Introduction

Soldering techniques are the backbone of electronics manufacturing, playing a crucial role in ensuring reliable connections between components. With various methods available, it’s essential to understand the nuances of each technique to make informed decisions that affect product quality and production efficiency. This guide will delve into selective wave soldering, wave soldering, and reflow soldering, helping you navigate the complexities of these processes.

Understanding Soldering Techniques

At its core, soldering is the process of joining two or more electronic components together using a filler material known as solder. The best solder for electronics is often determined by the specific requirements of the project, including thermal conductivity and melting point. Each technique—whether it be selective wave soldering or traditional wave soldering—has unique characteristics that influence how effectively they can be employed for soldering PCB boards.

The Importance of Choosing the Right Method

Selecting the appropriate soldering method can significantly impact both production time and product reliability. A good solder for electronics not only ensures strong connections but also minimizes defects during assembly processes like soldering components on PCB boards. By understanding when to use selective wave soldering versus other methods, manufacturers can optimize their workflows and enhance overall product performance.

Overview of Selective, Wave, and Reflow Soldering

Selective wave soldering involves targeted application of molten solder to specific areas on a PCB, making it ideal for complex assemblies with sensitive components. Wave soldering employs a continuous flow of molten metal that immerses entire PCBs for efficient mass production, while reflow soldering utilizes heat to melt pre-applied paste on surface mount devices (SMDs). Each method has its strengths; thus, knowing their differences equips manufacturers with tools to choose wisely based on their specific needs.

What is Selective Soldering?

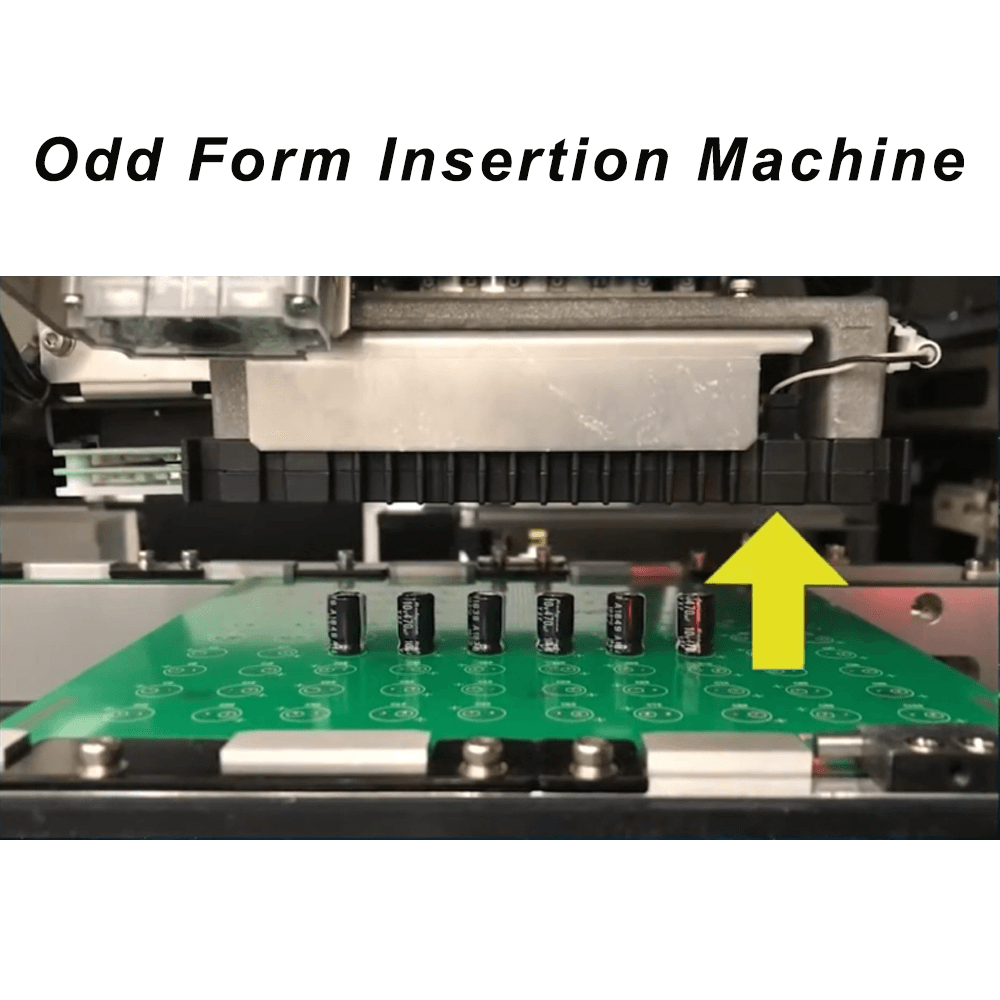

Selective soldering is a specialized technique used in electronics manufacturing to join components to a printed circuit board (PCB) without subjecting the entire assembly to heat. This method allows for precise application of solder only where it is needed, making it an ideal choice for intricate PCB designs that include heat-sensitive components. By using a selective wave soldering machine, manufacturers can achieve high-quality connections while minimizing damage to surrounding areas.

Advantages of Selective Soldering

One of the standout advantages of selective soldering is its precision; it targets specific areas on a PCB, ensuring that only the necessary components are soldered. This method reduces the risk of overheating and damage, which can occur with traditional wave soldering techniques that expose the entire board to molten solder. Additionally, selective wave soldering machines often lead to less waste and lower costs in materials since they use only the required amount of good solder for electronics.

Another benefit lies in its versatility; selective soldering can handle various component types and sizes, making it suitable for both through-hole and surface-mount devices. Furthermore, this technique enhances production speed by allowing simultaneous processing of multiple boards without compromising quality. In an industry where efficiency is key, these advantages make selective wave soldering an attractive option.

Applications in the Industry

Selective soldering finds its niche across various industries due to its ability to accommodate complex assemblies with diverse component types. It’s particularly prevalent in sectors like telecommunications, automotive electronics, and medical devices—where reliability and precision are paramount. For example, when dealing with sensitive components on a PCB board that might be adversely affected by excessive heat from wave or reflow processes, selective wave soldering becomes essential.

Moreover, manufacturers often turn to this method when working with multi-layer boards or those requiring high-density interconnections—situations where traditional methods may falter or cause defects. The ability to selectively target specific joints also means that companies can maintain stringent quality control while meeting tight production deadlines.

How Bensun Implements Selective Soldering

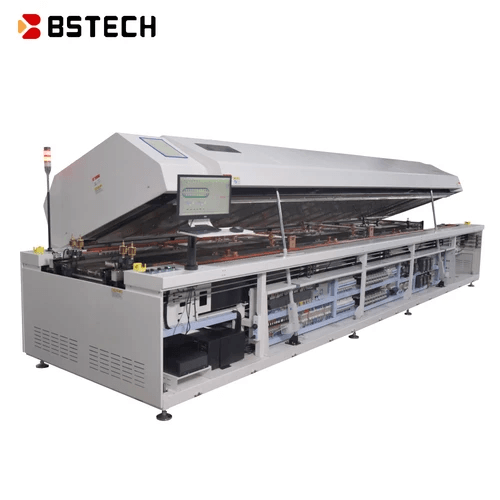

At Bensun, we pride ourselves on utilizing cutting-edge technology in our selective wave soldering processes to ensure top-notch quality and efficiency for our clients' needs. Our advanced selective wave soldering machines are designed not just for functionality but also adaptability; they cater seamlessly to varying project requirements while maintaining optimal performance levels throughout production runs. We understand that choosing good solder for electronics can significantly impact overall results; thus we source only the best options available on the market for our applications.

Bensun's team meticulously trains operators on best practices related to selective solder techniques—this ensures every component gets precisely what it needs during assembly without compromising other parts of the PCB board design process. By implementing rigorous testing protocols alongside our innovative machinery solutions, we guarantee consistent output quality that meets or exceeds industry standards.

Exploring Wave Soldering

Wave soldering is a robust and widely used technique in the electronics manufacturing industry, particularly for soldering components onto PCB boards. This method involves passing a PCB board over a wave of molten solder, which creates strong connections between the electronic components and the board itself. The process is efficient for high-volume production, making it a favorite among manufacturers looking to streamline their operations.

The Process of Wave Soldering

The wave soldering process begins with the preparation of the PCB board, where components are placed on designated pads. Once everything is in position, the board moves through a preheating zone to remove moisture and prepare it for soldering. Following this step, the PCB passes over a wave of molten solder that adheres to exposed metal surfaces, effectively creating permanent connections as it cools down.

One of the key features of wave soldering is its ability to handle multiple components simultaneously, making it an ideal choice for complex assemblies with numerous parts. The selective wave soldering machine can be customized to accommodate different PCB designs and component layouts, ensuring versatility in production lines. By understanding this process better, manufacturers can optimize their use of wave soldering for various applications.

Benefits and Limitations

Wave soldering offers several benefits that make it an attractive option for many electronic assembly processes. For starters, it's incredibly efficient; once set up properly, it can produce high volumes of PCBs in a short amount of time. Additionally, using good solder for electronics ensures reliable connections that stand up to thermal and mechanical stress during operation.

However, like any technique, wave soldering has its limitations. It may not be suitable for all types of components—particularly those that are sensitive to heat or have fine pitch leads—and can sometimes lead to issues like bridging if not carefully managed. Manufacturers need to weigh these factors when deciding whether selective wave soldering or another method would be best suited for their specific needs.

Key Industries Utilizing Wave Soldering

Wave soldering finds its place across various industries due to its efficiency and reliability in producing quality electronic assemblies. Key sectors include consumer electronics, automotive manufacturing, telecommunications equipment production, and industrial machinery—essentially any field requiring robust PCBs populated with numerous electronic components will benefit from this technique.

In consumer electronics alone—think smartphones or laptops—wave soldering helps ensure that millions of devices function flawlessly by securely connecting all necessary parts on their PCBs with precision using the best solders available on the market today. As technology advances and products become more complex with smaller components needing assembly on PCB boards, selective wave soldering will likely continue playing an essential role in meeting industry demands.

The Reflow Soldering Process

Reflow soldering is a widely used technique in electronics manufacturing, particularly for soldering components on PCB (Printed Circuit Board). This method involves the application of heat to melt solder paste, which then solidifies to create reliable electrical connections. Understanding how reflow soldering mechanics work is essential for selecting the best solder for electronics applications.

Understanding Reflow Soldering Mechanics

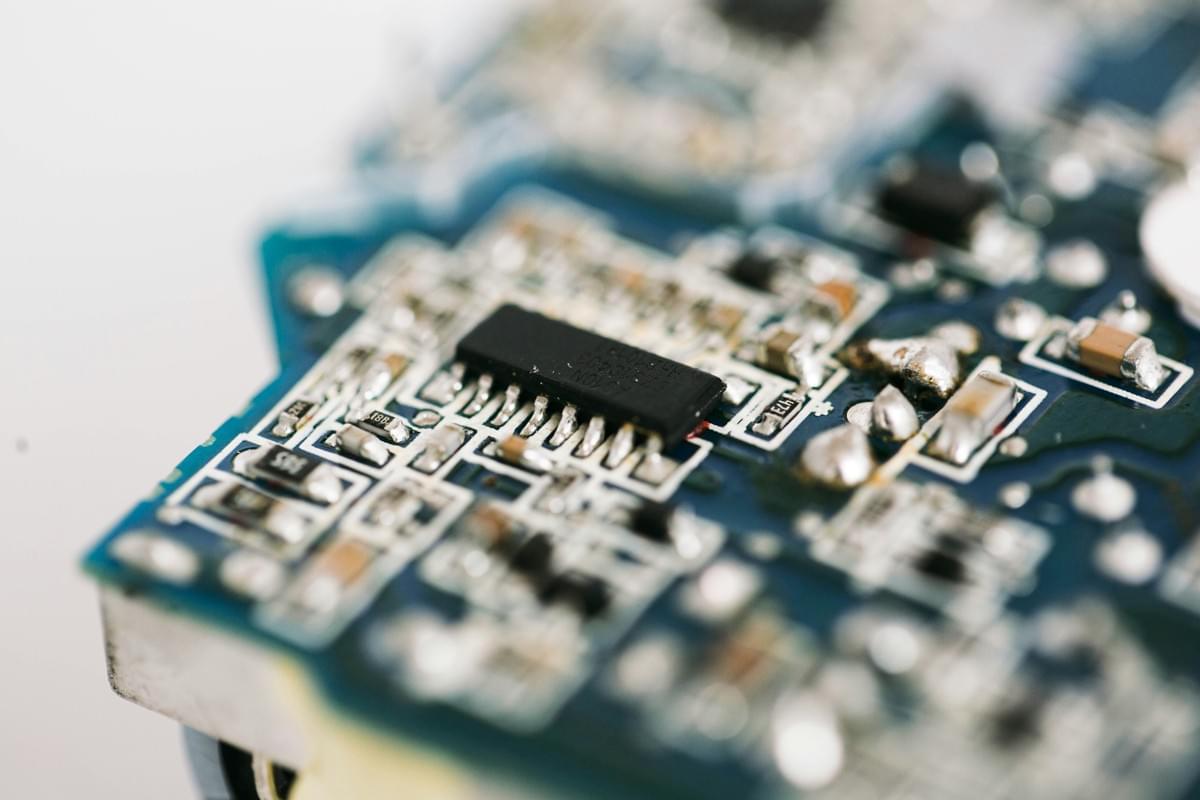

At its core, reflow soldering begins with applying a solder paste that contains tiny spheres of solder mixed with flux onto the PCB pads. Once the components are placed on these pads, the assembly is heated in a reflow oven where temperature profiles are carefully controlled. This process ensures that the flux activates and helps the solder flow smoothly, creating strong joints without damaging sensitive components.

The heating phase typically consists of three stages: preheating, soaking, and reflow. During preheating, the assembly gradually warms up to avoid thermal shock; soaking maintains a stable temperature before reaching melting point; and finally, reflow allows the molten solder to form connections as it cools down. This precision makes reflow an excellent choice when working with delicate parts or densely populated boards.

Benefits of Reflow Soldering

One of the primary advantages of reflow soldering is its ability to handle surface mount devices (SMDs) effectively, making it ideal for modern electronic assemblies. The process can accommodate various component sizes and shapes while ensuring consistent quality across multiple units—perfect for mass production scenarios where uniformity matters most. Additionally, using good solder for electronics enhances reliability and minimizes defects in manufacturing processes.

Another benefit lies in reduced labor costs since automated systems can manage large batches efficiently without sacrificing quality. Furthermore, unlike selective wave soldering methods that may struggle with complex geometries or mixed technology boards, reflow offers versatility in design choices while maintaining high throughput rates. Ultimately, this makes it a favored method among manufacturers looking to optimize their production lines.

Comparison with Other Soldering Techniques

When comparing reflow soldering to selective wave soldering and traditional wave soldering techniques, several key differences emerge regarding application suitability and operational efficiency. Selective wave soldering excels at targeted areas but may not be as efficient when dealing with entire PCBs filled with SMDs—this is where reflow shines by accommodating both through-hole and surface mount components seamlessly.

Wave soldering generally involves immersing PCB assemblies into molten solder waves; however, this technique can lead to potential issues such as bridging between closely spaced pins or thermal damage due to prolonged exposure to high temperatures—challenges that are less pronounced in controlled reflow environments. Moreover, while selective wave machines provide precision for specific areas on PCBs needing attention during assembly processes; they often lack flexibility compared to full-scale reflow systems designed specifically for larger production runs.

In conclusion, while each method has its merits depending on project requirements—be it selective wave or traditional wave methods—reflow stands out as a highly adaptable solution capable of meeting diverse needs across different industries efficiently and effectively.

Selective vs. Wave Soldering

In the world of electronics manufacturing, both selective wave soldering and wave soldering have carved out their niches, each boasting unique strengths. While they share the common goal of efficiently soldering components onto PCB boards, their methods and ideal applications differ significantly. Understanding these differences can help manufacturers determine which process best suits their production needs.

Key Differences and Similarities

Selective wave soldering focuses on specific areas of a PCB board, allowing for targeted application of solder to individual components without impacting surrounding areas. In contrast, wave soldering involves submerging the entire board into a wave of molten solder, making it effective for through-hole components but less precise for mixed technologies. While both methods utilize molten solder to create reliable electrical connections, selective wave soldering is often preferred for complex boards with sensitive components that require careful handling.

When to Choose One Over the Other

Choosing between selective wave soldering and traditional wave soldering largely depends on the complexity of your PCB design and the types of components involved. If you’re working with a densely populated board or surface-mount devices alongside through-hole parts, selective wave soldering is likely your best bet due to its precision and ability to minimize thermal stress on sensitive elements. On the other hand, if you’re dealing with simpler designs featuring primarily through-hole components, traditional wave soldering can be more efficient and cost-effective.

Real-World Applications of Each

Selective wave soldering shines in industries where precision is paramount, such as medical device manufacturing or aerospace electronics, where even minor defects can lead to catastrophic failures. Conversely, traditional wave soldering is commonly found in high-volume production settings like consumer electronics assembly where speed is essential and component placement is straightforward. Both techniques are integral to modern electronics manufacturing; thus understanding their strengths allows companies to optimize their processes effectively.

Reflow Soldering vs. Selective and Wave

When it comes to soldering techniques, reflow soldering, selective wave soldering, and traditional wave soldering each have their unique strengths and weaknesses. Understanding these pros and cons can help manufacturers make informed decisions about which method best suits their needs. By evaluating factors such as efficiency, cost-effectiveness, and application suitability, businesses can optimize their soldering processes for better results.

Pros and Cons of Each Method

Reflow soldering is often praised for its ability to create reliable connections on densely populated PCB boards due to its uniform heating process. However, it may not be the best choice for larger components or those that require more localized heat application. On the other hand, selective wave soldering excels in such scenarios by targeting specific areas on a PCB while minimizing thermal stress on sensitive components; however, it typically has a slower throughput compared to reflow methods.

Wave soldering provides a high-speed solution ideal for through-hole components but can struggle with surface-mount technology (SMT) applications due to its blanket approach. The trade-off here involves balancing speed with precision—while wave soldering is efficient for bulk production runs, it may not yield the same quality as selective methods when dealing with intricate designs or mixed technologies on a single board. Ultimately, choosing the best solder for electronics depends greatly on factors like component type and production volume.

Best Practices for Each Soldering Technique

For reflow soldering, it's essential to ensure that the temperature profile is meticulously calibrated to avoid issues such as cold joints or thermal damage during the process of soldering components on PCB boards. Using a good solder for electronics that matches your specific requirements can also significantly impact performance; lead-free solders are increasingly popular due to environmental considerations but may require different temperature settings than traditional options.

In contrast, when employing selective wave soldering machines, operators should focus on optimizing nozzle design and flux application to enhance joint quality while reducing defects like bridging or insufficient wetting. Regular maintenance of equipment is crucial here since any buildup can affect performance over time—keeping machinery in top condition allows you to achieve consistent results across multiple production runs. For wave soldering processes, ensuring proper preheating of PCBs helps improve adhesion and flow characteristics of the molten solder; this step cannot be overlooked if you want optimal results from your chosen method.

Choosing the Right Solution for Your Needs

Selecting between reflow versus selective wave or traditional wave techniques ultimately hinges on your specific project requirements—consideration of factors like product complexity and production scale will guide your decision-making process effectively. If you're working with high-density PCBs featuring numerous SMT components, reflow might be your go-to solution; however, if you're dealing with larger through-hole parts or mixed technology boards needing precision application without excessive heat exposure, then selective wave might be more appropriate.

Moreover, understanding what constitutes good solder for electronics is vital in ensuring long-lasting connections regardless of which method you choose—research various solders available in today’s market while weighing their benefits against costs associated with each technique's implementation. As technology continues evolving within the industry landscape surrounding PCB assembly practices—investments in modern machinery tailored towards these methods will pay dividends in terms of efficiency gains over time.

Conclusion

In the world of electronics, selecting the right soldering technique is crucial for ensuring the quality and reliability of your products. We’ve explored three primary methods: selective wave soldering, wave soldering, and reflow soldering. Each method has its unique advantages and applications, making it essential to understand their differences to make informed decisions.

Recap of Soldering Methods

Selective wave soldering involves targeted application, ideal for complex PCB layouts with sensitive components. Wave soldering, on the other hand, is a more traditional method that immerses entire boards in molten solder, making it suitable for high-volume production. Reflow soldering utilizes heat to melt solder paste on components before cooling, providing excellent results for surface-mounted devices.

Making an Informed Choice

Choosing between selective wave soldering and other methods hinges on your specific needs—volume production versus precision placement. If you're working with a PCB board that features a mix of through-hole and surface-mounted components, a selective wave soldering machine might be your best bet for efficiency without compromising quality. Conversely, if you’re focusing solely on surface-mounted components or high-volume runs, reflow or traditional wave soldering may prove more advantageous.

The Future of Soldering Technology

The landscape of soldering technology is rapidly evolving with advancements in materials and techniques. Innovations in selective wave soldering continue to enhance precision while reducing waste—an essential factor in today’s eco-conscious manufacturing environment. As we look ahead, expect even better options for selecting the best solder for electronics that not only meet but exceed industry standards.