Introduction

In the fast-paced world of electronics, surface mount technology (SMT) has revolutionized how we approach circuit board manufacturing. This innovative method allows for the efficient assembly of components directly onto the surface of printed circuit boards (PCBs), significantly enhancing production speed and reliability. As demand for compact and high-performance devices grows, understanding the importance of surface mount technology equipment becomes essential for staying competitive in PCB manufacturing and assembly.

PCB manufacturing and assembly is a complex process that involves multiple steps, from design to final inspection. The integration of SMT in this workflow streamlines operations, reducing both time and costs associated with traditional methods like through-hole technology. By leveraging advanced techniques in PCB assembly manufacturing, companies can produce high-quality products that meet market demands while ensuring precision and efficiency.

Key equipment in SMT processes plays a critical role in determining the success of PCB manufacturing. From pick-and-place machines to reflow ovens, each piece of machinery is designed to optimize performance during various stages of PCB assembly and manufacturing. Understanding how these tools work together not only enhances productivity but also ensures that quality control measures are effectively implemented throughout the PCB manufacturing process.

Understanding Surface Mount Technology Equipment

Surface mount technology (SMT) has revolutionized the landscape of PCB manufacturing and assembly, allowing for more compact designs and higher efficiency. This innovative approach involves mounting components directly onto the surface of a printed circuit board (PCB), which contrasts sharply with traditional methods. The purpose of SMT is not only to optimize space but also to enhance performance and reliability in circuit board manufacturing.

Definition and Purpose of SMT

Surface mount technology equipment is designed specifically for the unique requirements of modern PCB assembly. By enabling components to be placed on both sides of a circuit board, SMT allows manufacturers to create denser, more complex designs that are essential for today’s electronic devices. The primary purpose of SMT is to streamline the PCB manufacturing assembly process, reducing both time and costs while improving quality.

Comparison with Through-Hole Technology

When comparing surface mount technology with through-hole technology, several key differences emerge that highlight the advantages of SMT in pcb assembly manufacturing. Through-hole technology involves inserting component leads into holes drilled into the PCB, which can be cumbersome and limits design flexibility. In contrast, surface mount technology equipment allows for a much higher component density on PCBs, paving the way for smaller devices without sacrificing functionality or performance.

Benefits of Using SMT Equipment

The benefits of using surface mount technology equipment in pcb manufacturing are numerous and compelling. First, SMT significantly reduces the size and weight of electronic products by allowing designers to use smaller components that can be mounted directly onto the surface of a PCB. Additionally, this method enhances production speed due to faster placement processes facilitated by advanced machinery like pick-and-place machines—making it an ideal choice for high-volume pcb assembly and manufacturing operations.

Essential Components of SMT Equipment

In the world of PCB manufacturing and assembly, selecting the right equipment is crucial for achieving high-quality results. Surface mount technology equipment plays a pivotal role in ensuring efficiency and precision during the PCB assembly process. Among the essential components, JUKI pick and place machines, reflow ovens, and visual inspection machines stand out as key players that streamline operations.

JUKI Pick and Place Machines

JUKI pick and place machines are renowned for their speed and accuracy in placing surface mount components onto circuit boards. These machines are designed to handle various component sizes and types, making them versatile tools in PCB manufacturing assembly. With advanced features such as vision systems for alignment verification, JUKI machines significantly enhance productivity while minimizing errors during the PCB assembly process.

Moreover, their ability to integrate seamlessly with other surface mount technology equipment ensures that they fit perfectly into existing production lines. As a result, manufacturers can achieve a higher level of automation in their PCB assembly manufacturing operations. This not only reduces labor costs but also accelerates time-to-market for electronic products.

Reflow Ovens and Their Role

Reflow ovens play an integral role in the soldering process within surface mount technology equipment setups. After components have been placed on the circuit board by pick and place machines, reflow ovens apply heat to melt solder paste, creating strong electrical connections between components and the PCB substrate. The precision temperature control of these ovens is vital to prevent damage to sensitive electronic parts during circuit board manufacturing.

In addition to their primary function of soldering, modern reflow ovens often come equipped with advanced features such as profiling software that allows manufacturers to optimize thermal profiles based on specific component requirements. This adaptability is essential for ensuring consistent quality across different batches of PCB manufacturing assembly processes. Ultimately, a well-functioning reflow oven contributes significantly to overall product reliability.

Visual Inspection Machine Functionality

Visual inspection machines serve as the watchdogs of quality assurance in PCB assembly and manufacturing processes. These machines utilize high-resolution cameras combined with sophisticated software algorithms to detect defects such as misaligned components or insufficient solder joints on assembled PCBs. By integrating visual inspection into the workflow of surface mount technology equipment, manufacturers can identify issues early on before they escalate into costly problems down the line.

The implementation of these inspection systems not only enhances product quality but also boosts confidence among clients regarding reliability in circuit board manufacturing outputs. Furthermore, automated visual inspections reduce reliance on manual checks—freeing up valuable human resources for more complex tasks within PCB assembly processes. As a result, companies can maintain higher standards while optimizing efficiency throughout their production lines.

The PCB Manufacturing Process

The PCB manufacturing process is a complex and intricate journey that transforms raw materials into functional electronic devices. It involves various stages, from design to assembly, each playing a crucial role in ensuring the final product meets quality standards. Understanding this process is essential for anyone involved in circuit board manufacturing and the broader landscape of PCB assembly and manufacturing.

Steps in PCB Manufacturing

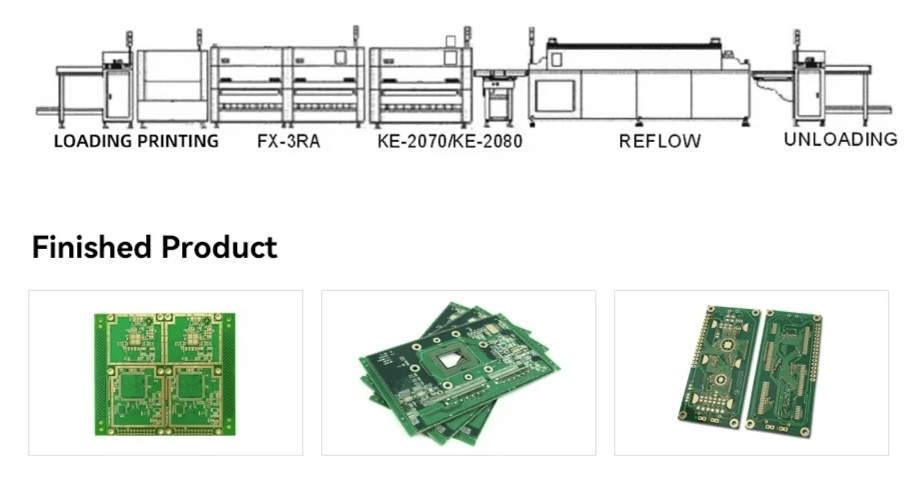

PCB manufacturing begins with the design phase, where engineers create detailed layouts using specialized software. Once the designs are finalized, they move on to material selection, typically involving substrates like FR-4 or flexible materials for specific applications. The next steps include etching copper layers, drilling holes for component placement, and applying solder masks—all foundational elements that prepare the circuit board for assembly.

After these initial steps, the actual assembly of components onto the printed circuit board begins. This is where surface mount technology equipment comes into play, allowing for efficient placement of components directly onto the board's surface. Following component placement, soldering processes such as reflow or wave soldering are employed to secure components firmly in place during PCB assembly manufacturing.

Integration of ASM and SMT Equipment

The integration of Automated Surface Mount (ASM) technology with traditional surface mount technology equipment streamlines the PCB manufacturing and assembly process significantly. ASM systems automate various tasks such as component feeding, placement accuracy checks, and even real-time data tracking throughout production runs. This automation not only increases productivity but also minimizes human error during critical phases of PCB assembly.

Moreover, combining ASM with SMT equipment allows manufacturers to achieve higher precision in placing components on densely populated boards while maintaining efficiency across varying production scales. This synergy between technologies enhances overall performance in circuit board manufacturing by reducing cycle times while ensuring consistent quality standards are met throughout each run of PCB manufacturing assembly.

Quality Control in PCB Assembly

Quality control is paramount in any aspect of PCB manufacturing to ensure reliability and functionality after deployment. Various methods are employed at different stages: from visual inspections using advanced machines to automated optical inspection (AOI) systems that detect defects before they escalate into costly issues later on. These measures ensure that every piece produced meets stringent industry standards before reaching customers.

In addition to inspections during production phases, implementing robust testing procedures post-assembly helps catch any errors that might have slipped through earlier checks during PCB assembly and manufacturing processes. Techniques like functional testing or X-ray inspection can identify hidden flaws within multilayer boards that may not be visible externally but could lead to device failure down the line.

By integrating thorough quality control measures into every step of circuit board manufacturing—from initial design through final testing—manufacturers can confidently deliver high-quality products that meet customer expectations while minimizing waste and rework costs associated with faulty assemblies.

The Importance of Automation in PCB Assembly

In the fast-paced world of PCB manufacturing and assembly, automation has emerged as a game-changer, driving efficiency and precision. By integrating advanced surface mount technology equipment into the production line, manufacturers can significantly reduce cycle times while enhancing the quality of their products. This shift towards automation is not just a trend; it’s a necessary evolution for any competitive player in circuit board manufacturing.

How Automation Enhances Efficiency

Automation streamlines various processes involved in PCB assembly manufacturing, from component placement to soldering and inspection. By employing automated systems, manufacturers can achieve higher throughput rates and minimize human error, which is crucial for maintaining quality standards in PCB manufacturing. Additionally, automated systems can operate continuously, allowing for increased production without the downtime that manual labor often entails.

Moreover, with real-time data collection and analysis capabilities embedded within these automated systems, manufacturers can monitor performance metrics closely and make swift adjustments as needed. This adaptability not only enhances overall efficiency but also ensures that defects are caught early in the process—further solidifying quality control measures in PCB assembly and manufacturing. Ultimately, this leads to reduced operational costs and improved profit margins.

Leading Automation Solutions in SMT

The market is brimming with innovative automation solutions tailored specifically for surface mount technology equipment that cater to various aspects of PCB assembly. Industry leaders such as JUKI offer sophisticated pick-and-place machines that excel at high-speed component placement with pinpoint accuracy. These machines play a vital role in streamlining the entire PCB manufacturing assembly process by ensuring components are placed correctly on PCBs before they undergo soldering.

Another key player is KIC's thermal profiling systems designed for reflow ovens; they ensure optimal heating profiles are achieved during soldering processes to prevent defects like cold solder joints or bridging. Furthermore, visual inspection machines equipped with AI capabilities provide unparalleled accuracy in identifying defects post-assembly—creating a seamless integration of ASM (Automated Surface Mount) equipment into traditional workflows.

These leading solutions not only enhance productivity but also contribute significantly to reducing waste by optimizing resource usage throughout the PCB manufacturing process.

Case Studies of Successful Automation

Several companies have successfully harnessed automation within their PCB assembly operations to great effect—setting benchmarks for others to follow suit. For instance, Company X integrated JUKI pick-and-place machines into its production line and reported a 30% increase in output while simultaneously reducing labor costs by 20%. This transition allowed them to scale up production without compromising on quality or delivery timelines—a critical factor in today’s competitive market landscape.

Another notable example is Company Y’s implementation of KIC thermal profiling alongside advanced visual inspection systems that resulted in an impressive reduction of defect rates from 5% down to 1%. This dramatic improvement not only enhanced customer satisfaction but also solidified their reputation as a reliable supplier within the circuit board manufacturing industry.

These case studies underscore how embracing automation not only optimizes operational efficiency but also fosters innovation within the realm of PCB assembly and manufacturing—ultimately paving the way for future advancements across the industry.

Choosing the Right SMT Equipment

Selecting the right surface mount technology equipment is crucial for efficient PCB manufacturing and assembly. A well-chosen machine can significantly enhance productivity, reduce costs, and improve overall quality in PCB assembly manufacturing. With various options available, understanding what to consider when making your selection can lead to a successful investment.

Factors to Consider in Equipment Selection

When choosing SMT equipment, several factors come into play that can impact your PCB manufacturing assembly process. First, assess the scale of your production; high-volume operations may require more advanced machines with faster speeds and greater precision. Second, evaluate the types of components you will be working with; some surface mount technology equipment is better suited for specific sizes or types of components than others.

Another important consideration is the level of automation you desire in your PCB assembly and manufacturing processes. Automated systems can enhance efficiency but may come with higher upfront costs compared to semi-automated or manual options. Finally, don’t overlook support and service options; reliable post-purchase support can save time and money down the line when issues arise.

Bensun Technology Solutions Overview

Bensun Technology Solutions stands out as a leader in providing high-quality surface mount technology equipment tailored for diverse PCB manufacturing needs. Their extensive range includes everything from pick-and-place machines to reflow ovens that cater to both small-scale startups and large manufacturers alike. With a commitment to innovation and customer satisfaction, Bensun ensures that their solutions not only meet industry standards but also adapt seamlessly to evolving technologies in circuit board manufacturing.

Their team of experts offers valuable insights into optimizing your PCB assembly processes while also providing training and resources for effective machine operation. By partnering with Bensun Technology Solutions, businesses gain access to state-of-the-art SMT equipment designed specifically for enhancing production capabilities in PCB manufacturing assembly environments.

The Flexibility of Equipment Sales and Rentals

In today’s fast-paced market, flexibility is key when it comes to acquiring surface mount technology equipment for PCB assembly and manufacturing tasks. Many companies find themselves needing specific machines only temporarily or during peak production periods; this is where rental options come into play. Renting SMT equipment allows businesses to scale their operations without committing substantial capital upfront while still benefiting from cutting-edge technology.

Moreover, purchasing used or refurbished machines from reputable sources like Bensun provides another avenue for cost-effective solutions without sacrificing quality in circuit board manufacturing processes. This flexibility enables companies engaged in PCB manufacturing assembly projects to adapt quickly based on demand fluctuations while maintaining high standards of efficiency.

Conclusion

In conclusion, the landscape of surface mount technology equipment is evolving rapidly, driven by innovation and the need for efficiency in PCB manufacturing and assembly. As we look toward the future, it's clear that advancements in automation and precision will continue to shape the PCB assembly manufacturing process. Embracing these changes not only enhances productivity but also ensures that manufacturers remain competitive in a global market.

Future Trends in Surface Mount Technology

The future of surface mount technology equipment is marked by exciting trends such as increased automation, artificial intelligence integration, and miniaturization of components. These advancements will streamline PCB manufacturing processes, making them faster and more efficient while reducing costs. Additionally, as circuit board manufacturing becomes more intricate, companies will need to adapt their PCB assembly methods to accommodate smaller and more complex designs.

Enhancing Quality in PCB Manufacturing

Quality control remains a cornerstone of successful PCB manufacturing assembly processes. By investing in high-quality surface mount technology equipment, manufacturers can ensure that every component is placed accurately and reliably during production. Enhanced inspection systems integrated into the PCB assembly process help identify defects early on, ultimately leading to improved product quality and customer satisfaction.

Making Informed Decisions in Equipment Investment

When it comes to investing in surface mount technology equipment for PCB assembly and manufacturing, informed decision-making is crucial. Factors such as production volume requirements, budget constraints, and scalability should guide your choices to maximize ROI. Working with reputable suppliers who offer flexible solutions—whether through sales or rentals—can also provide significant advantages as you navigate the ever-evolving landscape of circuit board manufacturing.