Introduction

In the fast-paced world of electronics manufacturing, SMT conveyors play a pivotal role in enhancing the efficiency of printed circuit assembly (PCA). These specialized systems are designed to transport printed circuit boards (PCBs) seamlessly through various stages of production, ensuring that each circuit on board is assembled with precision and care. Understanding SMT conveyor solutions is essential for any manufacturer looking to optimize their PCB production and assembly processes.

Understanding SMT Conveyor Solutions

SMT conveyor systems are engineered specifically for the demands of PCB manufacturing and assembly. They facilitate the movement of boards through multiple workstations, allowing for a streamlined workflow that minimizes downtime and maximizes productivity. With an array of options available, manufacturers can tailor their SMT conveyor solutions to meet unique operational needs while ensuring a smooth transition from one stage to the next.

The Importance of Efficient Conveyors

Efficient conveyors are crucial in maintaining high throughput rates in PCB manufacturing and assembly environments. By reducing bottlenecks in production lines, these systems enable manufacturers to respond quickly to market demands without sacrificing quality. In an industry where precision is key, having reliable SMT conveyors can significantly impact overall product quality and operational success.

Exploring Various Types of SMT Conveyors

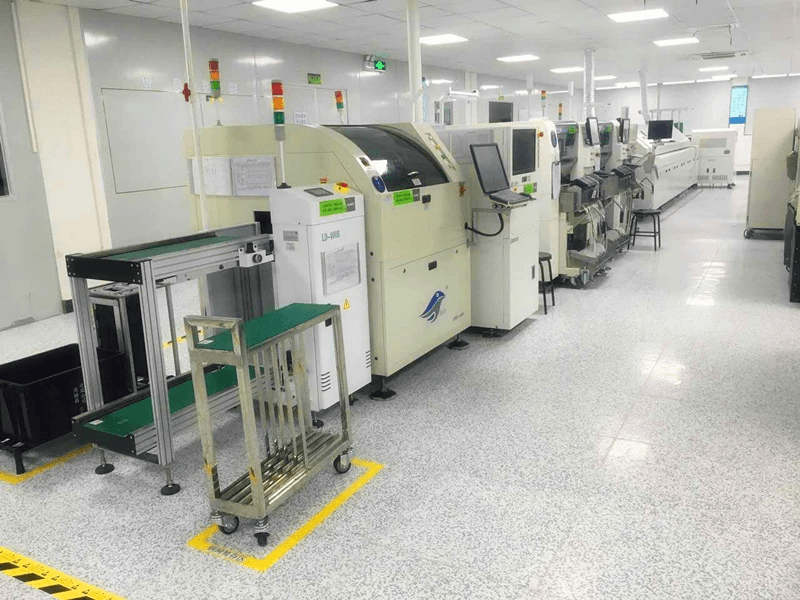

The landscape of SMT conveyors is diverse, offering various types tailored for specific applications within printed board assembly processes. From high-speed belt conveyors that ensure rapid transit to modular systems providing flexibility for changing layouts, there's an option for every need. Exploring these different types can help manufacturers identify which SMT conveyor best aligns with their PCB production and assembly requirements.

What is an SMT Conveyor?

In the world of printed circuit board (PCB) manufacturing and assembly, the SMT conveyor plays a pivotal role in ensuring efficient production processes. These conveyors are specifically designed to transport PCBs through various stages of assembly, from loading to inspection, all while maintaining high levels of precision and speed. Understanding the definition and functionality of SMT conveyors is essential for anyone involved in PCB production and assembly.

Definition and Functionality

An SMT conveyor is a specialized transport system used in printed board assembly (PBA) processes that facilitates the movement of circuit boards during manufacturing. These conveyors are engineered to handle sensitive components with care, ensuring they remain secure while traveling between different workstations. The primary functionality revolves around providing a seamless flow of materials, which is crucial for maintaining optimal efficiency in PCB manufacturing.

The design of an SMT conveyor allows it to accommodate various sizes and types of boards for circuits, making it versatile across different production lines. With features such as adjustable speeds and integration capabilities with other automated systems, these conveyors can be tailored to specific manufacturing needs. This adaptability enhances overall workflow management within PCB production and assembly environments.

Applications in Manufacturing

SMT conveyors find their applications primarily in electronics manufacturing, particularly within the realm of printed circuit assembly (PCA). They are utilized extensively in environments where multiple assembly processes occur sequentially or simultaneously—such as soldering, component placement, and testing—ensuring that every step flows smoothly into the next. By facilitating quick transitions between these stages, SMT conveyors significantly reduce downtime during PCB manufacturing.

Moreover, these conveyors can be adapted for use in various industries beyond electronics; however, they shine brightest when handling delicate components found on circuit boards. Their ability to manage high volumes while minimizing damage makes them indispensable tools in modern PCB production and assembly facilities. In essence, any manufacturer looking to streamline their operations should consider incorporating SMT conveyor solutions into their workflow.

Key Components and Features

Key components of an SMT conveyor include a robust frame structure designed for stability and durability under continuous operation conditions. Additionally, many models feature adjustable belts or rollers that allow for smooth transportation of PCBs without risk of damage—a critical consideration when dealing with intricate circuit designs on boards for circuits.

Other notable features often found on modern SMT conveyors include integrated sensors for real-time monitoring and control mechanisms that enhance user interface experiences during operation. Anti-static designs are also common to prevent electrostatic discharge (ESD), which could compromise sensitive electronic components during PCB manufacturing assembly processes. By understanding these components and features, manufacturers can select the right SMT conveyor solutions tailored specifically to their needs.

Benefits of Using SMT Conveyors

When it comes to optimizing the production process in printed circuit assembly, SMT conveyors are game-changers. They streamline the transportation of materials, ensuring that each board for circuit is efficiently handled throughout the manufacturing stages. By integrating these advanced systems into PCB manufacturing and assembly, companies can significantly enhance their overall productivity.

Enhanced Production Efficiency

One of the most significant advantages of using SMT conveyors is their ability to boost production efficiency. These systems facilitate a smooth flow of components, reducing bottlenecks that often occur during printed board assembly. When circuits on boards are moved seamlessly between workstations, manufacturers can achieve higher throughput in PCB manufacturing assembly, leading to timely completion of projects.

Moreover, with high-speed options available in SMT conveyor technology, businesses can adapt to varying production demands without sacrificing performance. This flexibility allows for quick adjustments when dealing with different types of products or changes in order volume. Ultimately, enhanced production efficiency translates into faster delivery times and increased customer satisfaction.

Reduced Labor Costs

Another compelling benefit of SMT conveyors is their potential to reduce labor costs significantly. By automating the movement of components within the manufacturing line, companies can minimize the need for manual handling during PCB production and assembly processes. This not only lowers labor expenses but also frees up skilled workers to focus on more complex tasks that require human intervention.

Additionally, with fewer personnel required on the floor managing material transport, manufacturers can allocate resources more effectively across various operations within printed circuit assembly. This strategic shift leads to optimized workforce utilization and improved overall productivity levels as employees engage in value-added activities rather than mundane tasks.

Improved Product Quality

Quality assurance is paramount in any manufacturing process; thus, using SMT conveyors plays a crucial role in enhancing product quality throughout PCB manufacturing and assembly stages. These systems ensure consistent handling of sensitive components while minimizing risks associated with manual handling errors or contamination during transport. As a result, circuits on boards maintain their integrity from start to finish.

Furthermore, many modern SMT conveyor solutions come equipped with anti-static designs specifically tailored for sensitive electronic parts used in printed board assembly processes. This attention to detail helps prevent damage caused by static electricity—a common concern when working with delicate components like those found in circuit boards for electronics applications.

In conclusion, investing in SMT conveyor technology not only streamlines operations but also elevates product quality standards while reducing operational costs—making it an essential component for any successful PCB production and assembly endeavor.

Types of SMT Conveyor Solutions

When it comes to optimizing your printed circuit assembly line, the type of SMT conveyor you choose can make all the difference. Each solution offers unique advantages tailored to specific needs in PCB manufacturing and assembly. Let’s dive into some standout options that can elevate your circuit on board production.

Bensun's PTK Intelligent Shuttle Conveyors

Bensun's PTK Intelligent Shuttle Conveyors are a game-changer for those in the PCB manufacturing assembly realm. These conveyors are designed with smart technology that allows for real-time monitoring and adjustments, ensuring seamless operation throughout the printed board assembly process. With their ability to handle various board sizes and configurations, they provide unmatched flexibility that is crucial in today’s fast-paced environment.

The PTK system is particularly effective for complex tasks where precision is key, such as moving delicate components during printed circuit assembly. This intelligent design not only enhances production efficiency but also minimizes errors, contributing significantly to improved product quality. As a result, manufacturers can confidently rely on Bensun's shuttle conveyors to streamline their operations and reduce labor costs.

Modular Conveyors for Flexibility

Modular conveyors are another excellent option for businesses looking to enhance their SMT conveyor systems. These versatile solutions allow manufacturers to easily reconfigure their production lines as needed, adapting quickly to changes in PCB production and assembly demands. The modular design means that you can add or remove sections without extensive downtime or costly modifications.

This adaptability is vital when dealing with varying sizes of boards for circuit applications or shifting from one project to another in printed circuit assembly tasks. Additionally, modular conveyors often come equipped with features like adjustable speeds and orientations, making them ideal for diverse manufacturing environments. Ultimately, this flexibility helps companies maintain a competitive edge while ensuring high-quality output.

High-Speed Belt Conveyors

For those who prioritize speed without sacrificing quality in their PCB manufacturing processes, high-speed belt conveyors are an essential choice. These systems are engineered specifically for rapid movement of boards through various stages of production—perfectly suited for high-volume printed board assembly operations. Their robust construction ensures reliability even under demanding conditions.

High-speed belt conveyors excel at transporting multiple circuits on board simultaneously while maintaining precise alignment necessary for effective soldering and inspection processes during PCB production and assembly phases. This efficiency not only boosts overall throughput but also contributes positively to reduced lead times—an aspect every manufacturer values highly today! By integrating these advanced conveyors into your workflow, you’ll find yourself well-equipped to meet growing market demands.

Key Features to Consider

When selecting an SMT conveyor for printed circuit assembly (PCA), it’s essential to focus on key features that can significantly impact your production efficiency and overall output quality. The right features not only enhance the functionality of your SMT conveyor but also ensure seamless integration into your existing PCB manufacturing and assembly processes. Here, we’ll explore three critical aspects: control mechanisms and user interfaces, anti-static designs for sensitive components, and integration with MES and automation systems.

Control Mechanisms and User Interfaces

The control mechanisms of an SMT conveyor play a vital role in its usability and effectiveness during the PCB production and assembly process. A user-friendly interface allows operators to easily monitor, adjust, and optimize the flow of boards for circuit manufacturing, reducing downtime due to manual errors or miscommunication. Advanced control features may include touchscreen displays, programmable logic controllers (PLCs), or even remote access capabilities, which can streamline operations significantly in a fast-paced environment.

Moreover, intuitive user interfaces contribute to quicker training times for new staff members working with printed board assembly systems. This ease of operation is crucial in maintaining high productivity levels while ensuring that sensitive components remain protected throughout the manufacturing cycle. Ultimately, investing in a conveyor with robust control mechanisms enhances not just efficiency but also operator satisfaction within your PCB manufacturing facility.

Anti-Static Designs for Sensitive Components

In the realm of printed circuit assembly, protecting sensitive electronic components from electrostatic discharge (ESD) is paramount for maintaining product integrity. An effective SMT conveyor should incorporate anti-static designs that help mitigate risks associated with ESD during transportation and handling of circuit on board assemblies. These designs often include materials that dissipate static electricity or conductive surfaces that ground any build-up before it can affect delicate components.

Furthermore, these anti-static features are especially critical when dealing with high-density PCBs where even minor static charges can lead to significant damage or malfunctioning products post-assembly. By ensuring your SMT conveyor has these protective elements integrated into its design, you not only safeguard your investment in equipment but also enhance the overall quality of your PCB manufacturing assembly process. This attention to detail ultimately translates into higher customer satisfaction as well as reduced returns due to defects.

Integration with MES and Automation Systems

Seamless integration of SMT conveyors with Manufacturing Execution Systems (MES) and other automation solutions is essential for modern PCB production lines aiming for maximum efficiency. Such integration allows real-time monitoring of production metrics while facilitating data-driven decision-making processes throughout the entire printed board assembly workflow. With automated tracking capabilities linked directly to MES platforms, manufacturers can gain insights into bottlenecks or inefficiencies quickly.

Additionally, integrating an SMT conveyor system within broader automation frameworks enables enhanced coordination between various stages of PCB manufacturing and assembly processes—from component placement through final testing phases—ensuring smooth transitions at each step along the way. This level of connectivity not only streamlines operations but also supports predictive maintenance strategies by providing valuable performance data over time. As a result, manufacturers are better equipped to adapt their production lines swiftly in response to changing demands or technological advancements.

Choosing the Right SMT Conveyor

Selecting the right SMT conveyor is a pivotal step in optimizing your printed circuit assembly (PCA) processes. With various options available, understanding your specific production needs will guide you towards the most effective solution for your PCB manufacturing and assembly operations. Whether you’re working on a complex circuit on board or straightforward printed board assembly, making an informed choice can significantly impact efficiency and output quality.

Assessing Your Production Needs

Before diving into the world of SMT conveyors, take a moment to assess your production needs thoroughly. Consider factors such as the volume of printed circuit boards (PCBs) you need to produce and the complexity of the assemblies involved. Different types of SMT conveyors cater to varying levels of automation and speed; knowing whether you require high-speed belt conveyors or modular designs will streamline your PCB manufacturing assembly process.

Additionally, think about how often you'll be changing production runs or layouts. If you frequently switch between different types of boards for circuit assemblies, investing in flexible conveyor systems like Bensun's PTK Intelligent Shuttle Conveyors could save time and enhance productivity. Ultimately, aligning your conveyor choice with your specific production needs ensures that you're set up for success in PCB production and assembly.

Evaluating Space and Layout Requirements

Space is often at a premium in any manufacturing environment, so evaluating layout requirements is crucial when choosing an SMT conveyor. Measure your available floor space carefully to determine what type of conveyor system can fit without cramping other operations or workflows. This consideration is especially important if you're integrating new equipment into existing setups for printed board assembly.

Moreover, think about how materials flow through your workspace; a well-planned layout not only enhances efficiency but also reduces unnecessary handling during PCB manufacturing and assembly processes. You might find that modular conveyors offer greater adaptability for tight spaces compared to traditional fixed systems. Properly assessing space will help ensure that every inch contributes positively to your circuit on board production line.

Cost Considerations and ROI

When it comes to selecting an SMT conveyor, cost considerations are paramount—but they shouldn’t be viewed in isolation from potential returns on investment (ROI). While it may be tempting to opt for cheaper solutions initially, consider how long-lasting performance impacts overall costs in PCB manufacturing assembly over time. Investing in high-quality equipment can lead to enhanced production efficiency, reduced labor costs, and ultimately improved product quality.

To calculate ROI effectively, analyze both direct costs—such as purchase price—and indirect costs like maintenance expenses associated with different models of SMT conveyors. Don’t forget about long-term benefits: faster cycle times can lead to increased output without compromising quality standards in printed circuit board assemblies. By weighing these factors thoughtfully against upfront expenditures, you'll make a more informed decision that aligns with both budgetary constraints and operational goals.

Conclusion

In the fast-paced world of printed circuit assembly, optimizing your production line efficiency is crucial for staying competitive. SMT conveyors play a pivotal role in streamlining processes, ensuring that each board for circuit moves seamlessly through the stages of pcb manufacturing and assembly. By integrating advanced conveyor systems, manufacturers can enhance workflow, minimize downtime, and ultimately boost output.

Optimizing Your Production Line Efficiency

To truly optimize production lines, companies must focus on the specific needs of their printed board assembly operations. Efficient SMT conveyor solutions can drastically reduce manual handling and errors associated with circuit on board placement. This not only increases throughput but also elevates product quality by minimizing defects during pcb production and assembly.

Future Trends in SMT Conveyor Technology

Looking ahead, trends in SMT conveyor technology indicate a shift towards even more intelligent and automated systems. Innovations such as AI-driven control mechanisms will allow for real-time adjustments based on production demands, enhancing flexibility in pcb manufacturing assembly processes. Additionally, the integration of IoT capabilities will enable better monitoring and predictive maintenance, further improving overall efficiency.

The Role of Bensun in Your Success

Bensun stands out as a leader in providing cutting-edge SMT conveyor solutions tailored to your unique needs. With a commitment to quality and innovation, Bensun ensures that your printed circuit assembly operations are equipped with state-of-the-art technology that drives success. By partnering with Bensun, you gain access to expertise that empowers you to thrive in the competitive landscape of pcb production and assembly.