Introduction

In the world of electronics manufacturing, the selective soldering system has emerged as a game-changer for PCB soldering processes. This technology allows for precise application of solder and flux to specific joints, ensuring high-quality connections while minimizing waste. Understanding how these systems work is crucial for manufacturers looking to enhance their production efficiency.

Understanding Selective Soldering Systems

Selective soldering systems utilize advanced machinery to apply solder and flux selectively, targeting only the areas that require connection. Unlike traditional wave soldering machines, which flood entire boards with molten solder, selective systems offer a more controlled approach. This precision not only improves the reliability of electronic assemblies but also reduces the risk of damaging sensitive components during the PCB soldering process.

The Importance of Cost-Effectiveness

By optimizing production processes and minimizing material waste through targeted application, companies can significantly lower their operational costs. Moreover, understanding the balance between cost and quality in selecting a system can lead to long-term savings without compromising performance.

Overview of Available Solutions

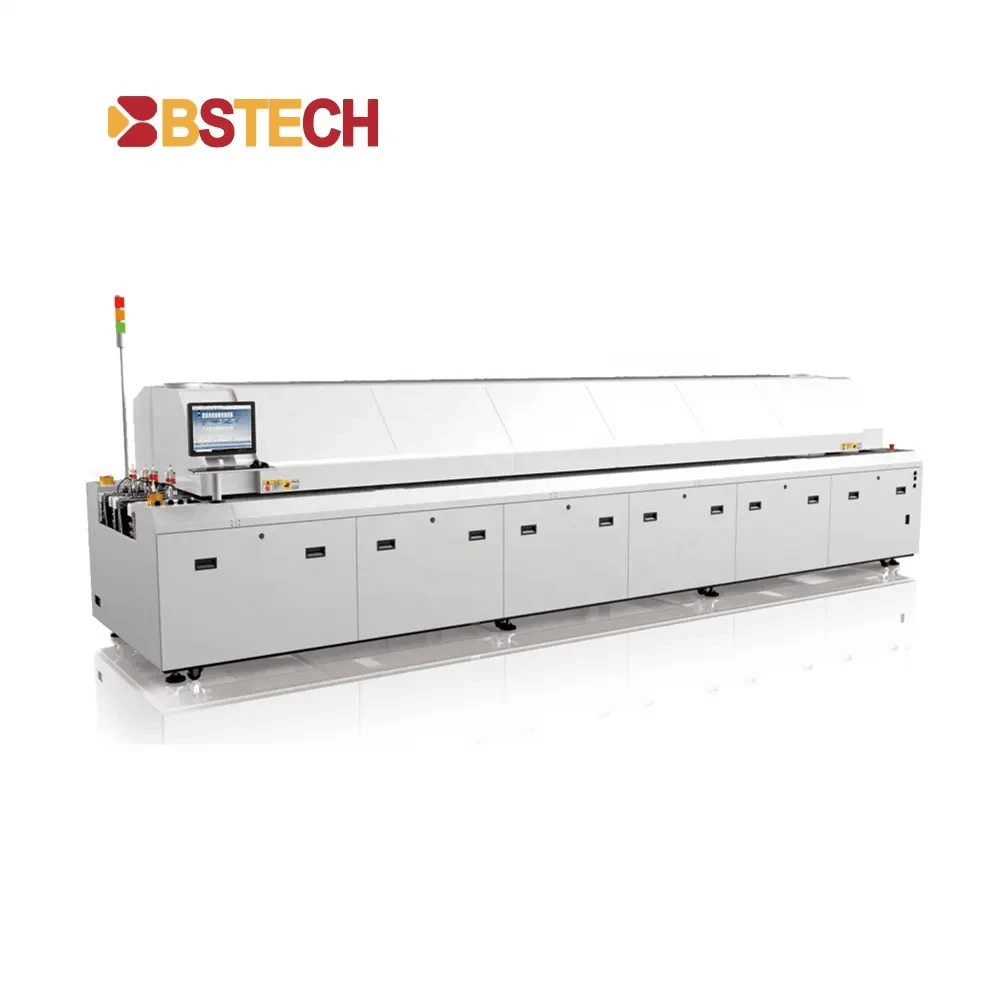

The market offers a variety of solutions tailored to meet diverse production needs in selective soldering systems. From budget-friendly options for beginners to advanced machines designed for high-volume production environments, there’s something for everyone. Companies like Bensun provide innovative offerings that cater to various industries while ensuring optimal performance in both SMD soldering and traditional PCB applications.

The Basics of Selective Soldering

In the world of PCB manufacturing, understanding the fundamentals of selective soldering is crucial for optimizing production efficiency and quality. This process is particularly vital for assembling electronic components with precision, especially in complex layouts where traditional methods may falter. Let’s dive into what selective soldering is all about and how it compares to other techniques like wave soldering.

Definition and Process Explained

Selective soldering refers to a targeted approach in the PCB soldering process, where only specific areas of a circuit board are soldered while leaving others untouched. This method typically involves using a selective soldering machine that precisely applies molten solder to designated joints, ensuring minimal thermal exposure to surrounding components. By utilizing specialized equipment, manufacturers can achieve high-quality connections without disturbing sensitive parts or risking damage during the wave soldering phase.

Comparing Selective and Wave Soldering

When comparing selective and wave soldering systems, it's essential to understand their distinct methodologies and applications. Wave soldering machines immerse entire PCBs in molten solder, which can be efficient but often leads to issues like bridging or overheating sensitive components. On the other hand, selective soldering equipment allows for greater control over where the heat and flux are applied, making it ideal for complex assemblies with surface mount devices (SMDs) that require careful handling.

Advantages of Selective Soldering

The advantages of using a selective soldering system are numerous and compelling for manufacturers looking to enhance their production lines. First off, this technique significantly reduces the risk of damaging delicate components by limiting exposure to heat—something wave soldering can't always promise. Additionally, selective systems allow for precise application of both solder and flux, improving overall joint integrity while minimizing waste—a win-win for any production environment aiming for cost-effectiveness.

Choosing the Right Selective Soldering System

When it comes to selecting a selective soldering system, understanding your production needs is paramount. Every manufacturing environment has unique requirements based on the types of components being used and the volume of production. Whether you're dealing with PCB soldering or integrating SMD soldering processes, identifying these needs will help you choose the most suitable selective soldering equipment.

Evaluating Your Production Needs

Evaluating your production needs involves a thorough analysis of your current and future projects. Consider factors such as the size of your PCB assemblies, component density, and whether you require compatibility with wave soldering machines for certain tasks. Additionally, think about how often you'll be changing setups; this will influence whether you need a versatile selective soldering system or a more specialized solution.

Understanding your workflow can also guide decisions about automation levels in your selective soldering equipment. If you're producing high volumes with little variation, an automated system might save time and reduce labor costs. Conversely, if flexibility is key due to frequent design changes or small batches, investing in a more adaptable solution could be beneficial.

Key Features to Look For

When shopping for a selective soldering system, there are several key features that should be on your checklist. First and foremost is precision; look for systems that offer fine control over solder application to minimize waste and ensure quality connections on sensitive components like those found in SMD soldering applications. Additionally, consider systems that allow for easy adjustments between different types of solders and fluxes to accommodate varying project requirements.

Another important feature is programmability; modern selective soldering machines often come equipped with software that allows operators to set parameters for different assemblies easily. This not only streamlines the process but also enhances repeatability across production runs—an essential aspect when considering cost-effectiveness in PCB soldering operations. Lastly, make sure the machine has robust maintenance features; downtime can be costly!

Popular Brands and Their Offerings

Companies like Bensun are known for their comprehensive range of selective soldering equipment tailored for various industries—from automotive electronics to consumer goods—ensuring there's something suitable for every manufacturer’s needs.

Other notable brands include Ersa and Heller Industries, both recognized for their high-quality wave soldering machines as well as selective options that cater specifically to complex assembly processes involving both through-hole and surface-mount devices (SMD). Each brand typically provides detailed specifications regarding compatible solders and fluxes which can assist you in making informed choices based on your production goals.

In conclusion, choosing the right selective soldering system requires careful consideration of your specific production needs alongside an understanding of available features from reputable brands like Bensun or Ersa. By evaluating these aspects thoughtfully, you’ll set yourself up for successful PCB assembly with efficient use of resources.

Cost-Effective Selective Soldering Equipment

For many manufacturers, investing in selective soldering equipment can seem daunting; however, there are plenty of budget-friendly options that deliver solid performance without breaking the bank. By understanding the various solutions available, you can make informed decisions that enhance your PCB soldering processes while keeping costs manageable.

Budget-Friendly Options for Beginners

For beginners venturing into the world of selective soldering, there are several affordable systems that provide excellent value. Entry-level machines often come with essential features tailored to small-scale production runs but still maintain high-quality standards for solder and flux application. Models like semi-automatic selective soldering machines allow new users to familiarize themselves with the process without a hefty investment, making them an ideal choice for startups.

Additionally, many manufacturers offer financing options or leasing agreements that can ease the initial financial burden associated with purchasing a wave soldering machine or selective soldering equipment. These arrangements allow businesses to gradually invest in their production capabilities while testing different techniques like SMD soldering alongside traditional methods. By starting small and scaling up as needed, you can effectively manage both your budget and production needs.

Bensun’s Solutions for Various Industries

Bensun stands out as a leading provider of cost-effective selective soldering systems tailored to meet diverse industry demands. Their range includes machines designed specifically for electronics manufacturing, automotive applications, and even medical device production—each optimized for different types of PCB soldering tasks. With a focus on quality and efficiency, Bensun’s solutions ensure that customers receive reliable equipment capable of handling various solders and fluxes while maintaining precision.

Moreover, Bensun offers customizable options that cater to specific requirements within industries—allowing businesses to choose features best suited for their unique applications. This flexibility helps companies avoid overspending on unnecessary capabilities while still achieving high-quality results in their wave soldering or selective processes. Investing in Bensun's equipment means you're not just purchasing hardware; you're gaining a partner committed to enhancing your production efficiency.

How to Balance Cost and Quality

Finding the right balance between cost and quality when selecting a selective soldering system is crucial for any manufacturer looking to optimize their operations. While it may be tempting to go with the cheapest option available, investing in higher-quality machines often pays off in terms of durability and performance over time—especially when considering ongoing maintenance costs associated with lower-end models. Look for systems that offer robust features without sacrificing reliability; this way you can ensure consistent results during both PCB and SMD soldering processes.

Another approach is evaluating total cost ownership rather than merely focusing on upfront expenses; consider factors such as energy consumption, ease of use, and availability of replacement parts when making your decision about which wave soldering machine or selective equipment suits your needs best. Engaging with industry leaders like Bensun allows you access not only to competitive pricing but also invaluable expertise on how best to implement these solutions into existing workflows efficiently without compromising quality standards.

In conclusion, navigating the landscape of cost-effective selective soldering equipment doesn’t have to be overwhelming if you know where to look and what factors matter most in your decision-making process.

Solder and Flux: Making the Right Choices

When it comes to PCB soldering, the right choice of solder and flux can make all the difference in achieving high-quality connections. In selective soldering systems, where precision is key, these materials play a crucial role in ensuring reliability and efficiency. Understanding their importance helps manufacturers optimize their processes, especially when comparing selective soldering with wave soldering techniques.

Importance of Solder and Flux in PCB Soldering

Solder and flux are essential components in any PCB soldering process, including selective soldering systems. Solder acts as a bridge that connects electronic components to the circuit board, while flux cleans and prepares surfaces for a strong bond. Without quality solder and flux, even the most advanced selective soldering equipment may fail to deliver optimal results.

In selective soldering applications, the right combination of these materials can enhance joint integrity and reduce defects significantly. This is particularly important for complex assemblies where precision is paramount; poor-quality materials can lead to cold joints or weak connections that compromise performance. Thus, selecting appropriate solder and flux not only ensures compliance with industry standards but also enhances overall production efficiency.

Types of Solder and Their Applications

There are various types of solders available on the market today, each tailored for specific applications within PCB manufacturing. Lead-based solders have long been favored for their excellent thermal properties; however, due to environmental regulations, many manufacturers now opt for lead-free alternatives like SAC (tin-silver-copper) alloys which are suitable for both wave soldering machines and selective soldering systems alike.

In addition to alloy composition, different forms of solder—such as wire or paste—are utilized based on the method being employed: wire for hand-soldered connections or paste when working with surface mount devices (SMD). Each type offers unique advantages depending on whether you're using a selective or wave soldering approach; thus understanding these distinctions is crucial in making informed decisions about your production line's needs.

Tips for Selecting the Right Flux

Choosing the right flux can be just as critical as selecting high-quality solder when operating a selective soldering system. The primary purpose of flux is to remove oxidation from metal surfaces during heating; therefore, it’s essential to select a type compatible with your chosen method—be it wave or selective—while also considering its cleaning requirements post-soldering.

There are several types of flux available: rosin-based for traditional methods or no-clean options that leave minimal residue ideal for high-speed production lines using advanced equipment like selective soldering machines. When selecting flux, consider factors such as activation level needed based on component sensitivity and whether you’ll require additional cleaning after assembly.

Ultimately, investing time into understanding your options will yield significant benefits down the line by improving joint reliability while minimizing rework costs associated with defective assemblies.

Maximizing Efficiency with Selective Soldering Machines

The efficiency of your production line can significantly benefit from the strategic use of selective soldering machines. These systems are designed to optimize the soldering process, minimizing material waste and maximizing output. By integrating a selective soldering system into your operations, you can streamline workflows and enhance overall productivity.

How to Improve Production Line Efficiency

Improving production line efficiency involves a careful assessment of your current processes and identifying bottlenecks that may hinder performance. One effective strategy is to incorporate selective soldering equipment, which allows for targeted application of solder and flux, reducing excess usage compared to traditional wave soldering methods. Additionally, implementing automation features in your selective soldering system can drastically cut down on manual labor time, leading to faster turnaround times and higher throughput.

Another approach is training staff on best practices for PCB soldering techniques with selective systems. Well-trained operators can make quicker adjustments during production runs, ensuring that each component is perfectly soldered without unnecessary delays. By continuously monitoring performance metrics and making iterative improvements based on feedback, companies can maintain an agile production line capable of adapting to changing demands.

Integrating Selective Soldering with SMD Soldering

Integrating selective soldering with surface mount device (SMD) soldering creates a harmonious workflow that leverages the strengths of both methods. While wave soldering machines excel in handling bulk connections, selective systems shine when precision is required for delicate components or mixed technology boards. This combination allows manufacturers to efficiently manage diverse product lines while maintaining high quality in their PCB assembly processes.

To achieve seamless integration, consider using programmable logic controllers (PLCs) that coordinate both types of equipment effectively. This synchronization ensures optimal timing between processes and minimizes downtime during transitions from SMD to selective operations. Furthermore, employing shared software platforms for programming allows for easier updates and modifications as new products are introduced into the lineup.

Case Studies of Successful Implementations

Several companies have successfully implemented selective soldering systems alongside traditional wave soldering machines to enhance their manufacturing capabilities. For instance, a leading electronics manufacturer reported a 30% increase in production efficiency after integrating selective equipment into their existing PCB assembly line while optimizing their use of solder and flux materials. By carefully analyzing their production needs and investing in tailored solutions from reputable brands like Bensun, they achieved remarkable results without sacrificing quality or consistency.

Another notable case involved an automotive parts supplier who faced challenges meeting stringent industry standards while managing high-volume orders. With the addition of a state-of-the-art selective soldering system paired with advanced process controls, they not only improved compliance but also reduced scrap rates significantly—demonstrating that thoughtful integration can lead to substantial cost savings over time.

In conclusion, maximizing efficiency through selective soldering requires thoughtful planning and execution but pays off handsomely in terms of productivity gains and quality assurance.

Conclusion

In the ever-evolving landscape of electronics manufacturing, understanding the nuances of selective soldering systems is crucial for businesses aiming to enhance their production capabilities. As we move forward, the integration of advanced technologies will redefine how we approach solder and flux applications, making processes more efficient and cost-effective. With a keen eye on future trends, companies can position themselves to leverage these innovations for maximum benefit.

Future Trends in Selective Soldering

The future of selective soldering is poised for exciting advancements as automation and artificial intelligence take center stage in manufacturing processes. Expect to see improvements in wave soldering machines that incorporate smart technology for real-time monitoring and adjustments, ensuring optimal performance with minimal human intervention. Additionally, the demand for eco-friendly solder and flux solutions will rise, pushing manufacturers toward sustainable practices that align with global environmental goals.

Investing in Quality Soldering Solutions

Investing in quality selective soldering equipment is not merely a choice; it’s a necessity for companies looking to maintain a competitive edge. While budget-friendly options may initially seem appealing, they often compromise on performance and reliability—leading to higher costs down the line due to rework or equipment failure. By prioritizing quality in your PCB soldering processes, you ensure long-term savings and superior results that can elevate your product offerings.

Partnering with Industry Leaders like Bensun

When it comes to navigating the complexities of selective soldering systems, partnering with industry leaders like Bensun can make all the difference. Their expertise spans across various sectors, providing tailored solutions that address specific needs while maximizing efficiency in both SMD soldering and traditional methods like wave soldering. Collaborating with such established brands not only grants access to cutting-edge technology but also fosters innovation through shared knowledge and resources.