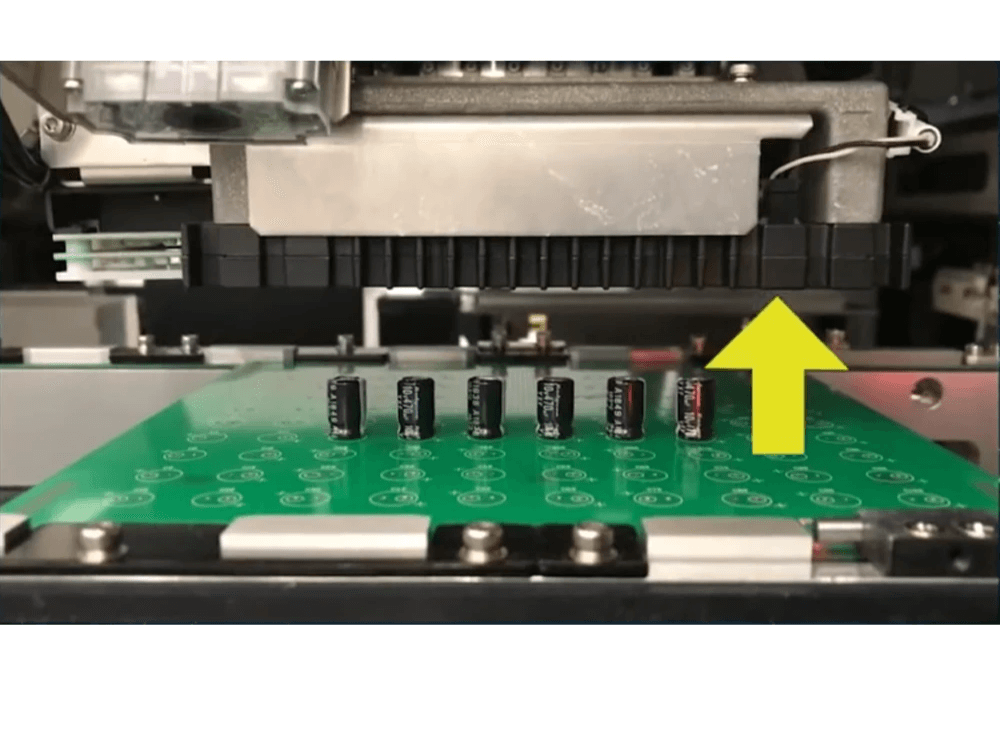

Insertion machines, particularly automatic insertion machines for electronic components, are designed to streamline the assembly process in electronics manufacturing. They utilize sophisticated technology to accurately place components on PCBs, reducing human error and increasing speed compared to manual methods. From pick & place machines to wave soldering systems, these machines come in various forms tailored to meet specific production needs.

Importance of Selecting the Right Machine

Choosing the right machine SMT (Surface Mount Technology) is essential for maximizing efficiency and minimizing costs in your manufacturing setup. An automatic insertion machine for electronic components can drastically reduce assembly times while ensuring precision placement of components. Furthermore, investing in high-quality SMT machines can lead to fewer defects and enhanced product reliability, making it vital to consider all available options before making a decision.

Overview of Electronic Component Insertion

Electronic component insertion involves placing various parts onto a PCB during the manufacturing process, which is a critical step in creating functional electronic devices. This process can be executed manually or through automated systems like SMT machines that offer higher throughput rates and better consistency. As technology advances, manufacturers are increasingly leaning towards automation with advanced pick & place machinery that integrates seamlessly with existing systems for optimal performance.

Types of Insertion Machines

Differences Between Automatic and Manual Models

Automatic insertion machines are designed for high-volume production, utilizing advanced technology to place electronic components with precision and speed. In contrast, manual models require human operators to insert components, which can lead to variability in quality and efficiency. The choice between these two often boils down to production scale; if you're aiming for mass production, an automatic insertion machine for electronic components is likely your best bet.

Manual models may be more suitable for small-scale operations or prototyping where flexibility is key. However, they demand more labor input and can slow down the overall manufacturing process. On the other hand, automatic machines like pick & place machines significantly reduce labor costs while increasing throughput—making them a staple in modern electronics manufacturing.

Benefits of an Automatic Insertion Machine for Electronic Components

Investing in an automatic insertion machine for electronic components offers several advantages that cannot be overlooked. First and foremost is speed; these machines can dramatically increase output by rapidly placing components onto PCBs compared to manual methods. This efficiency not only shortens lead times but also enhances overall productivity in your manufacturing equipment.

Moreover, accuracy is another critical benefit—automatic machines minimize human error during component placement, ensuring consistent quality across batches. With features like vision systems integrated into many SMT machines, you get real-time feedback on placement accuracy, further boosting reliability in production runs. This means fewer defects and less time spent on rework or repairs due to misplaced components.

Lastly, automation allows manufacturers to allocate their workforce more effectively by freeing up skilled workers from repetitive tasks so they can focus on higher-value activities such as design improvements or troubleshooting complex issues within the production line.

Comparing SMT Machines and Traditional Methods

When comparing SMT (Surface Mount Technology) machines with traditional methods like wave soldering or through-hole techniques, it's clear that SMT offers significant advantages in terms of efficiency and versatility. SMT machines excel at placing a wide variety of electronic components onto PCBs quickly while maintaining high precision—something traditional methods struggle with when dealing with smaller parts or densely packed boards.

While wave soldering has its merits—especially for through-hole components—it typically involves longer cycle times and additional steps such as preheating boards before soldering takes place. This not only complicates the process but also increases energy consumption compared to modern machine SMT solutions that streamline assembly lines considerably.

In summary, embracing an automatic insertion machine for electronic components over traditional methods not only enhances speed but also improves reliability and flexibility in your manufacturing processes—a win-win situation!

Key Features to Consider

When selecting an automatic insertion machine for electronic components, several key features will significantly influence your manufacturing efficiency and product quality. Understanding these features can help you make an informed decision and ensure that your investment yields the best possible results. Let’s dive into the critical aspects of speed, size, and technology integration.

Speed and Efficiency in Manufacturing Equipment

Speed is often a top priority when evaluating manufacturing equipment, especially with the increasing demand for rapid production cycles. An automatic insertion machine for electronic components can dramatically enhance throughput compared to manual methods or traditional SMT machines. The efficiency of a pick & place machine allows for quicker assembly times, reducing labor costs and improving overall productivity in your manufacturing line.

Moreover, modern SMT machines are designed to optimize the insertion process, minimizing downtime while maximizing output. High-speed operation not only facilitates faster production but also ensures consistency in placing electronic components accurately on PCBs. In today’s competitive landscape, investing in fast and efficient machinery is crucial for staying ahead of the game.

Size and Compatibility with PCB Design

Another essential factor to consider is the size of your automatic insertion machine for electronic components and its compatibility with various PCB designs. A compact machine can fit into tighter spaces on your production floor while still delivering high performance; however, it must also accommodate larger boards if needed. Evaluating the dimensions of both the machine SMT and your PCBs will help ensure seamless integration into your existing setup.

Compatibility doesn’t just stop at physical dimensions; it extends to how well the machine can handle different types of electronic components as well as varied layouts on PCBs. An ideal insertion machine should be versatile enough to adapt to changing design requirements without compromising quality or speed. This flexibility can save you time and money by reducing downtime associated with switching between different PCB configurations.

Technology Integration with Existing Systems

In an era where technology evolves rapidly, ensuring that your automatic insertion machine integrates smoothly with existing systems is paramount for operational success. Whether you have legacy systems or newer setups involving wave soldering processes, compatibility plays a significant role in streamlining operations across various stages of production. Choosing an advanced SMT machine that supports easy integration will enhance workflow efficiency.

Furthermore, consider whether the selected equipment allows data sharing between machines or interfaces seamlessly with software solutions used for inventory management or quality control checks. Effective technology integration not only boosts productivity but also provides valuable insights into performance metrics that can drive continuous improvement initiatives within your organization. Ultimately, selecting a well-integrated automatic insertion machine ensures you are set up for long-term success in electronic component manufacturing.

Leading Brands in Insertion Machines

In the world of electronic manufacturing, choosing the right insertion machine is crucial for efficiency and quality. Several brands have established themselves as leaders in this niche, offering a range of automatic insertion machines for electronic components that cater to different production needs. Understanding what these brands offer can help manufacturers make informed decisions about their production equipment.

Bensun Technology and Their Offerings

Bensun Technology has carved a niche for itself with its innovative automatic insertion machines designed specifically for electronic components. Their lineup includes advanced pick & place machines that streamline the assembly process, enhancing both speed and precision. With a focus on integrating cutting-edge technology into their SMT machines, Bensun ensures that their clients receive top-notch manufacturing equipment capable of meeting modern demands.

What sets Bensun apart is not just the quality of their products but also their commitment to customer support and training. They provide comprehensive resources to help clients maximize the potential of their SMT machines, ensuring smooth operations from day one. By investing in a Bensun automatic insertion machine for electronic components, manufacturers can expect enhanced productivity and reduced operational costs.

Notable Competitors in the Market

While Bensun Technology is a key player, several other notable competitors also offer robust solutions in the realm of automatic insertion machines for electronic components. Companies like Yamaha Motor Co., Panasonic, and Juki are renowned for their high-performance SMT machines that cater to various industry needs. Each brand brings unique features and technologies to the table, making it essential for manufacturers to evaluate all options before making a purchase.

These competitors have made significant strides in innovation as well; they often introduce new features aimed at improving speed and efficiency while reducing waste during production processes like wave soldering. By comparing offerings from these brands with those of Bensun, manufacturers can find an automatic insertion machine tailored perfectly to their requirements without compromising on quality or performance.

Innovations by Industry Leaders

The landscape of manufacturing equipment is constantly evolving due to technological advancements spearheaded by industry leaders in electronic component assembly machinery. Innovations such as AI-driven automation systems are becoming increasingly common among top brands, allowing for smarter decision-making during production cycles with minimal human intervention required. This shift not only enhances efficiency but also significantly reduces errors associated with manual handling.

Moreover, many leading companies are focusing on sustainability by developing energy-efficient SMT machines that minimize power consumption without sacrificing performance levels—an essential consideration given today's eco-conscious market trends. Investing in these advanced technologies will ensure that businesses remain competitive while contributing positively to environmental goals.

In summary, whether you opt for an automatic insertion machine from Bensun Technology or one from another leading brand like Yamaha or Panasonic, understanding the innovations shaping this sector will empower you to make informed choices tailored to your specific manufacturing needs.

Cost Considerations

When it comes to investing in an automatic insertion machine for electronic components, cost is a pivotal factor that can make or break your manufacturing budget. Understanding the initial price tag is just the tip of the iceberg; you also need to consider long-term expenses and potential savings. In this section, we’ll delve into budgeting strategies, hidden costs associated with SMT machines, and ultimately whether the investment pays off.

Budgeting for Your Automatic Insertion Machine

Budgeting for an automatic insertion machine for electronic components requires a comprehensive understanding of both upfront and ongoing costs. Initial prices can vary significantly depending on the features and capabilities of the machine you choose; some high-end models may seem like a hefty investment but offer substantial benefits over time. It’s crucial to create a detailed budget that includes not only the purchase price but also installation, training, and any necessary modifications to your existing manufacturing equipment.

In addition to the purchase cost, consider how financing options might fit into your budget strategy. Many manufacturers offer leasing programs or financing plans that can ease the burden of upfront costs while allowing you access to cutting-edge technology like pick & place machines and SMT machines. By carefully planning your budget around these factors, you'll be better positioned to make a financially sound decision that meets your production needs.

Hidden Costs of SMT Machines and Accessories

While budgeting for an automatic insertion machine for electronic components is essential, don’t overlook the hidden costs that can sneak up on you later down the line. For instance, maintenance expenses are often underestimated; regular upkeep is necessary to ensure optimal performance of SMT machines and avoid costly breakdowns during production runs. Additionally, you might find yourself needing accessories or upgrades—such as specialized nozzles or wave soldering equipment—that were not part of your initial plan.

Training staff on how to operate new equipment is another potential expense that shouldn’t be ignored. While some manufacturers provide training as part of their service package, others may charge extra fees—so always clarify this when making inquiries about different models or brands. These hidden costs can add up quickly if you're not prepared; therefore, it’s wise to conduct thorough research before committing to any specific machine.

Return on Investment: Is It Worth It?

Evaluating whether an automatic insertion machine for electronic components is worth its cost boils down to calculating return on investment (ROI). The efficiency gains from using advanced manufacturing equipment like pick & place machines can lead directly to increased production rates and reduced labor costs over time—making them potentially lucrative assets in your facility. To determine ROI accurately, consider factors such as improved output quality, reduced rework rates due to better precision in component placement by SMT machines.

Another aspect of ROI involves assessing how much time will be saved in setup and operation compared with traditional methods—especially if you're currently using manual processes or outdated technology like older wave soldering techniques. If switching to modern automated solutions allows you faster turnaround times on projects while maintaining high-quality standards across all products produced, then it's likely you'll see significant returns sooner than expected! Ultimately, weighing these benefits against initial outlays will help clarify whether investing in an automatic insertion machine truly makes financial sense for your business.

Maintenance and Support

When it comes to electronic components and manufacturing equipment, maintenance is not just a suggestion; it's a necessity. Regular upkeep of your automatic insertion machine for electronic components can significantly enhance performance and longevity. Neglecting maintenance can lead to costly downtimes, inefficient production processes, and ultimately, a decline in product quality.

Importance of Ongoing Maintenance for SMT Machines

Ongoing maintenance for SMT machines is crucial in ensuring that these intricate pieces of machinery operate at peak efficiency. Regular checks help identify potential issues before they escalate into major problems, which can disrupt the manufacturing process and delay project timelines. Furthermore, maintaining your pick & place machine not only preserves its functionality but also enhances the accuracy with which it places electronic components on PCBs.

The cost-effectiveness of regular maintenance cannot be overstated; it often saves money in the long run by preventing unexpected repairs or replacements. For instance, routine cleaning can prevent dust accumulation that might interfere with the delicate operations of SMT machines. In addition to preserving your investment, proper care ensures compliance with industry standards and regulations.

Finding Reliable Support Services

Finding reliable support services for your automatic insertion machine for electronic components is essential to ensure you have expert assistance when needed. Look for service providers who specialize in SMT machines and have a proven track record in the industry; their expertise will make all the difference during troubleshooting or repairs. It's also beneficial to choose support services that offer comprehensive packages including regular check-ups, emergency repairs, and technical training for your staff.

Consider asking other manufacturers about their experiences with support services—word-of-mouth recommendations are often invaluable when making this decision. Additionally, many leading brands provide their own customer service teams trained specifically on their equipment; leveraging these resources can streamline problem-solving processes significantly. Remember that timely access to support services can minimize downtime, keeping production flowing smoothly.

How to Maximize Machine Lifespan

Maximizing the lifespan of your machine SMT involves more than just routine maintenance—it requires strategic practices throughout its operational life cycle. First off, ensure that operators are well-trained on how to use the automatic insertion machine for electronic components correctly; improper handling is one of the main causes of premature wear and tear. Furthermore, integrating technology such as predictive maintenance software could help anticipate potential failures before they occur.

Another key factor is ensuring compatibility between different pieces of manufacturing equipment; mismatched systems can lead to unnecessary strain on machines like wave soldering units or pick & place machines if not managed properly. Finally, keeping an organized workspace around your SMT machines helps prevent accidents that could damage sensitive parts during operation or cleaning routines—after all, a tidy space promotes efficient work!

Conclusion

In wrapping up our discussion on insertion machines, it's clear that selecting the right equipment is crucial for optimizing your manufacturing processes. An automatic insertion machine for electronic components can significantly enhance efficiency, accuracy, and overall production quality. With various options available, understanding each machine's unique features will help you make an informed decision tailored to your specific needs.

Recap of Essential Selection Criteria

When choosing an automatic insertion machine for electronic components, there are several key factors to consider. Speed and efficiency should be at the forefront of your decision-making process; after all, who doesn't want a pick & place machine that can keep up with demand? Additionally, compatibility with existing PCB designs and technology integration will ensure a smooth operation within your current setup—saving you time and potential headaches down the line.

The Role of Advanced Technology in Manufacturing

The landscape of manufacturing equipment has evolved dramatically with advancements in technology. Modern SMT machines not only provide speed but also enhance precision in placing electronic components on PCBs—making them indispensable in today's fast-paced production environments. Wave soldering techniques have also seen improvements through automation, reducing manual labor while increasing reliability and consistency in soldering processes.

Moving Forward: Choosing Your Insertion Machine

As you embark on the journey to select your next insertion machine, consider both your current requirements and future growth potential. Investing in a high-quality SMT machine today can yield significant returns as demand for electronic components continues to rise globally. Remember to weigh hidden costs against projected ROI; sometimes what seems like a bargain may end up costing more than anticipated when maintenance or additional accessories come into play.