Introduction

In the rapidly evolving world of electronics manufacturing, SMT automatic chip mounters have become indispensable tools in the assembly of printed circuit boards (PCBs). These cutting-edge machines streamline the process of placing tiny components onto PCBs with remarkable speed and accuracy, significantly enhancing production capabilities. As industries continue to demand higher efficiency and precision, understanding the role of auto machining in PCB assembly has never been more crucial.

Overview of SMT Automatic Chip Mounters

SMT automatic chip mounters are specialized machines designed to automate the placement of surface mount devices (SMDs) onto PCBs. They utilize advanced technology to ensure that components are positioned accurately and efficiently, which is essential for maintaining high-quality standards in electronics manufacturing. With various models available, each offering unique features and capabilities, these smt machines cater to diverse production needs across different sectors.

Importance of Auto Machining in PCB Assembly

The significance of auto machining in PCB assembly cannot be overstated; it not only boosts productivity but also minimizes human error during the manufacturing process. By employing pick & place machines, manufacturers can achieve consistent results while reducing labor costs associated with manual assembly methods. This shift towards automation has led to faster turnaround times and improved overall quality in electronic products.

Evolution of Pick and Place Machines

The evolution of pick and place machines has transformed how electronic components are assembled on PCBs over the years. Initially simple devices, modern pick and place machinery now incorporates sophisticated technologies such as vision systems and artificial intelligence to enhance performance further. As a result, today's smt machinery is not only faster but also smarter—adapting seamlessly to varying production demands while ensuring optimal precision throughout the assembly process.

Understanding SMT Technology

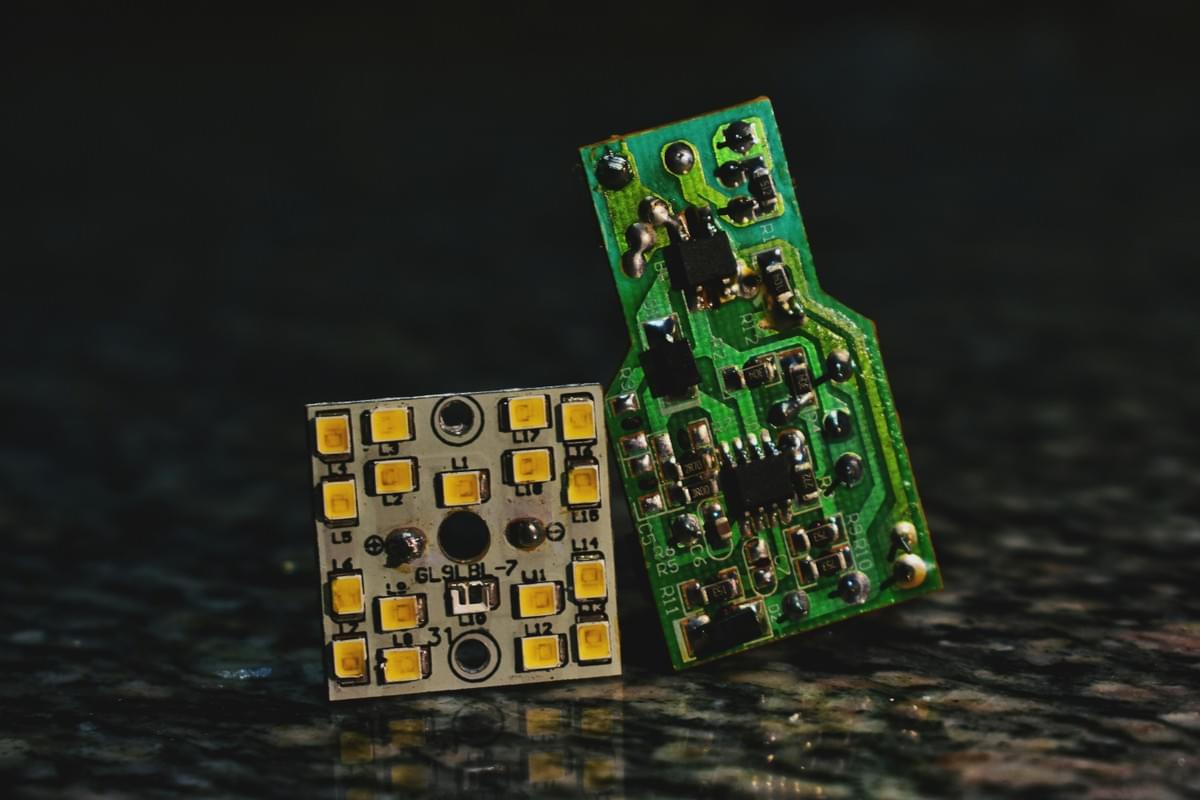

Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). This method allows for a more compact design, enabling manufacturers to produce smaller and more efficient devices. At the heart of this technology are SMT automatic chip mounters, which streamline the assembly process and enhance production capabilities.

Basics of Surface Mount Technology

At its core, Surface Mount Technology involves mounting electronic components directly onto the surface of PCBs rather than inserting them through holes. This innovation reduces the size and weight of electronic assemblies while improving electrical performance. By utilizing SMT machinery, manufacturers can achieve higher density layouts, which is essential in today’s fast-paced tech landscape.

The shift to SMT has also led to a decrease in manufacturing costs, as it requires fewer materials and less labor compared to traditional methods. Additionally, with auto machining techniques being integrated into PCB assembly processes, efficiency levels have skyrocketed. The precision offered by modern pick & place machines ensures that components are accurately positioned on the board every time.

Types of SMT Machines and Their Functions

SMT machines come in various types, each designed for specific functions within the PCB assembly process. The most prominent among these are pick and place machines, which automate the placement of components onto PCBs with remarkable speed and accuracy. Other types include solder paste printers for applying solder paste to pads on boards and reflow ovens that heat solder paste to create reliable electrical connections.

Each type of SMT machine plays a critical role in ensuring that production lines operate smoothly and efficiently. For instance, while a pick & place machine focuses on component placement, solder paste printers ensure that the right amount of solder is applied for optimal connectivity. Together, these machines form an integrated system that enhances overall productivity in manufacturing environments.

The Role of Pick and Place Machines

Pick and place machines are often considered the backbone of any SMT assembly line due to their pivotal role in placing components accurately on PCBs. These sophisticated devices use advanced vision systems to identify component locations before picking them up with precision grippers or vacuum systems. Once lifted, they swiftly move to position each component exactly where it needs to be on the board.

The efficiency brought by pick & place machines allows manufacturers to significantly increase their output while minimizing errors associated with manual assembly processes. With features like programmable settings and real-time monitoring capabilities, these machines adapt easily to various production needs—making them indispensable in modern electronics manufacturing environments. As technology continues evolving with advancements like AI integration into auto machining processes, we can expect even greater improvements in how pick and place machines function.

Key Advantages of Automatic Chip Mounters

In the fast-paced world of electronics manufacturing, SMT automatic chip mounters have become indispensable. These machines offer a range of advantages that enhance the efficiency and effectiveness of PCB assembly processes. With advancements in auto machining technology, the capabilities of pick and place machines have skyrocketed, making them essential tools for modern manufacturers.

Increased Efficiency in Production

One of the most significant benefits of using an SMT automatic chip mounter is the remarkable increase in production efficiency. These machines can place thousands of components per hour, far surpassing manual assembly methods. By automating the process with a pick & place machine, manufacturers can significantly reduce cycle times and boost overall throughput.

Moreover, the integration of advanced software and robotics in these SMT machines allows for quick changeovers between different product lines. This adaptability ensures that production remains agile and responsive to market demands without sacrificing speed or quality. As a result, businesses can meet tight deadlines while maintaining high standards—a win-win situation for any manufacturer.

Enhanced Precision and Quality

Precision is paramount in PCB assembly, and SMT machinery excels in this aspect as well. Automatic chip mounters are designed to achieve an accuracy level that is often unattainable through manual processes; they can consistently position components with micrometer-level precision. This enhanced accuracy leads to fewer defects during assembly, which ultimately translates into higher quality end products.

Furthermore, modern pick and place machines are equipped with sophisticated vision systems that inspect each component before placement. This real-time feedback loop ensures that any potential errors are caught early on—before they become costly mistakes down the line. The result? A more reliable product that meets stringent industry standards.

Reduction of Labor Costs

Implementing an SMT automatic chip mounter not only streamlines production but also leads to significant labor cost savings. With a pick & place machine handling most tasks traditionally performed by human operators, companies can reallocate their workforce to more strategic roles within their operations. This shift allows businesses to operate leaner while still maintaining output levels.

Additionally, as auto machining technology continues to advance, fewer personnel are required for supervision or intervention during production runs. The combination of reduced labor needs and increased output creates a compelling business case for investing in SMT machinery today—especially when considering long-term operational costs versus initial investments.

Leading Players in the Market

In the competitive landscape of SMT machinery, several key players stand out for their innovative contributions to the industry. This section explores Bensun Technology Co., Ltd. and JUKI, highlighting their unique offerings and advancements in pick and place machines. Additionally, we will compare these brands with other notable manufacturers to provide a comprehensive view of the market.

Bensun Technology Co., Ltd. Overview

Bensun Technology Co., Ltd. has carved out a significant niche in the realm of SMT automatic chip mounters with its commitment to quality and innovation. Specializing in advanced auto machining solutions, Bensun’s pick & place machines are designed for high efficiency and precision, making them ideal for various PCB assembly applications. Their dedication to R&D enables them to stay ahead of trends, ensuring that customers receive cutting-edge technology tailored to their needs.

The company’s flagship products include a range of SMT machines that cater to different production scales—from small batch runs to large-scale manufacturing lines. Each machine is equipped with state-of-the-art features such as intelligent vision systems and flexible component handling capabilities, setting Bensun apart from competitors in the smt machinery space. Moreover, their customer support is renowned for being responsive and knowledgeable, further solidifying Bensun's reputation as a go-to provider for SMT solutions.

JUKI’s Innovations in Pick and Place Machines

JUKI has long been recognized as a leader in the field of pick and place machines, continually pushing boundaries through innovative technologies that enhance productivity on assembly lines. Their latest models incorporate advanced auto machining techniques that not only increase speed but also improve accuracy—crucial factors in today’s fast-paced electronics manufacturing environment. JUKI's commitment to integrating AI into their smt machines exemplifies how they are adapting to modern demands while maintaining high-quality standards.

One standout feature of JUKI's pick & place machine lineup is their ability to handle an extensive range of components with varying sizes and shapes seamlessly—this versatility makes them particularly appealing for companies looking to streamline production without sacrificing quality or adaptability. Additionally, JUKI invests heavily in user-friendly interfaces that simplify operation while providing real-time data analytics for better decision-making on the factory floor. As such, they remain at the forefront of smt machinery innovation.

Comparison with Other SMT Machinery Brands

When evaluating leading brands like Bensun and JUKI against others in the market, several factors come into play: performance metrics, customer service reputation, technological advancements, and pricing strategies all contribute significantly to brand positioning within the SMT landscape. While some manufacturers may offer lower upfront costs on their pick & place machines, they often fall short regarding long-term reliability or support services compared to established names like Bensun or JUKI.

Moreover, emerging brands may introduce novel features aimed at capturing market share; however, they often lack comprehensive service networks essential for maintaining complex smt machinery over time. In contrast, both Bensun Technology Co., Ltd., known for its robust customer assistance program and JUKI’s extensive global presence ensure that clients receive not just equipment but also ongoing support crucial for maximizing operational efficiency with automatic chip mounters.

As companies consider investing in new automation technologies such as pick and place machines or upgrading existing equipment within PCB assembly lines—the choice between established players versus newer entrants becomes increasingly critical based on specific needs related to performance reliability versus cost-effectiveness.

Future Trends in PCB Assembly

The landscape of PCB assembly is rapidly evolving, driven by innovations in auto machining and the integration of advanced technologies. As manufacturers strive for greater efficiency and precision, the role of SMT automatic chip mounters becomes increasingly prominent. This section will explore key advancements shaping the future of PCB assembly, including cutting-edge auto machining technology, the impact of artificial intelligence on SMT processes, and the broader shift towards smart manufacturing.

Advancements in Auto Machining Technology

Auto machining technology is advancing at a breakneck speed, with new features being integrated into pick and place machines that enhance their capabilities. Modern SMT machines now incorporate sophisticated sensors and real-time data analytics to optimize production lines continuously. These advancements not only improve accuracy but also facilitate faster changeovers between different assembly tasks, making them indispensable for manufacturers looking to stay ahead in a competitive market.

Moreover, innovations such as modular designs allow for easy upgrades to existing SMT machinery without requiring complete replacements. This flexibility means that businesses can adapt to changing demands without breaking the bank or halting production entirely. As these technologies evolve further, we can expect even more streamlined processes that will redefine what’s possible in PCB assembly.

Impact of AI on SMT Processes

Artificial intelligence is poised to revolutionize how we approach surface mount technology (SMT) processes within PCB assembly lines. By leveraging AI algorithms, pick & place machines can learn from previous placements and adjust their operations accordingly to minimize errors and maximize efficiency. This intelligent automation not only speeds up production but also enhances quality control by identifying potential issues before they escalate into costly problems.

AI-driven analytics enable manufacturers to predict maintenance needs for their SMT automatic chip mounters based on usage patterns and performance metrics. This predictive maintenance reduces downtime significantly—a crucial factor when every second counts in high-volume production environments. As AI continues to integrate with SMT machinery, expect smarter systems capable of self-optimizing based on real-time feedback from the assembly line.

The Shift Towards Smart Manufacturing

The transition towards smart manufacturing represents a paradigm shift that emphasizes connectivity and automation across all facets of production—including PCB assembly using pick & place machines. Smart factories utilize IoT (Internet of Things) devices that communicate seamlessly with each other, allowing for real-time monitoring and adjustments throughout the manufacturing process. This interconnectedness ensures that every component—from raw materials to finished products—is optimized for maximum efficiency.

In this new era of manufacturing, SMT machinery plays a pivotal role as part of an integrated ecosystem designed to enhance productivity while reducing waste and errors significantly. The adoption of smart technologies allows companies to respond swiftly to market changes or disruptions without compromising quality or output rates—an essential advantage in today’s fast-paced business environment. Embracing these trends will not only keep manufacturers competitive but also pave the way toward sustainable practices within the industry.

Choosing the Right Pick and Place Machine

Selecting an appropriate pick and place machine is crucial for optimizing your assembly line's performance. With various models and features available, understanding the specific needs of your production process can significantly impact efficiency. Factors such as speed, accuracy, and compatibility with different types of SMT machinery should be carefully evaluated to ensure a seamless integration into your operations.

Factors to Consider for Your Assembly Line

When choosing an SMT automatic chip mounter, several factors come into play that can influence your decision-making process. First, consider the volume of production; high-output lines may require faster pick & place machines with advanced automation capabilities to keep up with demand. Additionally, assess the types of components you will be using; some pick and place machines are better suited for smaller or more intricate parts while others excel in handling larger components.

Another essential factor is the level of precision required in your assembly processes. High-precision applications benefit from machines equipped with advanced vision systems that enhance placement accuracy, which is vital for maintaining product quality in PCB assembly. Finally, think about future scalability; investing in a versatile pick and place machine that can adapt to evolving production needs will save both time and money down the road.

Customization Options Available

Customization plays a pivotal role when selecting a pick and place machine tailored to your unique requirements. Many SMT machinery manufacturers offer modular designs that allow you to configure various components based on your specific production goals. This flexibility enables you to optimize workflows by integrating features like additional feeders or specialized nozzles tailored for different component sizes.

Moreover, software customization options can enhance operational efficiency by allowing users to program specific settings that align with their assembly line processes. Advanced programming capabilities also facilitate quick changeovers between product runs without extensive downtime—a significant advantage in today’s fast-paced manufacturing environments where auto machining is key to maintaining competitive edge.

Case Studies of Successful Implementations

To illustrate the impact of selecting the right pick and place machine, consider these successful implementations from industry leaders who have embraced SMT technology effectively. Company A experienced a 30% increase in productivity after upgrading their existing machinery to a state-of-the-art SMT automatic chip mounter featuring real-time monitoring capabilities—allowing them to identify bottlenecks quickly.

In another example, Company B leveraged customization options on their newly acquired pick & place machine which enabled them to handle diverse component types without sacrificing speed or quality. This adaptability resulted in reduced labor costs as fewer operators were required on the line while maintaining high standards of precision during PCB assembly.

Lastly, Company C's transition from manual processes to fully automated solutions not only streamlined their operations but also improved product consistency across multiple production batches—showcasing how investing wisely in suitable SMT machinery can lead directly to enhanced operational success.

Conclusion

In conclusion, SMT automatic chip mounters are revolutionizing the PCB assembly landscape. Their ability to enhance production efficiency and precision makes them indispensable in modern manufacturing environments. As we embrace advancements in auto machining, it’s clear that pick and place machines will continue to lead the charge in streamlining processes.

Key Takeaways on SMT Automatic Chip Mounters

SMT automatic chip mounters are pivotal for achieving high-speed assembly with unparalleled accuracy. They significantly reduce human error while maximizing throughput, making them essential for any competitive electronics manufacturer. Understanding the functionality and advantages of these machines can empower businesses to optimize their production lines effectively.

The Future of PCB Assembly and Efficiency

The future of PCB assembly is poised for a technological renaissance, driven by innovations in auto machining and smart manufacturing practices. With AI integration into pick & place machines, we can expect even greater levels of automation and efficiency in the coming years. This shift will not only enhance productivity but also enable manufacturers to adapt quickly to market demands.

Why Bensun is Your Go-To for SMT Solutions

When it comes to SMT solutions, Bensun stands out as a leader in providing cutting-edge technology with exceptional support services. Their range of pick and place machines combines reliability with advanced features tailored for diverse manufacturing needs. Choosing Bensun means investing in quality, innovation, and a partnership that prioritizes your success.