Introduction

In the fast-paced world of manufacturing, understanding pick and place automation equipment is crucial for staying competitive. This technology not only enhances efficiency but also ensures precision in printed circuit assembly (PCA). As industries increasingly turn to robotic automation, the significance of these systems in optimizing production lines cannot be overstated.

Understanding Pick and Place Automation Equipment

Pick and place automation equipment refers to sophisticated machines designed to streamline the assembly process by accurately placing components onto circuit boards. These systems utilize advanced robotic arms that can manipulate tiny parts with remarkable precision, significantly improving the quality of assembled circuit boards. By automating these tasks, manufacturers can reduce human error while enhancing overall productivity.

Benefits of Using Robotic Automation

The benefits of using robotic automation extend far beyond mere efficiency gains; they include heightened accuracy and reduced operational costs. With robotic arms performing repetitive tasks in PCB assembly, companies can allocate human resources to more complex problem-solving roles, fostering innovation. Moreover, the integration of robotization and automation allows for faster adaptation to market demands, ensuring that businesses remain agile and competitive.

The Role of PCB Assembly in Modern Manufacturing

PCB assembly plays a pivotal role in modern manufacturing as it serves as the backbone for countless electronic devices we rely on daily. The advent of pick and place automation equipment has revolutionized this process by enabling rapid production cycles without sacrificing quality. As industries evolve towards smarter manufacturing solutions, understanding how robotic automation impacts PCB assembly becomes essential for any forward-thinking organization.

What is Pick and Place Automation Equipment?

In the realm of modern manufacturing, pick and place automation equipment has become a cornerstone for efficiency and precision, particularly in printed circuit assembly (PCA). This technology employs robotic arms to automate the process of placing components onto circuit boards with remarkable accuracy. By eliminating manual handling, this system enhances production speed while ensuring consistent quality in assembled circuit boards.

Definition and Function

Pick and place automation equipment refers to a sophisticated assembly system designed to automatically pick up electronic components and precisely place them onto a PCB during the assembly process. The fundamental function of this equipment is to streamline circuit board assembly by minimizing human intervention, thereby reducing errors associated with manual labor. This not only speeds up production but also ensures that each component is placed accurately according to design specifications.

Key Components of the System

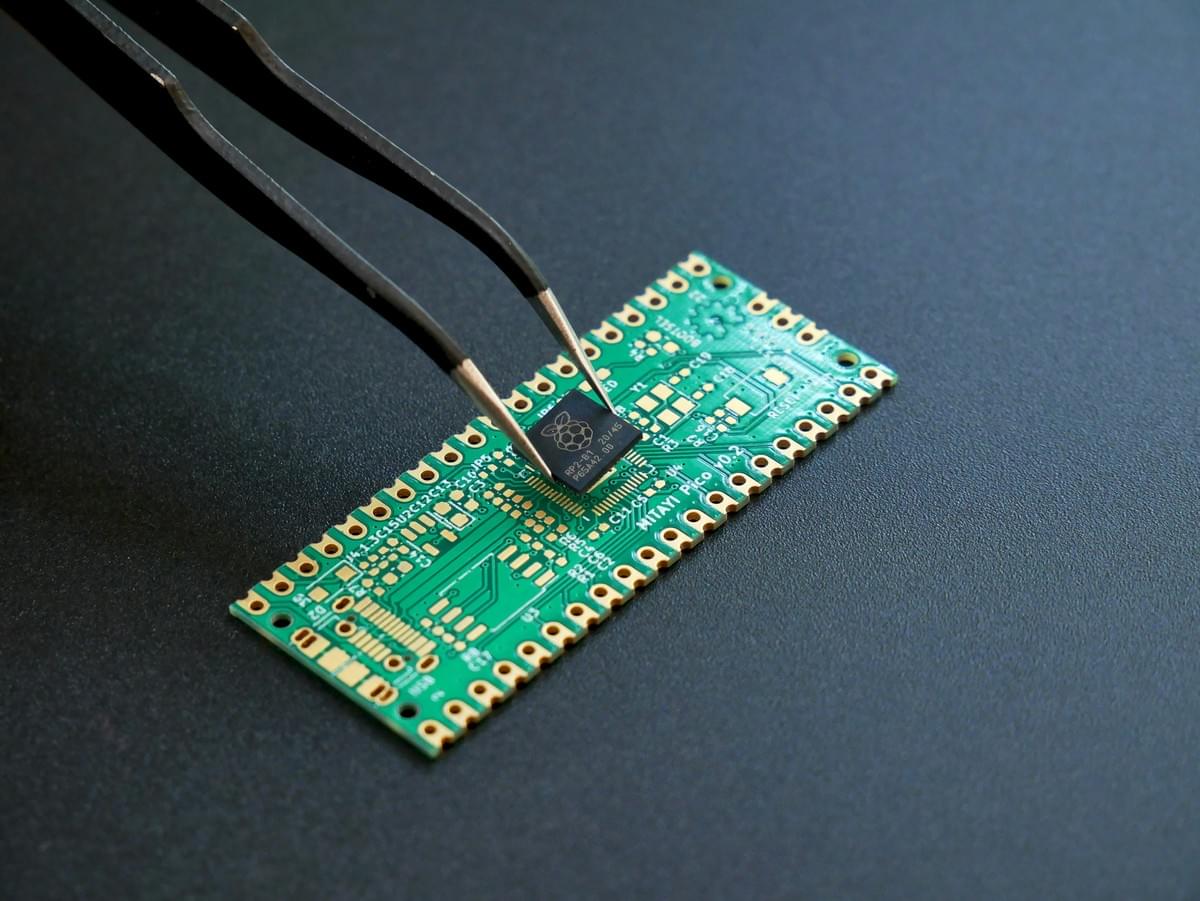

The key components of pick and place automation equipment include a robotic arm, vision systems, feeders, and control software. The robotic arm is responsible for the actual movement—picking components from feeders or trays and placing them on the PCB with high precision. Vision systems enhance accuracy by allowing the machine to recognize component placements visually, while feeders supply components in an organized manner for seamless operation; all coordinated through advanced control software that manages tasks efficiently.

How It Works in Production Lines

In production lines, pick and place automation equipment operates as part of an integrated system designed for rapid PCB assembly. Initially, components are fed into the machine from various feeders based on predefined configurations set by operators using control software. The robotic arm then swiftly picks each component from its designated position before accurately placing it on the circuit board; this cycle continues at high speed until an assembled circuit board emerges ready for further processing or testing—significantly enhancing overall productivity.

The Advantages of Robotic Arms

In the realm of printed circuit assembly, robotic arms have become indispensable due to their myriad advantages. These advanced machines are designed to enhance precision, efficiency, and flexibility in manufacturing processes. With the rise of pick and place automation equipment, businesses can achieve higher quality standards while streamlining production workflows.

Precision in Circuit Board Assembly

When it comes to circuit board assembly, precision is paramount. Robotic arms excel in this area by employing advanced algorithms and high-resolution sensors that ensure each component is placed accurately on the assembled circuit board. This level of precision not only minimizes errors but also significantly reduces waste, making robotic automation a smart investment for any PCB assembly operation.

The capabilities of robotic arms mean they can handle delicate components with ease, ensuring that even the smallest parts are positioned correctly without damage. This meticulous attention to detail is crucial for maintaining the integrity of modern electronic devices. As a result, manufacturers can trust that their pick and place automation equipment will deliver consistent quality across every batch produced.

Increased Efficiency and Speed

Time is money in manufacturing, and robotic arms are champions at maximizing both efficiency and speed. With their ability to operate continuously without breaks or fatigue, these machines can dramatically increase throughput in PCB assembly lines compared to traditional methods reliant on human labor. A well-implemented pick and place automation equipment system can lead to faster production cycles while maintaining high-quality standards.

Moreover, robotic arms can perform multiple tasks simultaneously—such as picking components from one location while placing them onto an assembled circuit board—thereby further enhancing operational efficiency. This dual functionality means that manufacturers can meet rising market demands without compromising on quality or increasing labor costs significantly. In an era where speed often dictates success, embracing robotization and automation becomes essential for staying competitive.

Flexibility in Manufacturing Processes

The landscape of manufacturing is ever-evolving; therefore, flexibility is crucial for adapting to changing market demands. Robotic arms offer remarkable versatility that allows them to be reprogrammed quickly for different tasks within PCB assembly processes. Whether it's switching between various types of components or adjusting settings for different product lines, these machines make it easy to pivot when necessary.

Additionally, modern pick and place automation equipment can integrate with other systems seamlessly—enabling manufacturers to create highly adaptable production environments tailored to specific needs or trends in technology. This flexibility not only enhances productivity but also fosters innovation as companies explore new products or variations without significant downtime or reconfiguration costs associated with traditional setups. Ultimately, investing in robotic arms equips businesses with the tools needed for sustained growth amidst rapid industry changes.

The Impact of Robotization and Automation

In today's fast-paced manufacturing environment, robotization and automation have become key players in enhancing productivity and efficiency. The integration of pick and place automation equipment into production lines is revolutionizing how businesses approach printed circuit assembly. With robotic automation, companies can optimize their workflows, reduce errors, and ultimately deliver high-quality assembled circuit boards faster than ever before.

Streamlining Production Workflows

One of the most significant impacts of robotic arms in manufacturing is their ability to streamline production workflows. By automating repetitive tasks such as circuit board assembly, businesses can minimize downtime and ensure a smoother operation across the entire production line. This not only speeds up the process but also allows human workers to focus on more complex tasks that require critical thinking and creativity.

Moreover, pick and place automation equipment can be programmed to adapt to various product specifications without extensive reconfiguration—making it an incredibly flexible solution for manufacturers dealing with diverse PCB assembly needs. As a result, companies can swiftly adjust their production strategies in response to changing market demands without sacrificing quality or efficiency. This flexibility is vital in an era where consumer preferences evolve rapidly.

Lastly, the implementation of robotic automation leads to enhanced communication between different stages of production. With real-time data tracking capabilities integrated into these systems, manufacturers can monitor performance metrics closely, identify bottlenecks instantly, and make informed decisions that enhance overall productivity.

Reducing Labor Costs and Errors

The introduction of robotization into manufacturing processes significantly reduces labor costs associated with manual assembly tasks. As companies invest in advanced pick and place automation equipment, they find themselves relying less on manual labor for repetitive jobs like placing components onto printed circuit boards (PCBs). This shift not only cuts down on wage expenses but also minimizes the risk of human error—a common issue in traditional assembly lines.

Robotic arms excel at precision placement during circuit board assembly, ensuring that components are accurately positioned every time. This level of precision drastically lowers the chances of defects in assembled circuit boards caused by misalignment or incorrect component placement. Consequently, businesses benefit from fewer returns due to faulty products while simultaneously improving customer satisfaction through higher-quality outputs.

Furthermore, reducing errors through robotics translates into increased operational efficiency across the board. Companies can produce more units within a given timeframe while maintaining stringent quality control standards—ultimately leading to greater profitability as they meet demand without compromising on product excellence.

Adapting to Market Demands

In an ever-changing marketplace where consumer preferences fluctuate rapidly, adaptation is crucial for survival—and robotic automation provides just that edge for manufacturers today. With pick and place automation equipment capable of handling various configurations seamlessly, businesses can pivot quickly between different products or designs based on market trends without incurring significant downtime or additional costs associated with retooling.

The flexibility offered by robotic arms allows manufacturers to respond promptly when new opportunities arise or when existing products need adjustments due to shifting consumer interests—ensuring they stay ahead of competitors who may still rely on outdated manual processes for PCB assembly tasks. This adaptability not only enhances resilience but also fosters innovation within organizations as teams explore new possibilities enabled by automated systems.

As market demands continue evolving at a breakneck pace fueled by technological advancements and changing consumer behavior patterns—robotization will undoubtedly play an increasingly pivotal role in shaping future manufacturing landscapes while empowering organizations with tools necessary for sustained growth amid uncertainty.

Key Players in the Market

In the rapidly evolving landscape of pick and place automation equipment, several key players have emerged, each contributing uniquely to the advancements in PCB assembly and robotic automation. These companies are not only pushing the boundaries of technology but also shaping the future of circuit board assembly through innovative solutions. Understanding their roles can provide valuable insights into making informed decisions for your manufacturing needs.

Bensun Technology’s Role in Automation

Bensun Technology stands out as a prominent player in the realm of robotic automation, particularly known for its cutting-edge pick and place automation equipment designed specifically for printed circuit assembly. Their systems emphasize precision and efficiency, ensuring that every assembled circuit board meets stringent quality standards. With a commitment to innovation, Bensun continues to enhance its offerings by integrating advanced robotics into production lines, making it a go-to choice for manufacturers looking to streamline their processes.

Other Leading Brands in PCB Assembly

Beyond Bensun Technology, several other leading brands are making significant strides in PCB assembly and robotic arms technology. Companies like ASM Assembly Systems and Yamaha Motor Co., Ltd., have established themselves as industry leaders with robust product lines that cater to diverse manufacturing needs. Their focus on enhancing efficiency while reducing errors has positioned them favorably among businesses seeking reliable solutions for circuit board assembly.

Comparing Different Suppliers

When it comes to selecting suppliers for pick and place automation equipment, it's essential to compare features, costs, and support services offered by various manufacturers. Each supplier may offer unique advantages; some may excel in speed while others focus on precision or flexibility within their robotic automation systems. By conducting thorough research and evaluations based on your specific requirements—such as production volume or complexity—you can find the best fit that maximizes ROI from your investment in robotization and automation.

Best Practices for Implementing Automation

Implementing pick and place automation equipment is a strategic move that can significantly enhance your manufacturing processes. However, to maximize the benefits of robotic automation, it's crucial to adopt best practices tailored to your specific production environment. From assessing needs to ongoing maintenance, each step plays a vital role in ensuring your circuit board assembly runs smoothly and efficiently.

Assessing Your Production Needs

Before diving into the world of robotic arms and pick and place automation equipment, it’s essential to evaluate your production requirements thoroughly. This means analyzing current workflows, identifying bottlenecks, and determining where automation can make the most impact on printed circuit assembly. By understanding these elements, you can select the right technology that aligns with your operational goals while ensuring a seamless transition into robotization and automation.

Moreover, consider factors such as production volume, complexity of assembled circuit boards, and future scalability when assessing needs. This assessment will help you choose equipment that not only meets current demands but also adapts to future market changes or product variations in PCB assembly. Ultimately, a well-informed decision will lead to increased efficiency and reduced costs in the long run.

Training Staff for New Technologies

Once you've chosen the appropriate pick and place automation equipment for your operations, it's time to focus on training your staff effectively. The introduction of robotic arms into your production line may require employees to learn new skills related to operating advanced machinery or troubleshooting potential issues that arise during circuit board assembly. Investing in comprehensive training ensures that everyone is confident in using this innovative technology.

Additionally, fostering a culture of continuous learning will empower staff members to adapt more quickly as technologies evolve within robotic automation frameworks. Encourage team collaboration by sharing insights on best practices for maintaining productivity while utilizing automated systems effectively. With well-trained personnel at the helm of these advancements, you'll see improved performance across all aspects of PCB assembly operations.

Regular Maintenance and Upgrades

To keep your pick and place automation equipment functioning at peak performance levels, regular maintenance is non-negotiable. Establishing a proactive maintenance schedule helps prevent unexpected breakdowns or malfunctions during critical stages of printed circuit assembly processes—saving both time and money in repairs down the line. Routine checks on components like robotic arms ensure they remain calibrated correctly for precision tasks throughout their lifespan.

Moreover, staying informed about software updates or hardware enhancements can significantly improve efficiency within robotization and automation systems over time. As technology advances rapidly in this field, taking advantage of upgrades allows you to maintain competitiveness while optimizing existing capabilities within PCB assembly operations continuously. Remember: an ounce of prevention is worth a pound of cure!

Conclusion

In the rapidly evolving landscape of manufacturing, the significance of pick and place automation equipment cannot be overstated. As industries increasingly lean into robotic automation, understanding how these technologies enhance printed circuit assembly processes is essential for staying competitive. The future holds exciting advancements that promise to further revolutionize circuit board assembly, making it more efficient and precise.

Future Trends in Pick and Place Technology

The future of pick and place technology is bright, with innovations on the horizon that will redefine how we approach pcb assembly. Emerging trends include the integration of artificial intelligence and machine learning into robotic arms, enhancing their ability to adapt to various tasks dynamically. Additionally, advancements in sensor technology will enable more sophisticated quality control measures during the assembly process, leading to fewer defects in assembled circuit boards.

Choosing the Right Equipment for Your Needs

Selecting the right pick and place automation equipment requires a thorough assessment of your specific production needs. Factors such as production volume, complexity of circuit board assembly, and budget constraints should guide your decision-making process. Collaborating with suppliers who understand your requirements can help you find a robotic automation solution that fits seamlessly into your existing workflows.

Maximizing ROI with Automation Solutions

To truly reap the benefits of robotization and automation, it's crucial to focus on maximizing return on investment (ROI). This involves not only selecting appropriate equipment but also ensuring regular maintenance and staff training are prioritized to keep operations running smoothly. By continuously evaluating performance metrics and adapting strategies accordingly, manufacturers can enhance efficiency while minimizing costs associated with errors in circuit board assembly.