Introduction

In the fast-paced world of electronics, understanding both Surface Mount Technology (SMT) and Thru-Hole production is crucial for effective printed circuit manufacturing. These two techniques serve as the backbone of PCB printed circuit assembly, each with its unique advantages and applications. As technology evolves, so do the methods and equipment used to create reliable, high-quality electronic assemblies.

Understanding SMT and Thru-Hole Production

SMT involves placing components directly onto the surface of a printed PCB, which allows for more compact designs and higher component density. In contrast, Thru-Hole production uses leads that pass through holes in the PCB, providing stronger mechanical connections for larger components. Both methods have their place in electronic assembly, making it essential to understand their differences when choosing pick and place equipment.

Importance of Quality in Electronic Assembly

Quality is paramount in electronic assembly; even minor defects can lead to significant failures down the line. Ensuring that every component is accurately placed on a printed PCB is vital for optimal performance and longevity of electronic devices. Implementing advanced pick & place machines enhances precision in placement, ultimately leading to improved quality assurance throughout the manufacturing process.

Overview of Essential Equipment

To achieve excellence in PCB printed circuit assembly, specific equipment is indispensable. Key pieces include pick and place machines that automate component placement with remarkable accuracy and speed. Additionally, visual inspection systems play a critical role in verifying that every component has been correctly positioned before moving on to subsequent manufacturing stages.

The Role of Pick and Place Equipment

In the realm of printed circuit manufacturing, pick and place equipment plays a pivotal role in ensuring efficiency and precision. These machines are designed to automate the assembly process by accurately placing components onto printed PCBs. With advancements in technology, pick & place machines have become indispensable tools in electronic assembly operations.

How Pick and Place Machines Work

At the heart of every machine pick and place operation lies a sophisticated system that utilizes vision technology to identify component positions on the PCB. The pick and place machine employs suction or mechanical grippers to lift components from their trays or reels, then precisely places them onto designated spots on the printed PCB. This automation not only speeds up production but also minimizes human error, significantly enhancing the overall quality of electronic assembly.

Benefits in PCB Printed Circuit Assembly

The benefits of utilizing pick and place equipment in PCB printed circuit assembly are manifold. Firstly, these machines increase production speed; they can handle thousands of components per hour compared to manual methods that struggle to keep pace. Secondly, they ensure consistent accuracy, which is crucial for maintaining high-quality standards in electronic assembly; even the smallest misplacement can lead to costly errors down the line.

Leading Brands: Yamaha and Universal Instruments

When it comes to leading brands in the world of pick and place equipment, Yamaha and Universal Instruments stand out prominently. Yamaha's innovative designs focus on flexibility and speed, making their machines ideal for various production environments. Similarly, Universal Instruments offers a range of highly efficient pick & place machines known for their reliability and ease of use—both brands continue to push boundaries in improving printed circuit manufacturing processes.

Essential Thru-Hole Technology

Thru-hole production plays a crucial role in the landscape of electronic assembly, particularly for applications requiring robust connections. This technique involves inserting component leads through holes drilled into a printed circuit board (PCB) and soldering them on the opposite side. While surface mount technology (SMT) has gained popularity, thru-hole production remains essential for certain components and applications that demand durability and reliability.

What is Thru-Hole Production?

Thru-hole production is a method used in printed circuit manufacturing where electronic components are mounted by inserting their leads through pre-drilled holes in a printed PCB. This technique provides strong mechanical bonds, making it ideal for components that may experience physical stress or thermal cycling. In addition to strength, thru-hole technology allows for easier handling and placement of larger components, which can be particularly advantageous during the assembly process.

Comparing Thru-Hole and SMT Techniques

When comparing thru-hole and SMT techniques, one must consider several factors including size, cost, and application suitability. While pick and place equipment excels at placing smaller surface-mounted devices quickly and efficiently on PCBs, thru-hole production shines when it comes to larger components that require secure connections. Additionally, while SMT often leads to higher density designs with more compact layouts, the durability of thru-hole connections makes them indispensable in high-stress environments such as aerospace or military applications.

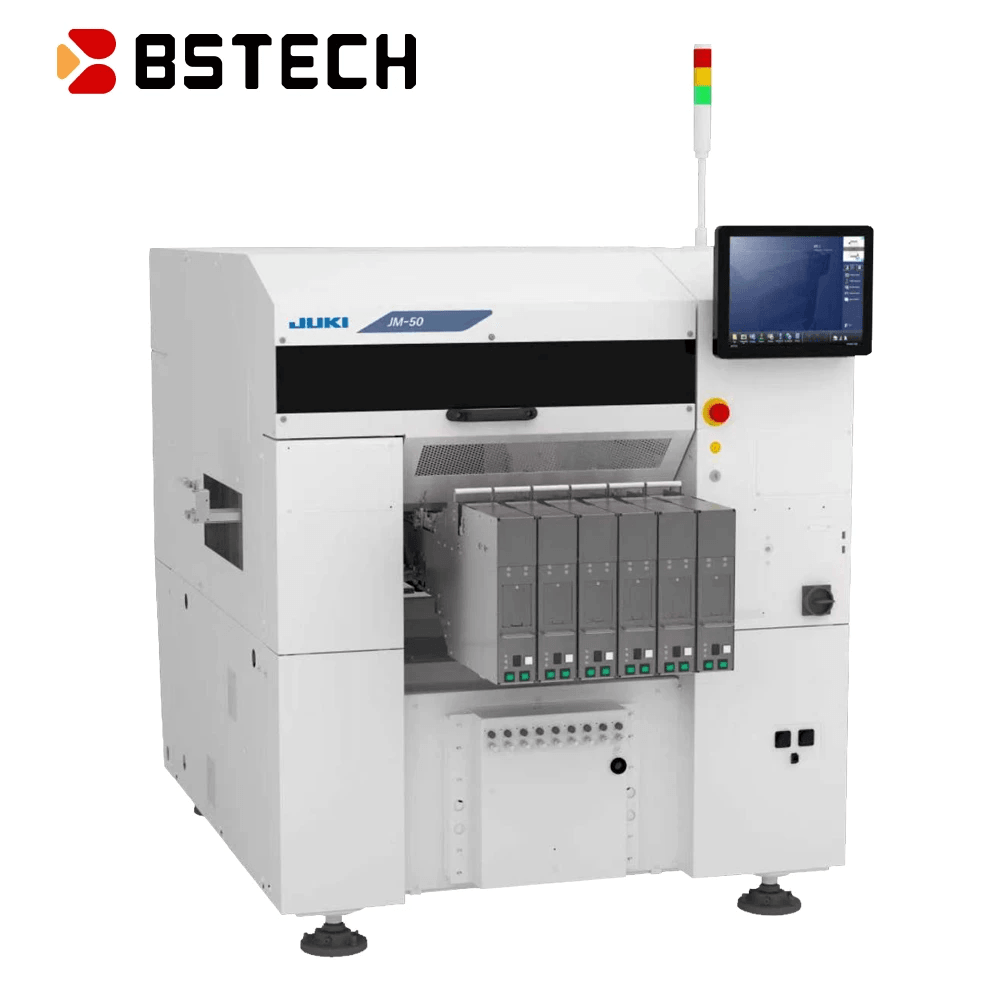

Key Players in Thru-Hole Machines: JUKI and Fuji

In the world of thru-hole machines, JUKI and Fuji stand out as leading manufacturers known for their innovative solutions tailored to electronic assembly needs. JUKI offers advanced machines that combine speed with precision to ensure reliable placement of components during the manufacturing process. Similarly, Fuji's commitment to quality engineering results in highly efficient machines designed specifically for both pick & place machine operations as well as traditional thru-hole technologies.

Innovations in Printed Circuit Manufacturing

The landscape of printed circuit manufacturing is undergoing a significant transformation driven by technological advancements and evolving industry demands. As manufacturers strive for higher efficiency and lower costs, innovations such as automation and sophisticated pick and place equipment are playing pivotal roles. These developments not only enhance production capabilities but also improve the quality of electronic assembly, making it crucial for companies to stay ahead of the curve.

Emerging Trends in PCB Manufacturing

Emerging trends in PCB manufacturing reflect a growing emphasis on miniaturization and increased functionality within smaller footprints. The rise of IoT devices has led to an increased demand for compact printed PCBs that can house more components without compromising performance. Additionally, sustainability is becoming paramount; manufacturers are exploring eco-friendly materials and processes that reduce waste while maintaining high standards in electronic assembly.

Another trend gaining traction is the integration of advanced materials like flexible substrates, which offer versatility for various applications. This shift not only allows for innovative designs but also enhances the durability and performance of printed circuits under different environmental conditions. As these trends evolve, they underscore the importance of using cutting-edge pick and place machines that can adapt to new requirements efficiently.

The Impact of Automation on Efficiency

Automation has revolutionized the realm of printed circuit manufacturing by streamlining processes and minimizing human error. With sophisticated machine pick and place systems, manufacturers can achieve unprecedented levels of speed and precision during PCB assembly. This efficiency translates into reduced production times, allowing companies to respond swiftly to market demands without sacrificing quality.

Moreover, automated systems facilitate real-time monitoring and data collection throughout the production line, enabling continuous improvement efforts based on actionable insights. By leveraging data analytics alongside advanced pick & place machines, manufacturers can optimize their workflows further while ensuring consistent quality across all electronic assembly operations. The result? A more agile business model capable of competing in today’s fast-paced environment.

Noteworthy Technologies: Laser Direct Imaging

One standout technology reshaping printed circuit manufacturing is Laser Direct Imaging (LDI). This process eliminates traditional photolithography methods by using lasers to directly image patterns onto photoresist-coated substrates—resulting in higher resolution features with greater accuracy than ever before. LDI not only enhances design capabilities but also reduces material waste significantly compared to conventional techniques.

Incorporating LDI into the PCB production process complements existing equipment like pick and place machinery by ensuring that intricate designs are faithfully reproduced on each board produced. As a result, manufacturers can push boundaries further with complex layouts while maintaining high throughput rates—essentially marrying creativity with efficiency in electronic assembly projects. With this technology at their disposal, companies are well-positioned to meet future challenges head-on.

Complementary Equipment for Optimal Production

In the world of printed circuit manufacturing, having the right complementary equipment is essential for achieving optimal production efficiency and quality. While pick and place equipment is crucial for assembling components onto PCBs, additional machines enhance the overall process, ensuring that every step from fabrication to inspection is seamless. Understanding these machines can help businesses streamline their electronic assembly operations.

Additional Machines for Complete Lines

To create a fully functional PCB printed circuit assembly line, various additional machines are necessary to complement the pick and place machine. These include reflow ovens, solder paste printers, and wave soldering machines that work in harmony with pick and place equipment to ensure precision in component placement and soldering processes. Each machine plays a pivotal role in reducing production time while maintaining high-quality standards in printed PCB assemblies.

Moreover, integrating these machines into a complete line allows for greater automation, reducing manual intervention and minimizing errors during the electronic assembly process. The synergy between these machines enhances productivity by facilitating smoother transitions between each stage of production. Ultimately, investing in a complete line not only streamlines operations but also maximizes return on investment through improved output quality.

Importance of Visual Inspection Systems

Visual inspection systems are critical components in any modern PCB manufacturing setup that relies heavily on pick & place machine technology. These systems ensure that each assembled board meets stringent quality standards by identifying defects early in the production process. By incorporating advanced imaging technology, visual inspection systems can detect misaligned components or soldering issues that might otherwise go unnoticed.

The importance of visual inspections cannot be overstated; they serve as an essential safeguard against costly rework or product failures down the line. This proactive approach helps maintain high levels of customer satisfaction while protecting your brand's reputation within a competitive market. With automated visual inspection systems working alongside pick and place equipment, manufacturers can achieve higher throughput without compromising on quality.

Bensun Technology’s Comprehensive Solutions

Bensun Technology stands out as a leader in providing comprehensive solutions tailored to meet diverse needs within the realm of printed circuit manufacturing. Their offerings extend beyond just pick and place equipment; they provide an array of complementary machinery designed to optimize every aspect of electronic assembly processes. From advanced visual inspection systems to efficient reflow ovens, Bensun ensures that each component works seamlessly with others.

By choosing Bensun Technology’s solutions, businesses can rest assured they are investing in state-of-the-art machinery backed by expert support services. Their commitment to innovation means you’ll always have access to cutting-edge technologies designed to enhance your PCB printed circuit operations significantly. With Bensun’s holistic approach to manufacturing solutions, companies can maximize productivity while maintaining top-tier quality across all stages of assembly.

Contract Manufacturing Services Explained

In the world of electronic assembly, contract manufacturing services have become a lifeline for companies looking to streamline their production processes. By leveraging the expertise of specialized PCB assemblers, businesses can focus on innovation while outsourcing the complexities of printed circuit manufacturing. This approach not only saves time but also enhances product quality through professional oversight and advanced technology.

Benefits of Using Contract PCB Assemblers

Utilizing contract PCB assemblers offers several advantages that can significantly impact a company's bottom line. First and foremost, these professionals bring experience with cutting-edge technologies, including state-of-the-art pick and place equipment, which ensures high precision in assembling printed PCBs. Additionally, outsourcing allows companies to scale production up or down based on demand without incurring the costs associated with maintaining in-house capabilities.

Another key benefit is access to specialized knowledge and resources that may not be available internally. For example, a contract assembler can provide insights into the latest trends in electronic assembly and help optimize processes using advanced machine pick and place techniques. This collaboration often results in faster turnaround times and enhanced overall efficiency in printed circuit manufacturing.

How Bensun Technology Meets Diverse Needs

Bensun Technology stands out as a leading provider of contract manufacturing services tailored to meet various industry requirements. Their extensive experience with pick & place machines allows them to handle projects ranging from small-scale prototypes to large-volume production runs seamlessly. By understanding each client's unique needs, Bensun ensures that every aspect of electronic assembly is addressed effectively.

Moreover, Bensun's commitment to quality control means that every printed PCB undergoes rigorous testing before delivery. This meticulous approach guarantees that clients receive products that meet stringent standards while minimizing defects associated with less experienced manufacturers. The integration of innovative technologies further enhances their ability to adapt quickly to changing market demands.

Case Studies of Successful Partnerships

Bensun Technology has built a reputation for successful collaborations across various sectors by delivering exceptional results through its contract manufacturing services. One notable case involved partnering with an emerging tech startup focused on developing smart home devices; they utilized Bensun’s advanced pick and place equipment for rapid prototyping followed by full-scale production runs. This partnership enabled the startup to launch its product ahead of schedule while maintaining high-quality standards.

Another success story features a well-established automotive electronics company seeking efficiency improvements in its electronic assembly process. By leveraging Bensun's expertise in printed circuit manufacturing and machine pick and place technology, they achieved significant reductions in production time without compromising quality or performance metrics. These partnerships demonstrate how effective collaboration can lead to mutual growth and success within competitive markets.

Conclusion

In the fast-paced world of electronic assembly, understanding the significance of pick and place equipment is crucial for efficient printed circuit manufacturing. These machines serve as the backbone of PCB printed circuit assembly, ensuring precision and speed that manual methods simply can't match. As we look to the future, it's clear that advancements in pick & place machine technology will continue to drive innovation in the industry.

Key Takeaways on Pick and Place Equipment

Pick and place equipment revolutionizes how components are placed on printed PCBs, enhancing both accuracy and efficiency. The automation provided by a machine pick and place allows manufacturers to scale production while maintaining high-quality standards in electronic assembly. Ultimately, investing in advanced pick & place machines will yield significant returns through reduced labor costs and improved product reliability.

The Future of Printed Circuit Manufacturing

The landscape of printed circuit manufacturing is evolving rapidly with emerging technologies such as laser direct imaging and increased automation. These innovations not only streamline processes but also enhance overall quality control within PCB printed circuit assembly lines. As industry demands grow, manufacturers must adapt to these trends to stay competitive; thus, embracing advanced pick and place equipment will be essential for future success.

Why Choose Bensun Technology for Your Needs

When it comes to selecting a partner for your PCB assembly needs, Bensun Technology stands out with its comprehensive solutions tailored for various industries. Their commitment to quality ensures that every machine pick and place unit operates at peak performance while meeting diverse client requirements in electronic assembly projects. By choosing Bensun Technology, you gain access to cutting-edge technology and expertise that can elevate your production capabilities.