Introduction

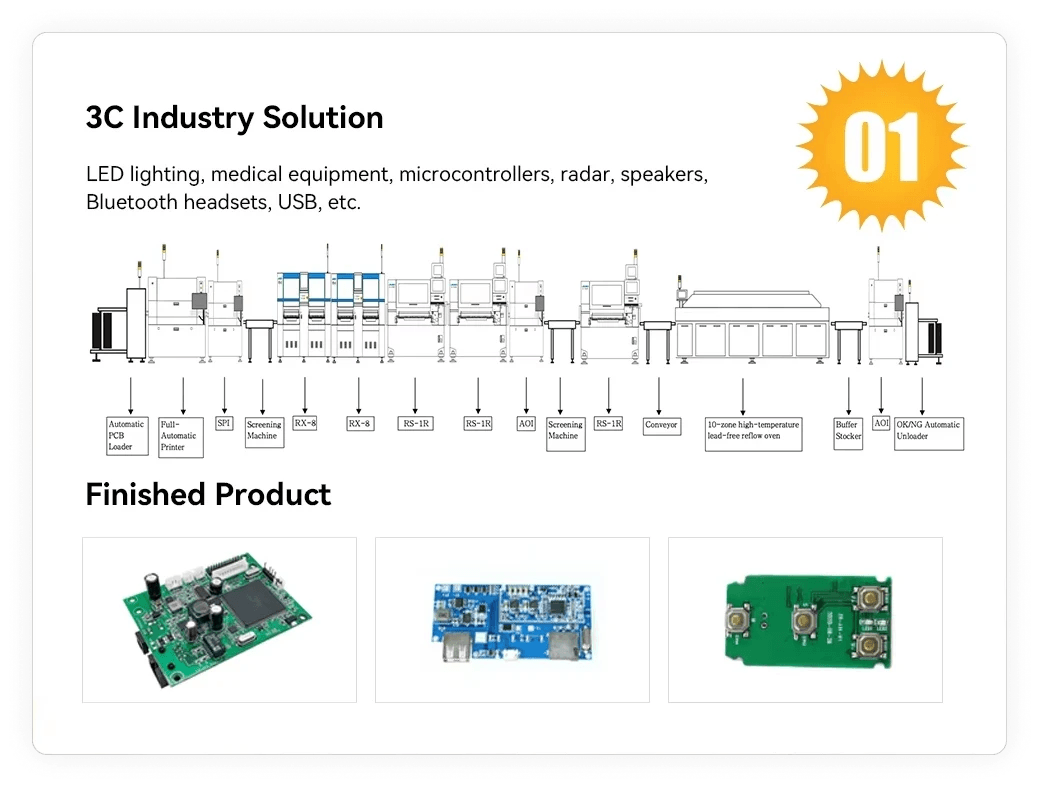

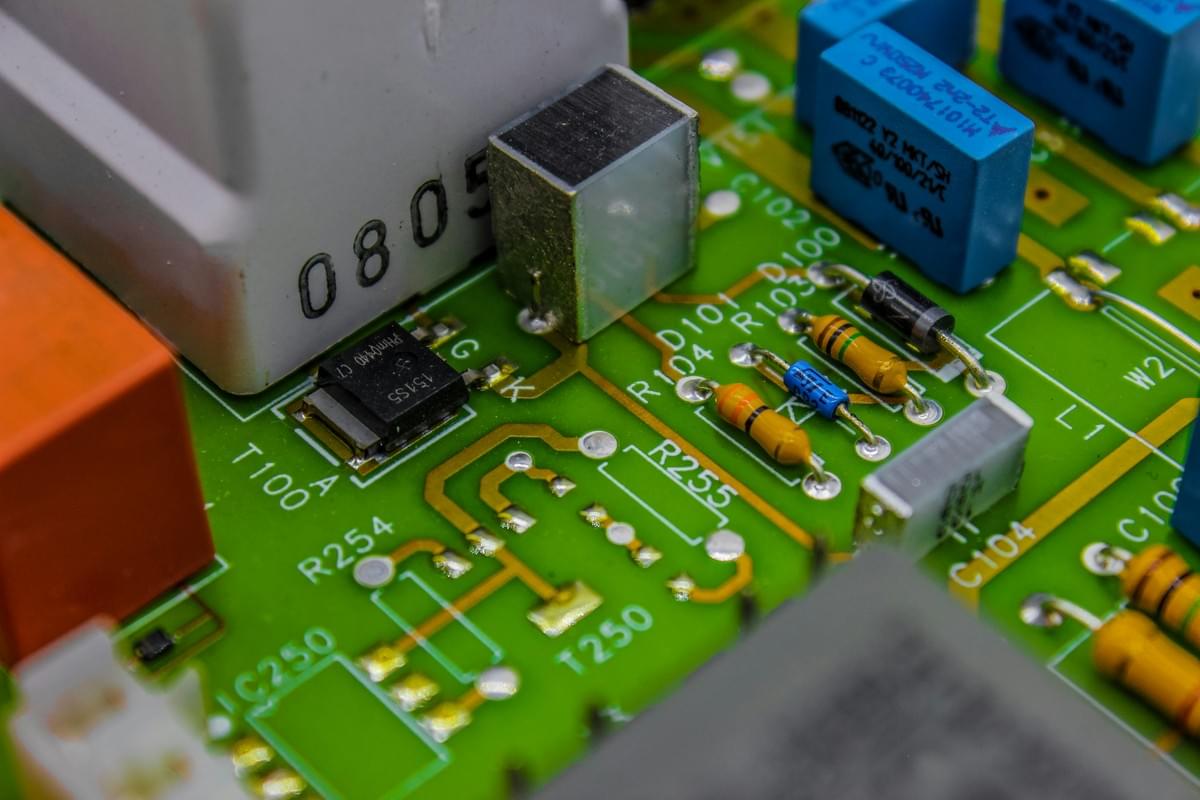

In the world of electronics manufacturing, SMT LED mounters play a crucial role in ensuring efficiency and precision in assembling printed circuit boards (PCBs). These machines are designed to accurately place surface mount components onto PCBs, which is essential for the production of modern electronic devices. With a plethora of options available, selecting the right SMT mounter can significantly impact your production quality and speed.

Understanding SMT LED Mounters

SMT LED mounters are specialized machines that automate the placement of surface mount technology (SMT) components, including LEDs, onto PCBs. They come equipped with advanced features that enhance placement accuracy and speed, making them indispensable for manufacturers aiming to keep up with market demands. When considering a China SMT mounter machine supplier, it’s important to understand how these machines operate and what makes them stand out from traditional assembly methods.

Why Choosing the Right Mounter Matters

Choosing the right SMT mounter supplier can make or break your production line's efficiency. An inappropriate choice may lead to increased downtime, higher error rates, and ultimately affect your bottom line. The right machine not only ensures compatibility with various board sizes but also aligns with your specific production needs—making it essential to invest time in research before committing to a purchase.

Overview of Key Features to Consider

When searching for an ideal SMT mounter from wholesale SMT mounter suppliers, several key features should be evaluated closely. Placement accuracy is paramount; even minor errors can result in costly rework or product failures down the line. Additionally, consider factors such as board size compatibility and ease of use—especially regarding software integration—as these will influence both operational efficiency and user experience in your manufacturing process.

Key Features of SMT LED Mounters

When it comes to selecting the right SMT LED mounter, understanding the key features is essential for optimizing your production line. These machines are crucial for placing components accurately on circuit boards, and their capabilities can significantly influence overall efficiency and output quality. In this section, we will explore three pivotal features: placement accuracy and speed, board size compatibility, and ease of use along with software integration.

Placement Accuracy and Speed

Placement accuracy is one of the most critical factors when choosing a China SMT mounter machine supplier. A high-precision SMT LED mounter ensures that components are placed exactly where they need to be, minimizing errors that could lead to costly rework or product failures. Speed is equally important; a faster machine can increase throughput without sacrificing quality, making it a valuable asset in high-volume production environments.

Moreover, modern SMT mounters are equipped with advanced vision systems that enhance placement accuracy while maintaining rapid operation speeds. This combination allows manufacturers to meet tight deadlines without compromising on quality standards. When evaluating wholesale SMT mounter suppliers, it's essential to ask about the specifications related to both speed and precision to ensure you're investing in a reliable machine.

Board Size Compatibility

Another vital consideration is board size compatibility when selecting an SMT LED mounter from China chip mounter machine factories. Different projects may require varying sizes of circuit boards; therefore, your chosen equipment should accommodate these variations seamlessly. A versatile machine can handle small prototypes as well as larger production runs without requiring extensive adjustments or downtime.

Additionally, some suppliers offer customizable options that allow you to modify the board handling capabilities based on your specific needs. This flexibility ensures that as your production demands evolve over time, your equipment can adapt accordingly without necessitating a complete overhaul of your setup. Thus, assessing board size compatibility should be at the forefront of discussions with potential SMT mounter suppliers.

Ease of Use and Software Integration

In today’s fast-paced manufacturing landscape, ease of use cannot be overlooked when considering an SMT LED mounter from wholesale SMT mounter suppliers. User-friendly interfaces and intuitive controls can significantly reduce training times for operators while enhancing overall productivity on the shop floor. Machines equipped with advanced software solutions also facilitate seamless integration into existing production lines.

Moreover, effective software integration means fewer disruptions during setup changes or maintenance tasks—a critical factor for any busy manufacturing environment striving for efficiency. When exploring options from various China chip mounter machine factories, inquire about their software capabilities and how easily they can integrate with other systems you may already have in place. Ultimately, investing in an easy-to-use system will pay dividends in time saved and increased operational effectiveness.

Evaluating Your Production Needs

When it comes to selecting the right SMT LED mounter, understanding your production needs is crucial. This involves a comprehensive evaluation of your volume requirements, customization options offered by suppliers, and future scalability considerations. By aligning these factors with your operational goals, you can make an informed decision that enhances efficiency and productivity.

Assessing Volume Requirements

The first step in evaluating your production needs is to assess your volume requirements. Are you a small-scale operation looking to produce limited quantities, or do you need a high-speed SMT mounter capable of handling large batches? Understanding this will guide you in choosing from various China SMT mounter machine suppliers that offer models tailored to different production scales.

Different SMT LED mounters come with varying placement speeds and capacities, so it's essential to match the machine's specifications with your expected output. For instance, if you're ramping up production for a new product line, opting for a high-capacity model from reputable China chip mounter machine factories may be the way to go. This assessment not only helps in selecting the right equipment but also ensures that you're prepared for fluctuating market demands.

Customization Options from Suppliers

Once you've gauged your volume requirements, it's time to explore customization options provided by various SMT mounter suppliers. Many wholesale SMT mounter suppliers offer configurable features that allow you to tailor machines according to specific manufacturing processes or product types. This flexibility can significantly enhance efficiency and reduce waste during production.

Customization might include adjustments in feeder configurations, software functionalities, or even hardware upgrades that cater specifically to unique components you'll be working with. Engaging directly with China chip mounter machine factories can provide insights into available custom solutions tailored for niche applications or specialized products. Ultimately, investing in a customizable SMT LED mounter could lead to smoother operations and better adaptability as market demands evolve.

Future Scalability Considerations

As you evaluate potential SMT LED mount machines, consider how well they align with future scalability needs. The last thing any manufacturer wants is to invest heavily in equipment that's already outdated before they've fully utilized it! Look for features that allow easy upgrades or expansions; this foresight can save both time and money down the line.

Many leading China SMT mounter machine suppliers design their products with scalability in mind—allowing businesses like yours to adapt as needed without starting from scratch every few years. Whether it’s adding more feeders or integrating advanced software capabilities down the road, ensuring compatibility is key for long-term success. So before making any final decisions on an SMT LED mounter purchase, think ahead about how your business might grow and what features will support that growth effectively.

Exploring Top SMT Mounter Suppliers

When it comes to selecting the right SMT LED mounter, knowing your suppliers is half the battle won. The market is brimming with options, especially from China, where many reliable SMT mounter suppliers are located. Here, we’ll delve into some notable names and what they bring to the table, helping you make an informed decision for your production needs.

Bensun Technology Co., Ltd. Overview

Bensun Technology Co., Ltd. is a prominent player in the realm of SMT mounters and has carved out a niche for itself among China chip mounter machine factories. Their commitment to innovation and quality ensures that their SMT LED mounters are not only efficient but also user-friendly. With a range of models tailored for different production scales, Bensun stands out as a dependable option among wholesale SMT mounter suppliers.

Their machines are designed with advanced technology that guarantees high placement accuracy and speed—critical features for any electronics manufacturer looking to optimize their workflow. Furthermore, Bensun offers excellent customer service and support, ensuring that clients can navigate any challenges they may face post-purchase seamlessly. This level of dedication makes them a top contender when considering an SMT LED mounter.

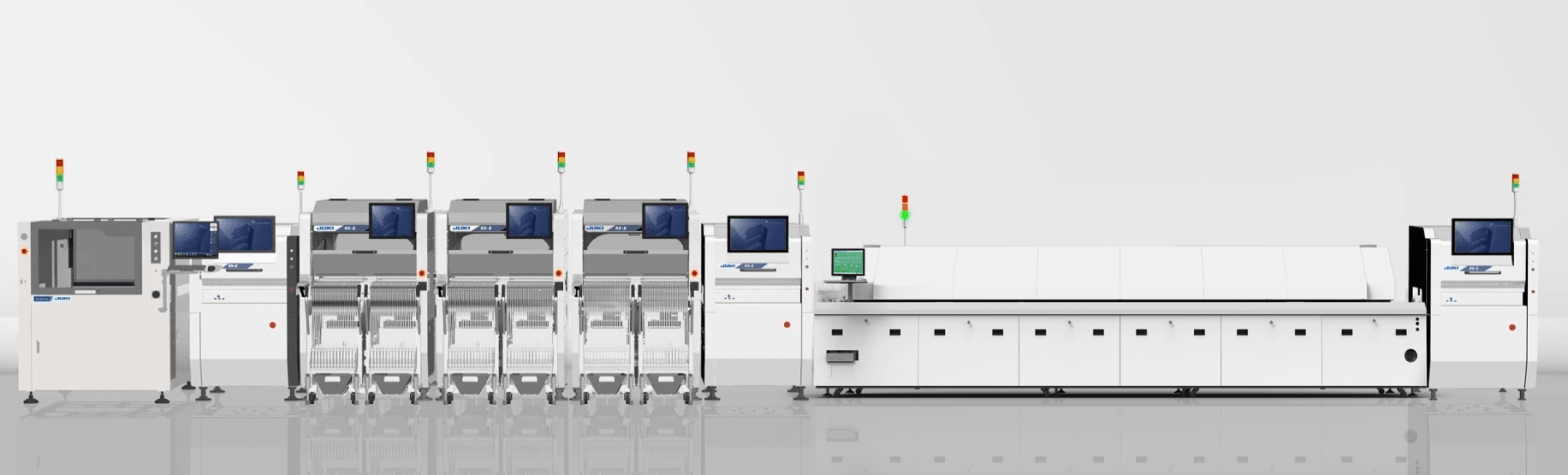

Key Offerings from JUKI and Other Brands

JUKI is another heavyweight in the world of SMT LED mounters, known for its cutting-edge technology and robust performance across various applications. Their machines are engineered to deliver exceptional placement accuracy while accommodating diverse board sizes—an essential feature for manufacturers dealing with multiple product lines. Additionally, JUKI’s software integration capabilities streamline operations significantly, making them a favorite among many in the industry.

Other notable brands worth mentioning include Panasonic and Yamaha; both have made significant strides in developing high-quality SMT mounters that cater to different production needs. These brands focus on enhancing user experience by offering intuitive interfaces and extensive customization options through their respective software platforms. When comparing these offerings with those from Chinese suppliers like Bensun or others, it's crucial to consider factors such as price point versus performance efficiency.

Comparing Features Across China SMT Mounter Suppliers

As you sift through various options available from China chip mounter machine factories, it’s essential to compare key features across different suppliers effectively. While price can be a determining factor when choosing an SMT LED mounter, it shouldn't overshadow critical aspects like placement speed, board compatibility, and ease of use offered by each supplier's equipment.

For instance, some wholesale SMT mounter suppliers may provide advanced models designed specifically for high-volume production runs while others might focus on flexibility for smaller batches or prototypes—tailoring their offerings based on market demand trends. Additionally, evaluating after-sales support becomes vital; having reliable maintenance services can save you time and money in the long run.

Ultimately, understanding what each supplier brings to the table will empower you to make an informed choice about which machine aligns best with your operational goals and budget constraints.

Cost Considerations for SMT LED Mounters

When investing in an SMT LED mounter, understanding the cost implications is crucial. The initial investment can be substantial, but it’s essential to weigh this against the long-term costs associated with ownership and operation. A well-chosen mounter can lead to savings over time through efficiency gains and reduced operational expenses.

Initial Investment vs. Long-Term Costs

The initial cost of a high-quality SMT LED mounter can vary significantly depending on the supplier and features included. While some may opt for a budget-friendly option from a China chip mounter machine factory, it’s important to consider how these choices impact long-term performance and reliability. Investing in a more robust machine from reputable wholesale SMT mounter suppliers may yield better returns through enhanced productivity and fewer breakdowns.

Moreover, the total cost of ownership should factor in not just the purchase price but also energy consumption, maintenance needs, and potential downtime costs associated with less reliable machines. By calculating these long-term costs alongside the initial investment, manufacturers can make more informed decisions when selecting an SMT mounter supplier that aligns with their production goals. Ultimately, choosing wisely now could save significant money down the road.

Evaluating Maintenance and Warranty Options

Maintenance is another critical aspect when considering different SMT LED mounters on the market today. Many China SMT mounter machine suppliers offer varying warranty options that cover parts and labor for specific periods; understanding these terms is vital to avoiding unexpected expenses later on. A comprehensive warranty can provide peace of mind, ensuring that if something goes wrong, you won’t be left footing a hefty repair bill.

Additionally, some suppliers may provide maintenance packages or service agreements that include regular check-ups or emergency support for your equipment. This proactive approach helps keep your SMT LED mounter running smoothly while potentially extending its lifespan significantly. When evaluating suppliers, don’t hesitate to ask about their maintenance offerings; they can often be as important as the machine itself.

Budgeting for Upgrades and Additional Equipment

As technology evolves rapidly within manufacturing sectors, budgeting for future upgrades should be part of any investment strategy related to SMT LED mountings. It’s wise to consider whether your chosen supplier offers modular options or add-ons that allow you to enhance your existing setup without needing an entirely new machine from scratch later on—this is particularly relevant when dealing with leading China chip mounter machine factories known for evolving tech solutions.

Furthermore, additional equipment like feeders or software upgrades might become necessary as production demands grow or change over time; planning ahead ensures you’re not caught off guard by sudden requirements down the line! By allocating resources towards potential future enhancements now rather than later will set you up for success in meeting evolving market challenges while maximizing your return on investment.

Making the Final Decision

Choosing the right SMT LED mounter is a critical step in optimizing your production line. With various options available from numerous suppliers, making an informed decision can save you both time and money in the long run. This section will guide you through essential steps to finalize your choice.

Testing and Demos with Wholesale SMT Mounter Suppliers

Before committing to a purchase, it’s wise to request demos or trials from wholesale SMT mounter suppliers. This hands-on experience allows you to assess the performance of different models and see how they fit into your workflow. Pay attention to placement accuracy, speed, and ease of use during these demonstrations; these factors are pivotal when selecting a China SMT mounter machine supplier.

In addition, don’t hesitate to ask for custom configurations during these tests. Many China chip mounter machine factories offer tailored solutions that can cater specifically to your production needs. By thoroughly testing various options, you’ll gain confidence that you're selecting an SMT LED mounter that aligns perfectly with your operational requirements.

Gathering User Feedback and Reviews

User feedback is invaluable when narrowing down your choices for an SMT LED mounter. Seek out reviews from other businesses that have purchased similar models; their insights can reveal potential issues or highlight features you might not have considered before. Online forums, industry publications, and direct testimonials are excellent resources for gathering this information about specific smt mounter suppliers.

Additionally, consider reaching out directly to companies using machines from the China chip mounter machine factories you’re interested in. They can provide firsthand accounts of reliability, ease of maintenance, and overall satisfaction with their SMT LED mounters. This grassroots research will help ensure you're making a well-informed decision based on real-world performance rather than just marketing hype.

Final Checklist Before Purchase

Once you've narrowed down your options based on demos and user feedback, it’s time for a final checklist before making that investment in an SMT LED mounter. Evaluate key criteria such as compatibility with existing equipment, support services offered by the supplier, and warranty terms—these elements significantly impact long-term satisfaction with your purchase.

Make sure you've also factored in future scalability—will this machine adapt as your business grows? Lastly, confirm all financial aspects including initial costs versus potential long-term savings; understanding these nuances will help ensure you choose wisely among various China SMT mounter machine suppliers.

Conclusion

In the ever-evolving world of electronics manufacturing, selecting the right SMT LED mounter is crucial for achieving optimal efficiency and product quality. Compatibility with existing systems and performance metrics directly influence production capabilities, making it essential to choose a reliable China SMT mounter machine supplier that meets your specific needs. Ultimately, investing in a high-performing smt mounter supplier ensures you remain competitive in a fast-paced market.

Importance of Compatibility and Performance

Compatibility between your SMT LED mounter and other production equipment cannot be overstated; it serves as the backbone of an efficient assembly line. A well-chosen mounter from reputable China chip mounter machine factories will not only enhance placement accuracy but also streamline workflow processes, reducing downtime significantly. Performance metrics such as speed and precision are vital; they ensure that your production line operates smoothly, delivering high-quality products consistently.

Long-Term Support and Service Options

When choosing a wholesale SMT mounter supplier, consider their long-term support services as part of your decision-making process. A reliable supplier should offer comprehensive maintenance plans and responsive customer service to address any issues that may arise post-purchase. This level of support can significantly extend the lifespan of your SMT LED mounter while ensuring that you remain productive even during unexpected downtimes.

Investing in Quality for Future Success

Investing in quality when selecting an SMT LED mounter is not just about immediate needs; it's about future-proofing your operations against evolving technology demands. By sourcing from established suppliers among China chip mounter machine factories, you can secure machines designed for scalability and enhanced features over time. Quality equipment leads to fewer breakdowns, lower operational costs, and ultimately contributes to greater profitability as you adapt to changing market conditions.