Introduction

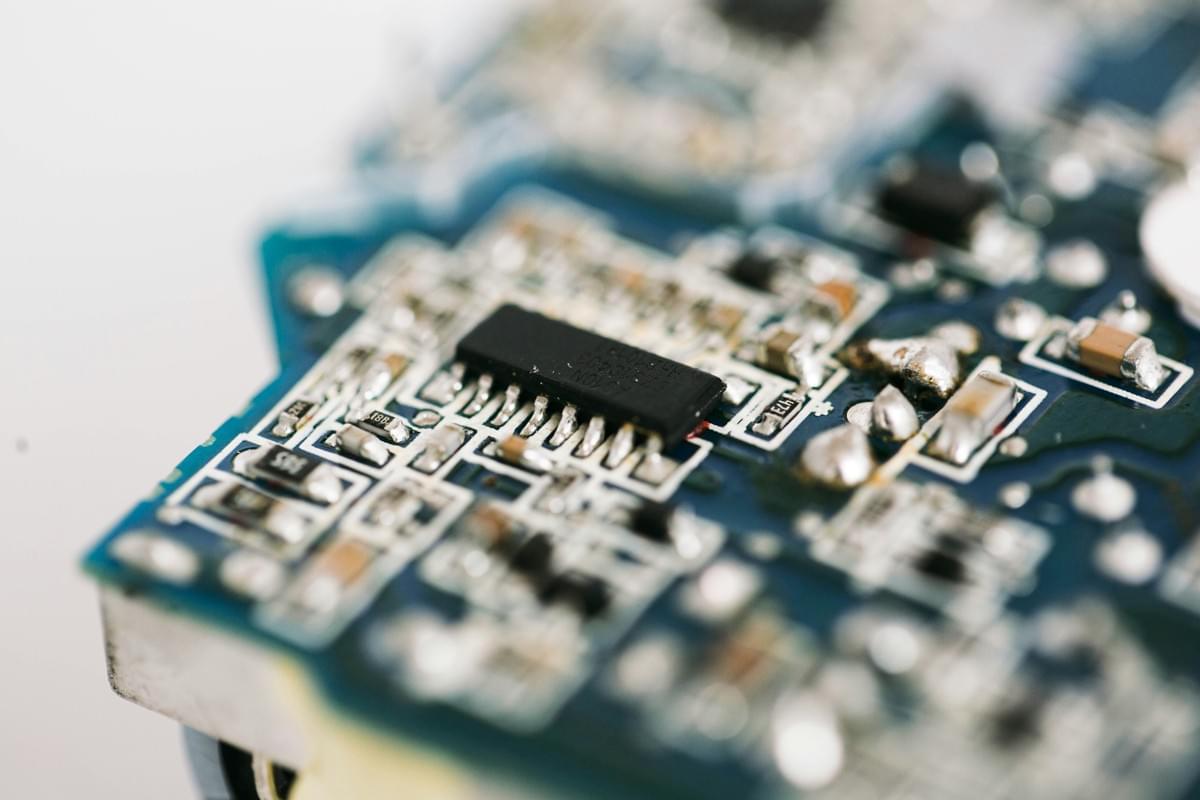

In the world of electronics manufacturing, the significance of solder paste printers cannot be overstated. These machines play a critical role in ensuring that printed circuit boards (PCBs) are assembled with precision and efficiency. With a variety of options available, understanding what a solder paste printer is and how it operates is essential for manufacturers looking to optimize their production processes.

Understanding SMT Stencil Printers

So, what is a solder paste printer? Essentially, it's a specialized device used to apply solder paste onto PCBs before components are placed for soldering. SMT stencil printers utilize stencils to accurately deposit the right amount of solder paste onto designated pads on the board, ensuring optimal connectivity and performance in electronic devices.

Importance in PCB Assembly

The importance of these printers in PCB assembly is paramount; they directly influence the quality and reliability of electronic products. A well-functioning solder paste printer can significantly reduce defects during assembly, leading to fewer reworks and higher overall productivity. Moreover, using an efficient SMT stencil printer can enhance the consistency of solder application across multiple boards, making it an indispensable tool for manufacturers aiming for excellence.

Key Players in the Market

When it comes to key players in the market for solder paste printers, several notable brands stand out due to their innovative technologies and reliable products. Companies like JUKI have established themselves as pioneers by offering advanced solutions that cater to various manufacturing needs. As competition grows, these industry leaders continue to push boundaries with new features and enhancements that elevate the capabilities of SMT stencil printers even further.

What is a Solder Paste Printer?

In the world of PCB assembly, understanding what a solder paste printer is crucial for ensuring high-quality production. A solder paste printer is a specialized machine that applies solder paste onto printed circuit boards (PCBs) through stencils, facilitating the attachment of electronic components. This process is vital in achieving precision and consistency in the manufacturing of electronic devices.

Definition and Functionality

So, what is a solder paste printer? At its core, it’s a device designed to transfer solder paste onto PCBs using a stencil that accurately defines where the paste should go. The functionality hinges on applying the right amount of pressure to ensure even distribution while preventing excess from spilling over onto areas where it’s not needed. This precision ensures that when components are placed on the board, they have sufficient solder to create strong electrical connections without risking short circuits or other issues.

Types of Solder Paste Printers

When diving into types of solder paste printers, you'll find several variations tailored to different production needs. Manual printers allow operators to control the application process directly but require more skill and can be slower than their automated counterparts. Automated models range from semi-automatic systems that still involve some human oversight to fully automated machines capable of handling high-volume production with minimal intervention—perfect for those looking to scale operations efficiently.

Advantages of Using Solder Paste Printers

The advantages of using solder paste printers are manifold and can significantly impact your PCB assembly line's efficiency and quality. For starters, these printers enhance accuracy in applying solder paste compared to manual methods or other techniques; this precision is critical in avoiding defects during assembly. Additionally, they can boost production speed—thanks to automation—allowing manufacturers to meet tight deadlines without sacrificing quality, making them an essential investment for anyone serious about PCB manufacturing.

The Role of SMT Stencil Printers

In the realm of PCB assembly, SMT stencil printers play a pivotal role, enhancing both the quality and efficiency of production processes. A solder paste printer is essential for applying solder paste accurately to circuit boards, which is crucial for ensuring reliable electrical connections. Understanding what a solder paste printer does can illuminate its importance in manufacturing and assembly lines.

How They Enhance Precision

Precision is the name of the game when it comes to solder paste application, and SMT stencil printers excel in this area. By utilizing advanced technologies, these printers ensure that solder paste is deposited exactly where it’s needed on the PCB, minimizing errors that could lead to costly defects. So, if you’re wondering what is a SMT stencil printer? Think of it as your trusty sidekick in achieving impeccable accuracy in your assembly process.

Moreover, precise application reduces the risk of bridging—where excess solder creates unintended connections between components—which can compromise device performance. The right pressure during printing can also enhance precision; many operators ask themselves what pressure is needed for solder paste printing? Generally, optimal pressure ensures a smooth flow without over-extruding or under-depositing.

Impact on Production Speed

Speed matters in manufacturing environments, and SMT stencil printers significantly boost production rates by streamlining the solder paste application process. With faster setup times and automated features, these machines allow manufacturers to churn out PCBs at an impressive pace without sacrificing quality. In fact, as companies strive for efficiency, understanding how a solder paste printer fits into their workflow becomes increasingly important.

Additionally, faster cycle times mean that businesses can meet tight deadlines while maintaining high standards—an essential balance in today's competitive market. When considering whether solder paste is as good as traditional methods like hand-soldering or screen-printing techniques for speed? The answer often leans towards automated solutions like SMT stencil printers due to their rapid output capabilities.

Cost-Effectiveness in Manufacturing

Investing in an SMT stencil printer can be a game-changer for cost management within PCB assembly operations. While initial costs may seem steep compared to manual methods or lower-end models, the long-term savings are undeniable—reduced labor costs and minimized waste lead to better overall profitability. This begs the question: Is investing in a high-quality solder paste printer worth it? Absolutely!

By optimizing material usage through precise applications and reducing rework caused by misaligned components or poor adhesion due to inaccurate paste deposition, these machines pay for themselves over time. Plus, with advancements continually emerging within this sector—think about how leading brands innovate—the cost-effectiveness only improves with newer models boasting enhanced features.

Leading Brands and Innovations

In the dynamic world of PCB assembly, several brands have emerged as leaders in the SMT stencil printer market. These companies are not just manufacturers; they are innovators pushing the boundaries of what is possible with solder paste printers. By integrating advanced technologies and focusing on precision, these brands ensure that production lines operate efficiently and effectively.

JUKI: The Pioneer of Precision

When discussing leading brands in solder paste printing, JUKI stands out as a true pioneer. Known for their commitment to quality and innovation, JUKI has developed some of the most reliable SMT stencil printers available today. Their machines are designed to enhance precision in solder paste application while also improving overall production speed—a combination that makes them a favorite among manufacturers.

JUKI's reputation is built on its ability to deliver high-performance solder paste printers that cater to various industry needs. With features such as adjustable pressure settings and user-friendly interfaces, they answer the question, What is a solder paste printer? by providing solutions that are easy to use yet sophisticated enough for complex applications. This balance of simplicity and technology solidifies JUKI's position as a leader in this competitive market.

Advances in SMT Printer Technologies

The landscape of SMT stencil printers is continually evolving thanks to rapid technological advancements. New innovations focus on enhancing both the functionality and efficiency of solder paste printers, ensuring manufacturers can meet growing demands without sacrificing quality. For instance, recent developments have introduced automated systems capable of adjusting pressure during printing—answering the burning question: What pressure is needed for solder paste printing?

Moreover, these advancements make it easier than ever for operators to troubleshoot common issues associated with solder paste application techniques. As manufacturers explore whether solder paste is as good as solder, they find themselves equipped with tools that offer superior performance through improved consistency and accuracy in application methods compared to traditional techniques like hand-soldering or other less precise methods.

As we look ahead at future trends in SMT printing technology, we can expect even more automation and intelligence integrated into these systems, making them more adaptable than ever before. The innovations coming from leading brands will undoubtedly continue shaping how PCB assembly processes evolve—ensuring that businesses stay competitive while maximizing efficiency through cutting-edge solutions.

Solder Paste Application Techniques

Solder paste application is a crucial step in the PCB assembly process, and understanding the various techniques can significantly impact the quality of your printed circuit boards. Among these techniques, stencil printing stands out as a favored choice due to its precision and efficiency. However, it's essential to explore how it compares with other methods and what best practices can be adopted for optimal results.

Stencil Printing vs. Other Methods

When considering What is a solder paste printer? one must recognize that stencil printing is often the go-to method for applying solder paste onto PCBs. This technique involves using a metal stencil to control the amount of solder paste deposited on each pad, ensuring uniformity across the board. In contrast, other methods such as screen printing or jetting may not offer the same level of accuracy or consistency, especially for fine-pitch components.

Is solder paste as good as solder? Absolutely! The quality of solder paste application directly affects solder joint reliability, which is where SMT stencil printers shine by providing precise deposits that enhance overall assembly quality. While alternatives exist, they often come with trade-offs in terms of speed or precision—making stencil printing a reliable choice for high-quality PCB production.

Best Practices for Application

To maximize efficiency when using a solder paste printer, there are several best practices worth following. First and foremost, ensure that your stencils are clean and free from debris before beginning the printing process; even minor contaminants can lead to poor adhesion or uneven deposits. Additionally, calibrating your printer settings—particularly pressure—can make all the difference; knowing What pressure is needed for solder paste printing? is key to achieving optimal results.

Maintaining consistent squeegee speed and angle during application further enhances print quality by ensuring even distribution of solder paste across pads. Regularly inspecting printed boards before component placement helps catch any issues early on; after all, prevention is better than cure! By following these best practices diligently, you can elevate your PCB assembly process significantly.

Troubleshooting Common Issues

Even with diligent practices in place when using an SMT stencil printer, issues may still arise during the solder paste application process. One common problem involves insufficient or excessive amounts of solder paste being applied to pads; this could lead to weak joints or bridges between components respectively. If you find yourself asking What is a SMT stencil printer? remember that these machines are designed specifically to minimize such errors through precise control mechanisms.

If you encounter problems like smudging or misalignment in your prints, consider adjusting squeegee pressure and checking for proper alignment between your board and stencil—these factors play pivotal roles in achieving flawless prints every time! Additionally, regular maintenance of your equipment will help mitigate many common issues associated with consistent performance over time.

Choosing the Right SMT Stencil Printer

When it comes to selecting the perfect SMT stencil printer, several factors need careful consideration to ensure you get the best fit for your PCB assembly needs. The market is flooded with options, making it crucial to understand what differentiates a solder paste printer from others and how these differences can impact your production. Whether you're a seasoned pro or just starting out, knowing what to look for can save you time and money in the long run.

Factors to Consider

First and foremost, understanding what is a solder paste printer will help guide your decision-making process. Look for features that enhance precision, such as adjustable pressure settings; after all, what pressure is needed for solder paste printing? Additionally, consider the size of your PCB boards and whether the printer can accommodate them without compromising quality. Don't overlook software compatibility either; an intuitive interface can significantly streamline your workflow.

Another essential factor is speed—how quickly can the machine produce high-quality prints? In fast-paced environments where time equals money, an efficient solder paste printer can make all the difference. Lastly, reliability should never be underestimated; choose brands known for their durability and excellent customer support.

Budgeting for Your Needs

Now that you've identified key features, it's time to talk numbers. Budgeting for a solder paste printer involves more than just the initial purchase price; you'll also want to account for maintenance costs and potential upgrades down the road. Is solder paste as good as solder? Well, while both are crucial components in PCB assembly, investing in quality equipment ensures that your production line runs smoothly without unexpected hiccups.

Consider creating a spreadsheet that outlines not only the cost of various models but also any additional expenses like training or software licenses you may incur. This way, you’ll have a comprehensive view of what each option truly entails financially.

Rental vs. Purchase Decisions

Finally, you'll need to weigh whether renting or purchasing a solder paste printer makes more sense for your specific situation. Renting might be ideal if you're just starting out or working on short-term projects; it allows flexibility without committing too much capital upfront. However, if you're planning on long-term use and regular production runs, investing in a reliable SMT stencil printer could save you money over time.

Evaluate how often you'll need to use the machine—if it's going to be part of your daily routine then ownership could be beneficial in terms of both cost savings and convenience. Ultimately, whichever route you choose should align with your business goals while maximizing efficiency in PCB assembly processes.

Conclusion

In the fast-paced world of PCB assembly, maximizing efficiency is paramount. The role of a solder paste printer cannot be overstated, as it ensures precise application of solder paste, which is crucial for the reliability and performance of electronic components. By employing advanced SMT stencil printers, manufacturers can streamline their processes and reduce waste, leading to both time and cost savings.

Maximizing Efficiency in PCB Assembly

What is a solder paste printer? It's not just a fancy gadget; it's an essential tool that elevates the quality of PCB assembly. These printers enhance accuracy by applying the right amount of solder paste to each pad, minimizing defects that could lead to costly reworks. When you consider factors like production speed and precision, investing in a high-quality SMT stencil printer becomes an obvious choice for any serious manufacturer.

Future Trends in SMT Printing

Looking ahead, the future trends in SMT printing suggest exciting advancements on the horizon. Innovations such as automated inspection systems integrated with solder paste printers will likely improve quality control even further. Additionally, as manufacturers explore new materials and techniques—like 3D printing—solder paste application methods will evolve, raising questions such as Is solder paste as good as solder? The answer may very well depend on how these technologies develop.

Final Thoughts on Solder Paste Printers

In conclusion, understanding what a SMT stencil printer does is key for anyone involved in electronics manufacturing. With the right equipment and techniques—including knowledge about what pressure is needed for solder paste printing—you can ensure your production line runs smoothly and efficiently. As we continue to innovate within this space, one thing remains clear: investing in a reliable solder paste printer is essential for achieving high-quality results in PCB assembly.