Introduction

In the world of electronics manufacturing, wave soldering is a crucial process that ensures reliable connections on printed circuit boards (PCBs). Understanding the essentials of wave soldering equipment can help businesses optimize their production lines and maintain high-quality standards. With various options available, making informed decisions about soldering machines is essential for achieving efficiency and effectiveness.

Understanding Wave Soldering Essentials

Wave soldering involves passing a PCB over a wave of molten solder, creating strong electrical connections, particularly for through-hole components. The process is favored for its ability to handle multiple connections simultaneously, making it ideal for high-volume production runs. Additionally, with the growing demand for lead-free solder options, manufacturers must adapt their wave machines to meet environmental regulations while maintaining performance.

The Importance of Choosing Quality Equipment

Selecting quality wave soldering equipment can significantly impact production efficiency and product reliability. Investing in robust and reliable soldering machines means fewer defects and less downtime due to maintenance issues. Furthermore, high-quality equipment often comes with advanced features that enhance compatibility with SMT soldering processes and reflow soldering systems.

Key Factors Impacting Your Decision

When choosing a wave soldering machine, several key factors come into play: production volume, frequency of use, and compatibility with existing systems like lead and lead-free solder applications. It’s vital to assess your specific needs carefully; this will ensure you select the right equipment that aligns with your operational goals. Additionally, understanding technological advancements in wave machines can provide insights into features that enhance overall productivity.

Types of Wave Soldering Machines

When it comes to wave soldering equipment, understanding the various types of machines available is crucial for making an informed decision. Each type serves a specific purpose and caters to different manufacturing needs, particularly when it comes to through-hole and surface mount technologies. By knowing the strengths and weaknesses of these machines, you can better align your choice with your production requirements.

Exploring Through-Hole vs. Surface Mount

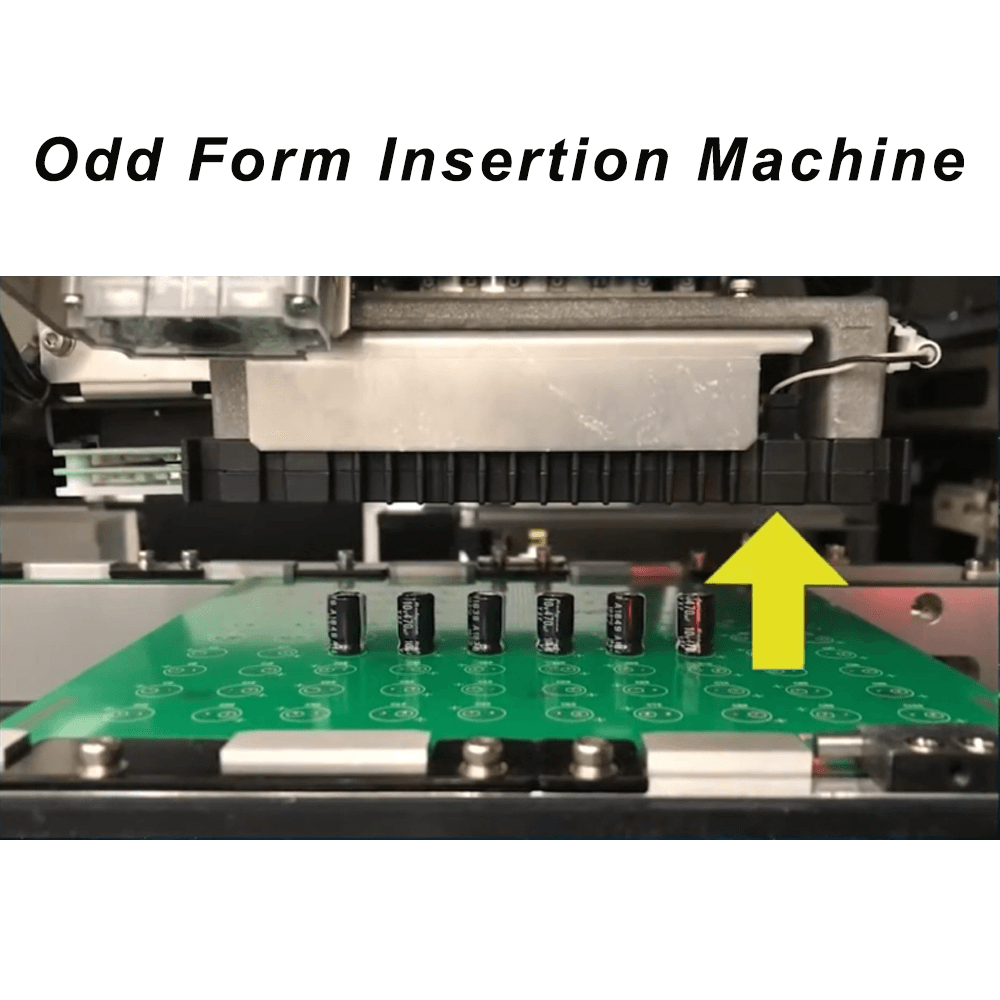

Through-hole technology (THT) involves inserting components into pre-drilled holes on a printed circuit board (PCB), which are then soldered in place using wave soldering machines. This method is well-suited for larger components that require robust mechanical support, making it ideal for applications where durability is paramount. On the other hand, surface mount technology (SMT) allows components to be mounted directly onto the surface of PCBs, enabling higher density layouts and reduced overall size—perfect for modern electronic devices.

In terms of wave soldering equipment, machines designed for through-hole applications typically feature wider waves to accommodate larger lead sizes while ensuring solid connections. Conversely, SMT soldering requires more precision and often integrates with reflow soldering processes to create reliable joints without compromising component integrity. Understanding these differences helps manufacturers choose the right soldering machine that matches their assembly line's specific needs.

The Benefits of Lead Free Solder Options

One significant trend in wave soldering is the shift towards lead free solder options due to environmental regulations and health concerns surrounding lead exposure. Lead free solders are formulated using alternative materials such as tin-copper or tin-silver-copper alloys that provide excellent thermal conductivity and reliability in electrical connections. By adopting lead free solutions in your wave machines, you not only comply with global standards but also enhance product safety.

Moreover, using lead free solders can improve overall product longevity since they tend to resist thermal fatigue better than traditional lead-based alternatives. However, it's essential to ensure that your wave soldering equipment is compatible with these newer materials as they may require different temperature profiles or adjustments in machinery settings during operation. This transition may seem daunting but offers long-term benefits such as reducing health risks associated with hazardous materials.

Understanding Lead Solder Applications

While many manufacturers are moving towards lead free options, understanding when and how to use lead solder remains vital for certain applications—especially in industries where performance criteria demand it. Lead solder has been a staple in electronics manufacturing due to its lower melting point compared to most lead free alternatives; this characteristic makes it easier on delicate components during assembly processes like reflow soldering or manual hand-soldering tasks.

Lead based solders also provide superior wetting properties which can be advantageous in complex PCB designs requiring intricate connections between multiple layers or densely packed components on SMT boards. However, manufacturers must weigh these advantages against environmental regulations and potential liabilities associated with using lead products in their operations—a balancing act that requires careful consideration when selecting appropriate wave machines.

In summary, while both through-hole and surface mount technologies have their unique advantages within wave soldering equipment contexts, choosing between them often hinges on specific production needs—whether opting for robust connections via THT or compact designs via SMT solutions will shape your decision-making process significantly.

Evaluating Production Needs

When it comes to wave soldering equipment, understanding your production needs is crucial for making the right investment. The type of soldering machine you choose can significantly impact not just the quality of your output but also your operational efficiency. By carefully assessing volume and frequency, compatibility with SMT soldering processes, and considerations for reflow soldering integration, you can ensure that your wave machines meet the demands of your production environment.

Assessing Your Volume and Frequency

First things first: how often will you be using this wave soldering equipment? If you're running a high-volume production line that churns out circuit boards daily, you'll need a robust soldering machine designed for heavy-duty use. Conversely, if you're only producing small batches occasionally, a more compact or semi-automatic model might suffice to save costs while still delivering quality results.

Frequency also plays a role in determining whether lead free solder or traditional lead solder is appropriate for your operations. Frequent changes in production runs might necessitate flexibility in your choice of materials and processes. Therefore, understanding both volume and frequency will help you select the right wave machines tailored to fit seamlessly into your workflow.

Compatibility with SMT Soldering Processes

In today's manufacturing landscape, many companies are adopting surface mount technology (SMT) alongside traditional through-hole methods. It’s essential to evaluate how well your chosen wave soldering equipment integrates with existing SMT processes since compatibility can streamline operations and reduce downtime. A well-suited soldering machine should be able to handle mixed technology boards efficiently without compromising quality.

Moreover, the ability to work effectively with lead free solder options is becoming increasingly important as industries shift toward more environmentally friendly practices. Look for features that enhance compatibility between wave machines and SMT setups; this could include adjustable settings or specialized nozzles designed for various component types. Ultimately, ensuring compatibility means fewer headaches down the line as you scale up production.

Considerations for Reflow Soldering Integration

Reflow soldering has become a staple in modern electronics manufacturing; therefore, considering its integration with wave soldering processes is vital when selecting equipment. Many manufacturers are now looking at hybrid systems that allow seamless transitions between reflow and wave machines without requiring extensive reconfiguration or setup time. This versatility can significantly enhance productivity by allowing quicker changeovers between different types of assemblies.

Additionally, it's crucial to evaluate how well the temperature profiles of lead free solder align across both methods—this ensures consistent results throughout the entire assembly process. If you're planning on using both techniques frequently, investing in specialized software or controls may provide greater precision during these transitions while minimizing defects caused by thermal stress on components. With careful consideration given to these factors, you can make informed decisions about integrating reflow capabilities into your overall manufacturing strategy.

The Role of Technology in Wave Machines

In the ever-evolving landscape of wave soldering, technology plays a pivotal role in enhancing performance and productivity. Modern wave soldering equipment is designed not only to meet the demands of high-quality soldering but also to adapt to the growing trends in lead-free solder applications. As you explore various soldering machines, understanding how technology integrates into these systems can help you make informed choices that benefit your production line.

Automation Features to Look For

Automation is no longer just a luxury; it has become a necessity in wave soldering processes. When evaluating wave machines, look for features like automatic flux application and programmable temperature profiles that can streamline operations while minimizing human error. These automation capabilities not only enhance consistency in lead solder applications but also improve overall efficiency when dealing with SMT soldering processes.

Moreover, advanced automation can significantly reduce labor costs by allowing fewer operators to manage multiple machines simultaneously. This means your team can focus on more critical tasks while the soldering machine handles repetitive actions with precision. Integrating such technologies into your production line ensures that you stay competitive while maintaining high standards for quality and reliability.

Innovations in Wave Soldering Equipment

The world of wave soldering is brimming with innovations aimed at improving functionality and sustainability. One notable trend is the development of eco-friendly wave soldering equipment that supports lead-free solder options without compromising on performance or quality. Innovations such as improved nozzle designs and enhanced heating mechanisms allow for better thermal management, ensuring optimal melting temperatures for both lead-free and traditional lead solders.

Additionally, manufacturers are increasingly incorporating smart technologies into their equipment, enabling real-time monitoring and diagnostics through IoT connections. This not only helps identify potential issues before they escalate but also allows for data-driven decision-making regarding maintenance schedules and operational adjustments. Such advancements are essential for keeping pace with modern manufacturing demands while ensuring reliability across all stages of reflow soldering integration.

Enhancements for Efficiency and Reliability

Efficiency and reliability are paramount when selecting wave machines for your production needs. Look for features like quick-change tooling systems that facilitate easy adjustments between different types of solders—be it lead or lead-free—to accommodate diverse project requirements seamlessly. These enhancements ensure minimal downtime during transitions while maximizing throughput.

Furthermore, investing in robust quality control mechanisms within your wave soldering equipment can dramatically reduce defects caused by improper heating or inadequate flux application—common pitfalls in manual processes. By prioritizing these technological enhancements, you create a more resilient manufacturing environment capable of adapting to varying product specifications without sacrificing quality or speed.

Maintenance and Support Considerations

When investing in wave soldering equipment, it’s crucial to consider the maintenance and support that come with it. A well-supported soldering machine can significantly extend its lifespan and ensure optimal performance over time. Companies that prioritize after-sales service often build long-lasting relationships with their clients, which is essential in the fast-paced world of electronics manufacturing.

Importance of After-Sales Service

After-sales service is a cornerstone of any successful wave soldering equipment provider. When issues arise—be it a malfunction or a need for adjustments—having access to prompt and effective support can make all the difference. Quality after-sales service not only resolves immediate concerns but also provides reassurance that you’re backed by experts who understand lead free solder and traditional lead solder applications alike.

Ease of Access to Replacement Parts

Another vital aspect of maintaining your wave machines is the ease with which you can obtain replacement parts. Regular wear-and-tear is inevitable, especially in high-volume production environments where SMT soldering processes are prevalent. Manufacturers that ensure a steady supply of parts will help you avoid prolonged downtimes, keeping your reflow soldering operations running smoothly without unnecessary interruptions.

Training Resources for Operators

Investing in training resources for operators using wave soldering equipment can yield significant returns on efficiency and quality assurance. Proper training ensures that your team understands how to handle both lead free solder and lead solder effectively, reducing errors during production runs. Additionally, well-trained operators are more likely to spot potential issues early on, preventing costly repairs or downtime associated with poorly maintained wave machines.

Top Brands in Wave Soldering Equipment

In the world of wave soldering, choosing the right equipment can make or break your production line. With numerous brands available, it’s essential to evaluate their offerings based on performance, reliability, and support. This section will delve into some leading brands in wave soldering equipment, including Bensun Technology and other notable manufacturers.

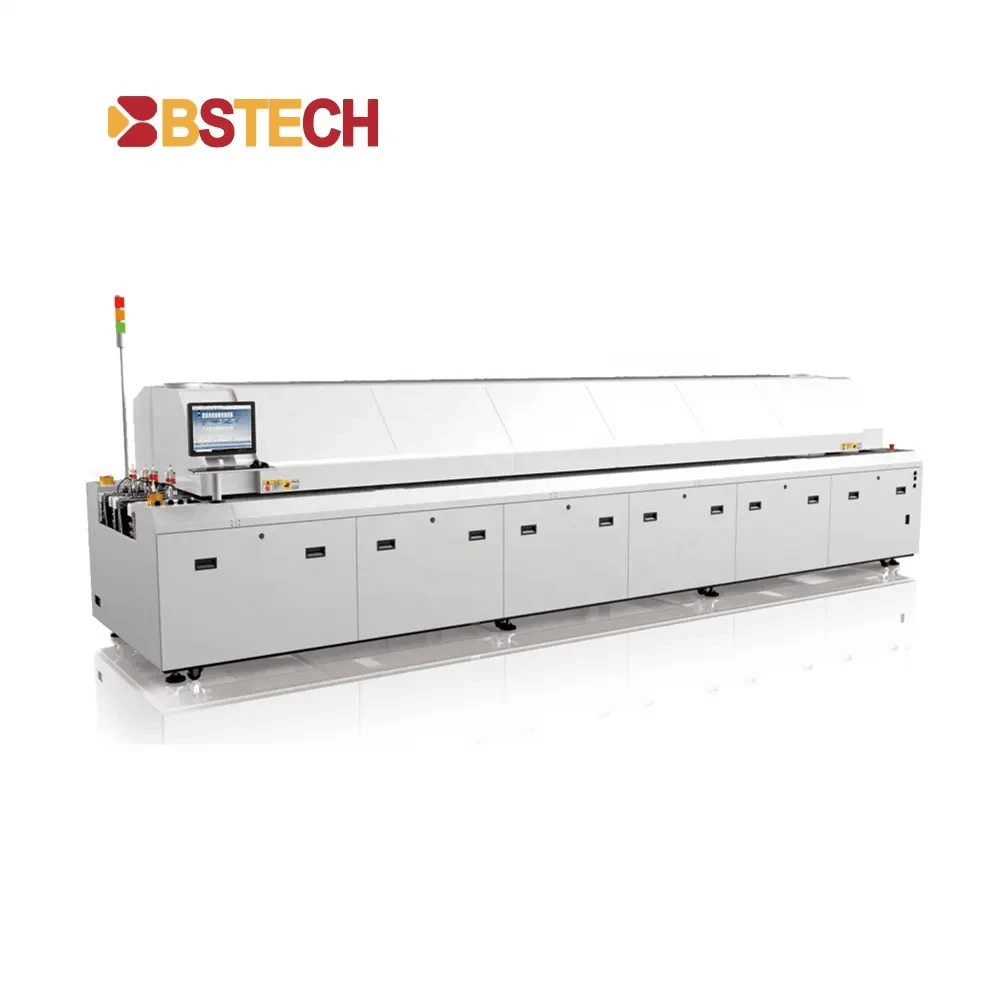

A Look at Bensun Technology

Bensun Technology stands out as a key player in the wave soldering equipment market. Known for its innovative approach to lead free solder applications, Bensun offers a range of soldering machines that cater to various production needs. Their commitment to quality ensures that users benefit from reliable performance and enhanced efficiency when integrating with SMT soldering processes.

One of the highlights of Bensun's machines is their compatibility with both lead solder and lead free solder options, making them versatile for different manufacturing requirements. Additionally, they incorporate advanced automation features that streamline operations and reduce manual labor. For those seeking a balance between cost-effectiveness and technological advancement in wave machines, Bensun Technology is undoubtedly worth considering.

Comparing Other Renowned Manufacturers

While Bensun Technology is impressive, it's important not to overlook other renowned manufacturers in the wave soldering arena. Brands like Vitronics Soltec and Ersa have earned reputations for producing high-quality equipment designed for both reflow soldering and wave soldering processes. These companies continuously innovate their products to meet evolving industry demands.

Vitronics Soltec is particularly noted for its robust lead free solder solutions that enhance environmental sustainability without compromising on quality or efficiency. Meanwhile, Ersa’s focus on user-friendly designs makes their machines appealing to operators looking for ease of use alongside top-notch performance in wave soldering applications. Each brand brings unique strengths to the table; therefore, evaluating them against your specific production needs is crucial.

User Reviews and Reputation

User reviews play a significant role in assessing the reputation of any brand offering wave soldering equipment. Many operators praise Bensun Technology for its responsive customer service and ease of maintenance; these factors contribute greatly to overall satisfaction when using their machines for lead free or lead solder applications. Positive feedback often highlights how well these machines integrate into existing SMT soldering workflows.

On the flip side, brands like Vitronics Soltec receive accolades for their durability under high-volume production conditions while ensuring minimal downtime during operations—a critical factor when considering investments in a new soldering machine. Reviews also indicate that user training resources provided by these manufacturers significantly enhance operator proficiency with complex systems like reflow or wave machines. Ultimately, examining user experiences can provide valuable insights into which brand will best suit your specific needs.

Conclusion

In the world of electronics manufacturing, wave soldering equipment plays a crucial role in ensuring quality and reliability. From understanding the differences between lead and lead-free solder to evaluating production needs, it's clear that making informed decisions is essential for success. By considering automation features and maintenance support, you can set your operations up for long-term efficiency.

Summary of Key Wave Soldering Insights

Throughout this guide, we’ve examined the vital aspects of wave soldering, including the types of solder used—both lead and lead-free options—and their applications in various settings. We also discussed how wave machines integrate with other processes like SMT soldering and reflow soldering, highlighting their versatility in modern manufacturing environments. Additionally, we explored the importance of choosing high-quality wave soldering equipment that meets your specific production requirements while ensuring consistency and reliability.

Final Thoughts on Equipment Selection

Selecting the right soldering machine isn’t just about picking a brand; it’s about aligning your choice with your operational goals and production demands. Whether you’re leaning towards lead-free solder for environmental compliance or traditional lead solder for specific applications, understanding each option’s benefits will guide you to make an informed decision. Remember to factor in after-sales service and training resources when evaluating potential suppliers; these elements can significantly impact your overall experience with wave soldering equipment.

Moving Forward with Confidence in Your Choice

As you embark on selecting your wave machines, carry forward the insights gained from this discussion to navigate through available options confidently. With a clear understanding of your needs—be it volume, compatibility with existing processes like SMT or reflow—you’ll be well-equipped to choose a solution that enhances productivity without compromising quality. Embrace innovation while staying grounded in practical considerations; this balance will ensure that your investment in wave soldering equipment pays off handsomely.