Introduction

In the ever-evolving landscape of electronics, the efficiency and reliability of printed circuit assembly (PCA) are paramount. At the heart of this process lies selective soldering equipment, a crucial player in ensuring that connections are made with precision and quality. Understanding how to navigate selective soldering equipment procurement can significantly enhance the quality of PCB manufacturing and assembly.

Understanding Selective Soldering Equipment

Selective soldering equipment is designed to target specific areas on a PCB board, applying solder only where it's needed. This minimizes waste and maximizes efficiency, making it an essential tool in modern PCB manufacturing processes. As manufacturers look to streamline operations, investing in high-quality selective soldering equipment becomes a strategic move that can yield long-term benefits.

The Role of PCB Assembly in Manufacturing

PCB assembly plays a critical role in the broader context of manufacturing, serving as the backbone for countless electronic devices we rely on daily. The integration of various components onto a single board is not just about functionality; it’s also about ensuring that these components work seamlessly together. Effective PCB manufacturing and assembly hinge on using advanced techniques like selective soldering to achieve optimal results.

Importance of Quality Solder Flux

Solder flux is an unsung hero in the world of electronics, facilitating better adhesion between solder and metal surfaces during the PCB manufacturing process. The right type of flux can significantly impact both the quality and durability of joints formed during assembly, making it essential for achieving reliable connections on any PCB board manufacturing project. Without high-quality solder flux, even the most sophisticated selective soldering equipment may fall short in delivering superior results.

Overview of Selective Soldering Equipment

Selective soldering equipment is a cornerstone of modern PCB manufacturing and assembly, facilitating precise soldering processes that enhance reliability and efficiency. Understanding the various types of machines available, their key features, and reputable brands can significantly impact your selective soldering equipment procurement decisions. In this section, we will explore the landscape of selective soldering machines to help you make informed choices for your printed circuit assembly needs.

Types of Selective Soldering MachinesThe most common types include wave soldering machines, which use a continuous wave of molten solder; and robotic selective soldering systems that offer precision through programmable movements. Additionally, there are hybrid systems that combine both technologies for optimal flexibility in PCB assembly board production.

Each type serves distinct purposes in the realm of PCB manufacturing and assembly, allowing manufacturers to choose based on their specific needs—be it high volume or intricate designs requiring meticulous attention. The choice between these machines often hinges on factors like production speed, complexity of the circuit boards being assembled, and budget constraints for selective soldering equipment procurement. Ultimately, understanding these options will help streamline your processes while ensuring high-quality results.

Key Features to Consider

Selecting the right selective soldering equipment involves evaluating several key features critical for effective PCB board manufacturing. First and foremost is the machine's ability to control temperature and flow rates accurately; this ensures optimal application of solder flux while minimizing defects during assembly. Another important feature is programmability—machines that allow for customizable settings can adapt more easily to varying production runs.

Additionally, ease of maintenance should not be overlooked when considering your options in selective soldering equipment procurement; reliable access to spare parts and technical support can save time and money down the road. Lastly, look for machines equipped with advanced safety features such as fume extraction systems or automatic shut-off mechanisms—these not only protect operators but also contribute positively to overall workplace safety during PCB manufacturing processes.

Brands to Explore

In the competitive world of selective soldering equipment procurement, certain brands stand out due to their reputation for quality and innovation in printed circuit assembly solutions. Notable names include Nordson EFD known for its precision dispensing technology; Heller Industries which specializes in reflow ovens; and OK International recognized for its advanced hand-solder tools tailored for intricate tasks within PCB assembly board environments.

Another prominent player is Juki Automation Systems which offers a range of automated solutions ideal for high-volume PCB manufacturing applications. Investing time into researching these brands can yield significant dividends when choosing machinery that aligns with your goals in PCB manufacturing assembly while ensuring you get value without compromising quality or performance standards.

The Selective Soldering Process

Selective soldering is a critical component in the PCB manufacturing and assembly landscape, ensuring that connections are made efficiently and effectively. Understanding the steps involved not only enhances the quality of printed circuit assembly (PCA) but also streamlines the entire process of PCB board manufacturing. By mastering these techniques, manufacturers can significantly reduce defects and improve overall product reliability.

Steps in PCB Manufacturing and Assembly

The journey of PCB manufacturing begins with designing a schematic that outlines the electrical connections required for the circuit. Once finalized, this design is transferred to a printed circuit assembly board through processes like etching and layering, creating a physical representation of the circuit. Following this, components are placed on the board using automated machines or manual labor before they undergo soldering—this is where selective soldering equipment comes into play.

After component placement, it's crucial to prepare for soldering by applying solder flux to ensure optimal adhesion between components and pads on the PCB assembly board. This step is essential as it helps prevent oxidation and improves wetting during solder application, thereby enhancing joint quality. Finally, once selective soldering is completed, thorough inspection processes are implemented to verify that all connections meet stringent quality standards before moving on to final packaging.

Integrating Solder Flux Effectively

Solder flux plays an indispensable role in selective soldering by facilitating better flow characteristics during the heating process. Integrating high-quality flux into your PCB manufacturing assembly can lead to improved joint integrity and reduced defects during production runs. By selecting appropriate flux types based on specific materials used in your PCB board manufacturing, you can enhance performance while minimizing rework costs.

Moreover, understanding how to apply solder flux effectively can save time in both setup and production phases of your project. For instance, using automated dispensing systems allows for precise application directly onto targeted areas without oversaturation—this minimizes waste while ensuring each connection receives adequate coverage. As you explore selective soldering equipment procurement options, consider how different machines handle flux application as part of their overall functionality.

Comparison to Other Soldering Techniques

When comparing selective soldering techniques with alternatives like wave or hand soldering, several factors come into play that may influence your choice during PCB manufacturing and assembly processes. Selective soldering stands out due to its precision; it allows for targeted application of heat only where needed without affecting surrounding components—ideal for complex assemblies with mixed technologies. This contrasts sharply with wave soldering which floods entire boards in molten metal; while effective for simpler designs, it risks damaging sensitive parts.

Additionally, hand-soldered joints may be more prone to human error compared with automated selective processes that maintain consistent quality across batches—an essential aspect when considering long-term reliability in products manufactured under strict guidelines like those found in aerospace or medical fields. Ultimately, understanding these differences will help inform decisions regarding selective soldering equipment procurement tailored specifically for your unique requirements within printed circuit assembly.

Evaluating Supplier Options

A reputable manufacturer not only provides quality machines but also ensures that you have access to the latest technology and support. By conducting thorough research, you can identify suppliers that align with your needs for printed circuit assembly and solder flux integration.

Researching Reputable Manufacturers

Start by compiling a list of potential manufacturers known for their expertise in selective soldering equipment procurement. Look for companies with a proven track record in PCB board manufacturing and positive customer reviews. Don’t forget to check industry forums and trade shows where manufacturers showcase their innovations; these platforms often reveal insights into product reliability and performance.

Another effective approach is to reach out to fellow professionals in the PCB manufacturing community for recommendations. Networking can provide firsthand accounts of experiences with various suppliers, giving you a clearer picture of which companies deliver on their promises regarding quality and service. Remember, a well-informed choice can significantly impact your printed circuit assembly efficiency.

Key Factors in Selective Soldering Equipment Procurement

When evaluating potential suppliers, consider several key factors that influence selective soldering equipment procurement decisions. First, assess the range of machines they offer; ensure they provide options that suit different PCB manufacturing requirements, from simple designs to complex assemblies. Additionally, scrutinize the technical support services they provide post-purchase; having reliable assistance can prove invaluable during troubleshooting or maintenance.

Another crucial aspect is understanding the warranty and service agreements associated with their products. A robust warranty reflects confidence in their equipment’s durability while offering peace of mind during production runs—especially when dealing with delicate solder flux applications in PCB assembly board processes. Lastly, consider pricing structures; while cost shouldn't be the sole deciding factor, it plays an essential role in balancing quality against budget constraints.

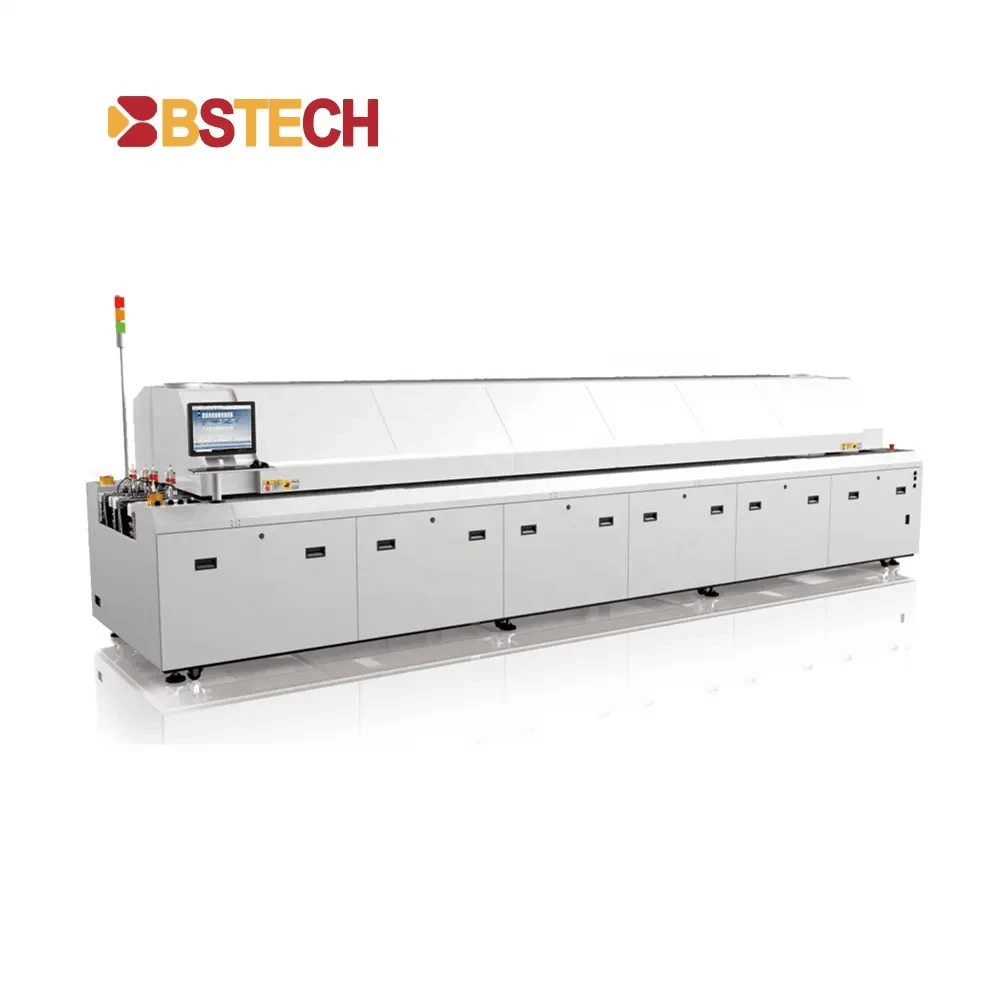

The Role of Bensun Technology

Bensun Technology stands out as a notable player in the realm of selective soldering equipment procurement due to its commitment to innovation and customer satisfaction within the PCB manufacturing landscape. They offer cutting-edge machinery designed specifically for efficient printed circuit assembly while ensuring compatibility with various types of solder flux used across industries. Their reputation is bolstered by positive feedback from clients who value both performance and reliability.

Moreover, Bensun Technology excels at providing comprehensive support throughout the entire lifecycle of their products—from initial consultation through installation and ongoing maintenance services tailored for optimal operation during PCB board manufacturing processes. This level of dedication helps businesses minimize downtime while maximizing productivity levels across all stages of production.

In conclusion, when navigating supplier options for selective soldering equipment procurement, thorough research combined with an understanding of what each manufacturer offers will lead you toward making informed decisions that enhance your overall PCB manufacturing efficiency.

Budgeting for Equipment Procurement

It’s not just about the initial purchase price; you need to consider the total cost of ownership (TCO) over the equipment's lifespan. This includes maintenance, operation costs, and potential downtime, which can all impact your bottom line.

Total Cost of Ownership Considerations

Understanding the total cost of ownership is essential when evaluating selective soldering equipment procurement options. TCO encompasses not only the purchase price but also factors like energy consumption, maintenance expenses, and even training costs for operators. By calculating these aspects upfront, you can avoid surprises later on and ensure that your investment in PCB board manufacturing pays off in the long run.

In addition to direct costs, consider indirect expenses such as lost productivity during maintenance or repairs and how these might affect your PCB assembly board timelines. A machine that seems cheaper upfront may lead to higher operational costs down the road if it requires frequent repairs or lacks efficient features. Therefore, a comprehensive analysis of TCO will help you make informed decisions that align with your budget while ensuring high-quality production standards.

Cost vs. Quality: Finding the Balance

In any selective soldering equipment procurement process, finding a balance between cost and quality is paramount for effective PCB manufacturing assembly. High-quality machines often come with a higher price tag but typically offer superior performance and reliability—two critical factors in producing top-notch printed circuit assemblies (PCAs). While it's tempting to opt for lower-cost options to save money initially, this could lead to increased downtime or inferior product quality over time.

Investing in quality equipment means fewer interruptions in your PCB manufacturing process due to breakdowns or inefficiencies caused by subpar machines. It's essential to weigh these long-term benefits against immediate budget constraints when making decisions about your solder flux application processes as well as other aspects of PCB assembly board production. Remember that investing wisely now can lead to significant savings and enhanced performance later on.

Financing Options for PCB Board Manufacturing

Navigating financing options for selective soldering equipment procurement doesn’t have to be daunting if you know where to look! Many manufacturers offer financing plans tailored specifically for businesses involved in PCB manufacturing and assembly—allowing you to spread out payments over time without straining your cash flow too much upfront. From leasing agreements that let you use cutting-edge technology without full ownership costs immediately, to loans specifically designed for industrial equipment purchases, there are plenty of avenues worth exploring.

Additionally, some suppliers may provide flexible payment terms based on production milestones or volume commitments related directly back to your printed circuit assembly needs—making it easier than ever for companies of all sizes to invest in high-quality machinery without breaking their budgets right away! Take advantage of these options while keeping an eye on interest rates and repayment terms so that they align with both short-term financial health and long-term business goals.

By thoroughly assessing financing opportunities alongside TCO considerations and balancing cost versus quality effectively, you'll be better equipped for successful selective soldering equipment procurement while enhancing overall efficiency in PCB manufacturing processes.

Maintenance and Support for Equipment

Maintaining selective soldering equipment is crucial for ensuring the longevity and efficiency of your PCB manufacturing and assembly processes. Regular maintenance not only helps prevent unexpected breakdowns but also enhances the overall quality of your printed circuit assembly. By investing time and resources into upkeep, manufacturers can avoid costly interruptions that may arise from neglected machinery.

Importance of Regular Maintenance

Regular maintenance of selective soldering equipment is a non-negotiable aspect of effective PCB board manufacturing. Just like a well-oiled machine, consistent upkeep ensures that all components function smoothly, minimizing the risk of defects during the soldering process. Furthermore, when solder flux application is optimized through proper maintenance, it leads to better adhesion and overall performance in printed circuit assembly.

Choosing a Supplier with Strong Support

When it comes to selective soldering equipment procurement, selecting a supplier who offers robust support services can make all the difference in maintaining operational efficiency. A reliable supplier not only provides high-quality machinery but also offers training, troubleshooting assistance, and timely parts replacement when needed. This support network becomes invaluable as you navigate the complexities of PCB manufacturing and assembly, ensuring you have expert guidance whenever challenges arise.

Resource Management for Optimal Performance

Effective resource management is key to achieving optimal performance in your selective soldering operations. This includes not just managing materials like solder flux efficiently but also ensuring that your workforce is trained to handle equipment properly. By balancing human resources with advanced technology in PCB board manufacturing, companies can streamline their processes while enhancing productivity and product quality.

Conclusion

In the ever-evolving world of PCB manufacturing and assembly, understanding the nuances of selective soldering equipment procurement is crucial for success. By maximizing efficiency in soldering processes, manufacturers can streamline production while minimizing waste and rework. Ultimately, a well-informed approach to selecting equipment can lead to significant gains in productivity and quality.

Maximizing Efficiency in Soldering Processes

Efficiency is the name of the game when it comes to selective soldering equipment procurement. Utilizing advanced machines not only speeds up the soldering process but also ensures that every joint is made with precision, reducing defects in printed circuit assembly (PCA). By integrating optimal solder flux applications during this process, manufacturers can further enhance throughput while maintaining high-quality standards.

Ensuring Quality in PCB Assembly

Quality assurance is paramount in PCB manufacturing and assembly; after all, it’s not just about getting the boards out the door but ensuring they perform reliably in their intended applications. The right selective soldering equipment plays a vital role in achieving this goal by providing consistent application of solder flux and minimizing thermal stress on components. Investing time and resources into quality control measures will pay off significantly as it leads to fewer failures down the line.

Making Informed Equipment Procurement Decisions

Navigating through various options for selective soldering equipment procurement can feel overwhelming, but informed decision-making simplifies this daunting task. Researching reputable suppliers and understanding key features that align with your specific needs are essential steps toward successful PCB board manufacturing. With careful planning and consideration, companies can invest wisely, ensuring their production lines are equipped for both current demands and future growth.