Introduction

In the fast-paced world of electronics manufacturing, efficiency and precision are paramount. Enter SMT LED mounting machines, a crucial component in the assembly process that ensures every LED chip is placed accurately and reliably. Understanding these machines can help businesses optimize their production lines and enhance overall output.

Understanding SMT LED Mounting Machines

SMT (Surface Mount Technology) LED mounting machines, often referred to as pick and place machines, are designed to automate the placement of electronic components onto printed circuit boards (PCBs). These sophisticated devices utilize advanced technology to accurately position LED chips with remarkable speed and precision. With features like automatic production line integration, these machines significantly reduce labor costs while improving product quality.

The Benefits of Factory Pricing

By purchasing directly from manufacturers like Bensun Technology, companies can access competitive rates that cut out middlemen markups. This cost-effective approach not only makes acquiring high-quality led chip mounter machinery feasible but also contributes to long-term savings through reduced operational expenses.

Choosing the Right Equipment for Your Needs

Selecting the right machine pick and place equipment requires careful consideration of various factors tailored to your specific production needs. It's essential to evaluate your production volume, types of components being used, and desired automation level when making this decision. By understanding your requirements and assessing different line SMT options available on the market, you can ensure that you invest in machinery that enhances productivity while meeting your operational goals.

Overview of SMT LED Mounting Machines

In the world of electronics manufacturing, SMT LED mounting machines play a crucial role in ensuring efficiency and precision. These machines are designed to automate the process of placing surface-mount components, specifically LEDs, onto printed circuit boards (PCBs). Understanding how these machines work can help manufacturers optimize their production lines and stay competitive in a fast-paced market.

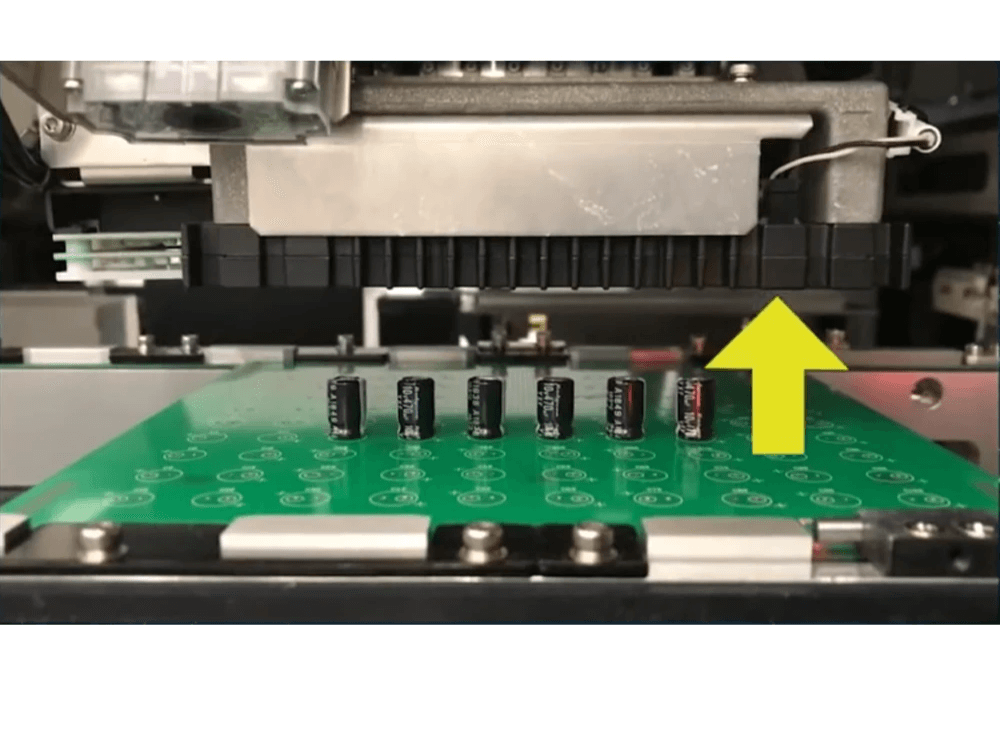

What is a Pick and Place Machine

At the heart of SMT technology lies the pick and place machine, an essential component that streamlines the assembly process. This sophisticated device uses advanced robotics to pick up electronic components from feeders and precisely place them onto PCBs. The speed and accuracy of a pick and place machine significantly reduce production time while enhancing product quality, making it indispensable for modern manufacturing operations.

Features of LED Chip Mounter Machinery

LED chip mounter machinery comes equipped with a plethora of features designed to boost productivity and ensure high-quality output. These machines often include multiple heads for simultaneous placement, vision systems for real-time inspection, and adjustable speeds tailored to different production needs. Additionally, many models offer flexibility in handling various component sizes, making them suitable for diverse applications across industries.

Importance of Automatic Production Lines

The integration of automatic production lines into manufacturing processes cannot be overstated; they are pivotal in achieving higher efficiency levels. By utilizing automated systems like SMT machines, companies can minimize human error while maximizing output speed. An automatic production line not only enhances consistency but also allows manufacturers to scale their operations seamlessly without compromising on quality or performance.

How Bensun Technology Leads the Market

In the competitive world of SMT machines, Bensun Technology stands out as a leader, consistently pushing the boundaries of innovation and reliability. Their commitment to excellence is evident in their advanced led chip mounter machinery, which is designed to meet the ever-evolving needs of manufacturers. By integrating cutting-edge technology into their pick and place machines, Bensun ensures that clients receive top-notch equipment that enhances productivity and efficiency.

Innovations in SMT Machines

These machines incorporate smart features such as real-time monitoring and adaptive algorithms that optimize placement accuracy and speed. As a result, users benefit from a seamless automatic production line experience that minimizes downtime while maximizing output.

Moreover, continuous research and development allow Bensun to introduce features like enhanced vision systems in their pick and place machine models. This not only improves precision but also reduces errors significantly during assembly processes. With these innovations, Bensun's line SMT solutions are equipped to handle complex tasks with ease, making them invaluable assets for manufacturers across various industries.

Reliability in Production Equipment

When it comes to reliability, Bensun’s led chip mounter machinery sets a high standard in the industry. Built with durable components and rigorous quality control measures, these machines are designed for longevity under demanding production conditions. Manufacturers can trust that investing in a machine pick and place from Bensun means fewer breakdowns and interruptions in their workflow.

Additionally, each piece of equipment undergoes extensive testing before reaching customers' facilities to ensure optimal performance right out of the box. This focus on reliability translates into consistent production output for businesses relying on automatic production lines for efficiency gains. With less time spent on repairs or replacements, companies can allocate resources more effectively toward growth initiatives.

Customer Support and Service Excellence

Bensun Technology prides itself not only on its innovative products but also on its exceptional customer support services tailored specifically for users of SMT machines. From initial consultations regarding machine pick and place requirements to comprehensive training sessions post-purchase, Bensun ensures clients feel supported every step of the way. Their dedicated team is readily available to address inquiries or troubleshoot issues promptly.

Moreover, after-sales service includes regular maintenance checks designed to keep led chip mounter machinery operating at peak performance throughout its life cycle. This commitment fosters long-term relationships with clients who appreciate having reliable partners invested in their success rather than just one-off sales transactions. Ultimately, choosing Bensun means gaining access not only to superior technology but also unparalleled service excellence that empowers businesses.

The Cost Advantage of Factory Pricing

Why Factory Prices Matter

Factory prices matter because they reflect the true cost of production without unnecessary markups. When you buy a pick and place machine directly from the manufacturer, you're not just saving money; you're also ensuring that you receive high-quality equipment built with precision and care. Additionally, factory pricing often includes better warranty options and customer support, which can be invaluable in maintaining your automatic production line.

Comparing Costs of Different Brands

Not all brands are created equal when it comes to price versus performance in the SMT machines market. While some companies may offer lower initial costs, they often compromise on quality or service, leading to higher long-term expenses due to repairs or replacements. In contrast, investing in reputable brands like Bensun for your machine pick and place needs ensures that you get reliable performance without hidden costs lurking around the corner.

Long-term Savings with Bensun Products

Choosing Bensun products means more than just an upfront savings; it's about long-term financial benefits as well. Their led chip mounter machinery is designed for durability and efficiency, which translates to fewer breakdowns and less downtime on your line SMT operations. Over time, these factors contribute significantly to cost savings—making Bensun not just a smart choice but a strategic investment for any manufacturer looking to optimize their automatic production line.

Key Applications of SMT Machines

SMT machines have revolutionized various industries, providing efficiency and precision in assembling electronic components. Their versatility makes them indispensable in sectors ranging from consumer electronics to automotive manufacturing and medical devices. Understanding these key applications can help businesses maximize their investment in led chip mounter machinery and pick and place machines.

Use in Consumer Electronics

The consumer electronics sector is one of the primary arenas for SMT machines, particularly for assembling smartphones, tablets, and other gadgets. With the rapid pace of technological advancement, manufacturers rely heavily on pick and place machines to ensure that components are placed accurately and quickly on printed circuit boards (PCBs). This efficiency not only speeds up production but also enhances the quality of the final product by minimizing errors associated with manual assembly.

Moreover, led chip mounter machinery plays a crucial role in facilitating high-volume production runs while maintaining consistency across batches. The automatic production line allows manufacturers to adapt swiftly to changing market demands without compromising quality or performance. In an industry where innovation is constant, having reliable SMT machines ensures that brands remain competitive.

Advantages in Automotive Manufacturing

In automotive manufacturing, SMT machines are essential for producing complex electronic systems found in modern vehicles. These systems include everything from infotainment units to advanced driver-assistance technologies, all requiring precise assembly provided by machine pick and place capabilities. The integration of SMT technology into automotive production lines has significantly improved both efficiency and safety standards.

Using line SMT processes allows manufacturers to streamline operations while reducing labor costs associated with manual assembly methods. Furthermore, the reliability offered by led chip mounter machinery means that automotive companies can maintain stringent quality control measures throughout their production cycles. This reliability translates into fewer recalls and enhanced customer satisfaction—key factors for success in a competitive market.

Role in Medical Device Production

The medical device industry demands the highest levels of precision due to the critical nature of its products—think life-saving devices like pacemakers or diagnostic equipment that require flawless functionality. Here, SMT machines play a vital role by ensuring that delicate electronic components are assembled accurately using advanced pick and place technology. The ability to automate these processes through an automatic production line not only increases output but also minimizes human error.

Moreover, led chip mounter machinery enables manufacturers to comply with stringent regulatory requirements while maintaining high-quality standards essential for patient safety. By leveraging machine pick and place systems within their operations, medical device producers can innovate faster while adhering to necessary guidelines without sacrificing quality or performance. This strategic advantage positions them favorably within this highly regulated industry.

Choosing the Right SMT Equipment

Selecting the right SMT equipment is a crucial step for any manufacturer looking to optimize their production process. With a variety of options available, including advanced led chip mounter machinery and efficient pick and place machines, understanding your specific needs is vital. This section will guide you through the factors to consider when choosing your machine pick and place and how to evaluate line SMT performance.

Factors to Consider for Machine Pick and Place

When considering machine pick and place options, several factors come into play that can significantly impact your production efficiency. First, assess the speed and accuracy of the led chip mounter machinery; these attributes are essential for meeting high-volume production demands without sacrificing quality. Additionally, consider the flexibility of the equipment: can it handle various component sizes? A versatile pick and place machine will ensure you can adapt to changing market needs without investing in new machinery every time.

Another critical factor is ease of use; operators should be able to quickly learn how to operate the machine effectively. Look for SMT machines with user-friendly interfaces that include intuitive programming features or touchscreen controls. Finally, don't overlook maintenance requirements; choose a model that offers straightforward servicing options to minimize downtime in your automatic production line.

Understanding Your Production Needs

Before making a purchase decision on SMT equipment, it's essential to have a clear understanding of your production needs. Consider factors such as volume requirements: Are you producing small batches or large-scale runs? Different types of led chip mounter machinery are designed for specific output levels, so aligning your choice with your anticipated production scale is crucial.

Also, think about component types you'll be handling; some pick and place machines excel with surface-mount devices while others are better suited for mixed technologies. Understanding these requirements will help you select an appropriate machine that enhances efficiency on your automatic production line while ensuring quality output across various applications.

Lastly, don’t forget about future growth; choose equipment that can grow with your business demands rather than just meeting current needs. Investing in scalable technology ensures you won’t have to replace or upgrade too soon as market conditions change.

Evaluating the Performance of Line SMT

Evaluating line SMT performance requires careful analysis of several key metrics that directly affect productivity and quality outcomes in manufacturing processes. Start by examining throughput rates—the number of components placed per hour—since this metric provides insight into how efficiently your chosen led chip mounter machinery operates under different workloads.

Next, assess placement accuracy; it’s vital that components are positioned correctly on PCBs (Printed Circuit Boards) since even minor misalignments can lead to product failures down the line. Look at specifications from manufacturers regarding their machines' precision rates; high-quality pick and place machines typically boast impressive accuracy statistics.

Finally, evaluate overall reliability by reviewing user feedback or conducting trials if possible; knowing how well an automatic production line holds up under pressure will give you peace of mind when making a significant investment in SMT technology. Remember: selecting reliable smt machines not only boosts productivity but also enhances product quality—key elements for long-term success in competitive markets.

Conclusion

In the fast-paced world of manufacturing, efficiency and cost-effectiveness are paramount. By leveraging affordable solutions like led chip mounter machinery and advanced pick and place machines, businesses can streamline their production processes without sacrificing quality. Embracing these technologies not only enhances productivity but also positions companies to thrive in a competitive market.

Maximizing Efficiency with Affordable Solutions

To maximize efficiency, investing in the right machinery is crucial. Automatic production lines equipped with reliable smt machines can significantly reduce operational downtime and increase output rates. By choosing cost-effective options such as machine pick and place systems, manufacturers can achieve higher precision while keeping expenses in check.

Investing in Quality for Long-term Gains

While upfront costs are important, the long-term benefits of investing in quality equipment cannot be overstated. High-quality led chip mounter machinery offers durability and reliability that cheaper alternatives often lack, leading to fewer breakdowns and maintenance issues over time. This investment pays off through improved performance and reduced operational costs, making it a smart choice for forward-thinking businesses.

Partnering with Bensun for Success

When it comes to selecting a supplier for your smt machines, partnering with a reputable company like Bensun can make all the difference. With their commitment to innovation and exceptional customer support, Bensun ensures you have access to cutting-edge technology tailored to your needs. By choosing Bensun's products, you not only enhance your production capabilities but also gain a trusted ally on your path to success.