Introduction

Soldering is an essential process in electronics, bridging the gap between components and functionality. With a plethora of soldering equipment available, from basic tools to sophisticated automated soldering equipment, understanding the right choice can significantly impact production efficiency and quality. This guide will explore the fascinating world of soldering machines, emphasizing the importance of selecting appropriate rework tools for various applications.

Discover the World of Soldering Equipment

The realm of soldering equipment is vast and diverse, encompassing everything from handheld tools to advanced automatic solder machines that streamline production lines. Each type of soldering machine serves specific purposes, catering to different industries and applications. As technology evolves, so does the sophistication of these machines, making it crucial for professionals to stay informed about developments in selective soldering systems and techniques.

Understanding the Importance of Rework Tools

Rework tools play a pivotal role in ensuring that electronic assemblies meet quality standards and function correctly after initial production. When issues arise during manufacturing or assembly processes, having access to efficient rework solutions can save both time and resources. Automated solutions like selective soldering machines not only enhance precision but also reduce waste, underscoring their significance in modern manufacturing environments.

Key Factors in Selecting Soldering Solutions

Choosing the right soldering solution requires careful consideration of several key factors including application requirements, budget constraints, and desired output quality. For instance, while an auto soldering machine might offer high-speed production capabilities, it may not be suitable for all types of components or materials used in selective soldering processes. Ultimately, understanding these factors ensures that businesses invest wisely in their equipment choices while maximizing efficiency in their operations.

Overview of Soldering Machines

Soldering machines are essential tools in electronics manufacturing, enabling the creation of reliable electrical connections. From manual devices to sophisticated automated soldering equipment, these machines cater to various production needs. Understanding the types and benefits of these soldering solutions can significantly enhance operational efficiency.

Types of Soldering Machines Explained

When it comes to soldering machines, there are several types designed for specific tasks. Manual soldering stations allow for hands-on control, ideal for small-scale projects or intricate work. On the other hand, automatic solder machines and auto soldering machines offer high-speed production capabilities, perfect for large-scale manufacturing environments where precision and speed are paramount.

Another popular choice is the selective soldering machine, which targets specific areas on a circuit board while minimizing heat exposure to surrounding components. This technique is particularly useful in complex assemblies where traditional methods might fail. By understanding these different types of soldering machines, manufacturers can choose the right solution that fits their unique production requirements.

Benefits of Using an Automatic Solder Machine

The benefits of using an automatic solder machine are manifold and can revolutionize a production line. First and foremost, these automated soldering equipment solutions significantly increase throughput by reducing cycle times compared to manual processes. This efficiency not only saves time but also reduces labor costs over time as fewer operators are needed to achieve higher outputs.

Moreover, automatic solder machines provide consistent quality in every joint they create; this reliability is critical in industries where defects can lead to costly failures or recalls. The precision offered by these systems minimizes human error and enhances overall product quality, ensuring that each connection meets stringent industry standards.

Lastly, investing in an automatic or selective soldering system allows companies to stay competitive in a fast-paced market by adapting quickly to changing demands without sacrificing quality or speed. As technology continues to advance, those who leverage these innovations will be better positioned for success.

How Selective Soldering Systems Improve Efficiency

Selective soldering systems have emerged as game-changers in the world of electronics assembly due to their targeted approach and efficiency improvements. By focusing only on specific joints that require attention while leaving others untouched, selective soldering machinery reduces unnecessary heat exposure—preserving sensitive components from damage during the process.

Additionally, selective soldering allows for more complex designs with dense layouts since it can navigate tight spaces that traditional wave or reflow methods cannot manage effectively. This capability means manufacturers can produce more intricate circuit boards without compromising on performance or reliability.

Furthermore, integrating a selective soldering machine into an assembly line streamlines workflows by minimizing rework needs and maximizing first-pass yields—ultimately leading to cost savings over time. As industries continue evolving towards automation and precision engineering, embracing selective soldering technologies will be vital for sustained growth and competitiveness.

The Rise of Automated Soldering Equipment

In recent years, the world of soldering has undergone a seismic shift toward automation. With the advent of automated soldering equipment, manufacturers are now able to achieve higher precision, increased speed, and reduced labor costs compared to traditional methods. This evolution is not only reshaping production lines but also enhancing the quality of electronic assemblies across various industries.

What is an Auto Soldering Machine?

An auto soldering machine is a highly efficient device designed to automate the process of soldering components onto circuit boards. These machines can perform tasks that would typically require skilled operators, thereby minimizing human error and increasing throughput. By utilizing advanced technology, such as selective soldering systems, auto soldering machines can adapt to various assembly requirements with remarkable ease.

The versatility of an automatic solder machine allows it to handle different types of components and configurations seamlessly. Whether it’s through wave soldering or reflow processes, these machines are engineered for optimal performance in high-volume production environments. Consequently, they have become indispensable tools for electronics manufacturers looking to stay competitive in today’s fast-paced market.

The Role of Technology in Soldering

Technology plays a pivotal role in transforming traditional soldering practices into streamlined automated processes. With innovations like programmable logic controllers (PLCs) and sophisticated software interfaces, modern soldering machines can execute complex tasks with precision and consistency. This technological integration not only boosts productivity but also enhances the overall quality control throughout the manufacturing process.

Moreover, advancements in selective soldering techniques have revolutionized how components are joined on printed circuit boards (PCBs). Automated systems equipped with vision technology can inspect joints in real-time, ensuring that every connection meets rigorous standards before moving on to subsequent stages of assembly. Such capabilities are essential for industries where reliability is non-negotiable—think aerospace or medical devices.

Industry Applications for Automated Solutions

Automated soldering equipment finds applications across a wide range of industries due to its efficiency and reliability. In consumer electronics, for instance, companies leverage automatic solder machines to produce everything from smartphones to laptops at lightning speed while maintaining impeccable quality standards. Similarly, automotive manufacturers utilize selective soldering machines for assembling intricate wiring harnesses and control modules that require precise connections.

Furthermore, sectors like telecommunications and industrial automation benefit immensely from these innovations as well; they rely on robust solutions that can handle complex assemblies efficiently while reducing downtime caused by manual errors or inconsistencies. As more businesses recognize the advantages offered by automated solutions—such as cost savings and improved product reliability—the adoption rate continues to soar across varied fields.

Exploring Selective Soldering Techniques

Selective soldering has emerged as a game-changer in the realm of electronics manufacturing, offering unique advantages over traditional methods. This technique allows for precise application of solder only where it's needed, minimizing waste and enhancing overall efficiency. With the integration of automated soldering equipment, manufacturers can achieve higher throughput while maintaining quality standards.

Advantages of Selective Soldering

One of the standout benefits of selective soldering is its ability to reduce thermal stress on components. Unlike traditional soldering machines, which can expose entire assemblies to high temperatures, selective soldering systems target specific joints, preserving sensitive parts from damage. Additionally, this precision leads to less flux usage and cleaner assemblies, making it an eco-friendly choice for modern manufacturers.

Another advantage lies in the versatility offered by selective soldering machines. These automated solutions can adapt to various board designs and layouts without requiring extensive reconfiguration. This flexibility not only saves time but also allows for rapid changes in production lines, catering to diverse product demands with ease.

Applications in Consumer Electronics

Selective soldering techniques are widely used across numerous applications in consumer electronics, particularly where intricate designs and components are involved. From smartphones to complex circuit boards found in smart appliances, the need for precise connections is paramount. Automated solutions like auto soldering machines ensure that even the smallest components receive reliable connections without compromising quality.

Moreover, industries such as automotive electronics have embraced selective soldering due to its reliability and efficiency. As vehicles become more technologically advanced with features like infotainment systems and driver-assistance technologies, robust electronic connections are critical for performance and safety. The ability of selective soldering systems to handle these complexities makes them indispensable tools in modern manufacturing environments.

Case Studies: Selective Soldering in Action

To illustrate the effectiveness of selective soldering techniques, consider a case study involving a leading smartphone manufacturer that integrated a selective soldering system into their production line. By using an automatic solder machine specifically designed for high-volume assembly tasks, they significantly reduced their defect rates while increasing productivity by 30%. The targeted application also minimized excess heat exposure on sensitive components like cameras and sensors.

Another compelling example comes from a company specializing in automotive electronics that adopted an advanced selective soldering machine for its circuit boards used in electric vehicles (EVs). By implementing this technology, they improved their assembly process's speed while ensuring that all critical connections were made with precision—an essential factor given the stringent safety regulations within the automotive industry.

In both cases, these organizations not only enhanced their operational efficiency but also demonstrated how investing in cutting-edge automated solutions can lead to substantial long-term benefits.

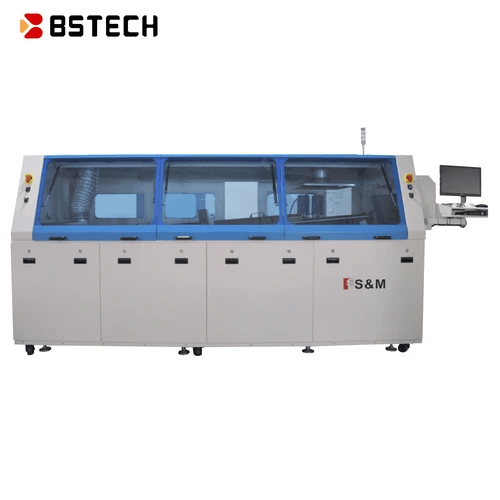

Equipment Spotlight: Bensun Technology Co., Ltd.

When it comes to the world of soldering solutions, Bensun Technology Co., Ltd. stands out as a leader in the field. With years of experience and a commitment to innovation, Bensun specializes in providing high-quality automated soldering equipment that meets the diverse needs of various industries. Their expertise encompasses everything from advanced automatic solder machines to selective soldering systems, ensuring that clients receive top-notch products tailored to their specific requirements.

Overview of Bensun's Expertise

Bensun has carved a niche for itself by focusing on precision and efficiency in soldering technology. Their team is dedicated to developing state-of-the-art solutions that enhance productivity while maintaining the highest quality standards. As a pioneer in automated soldering equipment, they have consistently delivered reliable and effective products, including selective soldering machines that cater to the evolving demands of modern manufacturing.

Key Products: JUKI Pick and Place Machines

Among their flagship offerings are JUKI Pick and Place Machines, which play a crucial role in streamlining assembly processes. These machines are designed for accuracy and speed, making them an essential component of any automated production line involving an auto soldering machine or selective soldering system. With features that optimize placement efficiency and reduce operational costs, JUKI machines exemplify Bensun's commitment to innovation in the field of soldering technology.

How Bensun Supports Various Industries

Bensun's impact extends across multiple sectors, providing tailored solutions for industries ranging from consumer electronics to automotive manufacturing. By integrating advanced automatic solder machines into their clients' workflows, they enable faster production times without sacrificing quality or reliability. Whether it's through selective soldering techniques or comprehensive support services, Bensun ensures that businesses can thrive with cutting-edge automated soldering equipment designed for today’s competitive landscape.

Choosing the Right Soldering Solution

Selecting the right soldering solution can feel like navigating a maze, especially with the plethora of options available today. Whether you’re eyeing an automatic solder machine or contemplating a selective soldering system, understanding your specific needs is essential. Factors such as production volume, product complexity, and budget constraints will play pivotal roles in your decision-making process.

Factors to Consider in Equipment Selection

When it comes to choosing a soldering machine, several critical factors come into play. First and foremost is the type of projects you’ll be working on; for intricate assemblies, a selective soldering machine may be more suitable than a standard auto soldering machine. Additionally, consider the level of automation required—automated soldering equipment can significantly enhance efficiency but may also come with higher upfront costs.

Another important factor is maintenance and support availability from manufacturers like Bensun Technology Co., Ltd., known for their expertise in this field. The longevity and reliability of your selected equipment are paramount; after all, no one wants to deal with unexpected downtimes due to faulty machinery. Lastly, think about future scalability—selective soldering systems that adapt to evolving production needs can save headaches down the line.

Rental vs. Purchase: Which is Better?

The age-old dilemma: should you rent or purchase your automatic solder machine? Renting provides flexibility and lower initial costs, making it an attractive option for businesses testing the waters with new technologies or fluctuating workloads. Conversely, purchasing equipment often leads to long-term savings if you're committed to consistent production levels.

Consider how often you'll use the equipment when making this decision; if it's only for short-term projects or prototypes, an auto soldering machine rental might make more sense financially. However, if you anticipate ongoing use and want full control over maintenance schedules and upgrades, investing in a selective soldering system could be your best bet. Ultimately, weigh both options carefully against your operational goals and financial capabilities.

Future Trends in Soldering Equipment

The landscape of automated soldering equipment is continually evolving as technology advances at breakneck speed. One trend gaining traction is increased integration of smart technologies into automatic solder machines—think IoT capabilities that allow real-time monitoring and predictive maintenance features for enhanced efficiency. This shift not only improves performance but also helps manufacturers stay ahead by minimizing downtime.

Another exciting development is the rise of eco-friendly practices within selective soldering processes; companies are increasingly focusing on sustainable materials and methods that reduce waste without compromising quality or precision. Furthermore, advancements in AI-driven solutions are paving the way for more intelligent auto soldering machines that can adapt their techniques based on real-time feedback from assembly lines.

In conclusion, staying informed about these trends will empower businesses to choose cutting-edge solutions that not only meet current demands but also prepare them for future challenges in manufacturing environments.

Conclusion

In wrapping up our exploration of soldering and rework equipment, it’s clear that the right tools can make or break your project. From automatic solder machines to selective soldering systems, each piece of equipment plays a crucial role in enhancing efficiency and precision. Understanding these tools enables manufacturers to optimize their production processes and maintain high-quality standards.

Recap of Soldering and Rework Equipment

We’ve delved into various types of soldering machines, including the rise of automated soldering equipment that is revolutionizing the industry. The automatic solder machine stands out for its ability to streamline operations while minimizing human error, making it an essential asset in modern manufacturing settings. Additionally, selective soldering techniques have proven invaluable in applications where precision is paramount, such as in consumer electronics.

Importance of Choosing the Right Tools

Selecting the right tools is vital for achieving optimal results in any project involving a soldering machine. Not all tasks require an auto soldering machine; understanding your specific needs will guide you toward either a selective soldering machine or a more traditional option. Moreover, investing in quality automated solutions not only boosts productivity but also enhances long-term profitability by reducing waste and rework.

Final Thoughts on Soldering Innovations

The future of soldering innovations looks promising with continuous advancements in technology driving improvements across various sectors. Automated soldering equipment will likely become even more sophisticated, integrating smart features that can adapt to different production environments seamlessly. As industries evolve, staying informed about these developments ensures that businesses remain competitive while leveraging the best tools available.