Introduction

In today's fast-paced manufacturing landscape, the power of automation is transforming how we approach production. The emergence of the china chip mounter machine has revolutionized the PCB assembly process, offering unprecedented efficiency and precision. As industries continue to innovate, understanding the future of PCB assembly becomes essential for staying competitive.

Discover the Power of Automation

Automation is no longer a luxury; it's a necessity in modern manufacturing. With machines like the pick and place machine leading the charge, companies can streamline their operations and enhance productivity significantly. By adopting advanced machine SMT technology, businesses are discovering new levels of efficiency that were once thought impossible.

Why Choose a China Chip Mounter Machine

When it comes to choosing equipment for PCB assembly, the china chip mounter machine stands out for its reliability and cost-effectiveness. These machines not only provide high-speed performance but also ensure accuracy in placing components on boards with minimal errors. Investing in a machine pick and place solution means embracing innovation while reaping substantial long-term benefits.

The Future of PCB Assembly

The future of PCB assembly lies in advanced machinery that enhances both speed and quality. With innovations in SMT machines, manufacturers can expect improved capabilities that cater to various industries—from consumer electronics to medical devices. As we look ahead, it's clear that embracing technologies like machine chip systems will pave the way for smarter manufacturing solutions.

Increased Efficiency

In the fast-paced world of electronics manufacturing, efficiency is key to staying competitive. The introduction of the china chip mounter machine has revolutionized how companies approach PCB assembly, making it possible to streamline production like never before. With advancements in machine chip technology, manufacturers can optimize their workflows and achieve higher output without sacrificing quality.

Streamlining Production with Machine Chip Technology

Machine chip technology has transformed traditional assembly lines into streamlined operations that maximize productivity. By utilizing a pick and place machine, businesses can automate the placement of components on printed circuit boards (PCBs), significantly reducing manual labor and minimizing human error. This efficiency not only speeds up production times but also allows for a more consistent quality across all units produced.

The integration of sophisticated software in modern SMT machines further enhances this process, enabling real-time adjustments and monitoring. With machine pick and place capabilities, manufacturers can easily adapt to changing demands or varying designs without extensive downtime for reconfiguration. Overall, embracing these technologies leads to an agile manufacturing environment capable of meeting market needs swiftly.

Advantages of High-Speed SMT Machines

High-speed SMT machines are game changers in the realm of PCB assembly, offering unparalleled speed without compromising precision. These machines are designed to handle large volumes of components efficiently, ensuring that production lines remain active with minimal interruptions. The ability to quickly switch between different types of components means that manufacturers can cater to diverse product lines without significant delays.

Moreover, high-speed performance translates directly into cost savings as companies can produce more units within a shorter timeframe. This increased output not only boosts revenue potential but also enhances customer satisfaction by ensuring timely deliveries. Investing in a high-speed china chip mounter machine is not just about keeping up; it's about leading the charge in innovation and efficiency.

Reducing Downtime with Advanced Features

One of the most significant benefits offered by modern PCB machines is their ability to minimize downtime through advanced features such as automatic calibration and quick changeovers. These smart systems allow for seamless transitions between different production runs while maintaining accuracy and consistency across all outputs. By incorporating such technologies into their operations, businesses can ensure that every minute spent on the production floor counts.

Additionally, many state-of-the-art SMT machines come equipped with predictive maintenance capabilities that alert operators before issues arise, further reducing unplanned interruptions during manufacturing processes. This proactive approach ensures equipment remains operational longer while enhancing overall productivity levels throughout the facility. Ultimately, investing in advanced machine SMT features translates into smoother operations and better bottom-line results.

Cost-Effectiveness

When it comes to manufacturing, cost is always a top concern. Investing in a China chip mounter machine can yield significant savings over time, as these machines are designed to optimize production processes and reduce waste. By automating the assembly line with SMT technology, companies can streamline operations and cut costs associated with labor and material inefficiencies.

How China Chip Mounter Machines Save Money

China chip mounter machines are engineered for efficiency, drastically reducing the cost per unit produced. With features like high-speed operation and precision placement, these machines minimize material waste and maximize output—meaning more products can be assembled in less time. The long-term savings from reduced labor costs and fewer errors make investing in a machine pick and place system an attractive choice for any manufacturer.

Comparing Costs: Manual vs. Automated Strategies

When comparing manual assembly methods to automated strategies using a pick & place machine, the differences become glaringly obvious. Manual processes often lead to higher labor costs due to the need for skilled workers, not to mention increased chances of human error that can result in costly rework or scrap materials. In contrast, a machine SMT solution not only speeds up production but also ensures consistent quality at a lower overall cost.

The Long-Term ROI of Investing in SMT

Investing in an SMT machine is not just about immediate savings; it's about long-term returns on investment (ROI). Over time, the efficiency gains from using advanced PCB machines translate into significant financial benefits that far outweigh initial purchase prices. Companies that adopt these technologies typically see improved profitability as they scale operations without proportionately increasing costs—making the case for integrating a china chip mounter machine into your production line stronger than ever.

Improved Precision

In the world of PCB assembly, precision is paramount, and this is where the prowess of a china chip mounter machine truly shines. By employing advanced technology, these machines ensure that every component is placed accurately on the circuit board, significantly reducing the chances of errors. With a reliable pick and place machine at your disposal, you can trust that your production will meet the highest standards of quality.

The Role of Pick and Place Machines in Accuracy

Pick and place machines are the unsung heroes of PCB assembly lines. These machines expertly handle components with meticulous precision, ensuring they are positioned correctly on each board. The integration of sophisticated software allows for real-time adjustments during operation, enhancing accuracy and minimizing human error—something manual methods simply can't compete with.

Minimizing Errors with Advanced PCB Machines

Embracing advanced PCB machines means embracing a future with fewer mistakes. With features like vision systems and laser-guided placement, modern SMT machines can detect discrepancies before they become costly errors. This level of automation not only boosts efficiency but also instills confidence in manufacturers who rely on these machines to deliver high-quality products consistently.

Innovations in Machine SMT Technology

The landscape of machine SMT technology is ever-evolving, bringing forth innovations that further enhance precision in manufacturing processes. Newer models of china chip mounter machines come equipped with AI-driven algorithms that optimize placement strategies based on real-time data analysis. Such advancements ensure that your pick & place operations are not only faster but also more accurate than ever before.

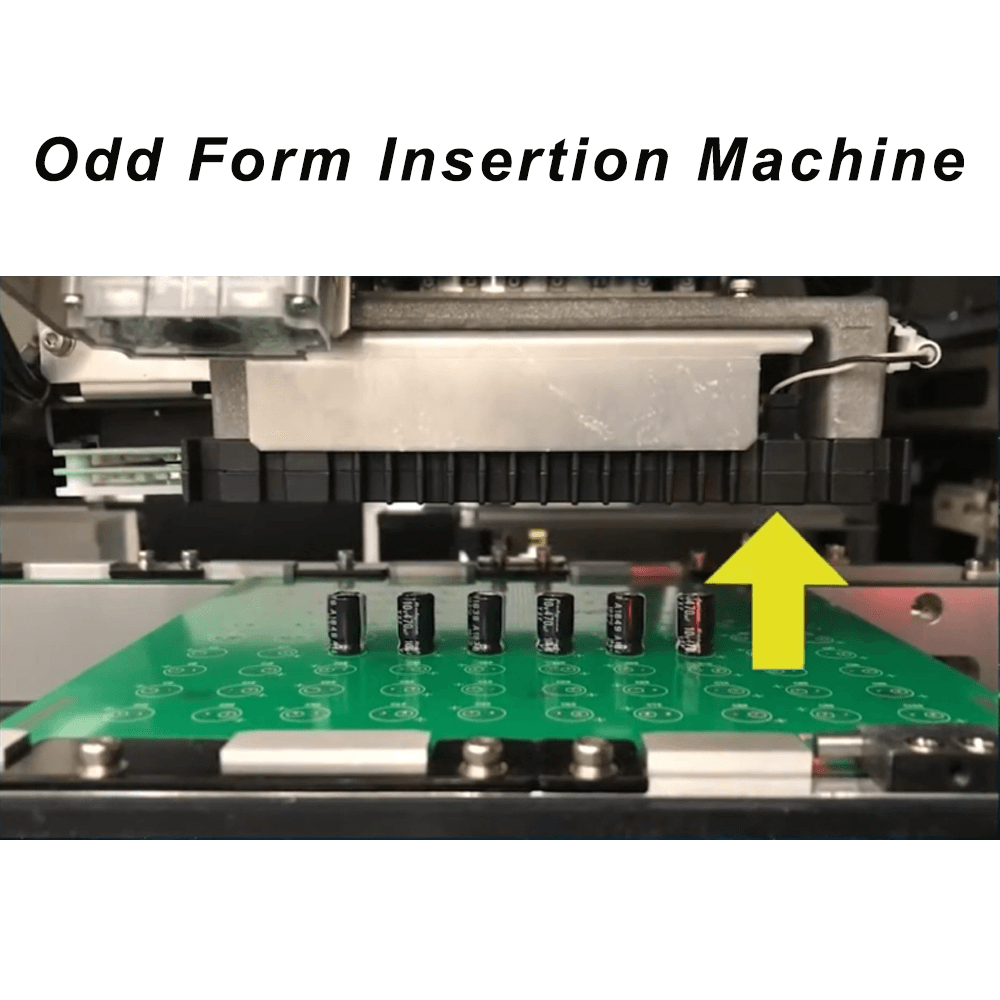

Versatility in Applications

The versatility of the China chip mounter machine is a game changer in the world of manufacturing. These machines are designed to adapt seamlessly to various industries, making them essential for businesses looking to enhance their production capabilities. Whether it’s high-volume consumer electronics or specialized medical devices, the machine pick and place technology can cater to diverse needs effectively.

Adapting to Various Industries

In today’s fast-paced market, industries require solutions that are not only efficient but also adaptable. The pick & place machine is engineered to handle a wide range of applications, from automotive components to telecommunications equipment. This adaptability ensures that manufacturers can respond quickly to changing demands without compromising on quality or speed.

From Consumer Electronics to Medical Devices

The reach of SMT machines extends far beyond just consumer electronics; they have become integral in sectors like healthcare and aerospace as well. In medical devices, precision is paramount, and the advanced capabilities of a PCB machine ensure that even the most delicate components are placed with accuracy. The reliability provided by machine SMT technology also reassures manufacturers that their products meet stringent regulatory standards.

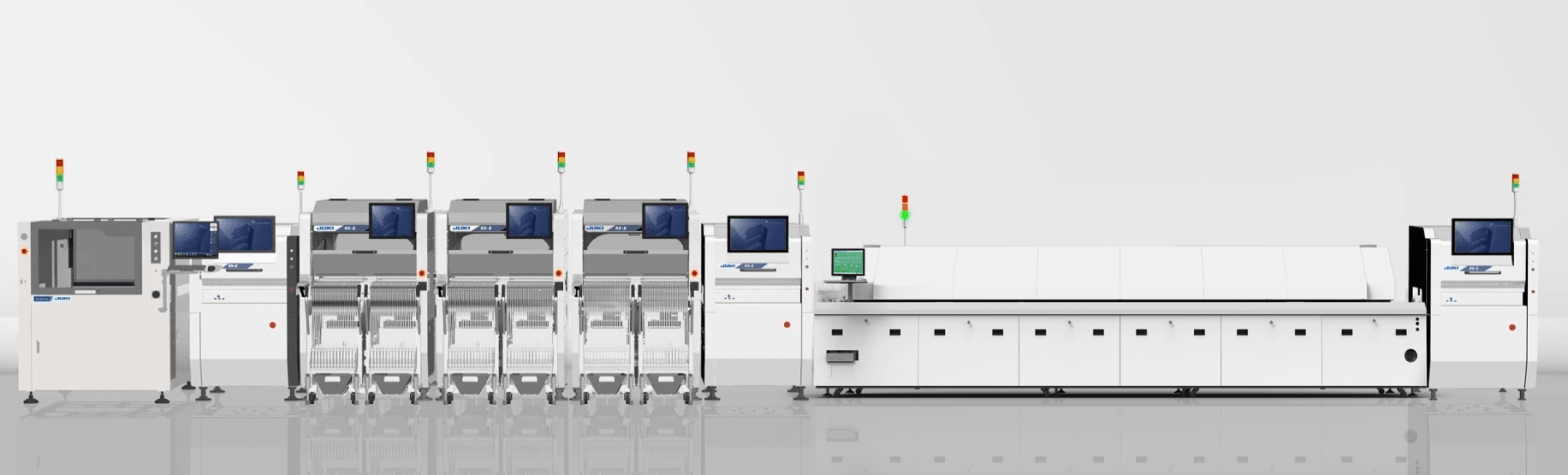

The Flexibility of Bensun Technology Co., Ltd. Products

Bensun Technology Co., Ltd. takes versatility up a notch with its innovative line of chip mounter machines tailored for various applications. With features that allow customization and scalability, these machines can grow alongside your business needs while maintaining efficiency and cost-effectiveness. Investing in Bensun's equipment means you’re not just purchasing a machine; you’re acquiring a flexible solution designed for future challenges.

Enhanced Quality Control

In the fast-paced world of electronics manufacturing, quality control has never been more critical. With the advent of advanced technologies, particularly in the realm of automation, companies are now able to implement rigorous quality checks that were previously unimaginable. The integration of visual inspection machines into the production line ensures that every component placed by a china chip mounter machine meets high standards, thus reducing defects and enhancing overall product reliability.

Ensuring Higher Standards with Visual Inspection Machines

Visual inspection machines play a pivotal role in maintaining high-quality standards in PCB assembly processes. These machines utilize sophisticated imaging technology to scrutinize each component placed by pick and place machines, ensuring that everything is precisely aligned and securely attached. By incorporating these visual aids into machine SMT operations, manufacturers can catch potential errors early on—before they escalate into costly reworks or product recalls.

The Impact of Automation on Product Quality

Automation has revolutionized how we approach product quality in manufacturing environments. By employing machine pick and place technology, companies can achieve an unprecedented level of consistency and precision across their production lines. This not only minimizes human error but also ensures that every unit produced meets strict quality benchmarks—ultimately leading to enhanced customer satisfaction and brand loyalty.

How Bensun's Equipment Redefines Quality Assurance

Bensun Technology Co., Ltd.’s equipment stands at the forefront of redefining quality assurance in electronics manufacturing. Their cutting-edge PCB machines incorporate advanced features such as real-time monitoring and adaptive learning algorithms that continuously improve performance over time. By investing in Bensun’s innovative solutions, manufacturers can confidently produce high-quality products while leveraging the efficiency offered by automated systems like china chip mounter machines.

Conclusion

In a world where efficiency and innovation reign supreme, embracing the capabilities of advanced machinery is no longer an option but a necessity. The China chip mounter machine stands at the forefront of this revolution, offering unparalleled speed and precision in PCB assembly. By integrating these machines into your production line, you're not just keeping up with industry standards; you're setting them.

Embrace Efficiency and Innovation

The shift toward automation in manufacturing processes has never been more critical, especially with tools like the pick and place machine leading the charge. These machines streamline operations, allowing for faster turnaround times while maintaining high-quality output. By adopting machine SMT technology, businesses can transform their production lines into models of efficiency that competitors will envy.

Investing in the Future of Manufacturing

Investing in a machine chip solution today means positioning your business for success tomorrow. With the rising costs associated with manual labor and inefficiencies, automated systems like SMT machines present a compelling case for long-term savings and higher ROI. As industries evolve, those who invest wisely in technology—like a reliable china chip mounter machine—will find themselves ahead of the curve.

Experience the Benefits with Bensun Technology

Bensun Technology Co., Ltd. offers cutting-edge solutions that redefine what it means to be competitive in today's market. Their range of PCB machines showcases versatility across various applications, ensuring that whether you’re producing consumer electronics or medical devices, you have the right tools at your disposal. Experience firsthand how integrating their pick & place machinery can elevate your operations to new heights.