Introduction

In the ever-evolving world of electronics manufacturing, the wave solder machine stands out as a crucial player in ensuring high-quality PCB assembly. This innovative equipment seamlessly melds solder and flux to create robust electrical connections, making it indispensable for modern production lines. Understanding how these components work together is vital for anyone looking to optimize their soldering processes.

Overview of Wave Solder Machines

Wave solder machines are designed to automate the process of soldering electronic components onto printed circuit boards (PCBs). These machines utilize a flowing wave of molten solder, allowing for efficient and uniform application on multiple joints simultaneously. With advancements in technology, today's best soldering equipment includes features that enhance precision and reduce waste, making wave soldering an attractive option for manufacturers.

Importance of Quality in PCB Soldering

Quality is paramount when it comes to PCB soldering, as poor connections can lead to device failures and costly repairs. In industries where reliability is non-negotiable, such as aerospace or medical devices, ensuring top-notch quality through effective use of lead-free solder becomes even more critical. By leveraging the capabilities of a wave solder machine combined with appropriate solder & flux choices, manufacturers can achieve consistent results that meet stringent quality standards.

How Solder and Flux Work Together

Solder and flux are two sides of the same coin in achieving optimal connectivity on PCBs. Flux on solder plays an essential role by cleaning surfaces and preventing oxidation during the heating process, which enhances adhesion and flow characteristics. When selecting the right combination of solder flux with your wave solder machine, you set the stage for successful bonding that withstands both time and temperature fluctuations.

What is a Wave Solder Machine?

Wave solder machines are pivotal in the world of PCB manufacturing, providing an efficient and reliable method for soldering electronic components onto printed circuit boards. These machines utilize a wave of molten solder to create strong, lasting connections between components and the PCB. By integrating both solder and flux, wave solder machines ensure optimal adhesion and performance during the soldering process.

Definition and Functionality

A wave solder machine is an automated system designed to facilitate the mass production of PCBs by applying molten solder to the underside of a board. The process involves passing the PCB over a wave of molten lead-free solder, where it makes contact with exposed pads that need to be connected to components. The functionality hinges on the effective use of flux on solder, which cleans surfaces and promotes better bonding, ensuring that every connection is as strong as possible.

Advantages of Wave Soldering

One major advantage of wave soldering is its ability to handle multiple connections simultaneously, significantly increasing production efficiency compared to manual methods. Additionally, wave solder machines can accommodate complex board designs with various component sizes and shapes without compromising quality. By utilizing lead-free solder options alongside high-quality flux, manufacturers can meet environmental standards while ensuring robust performance in their products.

Comparison with Other Soldering Techniques

When comparing wave soldering to other techniques like hand-soldering or reflow processes, several distinctions emerge that highlight its strengths. Unlike hand-soldering—which can be labor-intensive and prone to human error—wave solder machines provide consistency in application and reduce cycle times dramatically. Moreover, while reflow processes primarily rely on heat distribution for melting solder paste, wave solders employ a dynamic flow of molten metal that ensures thorough coverage across all joints made with high-quality solder & flux combinations.

Types of Wave Solder Machines

When it comes to wave solder machines, understanding the different types available is crucial for optimizing PCB manufacturing processes. Each type serves a specific purpose and has its own set of advantages, particularly when it comes to the interplay between solder and flux. Selecting the right soldering machine can significantly influence the quality and efficiency of your production line.

Selective vs. Conventional Wave Soldering

Selective wave soldering is a targeted approach that allows for precise application of solder and flux only where needed on a PCB. This method reduces waste and minimizes thermal stress on sensitive components, making it an excellent choice for complex boards with mixed technologies. In contrast, conventional wave soldering involves passing an entire PCB over a wave of molten solder, which can be more efficient but may lead to issues with heat-sensitive parts.

Both techniques utilize the same fundamental principles of solder and flux interaction; however, selective wave soldering offers greater control over the process. By applying specific amounts of flux on solder only where necessary, manufacturers can achieve superior results without compromising component integrity. Ultimately, choosing between selective and conventional methods depends on your production needs, component types, and desired quality levels.

Lead-Free Wave Solder Machines

As environmental concerns rise alongside regulatory requirements, lead-free wave solder machines have become increasingly important in modern electronics manufacturing. These machines utilize lead-free solder formulations that are designed to perform effectively while minimizing harmful substances in electronic products. The transition to lead-free options often requires adjustments in both equipment settings and material choices.

The combination of lead-free solders with appropriate flux on solder is critical for achieving reliable joints without defects such as cold joints or voids. Manufacturers must ensure that their selected solder flux complements their chosen lead-free materials to optimize performance under varying operating conditions. With advancements in technology, many leading brands now offer best-in-class lead-free solutions that meet both performance standards and environmental regulations.

Key Manufacturers in the Market

The market for wave solder machines is filled with key players known for producing high-quality equipment tailored to various manufacturing needs. Companies like Kester, Speedline Technologies, and Nordson DAGE are renowned for their innovative approaches to integrating advanced features into their machines while ensuring compatibility with various types of solders—including lead-free options—and effective use of suitable fluxes.

When selecting a manufacturer or model for your next investment in PCB assembly technology, consider factors like reliability, service support, and adaptability to evolving industry standards surrounding materials such as lead-free solders or new formulations of solder fluxes. The best manufacturers not only provide top-notch equipment but also offer resources for training operators on optimal usage practices—ensuring that you get the most out of your investment in a wave solder machine.

The Role of Solder and Flux

In the world of PCB manufacturing, the interplay between solder and flux is crucial for achieving high-quality connections. A wave solder machine relies heavily on these two components to create reliable joints that can withstand various stresses. Understanding their roles not only enhances performance but also ensures the longevity of electronic devices.

Understanding Solder Flux Composition

Solder flux is a chemical agent that plays a vital role in the soldering process, particularly in wave solder machines. It typically consists of a blend of organic acids, rosin, and solvents designed to remove oxidation from metal surfaces before soldering occurs. This cleaning action is essential because it allows for better wetting and adhesion of the solder to the components and PCB pads, ensuring strong electrical connections.

The composition of solder flux can vary widely depending on its intended application; some formulations are tailored specifically for lead-free solder, while others may be optimized for traditional tin-lead alloys. Knowing these differences can help manufacturers choose the best soldering equipment for their specific needs. Ultimately, understanding the composition of solder flux is key to achieving optimal results in any wave soldering operation.

How Flux on Solder Enhances Performance

Flux plays an indispensable role in enhancing the performance of both lead-free and conventional solders during wave soldering processes. When applied correctly, flux on solder helps reduce surface tension and promotes better flow characteristics, allowing molten solder to spread evenly across surfaces. This results in stronger joints with minimal defects such as cold solders or bridging—a common headache in PCB assembly.

Moreover, effective use of flux can significantly improve thermal conductivity between components and their pads, ensuring efficient heat transfer during operation. This is especially important when working with sensitive electronic parts that can't afford excessive heat exposure or poor connections. In summary, using appropriate flux not only elevates joint quality but also extends component life by reducing failure rates.

Choosing the Right Solder & Flux

Selecting the right combination of solder & flux is pivotal for achieving optimal results with your wave solder machine. Factors such as component type, board design complexity, and environmental regulations (like RoHS compliance) all influence this decision-making process. For instance, if you're working with lead-free applications, it's essential to choose compatible lead-free solders along with suitable fluxes designed specifically for those alloys.

Additionally, always consider your specific application requirements—certain industries may demand higher reliability standards which could dictate more specialized materials or formulations in your choice of soldering machine setup. By carefully evaluating your options based on these criteria, you’ll ensure that you’re equipped with the best tools available to achieve flawless results every time you fire up your wave solder machine.

Best Practices for Operating Wave Solder Machines

Operating a wave solder machine effectively requires attention to detail and adherence to best practices. Quality soldering relies heavily on the synergy of solder and flux, making it essential to optimize their application for superior results. By following these guidelines, you can ensure that your soldering machine performs at its best, leading to high-quality PCB assemblies.

Regular Maintenance Tips

Regular maintenance is crucial for keeping your wave solder machine in top condition. Start by routinely checking and cleaning the solder pot, ensuring that the lead-free solder remains free from contaminants that could affect performance. Additionally, inspect the flux on solder application nozzles and pumps; any blockages or wear can lead to inconsistent results, so addressing these issues promptly will save time and resources in the long run.

Another important aspect of maintenance is monitoring temperature settings across different components of your soldering machine. Overheating can degrade both the lead-free solder and the flux used in conjunction with it, resulting in poor adhesion or even damage to PCBs. Keeping a log of maintenance tasks not only helps track when services are due but also assists in identifying patterns that may indicate underlying problems with your equipment.

Lastly, always refer to your manufacturer's guidelines for specific maintenance routines tailored to your model of wave solder machine. Following these recommendations ensures longevity while maximizing efficiency—after all, nobody wants a breakdown during a critical production run!

Optimal Settings for Various Applications

Finding optimal settings for your wave solder machine is vital for achieving consistent results across different applications. The key lies in adjusting parameters such as temperature, conveyor speed, and preheat settings based on PCB design and component types being used. For example, thicker boards may require higher temperatures or longer exposure times to ensure proper melting of lead-free solder.

Moreover, consider the type of flux you are using; certain formulations work better with specific applications than others. Understanding how flux on solder interacts with various components can help you fine-tune those settings further—ensuring that every joint is perfectly executed without compromising component integrity or reliability.

Lastly, don’t hesitate to document successful settings as benchmarks for future projects; this will streamline processes and reduce trial-and-error time when operating your best soldering equipment again down the line.

Troubleshooting Common Issues

Even with proper operation practices in place, issues may occasionally arise when using a wave solder machine; knowing how to troubleshoot them effectively can save both time and materials. One common problem is insufficient wetting caused by inadequate flux application; if you notice poor adhesion or weak joints, check if there’s an issue with either the quality of your flux or its distribution method on the board before it reaches the wave.

Another frequent concern involves bridging between closely spaced pins—a result often linked back to incorrect temperature settings or improper conveyor speed through the molten wave of lead-free solder. Adjustments here might just be what you need; however, keep an eye out for other factors like board design which could also contribute.

Finally, always stay alert for signs of contamination within your wave solders—such as excessive dross formation—which indicates potential problems with either material quality or process parameters needing adjustment before they escalate into larger headaches down the road!

Innovations in Wave Soldering Technology

In the ever-evolving world of electronics manufacturing, wave solder machines are at the forefront of innovation. The latest trends focus on enhancing efficiency, sustainability, and precision in PCB assembly processes. As the industry embraces new technologies, understanding these innovations becomes essential for manufacturers looking to stay competitive.

Latest Trends and Developments

One of the most exciting developments in wave soldering technology is the integration of advanced monitoring systems that provide real-time data on solder and flux performance. These systems help operators fine-tune their settings, ensuring optimal results with every batch processed by the soldering machine. Moreover, manufacturers are increasingly adopting modular designs for their best soldering equipment, allowing for easier upgrades as new technologies emerge.

Another trend is the rise of smart wave solder machines equipped with IoT capabilities that facilitate remote monitoring and control. This connectivity allows operators to make adjustments on-the-fly based on live data analysis, significantly reducing downtime and improving overall productivity. With these advancements, companies can enhance their production lines while maintaining high standards for quality assurance.

Green Soldering Solutions

As environmental concerns continue to grow within the manufacturing sector, green soldering solutions have gained traction in wave solder technology. Many manufacturers are now focusing on lead-free solder options that not only comply with regulatory standards but also minimize environmental impact. By selecting eco-friendly materials combined with effective flux on solder applications, companies can ensure sustainable practices throughout their production processes.

Additionally, innovations like water-soluble flux formulations are becoming popular as they simplify post-solder cleaning processes while being less harmful to both users and the environment. These solutions not only promote a cleaner workspace but also enhance overall safety during production runs involving hazardous materials. Adopting green practices in wave solder machines is no longer just a trend; it’s becoming a standard expectation among consumers and regulatory bodies alike.

The Impact of Automation on Efficiency

Automation has revolutionized many aspects of manufacturing processes, including those involving wave solder machines. By integrating automated systems into PCB assembly lines, companies can achieve unprecedented levels of efficiency and consistency when using various types of solder & flux combinations. Automated handling reduces human error while ensuring that each component receives precise amounts of both solder and flux for optimal bonding.

Furthermore, automated inspection systems are now commonly integrated into wave solder setups to identify defects early in the process—saving time and resources down the line by preventing faulty products from reaching customers. This proactive approach not only enhances product quality but also reinforces customer trust in brands committed to delivering top-notch electronic components made with cutting-edge technology.

In summary, innovations in wave soldering technology highlight a shift towards smarter operations that prioritize quality and sustainability without sacrificing efficiency or effectiveness—making them essential tools for any forward-thinking manufacturer today.

Conclusion

As we wrap up our exploration of wave solder machines, it’s essential to recognize their pivotal role in the PCB manufacturing landscape. These machines not only streamline the soldering process but also ensure high-quality connections through the effective use of solder and flux. When employed correctly, a wave solder machine can significantly enhance production efficiency while maintaining the integrity of electronic components.

Summary of Wave Solder Machine Benefits

Wave solder machines offer numerous advantages that make them a preferred choice for many manufacturers. Their ability to handle large volumes of PCBs quickly and consistently is unmatched, providing an efficient solution for mass production. Additionally, when paired with the right solder and flux, these machines deliver robust joints that stand the test of time, ensuring reliability in electronic applications.

Choosing the Right Equipment for Your Needs

Selecting the best soldering equipment requires careful consideration of your specific production needs and goals. Factors such as PCB design complexity, volume requirements, and material compatibility should guide your decision-making process. Furthermore, understanding how different types of solder & flux interact can help you optimize your operations and achieve superior results with your chosen soldering machine.

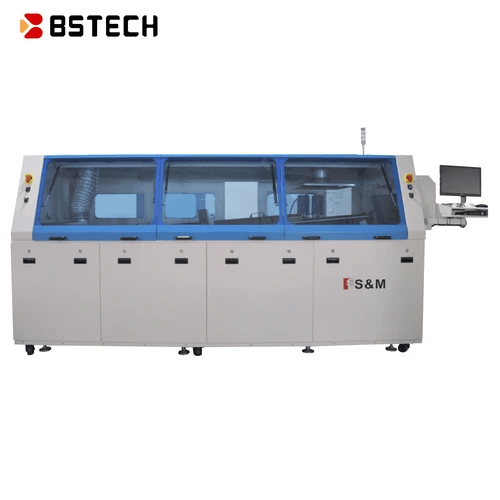

Bensun Technology's Contributions to PCB Manufacturing

Bensun Technology stands out in the realm of PCB manufacturing by offering innovative wave solder machines tailored to meet modern industry demands. Their commitment to quality ensures that every machine is equipped to handle lead-free solder effectively while maximizing efficiency through advanced automation features. By continuously pushing boundaries in technology and performance, Bensun is helping businesses elevate their production capabilities with top-notch solutions for wave soldering.