Introduction

In the fast-paced world of electronics manufacturing, JUKI automation systems have carved out a significant niche, combining precision with efficiency. Understanding how these systems operate is crucial for organizations looking to enhance their production capabilities. With a myriad of options available, selecting the right system can make all the difference between success and stagnation.

Understanding JUKI Automation Systems

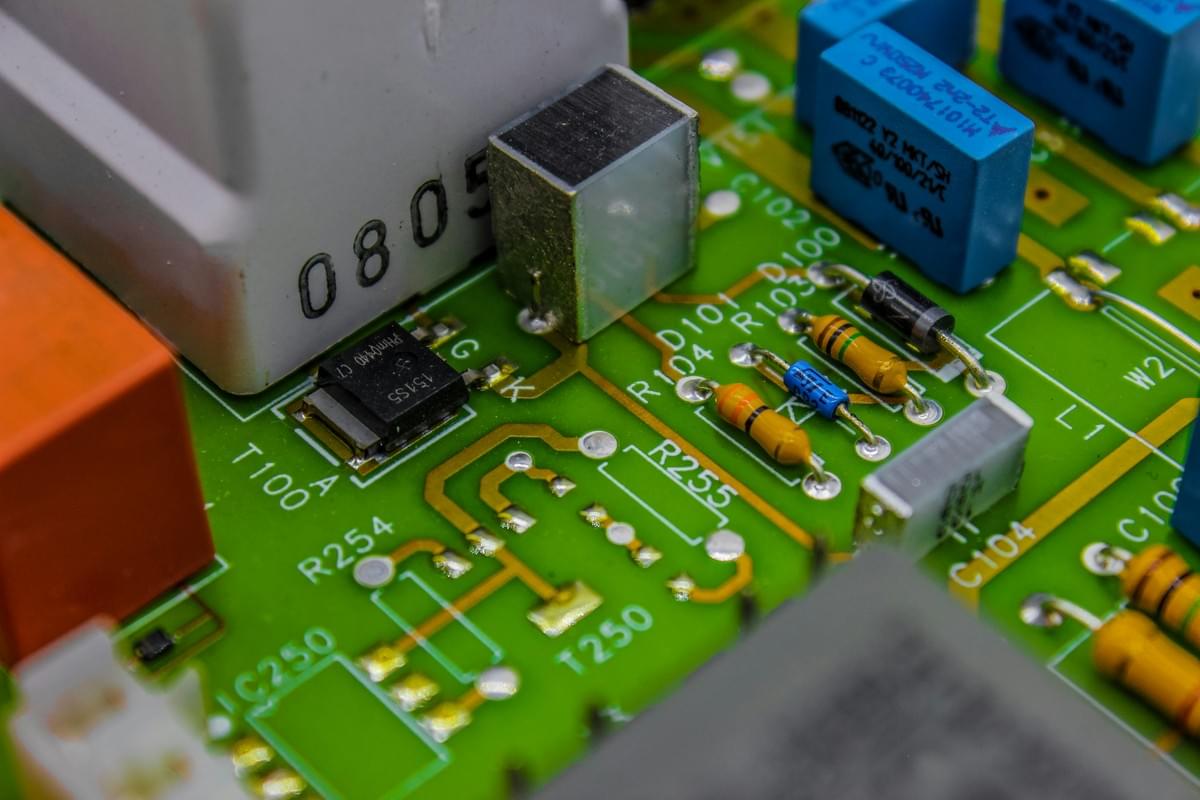

JUKI automation systems are designed to streamline the manufacturing process, ensuring that components are placed accurately and efficiently on printed circuit boards (PCBs). These systems utilize advanced technology to facilitate high-speed assembly while minimizing errors and waste. To truly appreciate what sets JUKI apart, it's essential to grasp their functionality and how they integrate into various production lines.

The Importance of Choosing the Right System

Choosing the right JUKI automation system is paramount for any manufacturer aiming to boost productivity and maintain quality standards. A well-suited system not only enhances operational efficiency but also aligns with specific production needs, whether it involves surface-mount technology (SMT) or through-hole components. The decision-making process should involve careful consideration of factors such as machine capabilities, scalability, and overall cost-effectiveness.

Key Terminology in JUKI Automation

Before diving deeper into JUKI automation systems, it's vital to familiarize oneself with key terminology that frequently arises in discussions about SMT machines and pick and place machines. Understanding terms like What is the difference between SMT and SMD? or How does a SMT machine work? can significantly aid in making informed decisions regarding equipment purchases. Additionally, knowing what SMT is used for will help clarify its role in modern manufacturing processes.

Overview of JUKI Automation Systems

When it comes to JUKI automation systems, understanding their unique offerings can significantly impact production efficiency and product quality. JUKI has established itself as a leader in the field of automation, particularly in the electronics manufacturing sector. With a focus on innovation and reliability, JUKI provides advanced solutions that cater to both small-scale operations and large-scale production lines.

What Makes JUKI Stand Out

JUKI stands out due to its commitment to precision engineering and cutting-edge technology. Their automation systems are designed with an emphasis on flexibility, allowing manufacturers to adapt quickly to changing production demands. Additionally, the integration of smart technologies into JUKI automation systems enhances real-time monitoring and control, setting them apart from competitors.

Another significant factor is the extensive range of options available within their product line; from SMT machines to pick and place machines, each system is tailored for specific applications. This variety ensures that businesses can find the perfect fit for their unique needs without compromising on quality or performance. Furthermore, JUKI's reputation for durability means that their systems are built to last, reducing long-term operational costs.

Benefits of JUKI Automation Systems

The benefits of using JUKI automation systems are manifold, starting with increased efficiency in production processes. By utilizing advanced SMT technology, these systems streamline workflow and minimize human error—key factors in maintaining high-quality standards. In addition, automating tasks such as component placement through SMT pick and place machines allows companies to scale operations without sacrificing precision.

Cost savings also play a crucial role; automated systems reduce labor costs while increasing output rates significantly. Moreover, with features like quick changeovers and user-friendly interfaces, training staff becomes easier than ever—enhancing overall productivity across the board. Ultimately, investing in JUKI's automation solutions results in a notable return on investment as companies adapt more readily to market demands.

Types of JUKI Automation Systems Available

JUKI offers a diverse array of automation systems tailored for various manufacturing needs; among them are SMT machines designed for surface mount technology applications and pick and place machines engineered for precise component placement. Each type serves distinct purposes but shares common goals: enhancing speed and accuracy while reducing waste during production processes.

For instance, SMT machines excel at soldering components directly onto printed circuit boards (PCBs), making them essential for modern electronics manufacturing—a process often confused with SMD (Surface Mount Device). Understanding what is the difference between SMT and SMD helps manufacturers choose the right system based on their specific requirements; while SMD refers specifically to components mounted on PCBs using surface mounting techniques, SMT encompasses all related processes involved in this method.

Additionally, there are specialized models within each category that address niche market needs—from high-speed pick-and-place options capable of handling complex assemblies to versatile SMT setups suited for rapid prototyping environments. This breadth ensures that every manufacturer can find an appropriate solution within the expansive portfolio offered by JUKI.

Comparing SMT and SMD Technologies

When diving into the world of JUKI automation systems, understanding the nuances between Surface Mount Technology (SMT) and Surface Mount Devices (SMD) is crucial. While these terms are often used interchangeably, they refer to different aspects of electronic assembly. In this section, we will unravel the differences, uses, and advantages of SMT in JUKI systems to help you make informed decisions for your production needs.

What is the Difference Between SMT and SMD

To put it simply, Surface Mount Technology (SMT) refers to the method of mounting electronic components directly onto the surface of printed circuit boards (PCBs). On the other hand, Surface Mount Devices (SMD) are the actual components that are mounted using this technology. So when someone asks, What is the difference between SMT and SMD?, it's all about distinguishing between the process (SMT) and the components themselves (SMD).

In JUKI automation systems, understanding this distinction can enhance your operational efficiency. By utilizing SMT processes with various SMDs tailored for specific applications, manufacturers can streamline their production lines while maintaining high quality. This clarity helps businesses choose suitable machines—like an SMT pick and place machine—designed specifically for their needs.

What is the SMT Used For

Surface Mount Technology finds its application across a wide range of industries—from consumer electronics to automotive manufacturing. It’s primarily used for assembling electronic circuits quickly and efficiently while minimizing space on PCBs. So when we ponder What is SMT used for?, we discover its role in creating compact devices with high functionality that meet modern consumer demands.

JUKI automation systems leverage SMT to improve production speed without compromising quality or reliability. The seamless integration of pick and place machines ensures precise placement of SMDs on PCBs during assembly, making it ideal for mass production scenarios where accuracy matters most. As technology continues to evolve, so does the application scope of SMT in various sectors.

Advantages of SMT in JUKI Systems

The benefits of incorporating Surface Mount Technology into JUKI automation systems are numerous and significant. First off, one major advantage is its ability to reduce PCB size while increasing component density—allowing manufacturers to create smaller devices without sacrificing performance or features. Additionally, using an SMT machine streamlines assembly processes by reducing handling times compared to traditional through-hole methods.

Another perk lies in cost-effectiveness; JUKI’s advanced pick and place machines ensure high-speed operations that lower labor costs while boosting productivity levels significantly. Moreover, with automated processes like these integrated into your production line, consistency in quality becomes a given rather than a goal—a win-win situation! Ultimately, embracing SMT within JUKI automation systems equips businesses with competitive advantages that cater to evolving market demands.

How Does a SMT Machine Work?

When we delve into the workings of an SMT machine, it’s essential to understand that it’s the backbone of modern electronics manufacturing. These machines enable high-speed production and precision assembly of electronic components onto printed circuit boards (PCBs). The process begins with the application of solder paste, followed by placing components accurately, which is where the magic happens in JUKI automation systems.

The Functionality of SMT Machines

So, how does a SMT machine work? At its core, an SMT machine employs a pick and place mechanism to position components on PCBs with incredible accuracy. It starts by loading the PCB onto a conveyor belt; then, using advanced vision systems and algorithms, it identifies where each component should go based on pre-programmed designs—this is crucial for ensuring that every part is placed correctly.

The pick and place machine picks up components from feeders using suction nozzles or mechanical grippers. After picking up a component, it swiftly moves to its designated spot on the PCB and places it down with precision. This seamless integration of speed and accuracy makes JUKI automation systems stand out in the competitive landscape of electronics manufacturing.

Components of SMT Machines

Understanding what makes up an SMT machine can help demystify how they function so efficiently. Key components include feeders that hold various electronic parts ready for placement; these can be tape-and-reel or tray-based systems depending on component size and type. Additionally, there are vision systems that ensure correct alignment before placement—if you’ve ever wondered about What is the difference between SMT and SMD? this technology plays a pivotal role in distinguishing between them.

Another critical aspect is the conveyor system that transports PCBs through various stages of assembly within the machine. Finally, there are control units powered by sophisticated software that manage everything from programming to real-time adjustments during operation—making sure your production line runs as smoothly as possible with minimal downtime.

Common Applications for SMT Machines

SMT machines are versatile tools used across numerous industries for various applications. They are primarily utilized in assembling consumer electronics like smartphones and tablets but extend their reach into automotive electronics, medical devices, and even aerospace technology due to their reliability and efficiency. When asking What is the SMT used for?, think about any modern electronic device you encounter daily—it likely owes its existence to an efficient SMT pick and place machine.

Moreover, JUKI automation systems facilitate rapid prototyping as well as mass production runs—allowing manufacturers to adapt quickly to changing demands without sacrificing quality or speed. The flexibility provided by these machines ensures they remain at the forefront in tackling increasingly complex designs while maintaining cost-effectiveness across all operations.

The Role of Pick and Place Machines

In the world of JUKI automation systems, pick and place machines play a pivotal role in streamlining assembly processes. These machines are designed to efficiently handle and position components on printed circuit boards (PCBs), ensuring precision and speed. By automating this critical task, manufacturers can significantly reduce labor costs and improve overall production efficiency.

What is a Pick and Place Machine

A pick and place machine is a sophisticated piece of equipment used primarily in the electronics manufacturing industry. It operates by picking components from a feeder or tray and placing them accurately onto PCBs, which are essential in SMT (Surface Mount Technology) processes. Understanding what is the SMT used for? The answer lies in its ability to facilitate high-speed assembly while maintaining exceptional accuracy—something that manual labor simply cannot match.

Features of JUKI Pick and Place Machines

JUKI pick and place machines come equipped with advanced features that enhance their functionality within JUKI automation systems. These machines boast high-speed operation capabilities, precise placement accuracy, and user-friendly interfaces that allow operators to easily program them for various tasks. Additionally, many models include vision systems for real-time inspection, ensuring that every component is placed correctly—an essential factor when considering what is the difference between SMT and SMD technologies.

Efficiency Gains with JUKI Automation

Integrating JUKI automation systems with pick and place technology leads to significant efficiency gains across production lines. By automating component placement using an SMT machine, manufacturers can achieve higher throughput rates while minimizing errors associated with manual handling. This not only accelerates production timelines but also enhances product quality—a win-win situation for any manufacturer looking to thrive in today's competitive market.

Selecting the Right JUKI Automation System

Choosing the right JUKI automation system is crucial for optimizing your production line. With various options available, understanding what suits your specific needs can significantly impact efficiency and output quality. This section will guide you through key factors to consider, essential questions to ask, and how to evaluate your production requirements.

Key Factors to Consider

When selecting a JUKI automation system, several factors come into play. Firstly, consider the scale of your operation; larger productions might benefit from advanced SMT machines equipped with high-speed pick and place machines for greater throughput. Secondly, assess the types of components you’ll be working with; understanding what is the SMT used for in your applications will help in determining which features are necessary.

Another critical factor is compatibility with existing systems. If you're already using certain technologies, ensure that the new JUKI automation systems can seamlessly integrate with them. Finally, factor in maintenance and support; a reliable after-sales service can save you time and money down the road.

Questions to Ask Before Purchasing

Before making a purchase decision, it’s essential to ask some probing questions about potential JUKI automation systems. Start by asking: What is the difference between SMT and SMD? Understanding this distinction will clarify which technology aligns better with your production goals.

Next, inquire about how does a SMT machine work? Knowing its functionality helps gauge whether it meets your operational needs effectively. Furthermore, ask about the specifications of their pick and place machine—what features do they offer that enhance efficiency?

Lastly, don't forget to discuss warranty and service options; having robust support can make all the difference when integrating new systems into your workflow.

Evaluating Your Production Needs

Evaluating your production needs involves a thorough analysis of current operations alongside future projections. Begin by assessing what is currently being produced: Are you focused on high-volume runs or low-mix/high-variability assembly? This will influence whether an advanced SMT pick and place machine or a more straightforward setup is required.

Consider also the types of products you manufacture; if they involve complex assemblies or require precision placement of components, investing in specialized JUKI automation systems may be beneficial. Additionally, think about scalability—will this system grow with you as demand increases?

Finally, take stock of budgetary constraints while keeping long-term gains in mind; sometimes investing more upfront in quality machinery pays off through increased productivity later on.

Conclusion

In the fast-paced world of manufacturing, maximizing productivity is not just a goal; it's a necessity. JUKI automation systems are designed to streamline processes and enhance efficiency, allowing businesses to stay competitive. By integrating these systems into your production line, you can significantly reduce downtime and boost output quality.

Maximizing Productivity with JUKI Systems

To truly maximize productivity with JUKI automation systems, it’s essential to understand how each component contributes to the overall workflow. For instance, knowing what is the SMT used for can help you leverage its capabilities effectively in various applications. The advanced features of SMT machines and pick and place machines ensure that components are placed accurately and swiftly, minimizing errors and enhancing throughput.

Moreover, understanding how does a SMT machine work allows operators to optimize settings for specific tasks, leading to even greater efficiency gains. When combined with JUKI's innovative technology, these machines become powerful tools in any production environment. Ultimately, investing in JUKI automation systems means investing in a future where productivity knows no bounds.

Choosing Between Different Automation Options

When faced with multiple options in automation technology, it’s crucial to weigh the benefits of each system carefully. One common question that arises is: what is the difference between SMT and SMD? Understanding this distinction helps manufacturers select the right process for their specific needs—whether they prioritize speed or precision.

Additionally, evaluating your options requires considering how well each system aligns with your production goals. For instance, if you're looking for flexibility and speed in assembly lines, an SMT pick and place machine might be your best bet. By carefully analyzing your requirements against available technologies like JUKI automation systems, you can make an informed decision that drives success.

Why Bensun Technology is Your Partner in Automation

In the realm of industrial automation solutions, Bensun Technology stands out as a trusted partner for integrating JUKI automation systems into your operations. With extensive knowledge about how does a SMT machine work and hands-on experience with pick and place machines, Bensun provides tailored solutions that meet unique business needs.

Choosing Bensun means gaining access not only to top-notch equipment but also expert guidance on implementing these technologies effectively across your production line. Whether you're curious about what is the SMT used for or need insights on optimizing SMD processes alongside SMT machinery, Bensun Technology has you covered every step of the way. Together with JUKI's innovative solutions, we can elevate your manufacturing capabilities beyond expectations.