Introduction

In the realm of electronics, where every millimeter counts and precision is paramount, the process of PCB depanelization emerges as a critical player in circuit board manufacturing. The efficiency of this process directly influences not only the quality of the final product but also the overall productivity of PCB board manufacturing operations. As we delve into this topic, it becomes clear that understanding how to optimize PCB depanelizers can significantly enhance circuit board production.

The Importance of PCB Depanelization

PCB depanelization is essential for transforming a larger panel of circuit boards into individual units ready for assembly and testing. This step ensures that each circuit on board meets strict quality standards while minimizing waste and maximizing yield during production. By utilizing advanced PCB depanelizers, manufacturers can achieve superior accuracy and consistency in their circuit board production processes.

How Efficiency Shapes PCB Manufacturing

Efficiency is the lifeblood of any successful manufacturing operation, particularly in the fast-paced world of PCB manufacturing. Streamlined processes not only reduce lead times but also lower costs associated with labor and materials, making it crucial to invest in effective depanelization technologies. With an efficient approach to circuit board manufacturing, companies can respond swiftly to market demands while maintaining high-quality standards.

Precision: The Heart of Circuit Board Production

Precision is at the core of effective circuit board production; it determines how well components fit together and function within electronic devices. Inaccuracies during depanelization can lead to costly errors down the line, impacting both performance and reliability. Therefore, employing state-of-the-art PCB depanelizers that prioritize precision ensures that each piece produced contributes positively to overall product integrity.

Understanding PCB Depanelization Machines

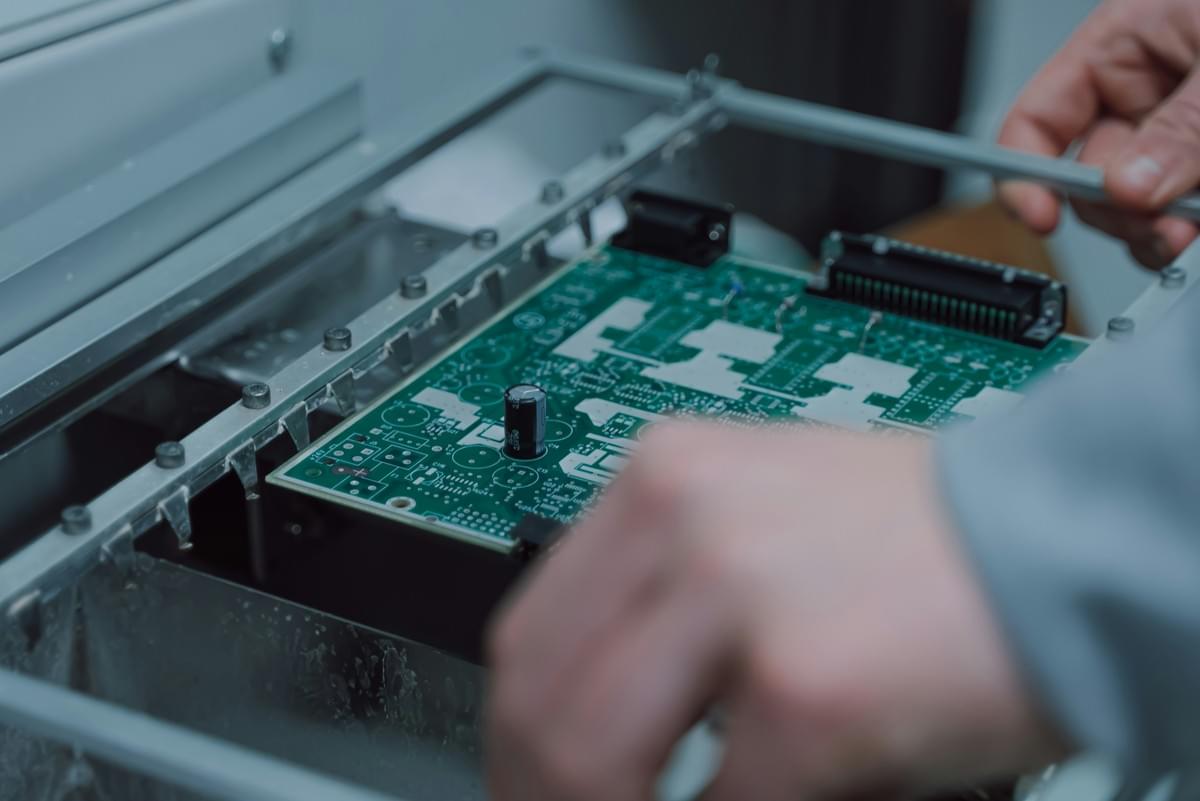

In the realm of PCB manufacturing, understanding the tools and technologies that drive efficiency is crucial. One of the most significant machines in this process is the PCB depanelizer, a device designed to separate individual circuit boards from their larger panelized forms. This technology not only enhances production speed but also ensures that each circuit on board meets high standards of quality and precision.

What is a PCB Depanelizer?

A PCB depanelizer is a specialized machine used to cut individual printed circuit boards from a larger panel, facilitating easier handling and assembly in subsequent manufacturing stages. These machines can utilize various cutting methods, ensuring that delicate components are not damaged during the separation process. By employing a PCB depanelizer, manufacturers can streamline their workflow while maintaining high levels of accuracy and reliability in circuit board production.

The Role in Circuit Board Manufacturing

In circuit board manufacturing, the role of a PCB depanelizer cannot be overstated; it serves as a critical link between fabrication and assembly processes. By efficiently separating PCBs from panels, these machines help reduce manual labor and minimize errors associated with traditional depanelization methods. This increased efficiency translates into faster turnaround times for PCB board manufacturing, allowing companies to meet demanding production schedules without sacrificing quality.

Types of Depanelization Technologies

There are several types of depanelization technologies available for use in modern PCB board production, each catering to different needs and applications within the industry. Laser depanelizers offer precise cutting capabilities with minimal thermal impact on components, making them ideal for intricate designs with sensitive parts. V-Cut solutions provide an economical option for standard designs by creating scored lines along which boards can be easily snapped apart, while router-based systems deliver robust performance for thicker materials or complex geometries requiring more aggressive cutting techniques.

Key Benefits of PCB Depanelization

PCB depanelization is a game changer in the realm of circuit board production, offering a myriad of benefits that enhance overall manufacturing processes. By employing advanced techniques, manufacturers can achieve superior precision and efficiency, ultimately leading to substantial cost savings. Let's delve into how these advantages manifest in the world of PCB manufacturing.

Enhanced Precision in Circuit Board Production

Precision is paramount when it comes to circuit board manufacturing, and a PCB depanelizer excels in this regard. These machines ensure that each cut is executed with pinpoint accuracy, minimizing the risk of damaging delicate components on the circuit on board. With enhanced precision, manufacturers can produce high-quality PCBs that meet stringent industry standards while maintaining the integrity of every circuit within the board.

Moreover, the use of specialized depanelization technologies allows for intricate designs to be realized without compromising quality. This level of accuracy not only boosts confidence in product reliability but also contributes to better performance in end applications. Ultimately, enhanced precision translates into fewer defects and reworks, which is music to any manufacturer’s ears.

Improved Efficiency for PCB Board Manufacturing

Efficiency is another key benefit brought by PCB depanelizers to the table—literally! By automating the separation process, these machines significantly reduce cycle times compared to manual methods or less sophisticated alternatives. This streamlined approach means that more PCBs can be produced within a shorter timeframe, allowing manufacturers to meet growing market demands without sacrificing quality.

Additionally, improved efficiency extends beyond just speed; it encompasses better resource management as well. With less material waste and reduced labor costs associated with manual handling, companies can allocate their resources more effectively across various aspects of PCB board manufacturing. In an industry where time truly equates to money, embracing efficient practices through advanced depanelization technology makes perfect sense.

Cost Reduction in Manufacturing Processes

Cost reduction is often at the forefront of any manufacturer’s agenda—and with good reason! Implementing a reliable PCB depanelizer can lead to significant savings throughout the production process by minimizing errors and enhancing yield rates during circuit board production. The initial investment may seem daunting; however, when weighed against long-term savings from reduced labor costs and material wastage, it quickly becomes clear that this technology pays for itself.

Moreover, as manufacturers scale their operations using efficient PCB board production methods like those enabled by depanelizers, they can achieve economies of scale that further drive down costs per unit produced. This financial advantage allows companies not only to improve their profit margins but also to remain competitive in an increasingly crowded market landscape where pricing strategies are essential for success.

In conclusion, adopting a PCB depanelizer isn't just about keeping up with technological advancements; it's about enhancing your entire production workflow—precision meets efficiency while slashing costs along the way!

Leading PCB Depanelization Technologies

In the world of PCB manufacturing, the choice of depanelization technology can significantly impact the efficiency and precision of circuit board production. With various methods available, manufacturers must consider their specific needs and production goals. This section explores three leading technologies: laser depanelization machines, V-Cut solutions, and router-based systems.

Laser Depanelization Machines

Laser depanelization machines are revolutionizing the way circuit boards are manufactured by providing unparalleled precision and versatility. Utilizing focused laser beams, these machines can cut through multiple layers of material without applying physical pressure, minimizing the risk of damage to sensitive circuits on board. The ability to create intricate designs with tight tolerances makes laser depanelizers an ideal choice for high-density PCB board manufacturing.

Moreover, laser systems offer a non-contact method that eliminates mechanical wear and tear on tools, ensuring consistent performance over time. This technology also allows for rapid prototyping and small-batch production runs without sacrificing quality or speed in circuit board production. As demand for miniaturized electronics grows, investing in a laser pcb depanelizer becomes increasingly essential for manufacturers looking to stay competitive.

V-Cut Depanelization Solutions

V-Cut depanelization is another popular method that has stood the test of time in PCB manufacturing due to its simplicity and effectiveness. This technique involves creating a series of V-shaped grooves along predefined lines on a circuit board that facilitate easy separation after assembly. V-Cut solutions are especially beneficial for high-volume PCB board production as they provide reliable results with minimal setup time.

One key advantage of V-Cut technology is its compatibility with various materials used in circuit board manufacturing, making it versatile across different applications. Additionally, this method maintains structural integrity during the cutting process while allowing for fast handling times post-depaneling—perfect for manufacturers looking to streamline their workflow without compromising quality in circuit board production. When considering cost-effectiveness alongside efficiency, V-Cut solutions often emerge as a top contender.

Router-Based Systems

Router-based systems represent another significant advancement in PCB depanelization technologies that cater to diverse manufacturing needs. These systems employ rotating cutting tools to separate individual PCBs from panels with high precision while accommodating complex geometries often found in modern circuit boards on boards today. The flexibility offered by router-based machines allows manufacturers to tackle various designs efficiently during PCB manufacturing processes.

Moreover, router-based systems can handle thicker substrates compared to other methods like V-Cutting or lasers while maintaining excellent edge quality—a crucial factor when it comes to ensuring reliable connections within electronic devices post-production. As an added benefit, these routers can be integrated into existing automated workflows seamlessly; thus enhancing overall productivity levels within any given facility focused on improving their PCB board manufacturing capabilities.

Choosing the Right PCB Depanelizer

Selecting the right PCB depanelizer is crucial for optimizing your circuit board manufacturing processes. With various options available, it’s essential to consider specific factors that align with your production needs and goals. The right choice can significantly enhance efficiency, precision, and ultimately, the quality of your circuit board production.

Factors to Consider in Selection

When choosing a PCB depanelizer, you must evaluate several key factors that impact its performance and suitability for your operation. First, assess the type of circuit boards you are producing; different technologies work better with various designs and materials used in PCB manufacturing. Additionally, consider the volume of production; high-volume environments may benefit from automated systems while lower volumes might be adequately served by manual or semi-automated options.

Another critical factor is precision; a high-quality PCB depanelizer will ensure clean cuts without damaging components on the circuit on board. Speed is also vital—your chosen machine should be capable of maintaining pace with your overall production line to avoid bottlenecks in PCB board manufacturing. Finally, think about maintenance requirements and support services offered by manufacturers to ensure long-term reliability.

Evaluating Brand Reliability

Brand reliability plays a significant role when selecting a PCB depanelizer since it can affect everything from performance to customer service experience. Researching manufacturer reputation through reviews and testimonials can provide insight into their track record within the circuit board manufacturing industry. Look for brands that have established themselves as leaders in technology innovation and customer satisfaction.

Additionally, consider how long the brand has been in business; longevity often indicates stability and expertise in developing reliable machinery for PCB board production. It's also wise to investigate warranty offerings and after-sales support—brands that stand behind their products are more likely to deliver dependable solutions tailored for efficient circuit board production processes.

Spotlight on Bensun Technology

Bensun Technology stands out as a reputable provider of advanced PCB depanelizers designed specifically for modern circuit board manufacturing needs. With years of experience under their belt, they have gained recognition for producing reliable machines that enhance efficiency while ensuring precision during the depanelization process. Their innovative solutions cater to various types of PCBs, making them suitable for diverse applications in electronic manufacturing.

One notable feature of Bensun's offerings is their commitment to customer service; they provide comprehensive support throughout the purchasing process and beyond, ensuring users maximize their investment in PCB depanelizers effectively. Furthermore, Bensun Technology continuously invests in research and development to remain at the forefront of technological advancements within the industry—an essential trait when considering future-proofing your circuit board production capabilities.

Integrating PCB Depanelization into Manufacturing

Integrating a PCB depanelizer into the manufacturing process can significantly enhance overall efficiency and output quality. By carefully orchestrating the flow of circuit board production, manufacturers can minimize bottlenecks and maximize throughput. The result is a more streamlined operation that not only meets but exceeds industry standards.

Streamlining the Production Line

To truly streamline the production line, it’s essential to consider how a PCB depanelizer fits into the larger picture of circuit board manufacturing. This machine reduces manual handling and optimizes workflow by automating the separation of individual PCBs from panels. With improved accuracy and speed, manufacturers can focus on other critical aspects of PCB board manufacturing while ensuring that each circuit on board is produced with precision.

Moreover, integrating advanced technologies like laser or router-based systems allows for faster processing times without compromising quality. As a result, businesses experience fewer errors and rework cycles, leading to significant cost savings in the long run. By adopting these practices, companies are not just keeping up with industry trends; they are setting them.

Case Studies of Successful Integration

Several companies have successfully integrated PCB depanelizers into their manufacturing processes, showcasing remarkable improvements in efficiency and productivity. For example, one leading electronics manufacturer reported a 30% increase in output after implementing laser depanelization technology in their circuit board production line. The transition allowed them to reduce labor costs while maintaining high-quality standards for their PCBs.

Another case involved a company specializing in automotive electronics that integrated V-Cut solutions into their assembly line. This adaptation not only streamlined operations but also enhanced precision—ensuring that each circuit on board met rigorous safety regulations without delays or defects. These success stories highlight how effective integration of PCB depanelizers can transform traditional manufacturing practices.

Future Trends in PCB Board Production

Looking ahead, several trends are likely to shape the future of PCB board production and its integration with depanelization technologies. One significant trend is the increasing demand for miniaturization in electronic devices; this will require even more precise cutting techniques from modern PCB depanelizers to handle smaller components effectively. As technology evolves, manufacturers will need to adapt their processes accordingly to remain competitive.

Furthermore, advancements in automation and AI-driven systems promise to revolutionize how we approach circuit board manufacturing entirely. These innovations could lead to smarter production lines where machines communicate seamlessly with one another, optimizing every step from design through assembly to final testing—ultimately enhancing both speed and accuracy in producing PCBs. Embracing these future trends will be key for companies looking to thrive in an ever-changing landscape.

Conclusion

In the fast-paced world of PCB manufacturing, maximizing production efficiency is not just a goal; it's a necessity. The integration of advanced PCB depanelizers into the circuit board production process enables manufacturers to achieve higher precision and speed, ultimately leading to better quality products. By optimizing the depanelization phase, companies can significantly enhance their overall output and reduce time-to-market for their circuit on board solutions.

Maximizing Production with PCB Depanelizers

PCB depanelizers are game-changers in the realm of circuit board manufacturing. With their ability to cut multiple boards simultaneously while maintaining exceptional accuracy, these machines ensure that each circuit board produced meets stringent quality standards. Moreover, by minimizing manual labor and reducing waste during the PCB board manufacturing process, businesses can streamline operations and enhance productivity like never before.

The Future of Circuit Board Manufacturing

The future of circuit board production looks bright as technology continues to evolve at an unprecedented pace. Innovations in PCB depanelization methods are paving the way for even more efficient processes that promise lower costs and higher yields. As manufacturers embrace automation and smart technologies, we can expect a significant transformation in how circuit boards are designed, produced, and assembled.

Partnering with Experts like Bensun Technology

Choosing the right partner for your PCB manufacturing needs can make all the difference in achieving optimal results. Companies like Bensun Technology specialize in providing cutting-edge solutions tailored to meet specific requirements within the circuit board production landscape. By collaborating with experts who understand both technology and market trends, manufacturers can harness the full potential of their PCB depanelizer systems and stay ahead of the competition.