Introduction

In the fast-paced world of manufacturing, automated insertion equipment has emerged as a game changer, particularly in the realm of printed circuit assembly (PCA). This technology streamlines processes, enhances precision, and significantly boosts productivity across various production lines. As industries increasingly rely on automation to meet growing demands, understanding the nuances of these advanced solutions becomes essential for manufacturers aiming to stay ahead.

Understanding Automated Insertion Equipment

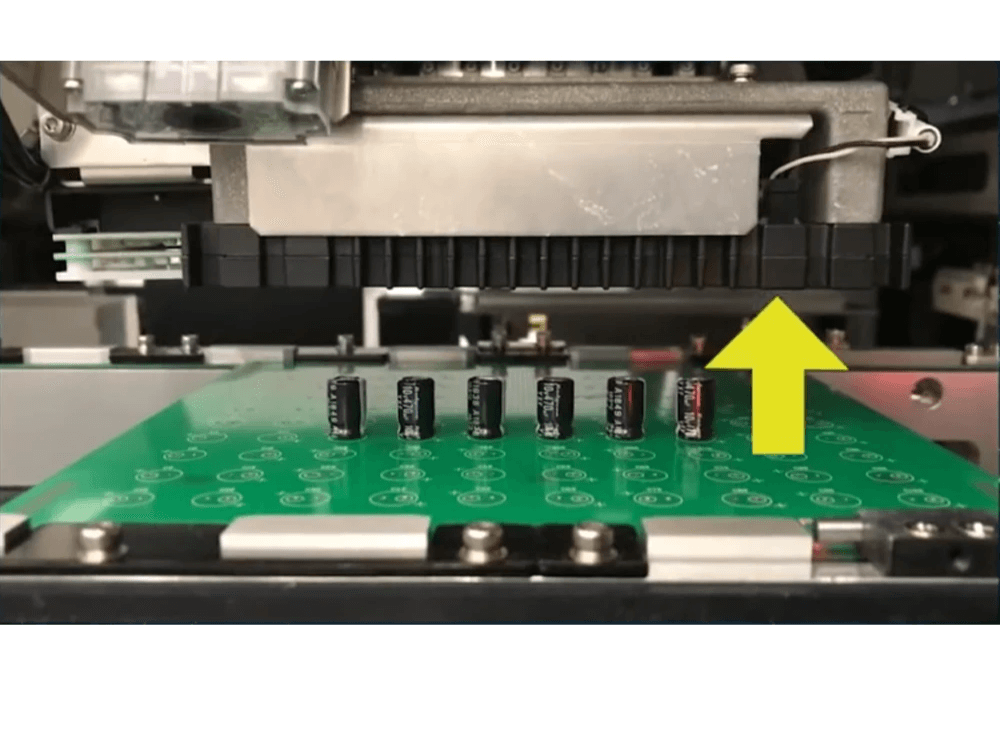

Automated insertion equipment refers to specialized machinery designed for the efficient placement of electronic components onto circuit boards during the printed circuit board assembly (PCBA) process. These machines utilize cutting-edge technology to ensure that each component is accurately positioned and securely attached, minimizing human error and maximizing throughput. By automating tasks traditionally performed by hand, manufacturers can achieve higher quality standards while reducing labor costs associated with manual assembly.

The Role of Efficiency in Manufacturing

Efficiency is the lifeblood of successful manufacturing operations; it dictates not only production speed but also overall profitability. In an era where time-to-market is critical, automated insertion equipment plays a pivotal role in enhancing assembly line efficiency by drastically reducing cycle times during PCB board assembly. With improved efficiency comes increased capacity to handle larger volumes of products without compromising quality—an essential factor in today’s competitive landscape.

Why Choose Advanced Solutions

Choosing advanced solutions like automated insertion equipment offers numerous advantages for manufacturers looking to elevate their operations. Not only do these systems provide superior accuracy in solder paste inspection and component placement, but they also offer versatility across different industries—from consumer electronics to automotive applications. By investing in such technology, businesses position themselves for growth while ensuring they remain agile enough to adapt to evolving market demands.

The Evolution of Automated Insertion Equipment

The journey of automated insertion equipment has been nothing short of transformative for the manufacturing landscape, particularly in printed circuit assembly (PCA). Initially, manual methods dominated, with skilled technicians painstakingly inserting electronic components into circuit boards. However, as the demand for efficiency and precision grew, so did the need for innovation in the processes surrounding PCB assembly.

Historical Context and Development

Automated insertion equipment made its debut in the late 20th century when manufacturers began to realize that traditional methods could not keep pace with burgeoning consumer electronics demands. Early machines were rudimentary at best, often struggling with complexity and speed during printed circuit board assembly. Over time, advancements in technology led to more sophisticated systems capable of handling multiple types of electronic components while ensuring higher accuracy and consistency.

Key Innovations Over the Years

The evolution of automated insertion equipment has been marked by several key innovations that have reshaped how PCB assembly is conducted. One notable advancement is the integration of solder paste inspection systems, which allow manufacturers to detect defects before they escalate into costly errors during production. Additionally, improvements in machine learning algorithms have enabled these systems to adapt dynamically to various production needs, enhancing their versatility across different manufacturing applications.

Leading Brands and Their Contributions

Several leading brands have played pivotal roles in advancing automated insertion equipment over the years. Companies like Panasonic and Siemens have pioneered technologies that significantly improve both speed and accuracy in printed circuit board assembly processes. Meanwhile, Bensun Technology has emerged as a key player by offering customized solutions tailored specifically for diverse industry requirements—demonstrating how innovation can meet unique challenges head-on.

Enhancing Production Speed with Automation

In today’s fast-paced manufacturing landscape, enhancing production speed is crucial for staying competitive. Automated insertion equipment plays a pivotal role in streamlining processes, particularly within printed circuit assembly (PCA) environments. By integrating automation into assembly lines, manufacturers can significantly reduce the time required for tasks such as solder paste inspection and the placement of electronic components on circuit boards.

Time Savings in Assembly Lines

Time is money, especially in industries reliant on printed circuit board assembly (PCBA). Automated insertion equipment can dramatically decrease cycle times by efficiently placing electronic components on a PCB board assembly without the delays associated with manual labor. This efficiency not only speeds up production but also allows companies to respond quicker to market demands and changes.

Moreover, automating tasks like solder paste inspection minimizes the need for manual checks, further expediting the process. As machines take over repetitive tasks, human operators can focus on more complex issues that require critical thinking and creativity. This shift ultimately leads to a more agile assembly line capable of meeting high-volume demands without sacrificing quality.

Impact on Overall Production Rates

The integration of automated insertion equipment has a profound impact on overall production rates across various manufacturing sectors. With faster cycle times and reduced downtime due to fewer errors, companies can achieve significantly higher output levels in printed circuit board assembly operations. In addition to speed, these systems enhance consistency and reliability—two crucial factors that contribute to maintaining high production rates.

Incorporating automation also allows manufacturers to optimize resource allocation effectively; fewer workers are needed for repetitive tasks while skilled labor can be redirected towards more value-added activities. As a result, businesses not only see an increase in their production numbers but also improve their operational efficiencies overall. This dual benefit transforms how manufacturers approach their workflows and sets new standards for productivity.

Case Study: Bensun Technology’s Approach

Bensun Technology exemplifies how embracing automated insertion equipment can yield remarkable results in enhancing production speed within PCB assembly lines. By implementing advanced automation solutions tailored specifically for electronic component placement and solder paste inspection processes, Bensun has achieved impressive reductions in cycle times while ensuring high-quality outcomes.

For instance, one of their recent projects involved upgrading an existing manual assembly line to an automated setup that utilized cutting-edge technology for PCB board assembly operations. The results were astounding: they reported a 30% increase in output within just months of installation while simultaneously reducing errors related to human oversight by nearly 50%. This case study illustrates how investing in automated solutions not only enhances production speed but also positions companies like Bensun Technology as leaders in the ever-evolving manufacturing landscape.

Reducing Labor Costs and Human Error

In the fast-paced world of manufacturing, reducing labor costs while maintaining quality is a top priority. Automated insertion equipment has revolutionized the way printed circuit assembly (PCA) is conducted, streamlining processes that once required extensive human intervention. By integrating these advanced solutions into production lines, manufacturers can achieve significant cost savings without compromising on precision or reliability.

Labor Savings with Automated Solutions

Automated insertion equipment drastically reduces the need for manual labor in tasks such as PCB assembly and solder paste inspection. This not only leads to lower labor costs but also allows companies to allocate their workforce to more strategic roles where human expertise is invaluable. As a result, organizations can operate with leaner teams while still meeting high production demands in electronic components manufacturing.

Moreover, automation enables manufacturers to maintain consistent output levels regardless of workforce fluctuations or absenteeism. With automated systems handling repetitive tasks in printed circuit board assembly (PCBA), businesses can ensure uninterrupted production and avoid delays caused by human factors. The efficiency gained through automation translates directly into increased profitability and competitiveness in the market.

Minimizing Mistakes in the Production Process

Human error is an unfortunate reality in any manufacturing process, particularly when it comes to complex tasks like assembling electronic components on a PCB board assembly line. Automated insertion equipment significantly minimizes these mistakes by employing precise algorithms and controls that guarantee accuracy during every step of production. This not only enhances product quality but also fosters greater confidence among customers regarding the reliability of their purchased electronics.

Additionally, advanced systems are equipped with integrated solder paste inspection technologies that detect flaws before they escalate into costly defects. By catching issues early in the printed circuit assembly process, companies can avoid rework and scrap—saving both time and resources that would otherwise be wasted on correcting errors made by human operators. The result is a smoother workflow with fewer interruptions caused by mistakes.

Real-World Examples of Error Reduction

Many manufacturers have successfully implemented automated insertion equipment to reduce errors significantly within their operations. For instance, Bensun Technology has demonstrated remarkable improvements in PCBA processes by adopting cutting-edge automation solutions that streamline component placement and inspection stages. Their case studies highlight how businesses have achieved up to 90% reduction in defects compared to traditional methods relying heavily on manual labor.

Another notable example comes from a leading electronics manufacturer that integrated automated systems into its PCB board assembly line, resulting in a dramatic decrease in misaligned components during soldering processes. This shift not only enhanced product quality but also improved overall production efficiency—demonstrating how effective automation can be at minimizing human error across various stages of manufacturing operations.

In conclusion, investing in automated insertion equipment not only reduces labor costs but also plays an essential role in minimizing mistakes throughout the entire production process—from printed circuit board assembly to final inspection stages for electronic components.

Versatility in Manufacturing Applications

In the world of manufacturing, versatility is key, especially when it comes to automated insertion equipment. This technology is not just a one-trick pony; it seamlessly adapts across various industries, from consumer electronics to automotive components. Such adaptability ensures that businesses can leverage automated solutions to enhance their production capabilities, regardless of their specific needs.

Adaptability Across Different Industries

Automated insertion equipment has proven itself invaluable across a multitude of sectors. In printed circuit board assembly (PCB assembly), for instance, the precision and speed offered by these machines are essential for meeting tight deadlines and high-quality standards. Whether it's electronic components for smartphones or circuit boards for medical devices, this technology scales effortlessly to meet diverse demands.

Moreover, industries like aerospace and defense also benefit significantly from automated insertion systems. These sectors require meticulous attention to detail and reliability—qualities that automated solutions provide with aplomb. Thus, the ability of automated insertion equipment to cater to different applications makes it an indispensable asset in modern manufacturing.

How Automated Insertion Equipment Fits Various Needs

The flexibility of automated insertion equipment allows manufacturers to address specific requirements efficiently. For example, during the solder paste inspection phase in PCB board assembly, these machines can identify defects that human operators might miss. This capability not only enhances quality control but also streamlines workflows by integrating seamlessly into existing processes.

Additionally, manufacturers can customize the features of their automated systems based on product specifications or production volumes. This means whether you're producing small batches or large quantities of printed circuit boards, there’s an automated solution tailored just for you. The result? Increased efficiency and reduced downtime across all stages of production.

Bensun Technology’s Customized Solutions

Bensun Technology stands out in providing tailored solutions for businesses looking to optimize their operations with advanced automated insertion equipment. They understand that no two manufacturing processes are identical; therefore, they offer customizable options that cater specifically to individual needs within PCB assembly and beyond. Whether it’s configuring machines for unique electronic components or enhancing solder paste inspection methods, Bensun ensures maximum compatibility with your workflow.

Furthermore, Bensun's commitment doesn’t end at installation; they provide ongoing support and adjustments as your production requirements evolve over time. Their expertise helps companies navigate the complexities of integrating automation into existing systems while ensuring minimal disruption during transitions. With Bensun Technology by your side, you’ll find your path toward efficient manufacturing paved with innovative solutions tailored just for you.

Future Trends in Automated Insertion Equipment

The landscape of automated insertion equipment is rapidly evolving, driven by technological advancements and the increasing demands of modern manufacturing. As industries strive for greater efficiency and precision, the integration of smart technologies into automated systems is becoming more prevalent. This trend not only enhances the capabilities of printed circuit board assembly (PCB assembly) but also revolutionizes how electronic components are handled throughout the production process.

Technological Advancements on the Horizon

Emerging technologies like artificial intelligence (AI) and machine learning are set to redefine automated insertion equipment in significant ways. These innovations will enable systems to adapt in real-time, optimizing processes such as solder paste inspection and electronic component placement with unprecedented accuracy. Moreover, advancements in robotics will allow for greater flexibility in PCB board assembly, accommodating various circuit board designs without extensive reconfiguration.

Additionally, IoT (Internet of Things) connectivity will facilitate seamless data exchange between machines, leading to smarter factory environments where automated insertion equipment can self-diagnose issues and predict maintenance needs. This proactive approach not only minimizes downtime but also ensures that production lines remain efficient and responsive to changing market demands. Overall, these technological enhancements promise a future where manufacturing processes are faster, smarter, and more reliable.

Predictions for Industry Growth

The demand for automated insertion equipment is expected to soar as industries increasingly recognize its value in enhancing production efficiency. Analysts predict that the global market for PCB assembly technology will grow significantly over the next decade due to rising labor costs and a push for higher quality standards across electronics manufacturing. Companies that invest early in advanced solutions will likely gain a competitive edge by streamlining operations and reducing lead times.

Moreover, sectors such as automotive electronics and consumer gadgets are anticipated to drive substantial growth within this industry segment. As these markets expand with new innovations—like electric vehicles or smart home devices—the need for precise printed circuit board assembly becomes even more critical. Thus, manufacturers who embrace automation now can position themselves favorably within this burgeoning landscape.

Implications for Manufacturers

For manufacturers looking to thrive amidst these trends, adapting to advancements in automated insertion equipment is essential. The shift towards automation not only promises cost savings through reduced labor expenses but also enhances product quality by minimizing human error during PCB assembly processes. By leveraging cutting-edge technologies like solder paste inspection systems integrated with AI capabilities, companies can ensure their electronic components meet stringent quality standards consistently.

Furthermore, embracing customization options offered by leading brands like Bensun Technology allows manufacturers to tailor solutions that meet their specific needs while staying ahead of competitors who may be slower to adapt. The implications extend beyond just operational efficiency; they encompass strategic positioning within an increasingly tech-driven marketplace where agility is key to success.

In summary, as we look toward the future of automated insertion equipment, it’s clear that those who invest wisely today will reap significant rewards tomorrow—both in terms of productivity gains and enhanced product quality across various applications.

Conclusion

In the rapidly evolving landscape of manufacturing, maximizing efficiency through automation is no longer a luxury but a necessity. Automated insertion equipment has become the backbone of modern production lines, especially in printed circuit board assembly (PCB assembly). By leveraging these advanced solutions, companies can streamline their processes and significantly reduce turnaround times, ultimately enhancing their bottom line.

Maximizing Efficiency with Automation

Automation in manufacturing facilitates remarkable time savings and precision that human labor simply cannot match. With automated insertion equipment, tasks such as solder paste inspection and the placement of electronic components on circuit boards are executed with unparalleled accuracy. This not only speeds up the PCB board assembly process but also ensures that quality control is maintained throughout production.

The Competitive Edge of Advanced Equipment

Investing in advanced automated insertion equipment provides manufacturers with a competitive edge that is hard to overlook. As industries continue to demand higher quality and faster delivery times, those utilizing cutting-edge technology benefit from reduced labor costs and minimized errors in production processes. The ability to adapt quickly to market demands while maintaining high standards sets apart successful manufacturers from their competitors.

Partnering with Experts Like Bensun Technology

To fully harness the potential of automated solutions, partnering with experts like Bensun Technology is essential for any manufacturer looking to thrive in this fast-paced environment. Their customized solutions for PCB assembly ensure that businesses can maximize efficiency while addressing specific needs across various applications. By collaborating with industry leaders who understand the intricacies of automated insertion equipment, companies can position themselves for sustained growth and innovation.