Introduction

In the fast-paced world of electronics, understanding the intricacies of surface mount technology (SMT) is essential for anyone involved in manufacturing. Surface mount assembly has revolutionized how components are integrated onto printed circuit boards (PCBs), allowing for more compact designs and improved performance. This introduction will explore what SMT is in electronics, its significance, and a glimpse into the innovative solutions available in SMT assembly.

Understanding Surface Mount Technology

Surface mount technology refers to a method where electronic components are mounted directly onto the surface of PCBs rather than being inserted through holes, as seen in traditional methods. This technique utilizes specialized equipment known as SMT assembly machines to place components with precision and speed. With advancements in SMT machines, manufacturers can achieve higher densities and improved reliability in their products.

Importance of SMT in Modern Electronics

The importance of surface mount technology cannot be overstated; it enables manufacturers to produce smaller, lighter devices that meet consumer demands for portability and efficiency. The SMT PCB assembly process has become the backbone of modern electronics, facilitating everything from smartphones to medical devices. As industries continue to evolve, adopting surface mount assembly processes ensures that companies remain competitive by optimizing production efficiency and reducing costs.

Overview of SMT Assembly Solutions

SMT assembly solutions encompass a range of services and technologies tailored to streamline the production process while maintaining quality standards. From pick-and-place machines that handle component placement to reflow soldering techniques ensuring solid connections, these solutions are integral to successful electronic manufacturing. By leveraging advanced SMT machinery and innovative processes, businesses can enhance their production capabilities while meeting diverse client needs.

What is SMT in Electronics

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing landscape, offering a more efficient way to assemble electronic components onto printed circuit boards (PCBs). By allowing components to be mounted directly onto the surface of PCBs, SMT has paved the way for smaller, lighter, and more complex devices. Understanding what SMT entails is crucial for anyone involved in electronics today.

Definition of Surface Mount Technology

Surface Mount Technology refers to a method where electronic components are mounted and soldered directly onto the surface of PCBs rather than through holes as used in traditional methods. This approach utilizes specialized surface mount assembly machines that can place tiny components with remarkable precision. When asking What is SMT in electronics? it’s essential to recognize its role in enabling high-density circuit designs and improving overall product performance.

Evolution of SMT in Electronic Manufacturing

The evolution of Surface Mount Technology began in the late 1960s but gained significant traction during the 1980s as manufacturers sought ways to improve efficiency and reduce costs. Initially met with skepticism, SMT quickly proved its worth by facilitating faster production times and accommodating smaller component sizes. Today, the SMT assembly process has become a standard practice across various industries, from consumer electronics to aerospace applications.

Benefits of Adopting SMT

Adopting Surface Mount Technology brings numerous benefits that make it an attractive option for manufacturers. First and foremost, it allows for higher component density on PCBs, which means more functionality can fit into smaller spaces—ideal for today’s compact devices. Additionally, the use of advanced Smt machines enhances production speed while minimizing manual labor costs associated with traditional through-hole technology.

Key Components of Surface Mount Assembly

When diving into the world of surface mount assembly, it's essential to understand the key components that make up this sophisticated process. Surface mount technology (SMT) has revolutionized how electronic devices are manufactured, offering speed and efficiency that traditional methods struggle to match. The machinery involved in SMT is critical for ensuring precision and reliability throughout the SMT PCB assembly process.

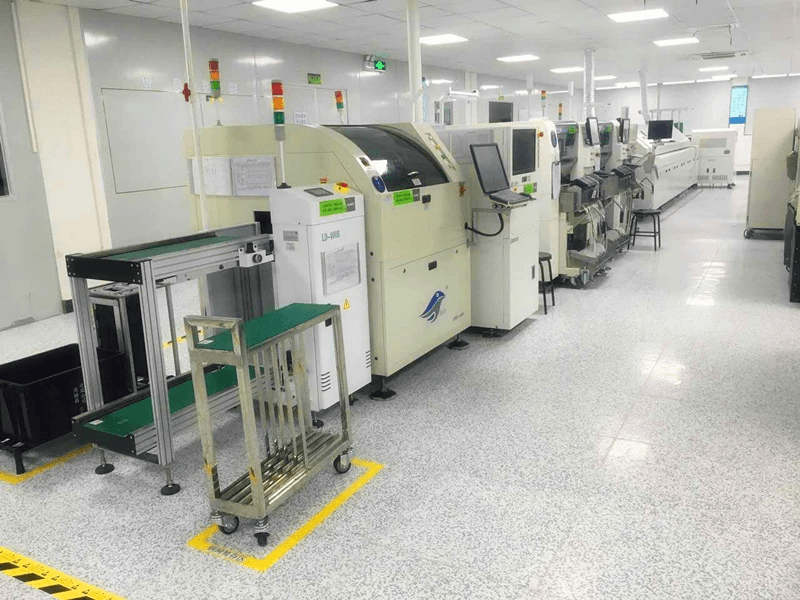

SMT Assembly Machines Overview

At the heart of surface mount assembly lies a variety of specialized machines designed to enhance productivity and accuracy. These SMT assembly machines include pick and place machines, solder paste printers, and reflow ovens, each playing a vital role in the overall SMT assembly process. By automating these steps, manufacturers can achieve higher throughput while maintaining stringent quality standards.

The evolution of these machines has been remarkable; they have advanced from simple manual devices to sophisticated automated systems capable of handling complex tasks with ease. Modern surface mount assembly machines not only improve speed but also reduce human error significantly—an essential factor in today's fast-paced electronics market. With innovations continuously emerging, companies must stay updated on what is SMT in electronics to remain competitive.

Role of Pick and Place Machines

Pick and place machines are arguably the stars of the surface mount assembly show, performing one of the most critical functions in the SMT PCB assembly process: accurately placing components onto printed circuit boards (PCBs). These machines utilize vacuum technology to pick up tiny components from feeders and place them precisely where they need to go on the board—often within mere millimeters tolerance levels.

The efficiency offered by pick and place machines significantly reduces production time while increasing placement accuracy compared to manual methods. As a result, companies can produce more complex designs at a faster rate than ever before—making it an indispensable part of what is SMT in company operations today. With their ability to handle various component sizes and types seamlessly, they're essential for any successful surface mount assembly line.

Importance of Reflow Soldering

Once components have been placed onto PCBs via pick and place machines, reflow soldering takes center stage as a crucial step in completing the surface mount assembly process. This technique involves applying solder paste to joints before heating them in an oven until they melt and create strong electrical connections between components and boards—a method that ensures durability.

Reflow soldering is essential for achieving reliable performance in electronic devices; it eliminates many issues associated with traditional soldering techniques like cold joints or excess flux residue. The effectiveness of this method has made it a standard practice within what is SMT in electronics today because it allows for high-density assemblies without compromising quality or reliability during production runs.

In conclusion, understanding these key components—SMT assembly machines, pick and place technology, and reflow soldering—is vital for anyone involved in or learning about surface mount technology. Each plays an integral role in streamlining operations while enhancing product quality throughout every stage of the SMT PCB assembly process.

The SMT Assembly Process

Surface mount assembly is a critical phase in the production of modern electronic devices, utilizing advanced techniques to ensure efficiency and precision. The SMT assembly process involves several key steps that transform raw materials into functional printed circuit boards (PCBs). Understanding these steps is essential for anyone interested in what SMT is in electronics and its importance in today's manufacturing landscape.

Steps in the SMT PCB Assembly Process

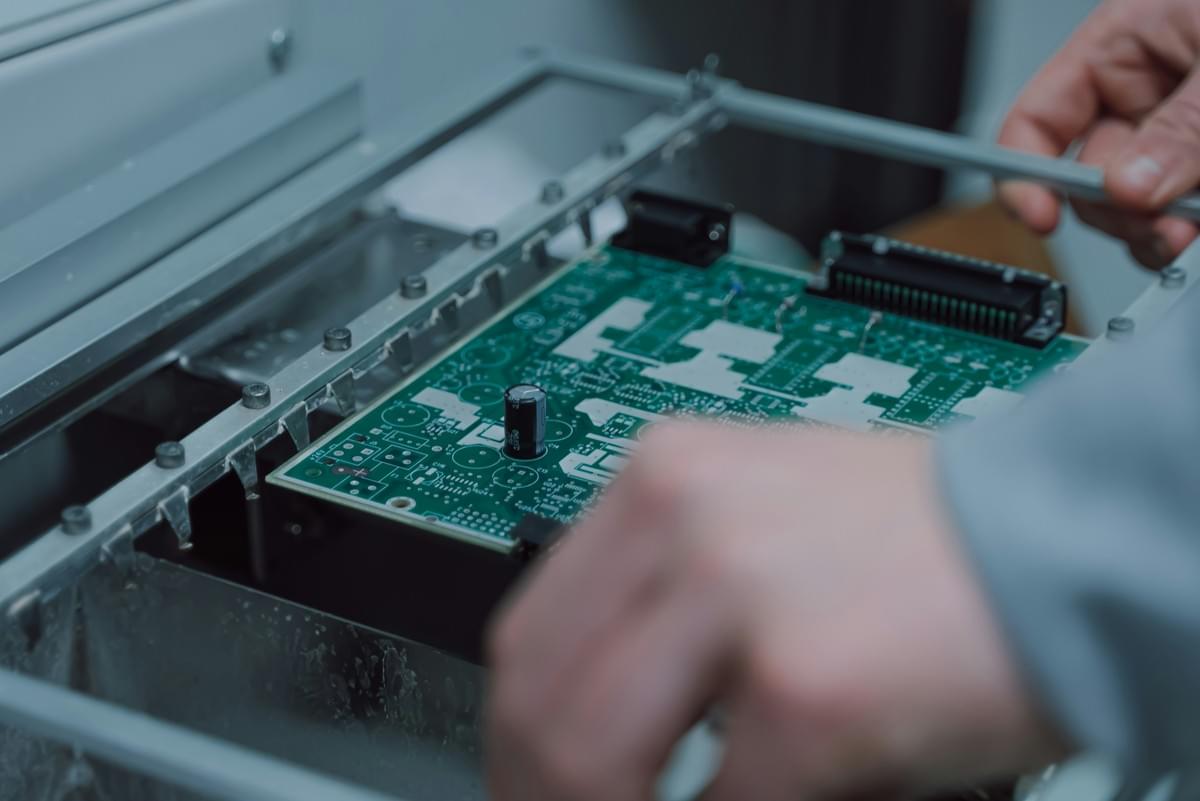

The SMT PCB assembly process begins with the preparation of the printed circuit board, which includes applying a solder paste onto designated pads using a stencil printer. This step is crucial as it ensures that the solder adheres correctly during the reflow process, allowing for optimal electrical connections. Next, surface mount components are placed on the board using an automated surface mount assembly machine, often referred to as a pick-and-place machine, which accurately positions components based on pre-programmed data.

Once all components are positioned, the boards move to reflow soldering ovens where heat is applied to melt the solder paste and create strong electrical connections. After cooling, each board undergoes inspection to verify that all components are correctly placed and soldered—a vital step in maintaining quality assurance throughout the SMT assembly process. Finally, any necessary testing procedures are conducted before packaging and shipping to clients.

Quality Control Measures in SMT

Quality control measures play a pivotal role in ensuring that every aspect of surface mount assembly meets stringent industry standards. During various stages of the SMT PCB assembly process, inspections such as Automated Optical Inspection (AOI) help identify defects or misalignments early on. This proactive approach minimizes errors and reduces waste—key benefits of adopting surface mount technology.

Moreover, statistical process control (SPC) techniques monitor machine performance and component quality throughout production runs. By analyzing data trends over time, manufacturers can make informed adjustments to their processes or equipment—ensuring consistency and reliability in their output. Ultimately, effective quality control not only safeguards product integrity but also enhances customer satisfaction by delivering high-quality electronics.

Comparison of SMT and Through-Hole Technology

When discussing what is SMT in company settings versus traditional methods like through-hole technology (THT), several distinctions emerge that highlight why many manufacturers favor surface mount technology today. One significant difference lies in component size; surface mount components are generally smaller than their through-hole counterparts, allowing for more compact designs with higher density layouts on PCBs.

Additionally, while THT requires drilling holes into PCBs for component leads—an extra step that adds time—surface mount assembly eliminates this need by attaching components directly onto pads on the board's surface. This not only speeds up production but also improves overall reliability due to fewer mechanical stress points during operation. As we continue exploring innovations within electronic manufacturing processes like these two technologies' evolution will undoubtedly shape future trends.

Innovations in SMT Equipment

In the fast-paced world of electronics, innovations in surface mount technology (SMT) equipment are crucial for maintaining efficiency and quality. The evolution of these machines has led to significant improvements in the SMT assembly process, enabling manufacturers to produce more complex designs with greater precision. As companies strive to meet increasing demands for miniaturization and functionality, advancements in SMT machine technology play a pivotal role.

Advancements in SMT Machine Technology

Recent advancements in surface mount assembly machines have transformed the landscape of electronic manufacturing. Modern SMT machines boast enhanced capabilities such as higher placement speeds, improved accuracy, and sophisticated vision systems that ensure precise component alignment during the SMT PCB assembly process. These innovations not only streamline production but also reduce waste, making them essential tools for any company looking to stay competitive.

Furthermore, cutting-edge features like smart sensors and real-time monitoring systems allow manufacturers to optimize their operations continuously. By integrating data analytics into the surface mount assembly process, companies can identify bottlenecks and improve overall efficiency. This level of sophistication is what sets today's SMT machines apart from their predecessors.

Role of Automation in Surface Mount Assembly

Automation has become a game-changer in surface mount assembly, revolutionizing how electronics are produced. Automated systems minimize human error while maximizing throughput—key factors that enhance the quality of the final product during the SMT PCB assembly process. With robotics taking over repetitive tasks like component placement and soldering, manufacturers can focus on more complex challenges without sacrificing speed or accuracy.

Moreover, automation allows for better scalability; as demand fluctuates, automated surface mount assembly lines can adapt quickly without requiring extensive reconfiguration or retraining of personnel. This flexibility is particularly beneficial for companies that handle varying volumes of production throughout different seasons or project phases. As we look ahead, it’s clear that automation will continue to shape the future of what is SMT in electronics manufacturing.

Future Trends in SMT Equipment

Looking towards the future, several trends are emerging within the realm of surface mount technology equipment that promise to further enhance production capabilities. One notable trend is the integration of artificial intelligence (AI) into SMT machines; AI can analyze vast amounts of data from previous runs to predict potential issues before they arise during the SMT assembly process. This predictive maintenance approach not only saves time but also reduces costs associated with unexpected downtime.

Additionally, sustainability is becoming increasingly important within electronic manufacturing; therefore, future innovations may focus on creating more energy-efficient surface mount assembly machines that utilize eco-friendly materials and processes. Such developments will not only benefit manufacturers by reducing operational costs but also align with global efforts toward environmental responsibility.

As we navigate through these exciting times in electronics manufacturing, understanding what is SMT in a company context becomes essential for staying ahead of competitors who may still rely on outdated methods or technologies.

Bensun Technology's SMT Solutions

Bensun Technology stands at the forefront of surface mount assembly, offering a comprehensive range of products and services tailored to meet diverse electronic manufacturing needs. Their expertise in Surface Mount Technology (SMT) allows them to provide cutting-edge solutions that enhance efficiency and reduce production costs. With a commitment to innovation, Bensun ensures that clients receive top-notch SMT assembly processes that are both reliable and scalable.

Range of Products and Services Offered

At Bensun Technology, the product lineup includes state-of-the-art surface mount assembly machines designed for various applications in the SMT PCB assembly process. These machines are engineered for precision, ensuring optimal placement accuracy while handling a wide array of components. Additionally, Bensun offers support services such as equipment maintenance, training for operators on using SMT machines, and consultation to help businesses optimize their surface mount technology practices.

In terms of services, Bensun provides end-to-end solutions from design assistance to final assembly. Their focus on quality control throughout the SMT assembly process guarantees that each product meets stringent industry standards. Whether you're looking for standard components or custom solutions tailored to specific requirements, Bensun’s offerings cater to all aspects of what is SMT in electronics today.

Contract Manufacturing and Custom Solutions

Bensun Technology excels in contract manufacturing by leveraging advanced surface mount technology techniques that streamline production workflows for their clients. By partnering with businesses across various sectors, they deliver customized solutions that align with unique project specifications and timelines. This flexibility makes them a preferred choice for companies seeking reliable partners who understand the intricacies of the SMT PCB assembly process.

Their ability to adapt quickly means they can accommodate changes in design or scale without compromising quality or efficiency. With a dedicated team focused on providing tailored contract manufacturing services, clients can rest assured that their projects will be handled with expertise from start to finish. This level of customization is what sets Bensun apart as a leader in surface mount assembly solutions.

Success Stories and Client Testimonials

Bensun Technology has built a reputation based on numerous success stories highlighting their proficiency in surface mount assembly solutions. Clients have praised their seamless integration into existing workflows and their ability to enhance productivity through innovative SMT machine technologies. Testimonials often mention how working with Bensun has transformed their approach to electronic manufacturing by simplifying complex processes involved in what is SMT in company operations.

One notable case involved a major electronics manufacturer struggling with high defect rates due to outdated equipment; after switching to Bensun’s advanced surface mount technology systems, they reported an impressive reduction in errors during the SMT assembly process by over 30%. Such success stories not only demonstrate the effectiveness of Bensun's offerings but also instill confidence among potential customers looking for dependable partners in electronic manufacturing.

Conclusion

As we wrap up our exploration of surface mount technology, it's clear that this assembly method is not just a passing trend but a cornerstone of modern electronics. The future of surface mount assembly looks promising, driven by continuous innovations and the ever-increasing demand for smaller, more efficient devices. With advancements in SMT machines and processes, the landscape of electronic manufacturing will evolve further, ensuring that surface mount technology remains at the forefront.

The Future of Surface Mount Technology

The future of surface mount technology is poised for remarkable growth as industries increasingly embrace automation and miniaturization. With the ongoing development of sophisticated SMT assembly machines, manufacturers can expect enhanced precision and faster production times in the SMT PCB assembly process. Moreover, as new materials and techniques emerge, we can anticipate even greater efficiencies and capabilities in what is SMT in electronics.

Choosing the Right SMT Assembly Partner

Selecting the right partner for your surface mount assembly needs can significantly impact your project’s success. When evaluating potential partners, consider their experience with various SMT processes and their ability to customize solutions to fit your specific requirements. A reliable partner should not only understand what is SMT in company but also offer comprehensive support throughout the entire SMT assembly process.

Final Thoughts on SMT Assembly Solutions

In conclusion, embracing surface mount technology is essential for any company looking to thrive in today’s competitive electronics market. As we've discussed throughout this guide, understanding both the benefits and intricacies of the SMT PCB assembly process can lead to better product outcomes and customer satisfaction. By leveraging advanced Smt machines and seeking out innovative partners, businesses can unlock new possibilities within their manufacturing operations.