Introduction

In the fast-paced world of electronics manufacturing, the wave soldering machine stands out as a critical player in ensuring high-quality PCB assembly. These machines are specifically designed to deliver consistent and reliable soldering results, making them an essential tool in the production line. As we delve into the intricacies of wave soldering, it becomes clear why this method is favored over alternatives like reflow soldering for certain applications.

Understanding Wave Soldering Machines

Wave soldering machines utilize a unique process that involves creating a wave of molten solder to join electronic components to printed circuit boards (PCBs). This technique is particularly advantageous for through-hole components, where traditional methods may fall short. By mastering the mechanics of wave machines, manufacturers can achieve impressive levels of efficiency and precision in their operations.

Importance of Soldering in PCB Manufacturing

Soldering is a fundamental process in PCB manufacturing, serving as the backbone for assembling electronic devices. Without proper solder joints, devices can suffer from connectivity issues and decreased performance, leading to costly failures down the line. Thus, choosing the right soldering machine—be it a wave or reflow oven—is crucial for ensuring product reliability and longevity.

Benefits of Choosing Wave Machines

Opting for wave soldering offers numerous benefits that enhance production capabilities and product quality. Wave machines are known for their high throughput rates, allowing manufacturers to meet demanding production schedules without sacrificing quality. Additionally, they provide superior joint integrity compared to other methods like reflow machines—making them an excellent choice for mass production environments.

What is a Wave Soldering Machine?

A wave soldering machine is a specialized piece of equipment used in the assembly of printed circuit boards (PCBs). This machine utilizes molten solder to create strong electrical connections between the components and the PCB, making it an essential tool in modern electronics manufacturing. Understanding how wave machines operate can significantly enhance production efficiency and joint quality in PCB assembly.

Mechanics of Wave Soldering

The mechanics behind wave soldering involve a unique process where a continuous wave of molten solder is generated within a solder pot. As PCBs pass over this wave, the components that need to be soldered dip into the liquid metal, allowing for seamless connections to form. This method ensures that all joints are adequately filled with solder, creating reliable and durable electrical pathways.

Wave machines operate by using various pumps and nozzles to maintain consistent wave profiles, which are crucial for effective soldering. The temperature control systems within these machines ensure that the solder remains at optimal temperatures for bonding without damaging sensitive electronic components. As a result, wave soldering stands out as an efficient method for mass production in PCB manufacturing.

Comparison with Reflow Soldering

When comparing wave soldering with reflow soldering, several key differences emerge that highlight their respective advantages and applications. Reflow ovens utilize heat to melt pre-applied solder paste on surface-mounted devices (SMDs), while wave machines directly immerse through-hole components in molten solder for connections. This distinction makes each technique suitable for different types of assemblies; while reflow works best with SMDs, wave machines excel at handling mixed technology boards featuring both through-hole and surface-mounted components.

Another notable difference lies in production speed and efficiency; wave machines often deliver higher throughput due to their continuous operation capabilities compared to reflow machines that require cycles of heating and cooling. Additionally, joint quality can vary between methods; while both techniques produce strong bonds when executed correctly, some manufacturers prefer wave systems for their ability to consistently achieve superior joint integrity under high-volume conditions.

Ultimately, choosing between a reflow machine or a wave soldering machine depends on specific project requirements such as board design complexity and component types involved in the assembly process.

Common Applications in PCB Assembly

Wave soldering finds its place across various applications within PCB assembly due to its ability to handle diverse component types effectively. Industries such as telecommunications, automotive electronics, consumer devices, and medical equipment frequently rely on this technology for assembling complex circuit boards quickly and efficiently. The versatility offered by these machines allows manufacturers to cater to high-volume production demands without compromising on quality.

Their capacity to accommodate different component sizes ensures compatibility across numerous product lines while maintaining consistent performance standards throughout production runs.

In summary, whether it's powering communication networks or ensuring medical devices function correctly under pressure—wave soldering plays an integral role in delivering reliable electronic solutions tailored for today's fast-paced market demands.

Key Components of Wave Soldering Systems

These systems are designed with precision engineering to ensure that every aspect of the soldering process is executed flawlessly. From the solder pot to temperature control, each component plays a vital role in ensuring the efficiency and effectiveness of a wave soldering machine.

Solder Pot and Wave Formation

The heart of any wave soldering machine is undoubtedly the solder pot, where molten solder is heated and maintained at a specific temperature. This pot creates a wave formation that facilitates the immersion of PCB assemblies into the liquid solder, ensuring that all joints receive optimal coverage. The shape and dynamics of this wave are critical; they determine how well components are wetted by solder during the process, which can significantly impact joint reliability compared to other methods like reflow soldering.

The design of the solder pot also influences other factors such as maintenance and longevity. A well-maintained pot not only improves efficiency but also reduces potential defects in joints, making it an essential focus area for operators using wave machines. By mastering the mechanics behind wave formation, manufacturers can leverage this technology for superior results in mass production settings.

Conveyor Systems in Wave Machines

Conveyor systems are another essential element within wave machines, acting as transport mechanisms that guide PCBs through various stages of the soldering process. These systems must be finely tuned to ensure that boards move at just the right speed—too fast might lead to insufficient wetting, while too slow could cause overheating or damage to sensitive components. Integrating conveyor technology with precise timing allows for seamless transitions between preheating stages and actual immersion into molten solder.

Moreover, modern conveyor designs often come equipped with adjustable heights and widths to accommodate different PCB sizes and configurations easily. This flexibility is particularly beneficial when dealing with diverse product lines or custom orders since it minimizes downtime associated with setup changes between runs. In essence, an efficient conveyor system enhances throughput while maintaining high-quality standards across various applications.

Temperature Control and Monitoring

Temperature control is paramount in any effective wave soldering operation; after all, consistent temperatures ensure uniform melting of the solder alloy used in these machines. Most advanced wave machines come equipped with sophisticated monitoring systems that track temperatures throughout different zones—such as preheat zones before entering the actual molten bath—to optimize thermal profiles for various types of assemblies effectively. This level of control not only aids in achieving excellent joint quality but also helps prevent issues like thermal shock or component damage.

Additionally, real-time monitoring allows operators to make immediate adjustments if deviations occur during production runs—an invaluable feature when working on high-volume projects where even minor fluctuations can lead to significant losses down the line. By investing time into understanding temperature management within their processes, manufacturers can maximize both efficiency and product reliability when utilizing their reflow ovens alongside traditional methods like reflow machines or SMT machines.

Advantages of Using Wave Soldering

When it comes to PCB assembly, wave soldering machines offer a plethora of advantages that make them a preferred choice in the industry. From high efficiency to superior quality, these machines have revolutionized the way we approach soldering tasks. Let’s dive into some of the standout benefits that wave soldering brings to the table.

High Throughput and Efficiency

One of the most compelling reasons to opt for a wave soldering machine is its remarkable throughput and efficiency. Unlike reflow soldering processes that can be time-consuming, wave machines allow for continuous operation, enabling manufacturers to process multiple boards simultaneously. This not only speeds up production but also maximizes resource utilization, making it an ideal solution for high-volume PCB manufacturing.

Moreover, the automated nature of wave soldering means that human error is significantly reduced, further enhancing production efficiency. By using a well-calibrated wave soldering machine, you can achieve consistent results in less time compared to traditional methods like reflow ovens or manual soldering techniques. In today’s fast-paced electronics market, where every second counts, this efficiency is crucial for maintaining competitive advantage.

Cost-Effectiveness in Mass Production

Cost-effectiveness is another major advantage offered by wave soldering systems over their reflow counterparts. While initial investments in a quality wave soldering machine may seem steep, the long-term savings are undeniable when considering factors like reduced labor costs and minimized material waste. In mass production scenarios where every penny counts, these savings can lead to significant profit margins.

Additionally, the speed at which these machines operate allows companies to increase their output without necessitating additional labor or equipment costs typically associated with other methods like reflow machines or SMT machines. This scalability makes wave soldering an attractive option for businesses looking to expand their operations without breaking the bank on new machinery or workforce training programs.

Superior Joint Quality

When it comes down to joint quality, few methods can rival what a well-tuned wave soldering machine delivers. The unique mechanics involved in creating waves of molten solder ensure excellent coverage and penetration into through-holes and surface mount components alike—something that might be challenging with reflow techniques alone. This results in robust connections capable of withstanding thermal cycling and mechanical stress better than those produced by other methods.

Furthermore, because wave machines provide consistent temperature control during the process, they help prevent common issues such as cold joints or insufficient wetting—problems often encountered with less sophisticated reflow ovens or manual techniques. With superior joint quality guaranteed through effective design and engineering principles inherent in modern wave systems, manufacturers can rest assured knowing they are producing reliable products that meet stringent industry standards.

Popular Wave Soldering Machines in the Market

The market for wave soldering machines is vibrant, with several manufacturers leading the charge in innovation and efficiency. Understanding the different offerings can help businesses choose the right soldering machine that suits their specific needs. In this section, we will explore three prominent players: Kester, Vectron, and Bensun Technology.

Kester and Their Innovations

Kester has been a longstanding name in the soldering industry, well-known for their commitment to quality and innovation in wave soldering technology. Their wave soldering machines are designed with advanced features that enhance performance while maintaining excellent joint quality, making them a favorite among PCB manufacturers. With an emphasis on reliability and efficiency, Kester's solutions often incorporate smart temperature control systems that rival those found in reflow ovens.

Moreover, Kester’s dedication to research allows them to continuously improve their wave machines by integrating new materials and processes into their designs. This focus on innovation ensures that users benefit from the latest advancements in wave soldering technology. As a result, many companies prefer Kester's machines over traditional reflow machines for high-volume production requirements.

Vectron’s Leading Solutions

Vectron stands out as a leader in providing cutting-edge solutions specifically tailored for high-speed PCB assembly processes using wave soldering techniques. Their range of wave soldering machines is engineered to maximize throughput while minimizing defects—an essential factor when competing against reflow soldering methods. Vectron's systems are also known for their user-friendly interfaces and robust construction, ensuring they withstand the rigors of continuous operation.

Additionally, Vectron has invested heavily in automation technologies that streamline operations further when paired with SMT machines. These enhancements allow manufacturers to achieve greater precision at lower costs compared to traditional methods like reflow ovens or manual soldering techniques. Companies looking for reliable equipment often turn to Vectron for its reputation as an industry innovator.

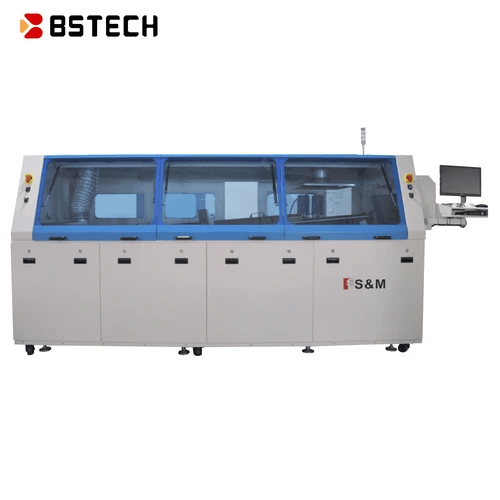

Bensun Technology and Customized Equipment

Bensun Technology specializes in creating customized equipment tailored specifically for various manufacturing needs within the electronics sector. Their wave soldering machines are highly adaptable and can be configured based on individual client specifications—making them ideal for businesses looking to optimize production lines without compromising quality or efficiency. With a strong focus on customer service, Bensun works closely with clients throughout the design process to ensure all requirements are met.

Bensun's commitment extends beyond just manufacturing; they also provide comprehensive maintenance support which is crucial for keeping wave machines operating at peak performance levels over time. This dedication helps reduce downtime significantly compared to other reflow machine options available on the market today. By trusting experts like Bensun Technology, manufacturers can rest assured they are investing wisely in their production capabilities.

Maintenance Tips for Wave Soldering Machines

Maintaining your wave soldering machine is crucial for ensuring consistent performance and longevity. Regular upkeep not only helps avoid costly downtime but also enhances the quality of your solder joints. Here are some essential maintenance tips to keep your wave machines running smoothly.

Regular Cleaning and Inspection

Keeping your wave soldering machine clean is paramount to its efficiency and effectiveness. Dust, flux residue, and other contaminants can accumulate over time, leading to poor soldering results and potential damage to the machine itself. Schedule regular inspections to check for wear and tear on components such as the conveyor system and solder pot, ensuring that everything is in optimal condition for reliable operation.

In addition to cleaning the exterior surfaces, pay special attention to the internal parts of the wave soldering system. The solder pot should be maintained at a consistent temperature, while also being free from oxidation or contamination that might compromise joint quality. By routinely cleaning these components, you can prevent issues that could arise during production runs.

Troubleshooting Common Issues

Even with diligent maintenance, you may encounter common problems with your wave soldering machine from time to time. One frequent issue is inconsistent wave formation, which can lead to uneven solder application on PCBs; this often requires adjusting parameters like pump speed or temperature settings in the solder pot. If you're facing challenges with component misalignment during assembly, it may be necessary to inspect the conveyor system for any obstructions or misalignments.

If you notice an increase in defects like cold joints or bridging during PCB assembly processes, it’s essential to troubleshoot quickly before they escalate into larger production issues. Investigate whether there's a problem with flux application or if there are fluctuations in temperature that could affect joint quality—this could indicate a malfunction within your reflow machine's heating elements as well. Keeping a close eye on these indicators will help ensure smooth operation across all stages of manufacturing.

Best Practices for Longevity

To extend the life of your wave soldering machine, adopting best practices is key—think of it as giving your SMT machine a little TLC! First off, always follow manufacturer guidelines regarding operational limits; overworking any machinery can lead to premature wear and tear or even catastrophic failure down the line. Additionally, keeping spare parts on hand—such as pumps or nozzles—can save valuable time when repairs are needed.

Another effective strategy involves training operators thoroughly so they understand both proper usage techniques and what signs indicate potential problems before they become serious issues. Encourage them to maintain logs detailing daily operations; this data can provide insights into patterns that might suggest upcoming maintenance needs or adjustments required for optimal performance in comparison with reflow ovens used in similar applications.

By implementing these maintenance tips regularly—cleaning diligently, troubleshooting effectively when issues arise, and following best practices—you'll be well-equipped to keep your wave soldering machines operating at peak performance levels while producing high-quality assemblies consistently!

Conclusion

In wrapping up our exploration of wave soldering machines, it's clear that this technology plays a crucial role in the PCB manufacturing landscape. As we look to the future, advancements in wave soldering will continue to enhance efficiency, reduce costs, and improve joint quality. The ongoing evolution of wave machines promises even greater integration with smart technologies and automation, making them indispensable for modern electronics production.

Future of Wave Soldering Technology

The future of wave soldering technology is bright, with innovations on the horizon that will revolutionize how we approach PCB assembly. Enhanced automation and precision are expected to make wave soldering machines even more efficient than today's models. Additionally, as manufacturers shift towards more sustainable practices, eco-friendly solutions for soldering processes will likely emerge alongside traditional methods like reflow soldering.

Choosing the Right Soldering Machine

Selecting the right soldering machine is pivotal for any PCB manufacturer looking to optimize their production line. Factors such as throughput requirements, component types, and budget constraints should guide your decision-making process when comparing various options like wave machines and reflow ovens. It's essential to evaluate not only the technical specifications but also how well a machine fits into your existing SMT machine setup.

Trusting Experts like Bensun Technology

When it comes to investing in a reliable wave soldering machine or any related equipment, trusting industry experts is crucial for long-term success. Companies like Bensun Technology specialize in delivering customized solutions tailored to specific manufacturing needs while ensuring top-notch support throughout the process. By partnering with experienced providers, manufacturers can confidently navigate their options and achieve optimal results in their PCB assembly operations.